زراعة

الصفحة الرئيسية » الصناعات » زراعة

زراعة

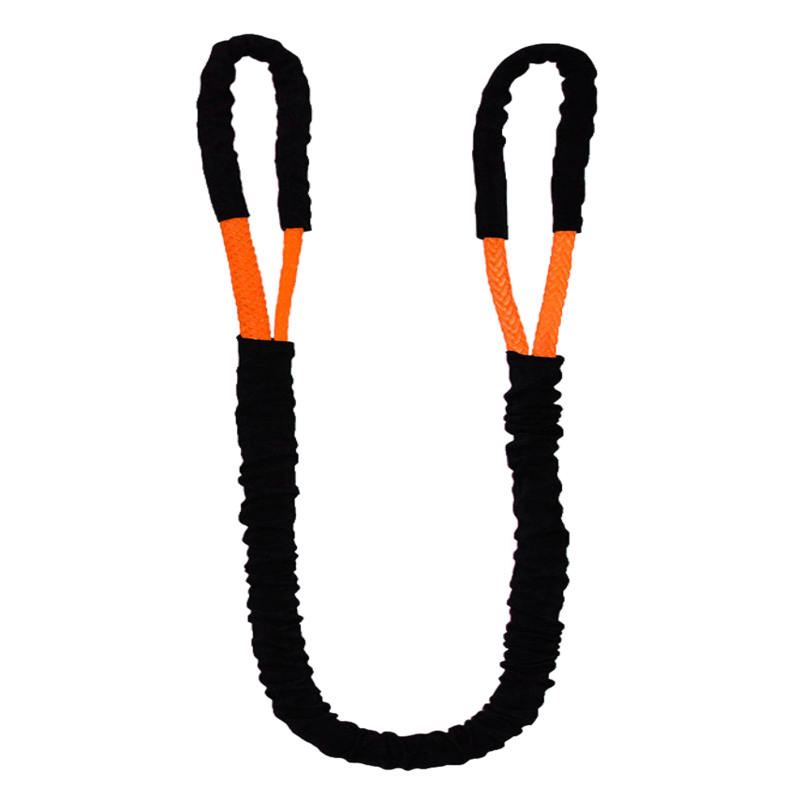

نقدم مجموعة متنوعة من المنتجات عالية الجودة، مصممة خصيصًا للتطبيقات والتحديات الزراعية. من بين منتجاتنا الأكثر مبيعًا: حبل التعافي الحركي, حبل ونش صناعي, حبال رفع اصطناعية.

بالإضافة إلى ذلك، فإننا نقدم أيضًا عناصر أساسية أخرى تلبي مهامك الزراعية مثل حبل السحب UHMWPE، وواقي جذع الشجرة، ولفافة السجل، وحزام السحب، والملحقات المتعلقة بالحبال وما إلى ذلك.

كيفية صنع

اكتشف عملية إنتاج حبال الاسترداد الزراعية عالية الأداء.

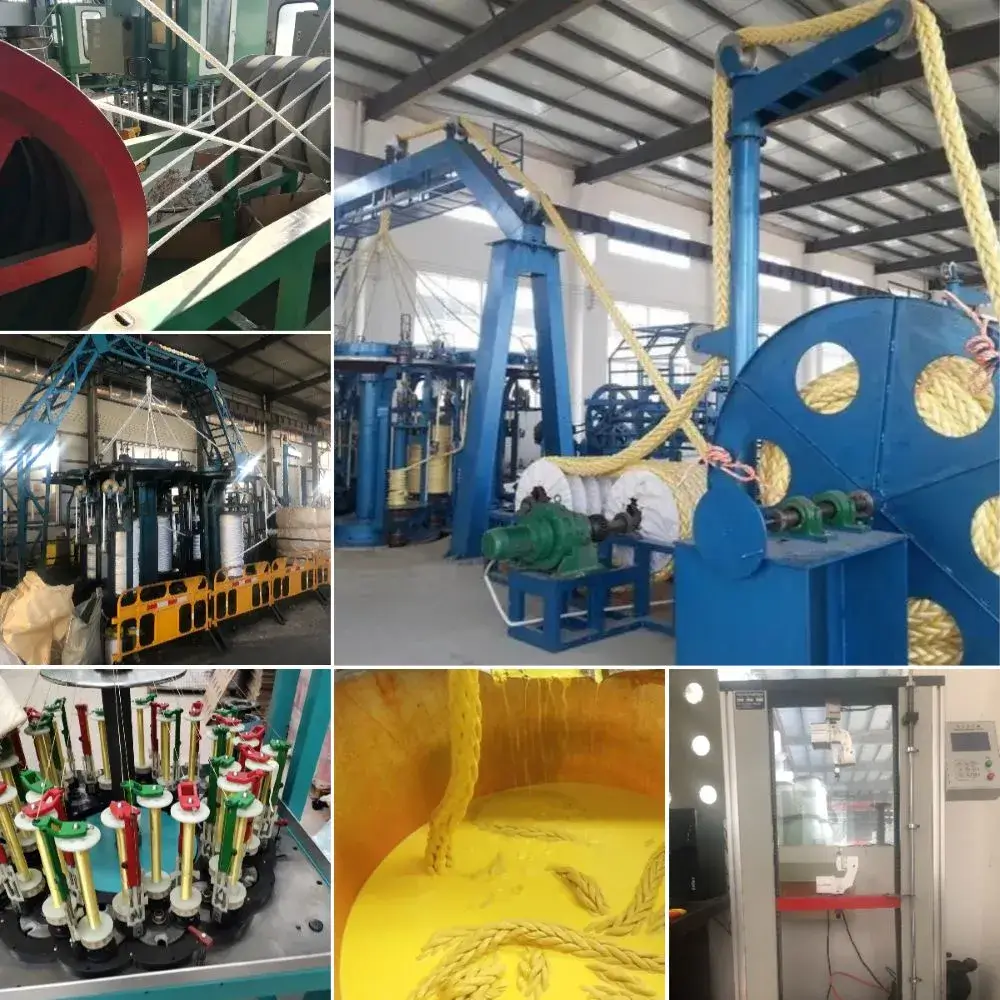

العملية 1

اختيار الألياف

نقوم بعناية باختيار الألياف الصناعية عالية الجودة، مثل النايلون، أو البوليستر، أو UHMWPE، لاستخدامها في حبالنا، مما يضمن القوة والمتانة.

العملية 2

الالتواء والتشكيل

تُلَفُّ الألياف المختارة معًا لتكوين خيوط، تُلَفُّ بدورها لتكوين خيوط. تُشكَّل الخيوط الملتوية بعد ذلك على شكل حبل.

العملية 3

وضع وتضفير

يتم وضع الحبل المشكل في آلة التضفير، والتي تقوم بضفر الحبل معًا باستخدام تقنيات وأنماط متخصصة لزيادة القوة والمتانة بشكل أكبر.

العملية 4

طلاء

يتم تطبيق طبقة حماية مخصصة مصنوعة من مواد عالية الجودة، مثل PVC أو البولي يوريثين، لتعزيز متانة الحبل ومقاومته للتآكل والماء والأشعة فوق البنفسجية.

العملية 5

المعالجة الحرارية والتجفيف

يخضع الحبل المضفر لعملية معالجة حرارية متخصصة لتثبيت الضفائر وزيادة قوتها. ثم يُجفف الحبل لإزالة أي رطوبة.

العملية 6

الاختبار

يخضع كل حبل استرداد من Duracordix لاختبارات دقيقة لضمان استيفائه لمعاييرنا العالية للقوة والمرونة. أي حبل لا يجتاز عملية الاختبار الخاصة بنا يتم التخلص منه.

- التركيز على الجودة

. ضبط الجودة

اكتشف كيف نضمن التميز الذي لا مثيل له في كل حبل من حبال الألياف

1. المواد الخام

حبالنا الاصطناعية مصنوعة فقط من مواد خام مطابقة لمعايير الجودة الصارمة لدينا. نتعاون مع موردين موثوقين لضمان جودة ثابتة وأداء مثالي لجميع منتجاتنا.

2. داخليًا

بفضل إنتاجنا الداخلي للحبال الاصطناعية، نتمتع بتحكم كامل في الجودة طوال عملية التصنيع. هذا يسمح لنا بالالتزام بمعاييرنا العالية وتقديم منتجات موثوقة لعملائنا.

3. الاختبار والتفتيش

تشمل عمليات الاختبار والتفتيش الدقيقة لدينا كل مرحلة من مراحل الإنتاج، من المواد الخام إلى المنتجات النهائية. وهذا يضمن جودة وسلامة حبالنا الاصطناعية.

4. التصنيع الآلي

ندمج الآلات والتكنولوجيا الآلية لضمان الدقة والاتساق في إنتاج الحبال الاصطناعية. هذا يقلل من الأخطاء البشرية ويضمن استيفاء جميع المنتجات لمعايير الجودة الصارمة لدينا.

5. الموظفين المهرة

يخضع فريقنا من العمالة الماهرة لتدريب وتعليم مستمر لمواكبة أحدث التقنيات في إنتاج الحبال الصناعية، مما يساعدنا على الحفاظ على أعلى مستويات الجودة والأداء.

- المعيار الدولي

ملكنا الشهادات

سهل وواضح

تعظيم رضا العملاء من خلال سهولة الشراء، وتقليل تكاليف الاتصالات والوقت.

الخطوة 1: تأكيد الحل (3-5 أيام)

أولاً، سنناقش احتياجاتك ونقترح عليك أفضل حل للحبال. خبرتنا الواسعة تضمن لك الحصول على أفضل منتج ممكن.

الخطوة 2: تقييم العينة (7-14 يومًا)

لضمان رضاكم عن منتجاتنا، نقدم لكم تقييمات عينات. اختبروا منتجاتنا قبل الطلب للتأكد من أنها تلبي متطلباتكم.

الخطوة 3: تأكيد الطلب (خلال 3 أيام)

بعد رضاك عن تقييم العينة، أكّد طلبك معنا. سنزودك بجميع التفاصيل اللازمة، بما في ذلك السعر ومدة التسليم وغيرها، لتكون على ثقة تامة بشرائك.

الخطوة 4: التصنيع بالجملة (30-45 يومًا)

نوفر خيارات تصنيع بكميات كبيرة للطلبات الكبيرة. تقنياتنا الإنتاجية المتطورة وموادنا عالية الجودة تضمن الاتساق والموثوقية في جميع الطلبات.

الخطوة 5: التسليم (30-45 يومًا)

ندرك أهمية التسليم في الوقت المحدد، لذا سنُبقيك على اطلاع دائم بتقدم الشحنة ونزودك بمعلومات التتبع. سيصل طلبك في الموعد المحدد.

الخطوة 6: خدمة ما بعد البيع

خدمتنا مستمرة بعد توصيل طلبك. إذا كانت لديك أي أسئلة أو استفسارات، ففريقنا جاهز دائمًا لمساعدتك. نحن ملتزمون بتقديم خدمة عملاء ممتازة وضمان رضاكم.

- شراء بدون ألم

لماذا تختار؟

- مقاوم للأشعة فوق البنفسجية: تمت معالجة حبالنا لمقاومة الأشعة فوق البنفسجية أكثر من غيرها، مما يضمن المتانة حتى تحت أشعة الشمس.

- القوة: مصممة لتحمل قوة شد تصل إلى ٥٠,٠٠٠ رطل. سواءً كنتَ تسحب أو ترفع، حبالنا لن تخذلك.

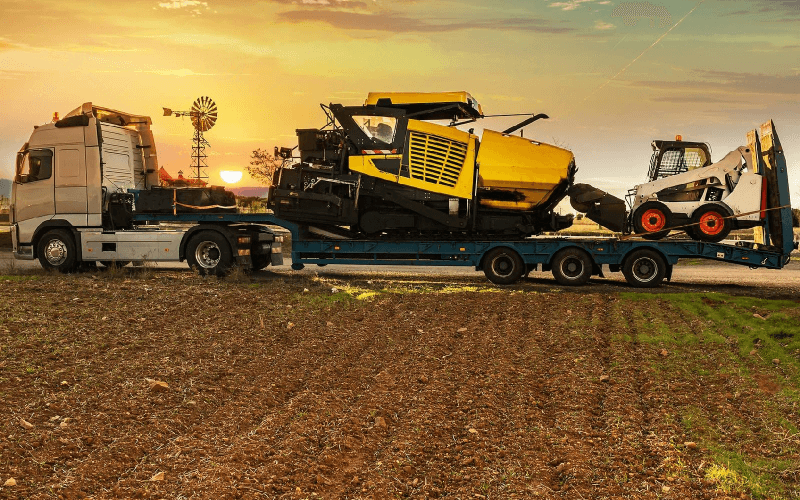

- الأمان: يتمتع حبلنا المخصص بسجل مثبت في ربط المعدات بشكل آمن أثناء النقل والاستخدام الميداني، مما يمنحك راحة البال.

- فعّال من حيث التكلفة: توقع توفيرًا يصل إلى 30% مقارنةً بالعلامات التجارية الرائدة. الجودة لا تأتي دائمًا بثمن.

- خدمة مخصصة: مع دعم العملاء على مدار الساعة طوال أيام الأسبوع، تعدك Duracrodix بتقديم المساعدة في أقل من ساعتين، مع إعطاء الأولوية لاحتياجاتك دائمًا.

- قابلة للتخصيص: سواء كنت بحاجة إلى طول أو قطر أو لون أو قوة مخصصة، فإن حبلنا مصمم خصيصًا لتلبية احتياجاتك الزراعية المحددة بسعر معقول.

الأسئلة الشائعة

الأسئلة الشائعة التي تتناول مخاوف العملاء ونقاط الألم

ما هي استخدامات الحبال والأشرطة الزراعية؟

تُستخدم الحبال والأشرطة الزراعية في التطبيقات الزراعية لمهام مثل تأمين المحاصيل، وترسيخ الأشجار، وسحب المعدات الثقيلة، والمزيد.

هل يمكن استخدام الحبال والأشرطة الزراعية بالتبادل؟

لا، فأنواع الحبال والأشرطة المختلفة لها نقاط قوة واستخدامات مختلفة، ومن المهم اختيار المنتج المناسب لكل مهمة زراعية محددة.

ما هي المواد التي تصنع منها الحبال والأشرطة الزراعية؟

يمكن تصنيع الحبال والأشرطة الزراعية من الألياف الطبيعية مثل القطن والسيزال، أو الألياف الاصطناعية مثل النايلون والبوليستر، والـUhmwpe وما إلى ذلك.

لماذا يتم تفضيل الحبال الاصطناعية في الزراعة؟

توفر الحبال الاصطناعية العديد من المزايا في الزراعة:

متانة: إنها تقاوم العوامل البيئية مثل الأشعة فوق البنفسجية والعفن والعفن.

قوة: وخاصة تلك التي مثل UHMWPE، يمكنها أن تتحمل الأحمال الثقيلة.

فعّالة من حيث التكلفة: إن العمر الأطول يعني استبدالات أقل.

مقاومة: إنها تطرد الماء ومعظم المواد الكيميائية الموجودة في البيئات الزراعية.

كيف تقارن الحبال الاصطناعية بالحبال الطبيعية من حيث القوة؟

في حين استُخدمت الحبال الطبيعية، مثل المانيلا والسيزال، تاريخيًا لقوتها الكامنة، إلا أن الحبال الاصطناعية الحديثة غالبًا ما تتفوق عليها في قوة الشد والمتانة. على سبيل المثال، تتمتع حبال UHMWPE بنسبة قوة إلى وزن أعلى من الفولاذ بما يتراوح بين ثمانية وخمسة عشر ضعفًا.

هل يمكن إعادة تدوير الحبال الصناعية المستخدمة في الزراعة؟

العديد من الحبال الصناعية قابلة لإعادة التدوير، لكن جدوى إعادة التدوير غالبًا ما تعتمد على نوع البوليمر ومرافق إعادة التدوير المحلية. استشر دائمًا الشركة المصنعة أو إدارة النفايات المحلية لمعرفة خيارات إعادة التدوير المناسبة.

كيف تحافظ على الحبال الصناعية للزراعة؟

الصيانة هي المفتاح لطول العمر:

• قم بالفحص بانتظام بحثًا عن التآكل أو التآكل أو التلف.

•نظّف بانتظام لإزالة الأوساخ والمواد الكيميائية والرطوبة. عادةً ما يكفي استخدام الصابون المعتدل والماء.

•يُحفظ بعيدًا عن أشعة الشمس المباشرة في مكان بارد وجاف.

• تجنب ملامسة الأسطح الحادة أو الكاشطة.

هل الحبال الصناعية المستخدمة في الزراعة مقاومة للأشعة فوق البنفسجية؟

تتمتع العديد من الحبال الصناعية، وخاصةً النايلون والبوليستر، بمقاومة جيدة للأشعة فوق البنفسجية. ومع ذلك، مع مرور الوقت والتعرض لفترات طويلة للأشعة فوق البنفسجية، قد تُضعف أي حبل.

ما هو عمر الحبل الصناعي المستخدم في الزراعة؟

يختلف عمر الحبال الصناعية باختلاف الاستخدام والعوامل البيئية. مع العناية المناسبة، تدوم الحبال الصناعية لسنوات عديدة. مع ذلك، قد تحتاج الحبال المستخدمة يوميًا في المهام الشاقة إلى استبدال أسرع.

هل تستطيع الحبال الاصطناعية التعامل مع الأحمال الثقيلة مثل البالات أو الآلات في الزراعة؟

نعم. تُستخدم حبال UHMWPE، المعروفة بمتانتها العالية، غالبًا في عمليات الرفع الثقيلة في الزراعة، مثل نقل البالات الكبيرة أو الآلات.

هل الحبال الاصطناعية آمنة للتعامل مع الحيوانات؟

يمكن استخدام الحبال الاصطناعية بأمان في التعامل مع الحيوانات، سواءً كأغلال أو أربطة أو أقفاص. تأكد دائمًا من خلو الحبل من أي جسيمات حادة أو كاشطة لتجنب أي ضرر.

هل تتمدد الحبال الصناعية المستخدمة في الزراعة؟

يختلف التمدد باختلاف المادة. النايلون مرن ويتمتع بتمدد كبير، مما يُفيد في امتصاص الصدمات. أما البوليستر والبولي إيثيلين عالي الكثافة (UHMWPE)، فيتمتعان بتمدد ضئيل، مما يجعلهما مثاليين للتطبيقات التي تتطلب ثباتًا.

كيف تؤثر الرطوبة على الحبال الصناعية المستخدمة في الزراعة؟

الحبال الصناعية، وخاصةً البولي بروبيلين والبولي إيثيلين، كارهة للماء، أي أنها تقاوم امتصاصه. هذه المقاومة للرطوبة تمنع التعفن، وهي مشكلة شائعة في الحبال الطبيعية.

هل يمكن إصلاح الحبال الاصطناعية المستخدمة في الزراعة إذا تعرضت للتلف؟

في حالة التآكل البسيط، قد يكون من الممكن إصلاح الألياف أو دمجها. أما في حالة التآكل الشديد أو التآكل أو تضرر سلامة هيكل الحبل، فمن الأفضل استبداله.

هل تأتي الحبال الصناعية للزراعة بألوان مختلفة؟

بالتأكيد. تتوفر بألوان متنوعة، مما يُسهّل الترميز أو التفضيلات الجمالية. كما يُوفّر اللون مقاومة للأشعة فوق البنفسجية أو وضوحًا أفضل.

هل يمكن استخدام الحبال الاصطناعية مع البكرات والرافعات في البيئات الزراعية؟

نعم. الحبال عالية القوة، مثل تلك المصنوعة من البولي إيثيلين عالي الكثافة (UHMWPE)، مناسبة بشكل خاص لأنظمة البكرات والرافعات والأجهزة الميكانيكية الأخرى.

هل الحبل الصناعي المستخدم في الزراعة مقاوم للزيوت والمواد الكيميائية؟

عادةً ما تقاوم الحبال الصناعية العديد من المواد الكيميائية والزيوت، ولكن ذلك يختلف باختلاف تركيبها. على سبيل المثال، يقاوم البولي بروبيلين معظم الأحماض، ولكنه قد يتلف بفعل عوامل مؤكسدة قوية. يُرجى مراجعة إرشادات الشركة المصنعة دائمًا عند استخدام الحبال بالقرب من المواد الكيميائية.