حبل UHMWPE

قوة وموثوقية لا مثيل لها للمهام الشاقة في البيئات الصعبة

الصفحة الرئيسية » نوع الحبل » حبل UHMWPE

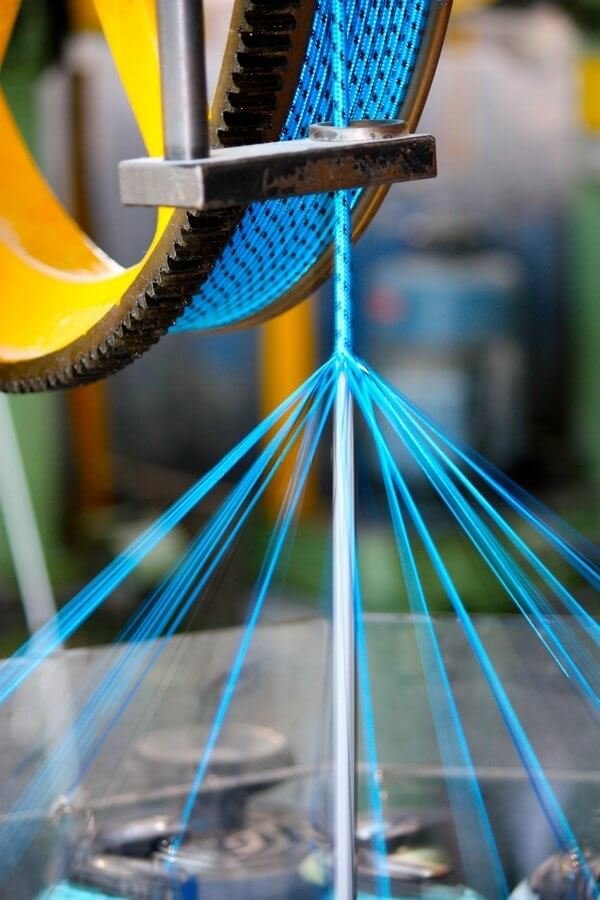

حبل UHMWPE هو نوع من الألياف الاصطناعية مصنوع من ألياف البولي إيثيلين عالية الوزن الجزيئي. مصمم للتعامل الأمثل، فهو مقاوم للتآكل ويوفر أداءً يدوم طويلاً حتى في الظروف القاسية.

- خفيف للغاية: سهولة التعامل والنقل

- قوة عظيمة: دائمة وموثوقة

- أكثر أمانًا: ارتداد أقل ومخاطر أقل

- متعدد الاستخدامات: تطبيقات عديدة

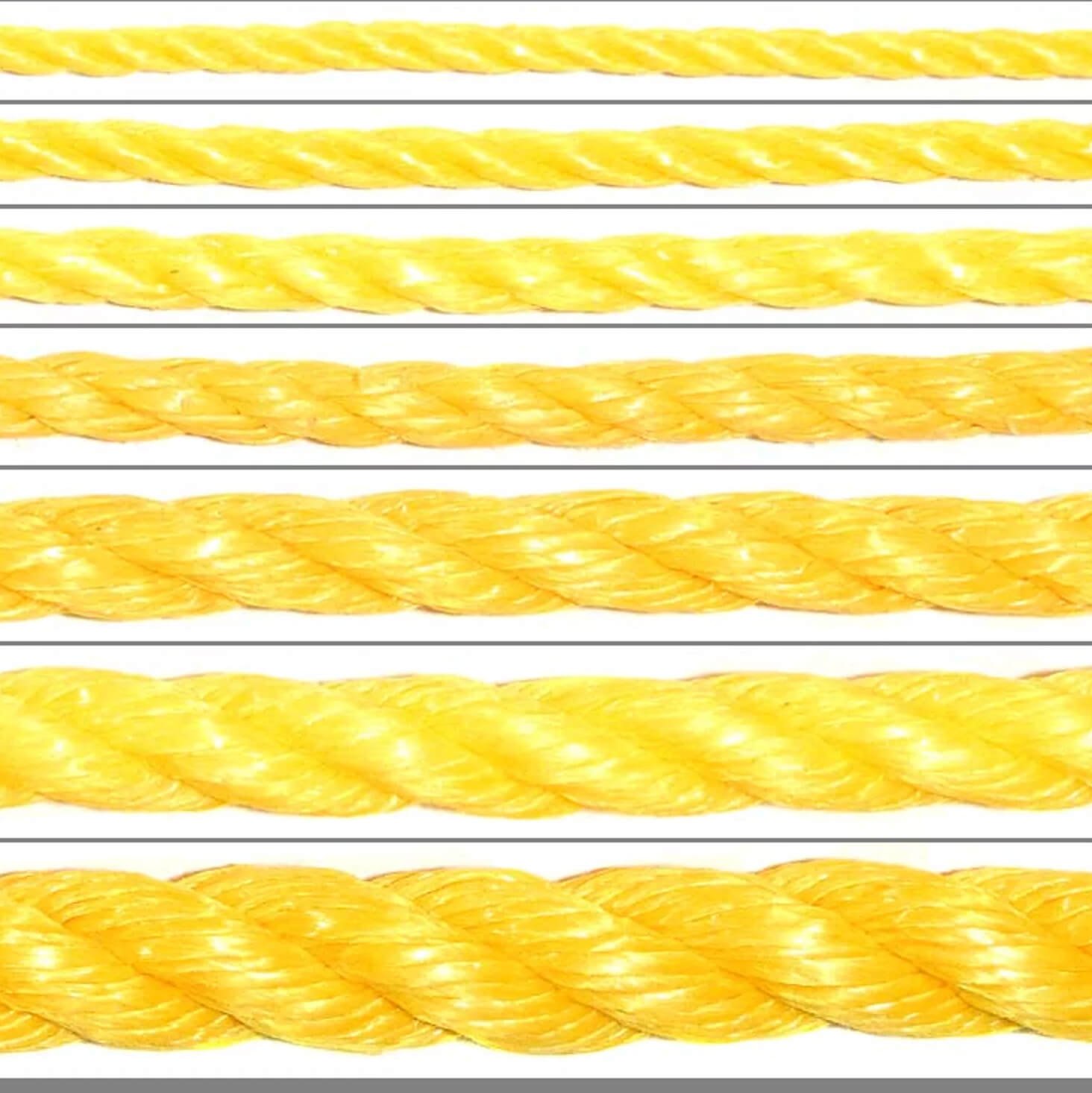

منتجاتنا من حبال البولي إيثيلين عالي الوزن الجزيئي

عام التطبيقات

مُصمم لتحقيق أداء موثوق وفعال في تطبيقاتك المحددة.

4X4 على الطرق الوعرة: سواء كان حبل الرافعة أو القيد الناعم، فإن منتجاتنا تعمل على تعزيز قدرات استرداد سيارتك وسلامتها في مجال 4×4.

البحرية والسفن: يمكن لمنتجاتنا تحسين كفاءة وسلامة العمليات البحرية والرياضية، كما تعمل على تعزيز قدرتك على التعامل مع مختلف البيئات القاسية.

النفط والغاز: لا تساعد منتجاتنا في تثبيت المعدات وسحبها ورفعها على منصات النفط فحسب، بل تضمن أيضًا اتصالاً فعالاً بالسفن.

صيد السمك: تعمل منتجات الحبال UHMWPE الخاصة بنا مثل شبكات الصيد والأقفاص على تعزيز كفاءة الصيد لديك، وتقليل تكرار الاستبدال، وخفض التكاليف الإجمالية لعمليات الصيد وتربية الأحياء المائية.

- صفات

رئيسي سمات

استكشاف الميزات الأساسية لحبل UHMWPE من Duracordix

نقطة الانصهار 135 درجة مئوية - 145 درجة مئوية

مقاومة الحجم: <10^14 Ω.سم

استعادة الرطوبة: لا شيء

انكماش الماء المغلي: <1%

الموصلية الحرارية: 20 واط/م·ك

مقاومة كيميائية ممتازة ضد الماء المقطر، مياه البحر، الكيروسين (منظف 10%)، البنزين، حمض الهيدروكلوريك، حمض الخليك، التولوين، محلول هيدروكسيد الصوديوم، محلول هيدروكسيد الأمونيوم.

حتى بعد التعرض المستمر للضوء لمدة 1500 ساعة، يظل معدل الاحتفاظ بالقوة أعلى من 90%، في حين أن الألياف الكيميائية الأخرى عادة ما يكون معدل الاحتفاظ بها حوالي 40% أو حتى أقل.

بعد إجراء آلاف دورات اختبار التحميل في ظل ظروف المياه، تظل قوتها غير متأثرة تقريبًا - مما يُظهر أداءً ممتازًا في تحمل التعب والشد.

الكثافة: 0.97 جم/سم3

القوة: 35-40 جرام/يوم

معامل المرونة: 1000-1500 جم/يوم

الاستطالة عند الكسر: 3.5%

- uhmwpe مقابل الفولاذ

المزايا

حبال UHMWPE تحل نقاط ضعفك فيما يتعلق بالسلامة والتعامل وكفاءة العمل

أخف من الفولاذ

أقوى في الوزن

أكثر أمانًا، ارتداد منخفض

حبال UHMWPE تزن 85% أقل من الأسلاك الفولاذية، مما يجعلها بعيدة أسهل في التعاملوالنقل والتشغيل - كل ذلك دون المساس بالقوة والأداء.

توفر حبال UHMWPE قوة لا تصدق—10 مرات أقوى من حبال أسلاك الفولاذ بنفس الوزن. هذه المتانة التي لا مثيل لها توفر مصداقية أنت بحاجة، حتى في أصعب شروط.

عندما تنكسر حبال UHMWPE، فإنها تكون بعيدة أقل ارتدادًامن حبال الأسلاك الفولاذية، مما يجعلها أكثر أمانًا بثلاث مرات. هذا مخفض قبعة سناباك رائعة يخفض خطر الإصابة أثناء العمليات.

| مادة الحبل | الميزات الرئيسية | قوة الشد | استطالة | مقاومة التآكل | مقاومة الأشعة فوق البنفسجية | المقاومة الكيميائية | أمثلة التطبيق |

|---|---|---|---|---|---|---|---|

| بولي إيثيلين عالي الكثافة | خفيفة الوزن للغاية، قابلة للطفو | استثنائي (أقوى بـ 15 مرة من الفولاذ من حيث الوزن) | منخفض (3-4%) | ممتاز | جيد | ممتاز | البحرية، الرافعات، الرفع، الرياضات الخطرة |

| نايلون | ناعمة ومرنة وتمتص الصدمات | قوي (متوسط مقارنة بـ UHMWPE و Kevlar) | عالية (25-30%) | جيد-ممتاز | جيد-مقبول | جيد | خطوط الربط، خطوط المرساة، حبال السحب |

| كيفلر | مقاوم للهب والحرارة وغير موصل للكهرباء | ممتاز (أقوى بخمس مرات من الفولاذ من حيث الوزن) | منخفض جدًا (2%) | ممتاز | ممتاز | جيد | بالونات الهواء الساخن، وخطوط الإنقاذ، والتطبيقات الكهربائية |

- اختر المقاس المناسب

اِصطِلاحِيّ مواصفة

| القطر | وزن | كيتكس | قوة الكسر | ||||

|---|---|---|---|---|---|---|---|

| مم | بوصة | 100م(كجم) | معيار | خطأ | طن | كن | |

| 5.00 | 3/16 | 1.70 | 16.62 | ±5% | 2.00 | 19.00 | |

| 6.00 | 1/4 | 2.30 | 23.00 | ±5% | 3.18 | 31.00 | |

| 8.00 | 5/16 | 4.10 | 40.00 | ±5% | 6.35 | 63.00 | |

| 9.00 | 23/64 | 5.10 | 50.50 | ±5% | 7.83 | 78.00 | |

| 9.50 | 3/8 | 5.60 | 55.75 | ±5% | 8.32 | 83.00 | |

| 10.00 | 13/32 | 6.10 | 61.00 | ±5% | 9.32 | 93.00 | |

| 11.00 | 7/16 | 7.50 | 74.00 | ±5% | 10.40 | 103.00 | |

| 12.00 | 1/2 | 8.80 | 87.00 | ±5% | 12.12 | 121.00 | |

| 14.00 | 9/16 | 12.00 | 119.00 | ±5% | 15.40 | 153.00 | |

| 16.00 | 5/8 | 15.50 | 151.00 | ±5% | 20.60 | 205.00 | |

| 18.00 | 3/4 | 19.00 | 190.00 | ±5% | 23.90 | 238.00 | |

| 20.00 | 13/16 | 23.00 | 225.00 | ±5% | 28.99 | 289.00 | |

| 22.00 | 7/8 | 28.00 | 276.00 | ±5% | 33.00 | 322.00 | |

| 24.00 | 1 | 37.00 | 368.00 | ±5% | 38.00 | 371.00 | |

| 28.00 | 1-1/8 | 50.00 | 490.00 | ±5% | 57.50 | 562.00 | |

| 32.00 | 1-5/16 | 62.50 | 621.00 | ±5% | 68.50 | 671.00 | |

| 36.00 | 1-1/2 | 77.00 | 767.00 | ±5% | 80.40 | 789.00 | |

| 40.00 | 1-5/8 | 87.00 | 868.00 | ±5% | 98.20 | 964.00 | |

| 44.00 | 1-3/4 | 96.00 | 955.00 | ±5% | 118.00 | 1158.00 | |

| 48.00 | 2 | 114.00 | 1137.00 | ±5% | 139.00 | 1364.00 | |

| 56.00 | 2-1/4 | 159.00 | 1547.00 | ±5% | 184.00 | 1805.00 | |

| 60.00 | 2-1/2 | 180.00 | 1784.00 | ±5% | 199.00 | 1952.00 | |

| 64.00 | 2-5/8 | 209.00 | 2021.00 | ±5% | 222.00 | 2178.00 | |

| 72.00 | 3 | 268.00 | 2598.00 | ±5% | 274.00 | 2688.00 | |

| 80.00 | 3-1/4 | 328.00 | 3195.00 | ±5% | 333.00 | 3266.00 | |

| 88.00 | 4 | 427.00 | 4170.00 | ±5% | 390.00 | 3825.00 | |

| 96.00 | 3-5/9 | 509.00 | 4970.00 | ±5% | 455.00 | 4463.00 |

ملحوظة: تتوفر أحجام أكبر عند الطلب لتلبية احتياجات مشروعك المحددة

Duracordix هو حبل UHMWPE الشركة المصنعة والمورد في الصين.

بغض النظر عما إذا كنت تبحث عن مورد الجملة أو حبل UHMWPE المصنوع حسب الطلب، يمكننا جميعًا مساعدتك. اتصل بـ Duracordix الآن.

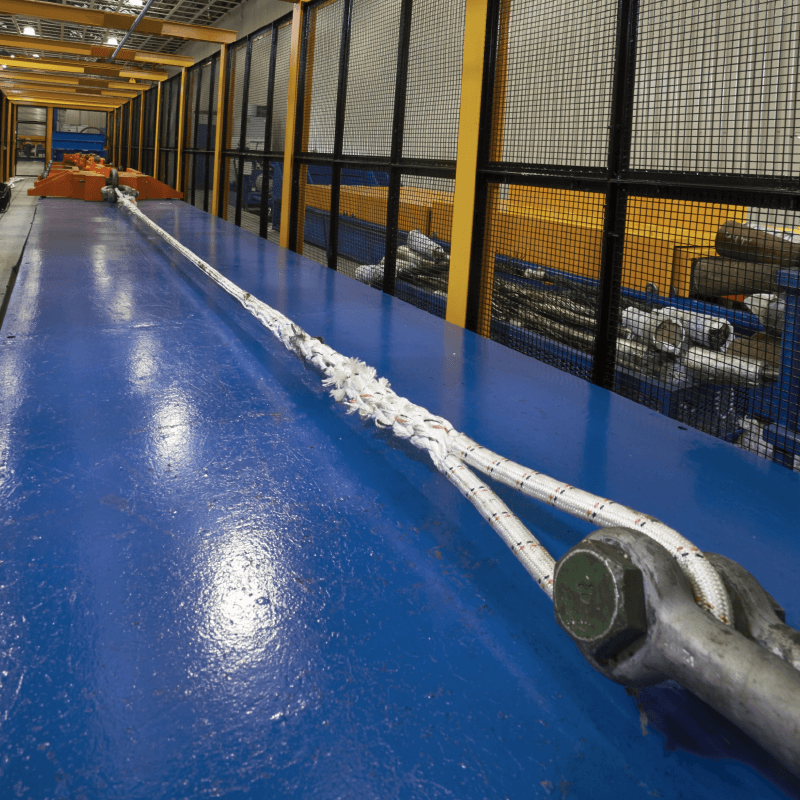

- ضبط الجودة

اختبار حبل البولي إيثيلين عالي الوزن الجزيئي

تُجري شركة دوراكورديكس اختبارات دورية للحبال لضمان جودتها وتلبية احتياجاتكم.

التخصيص خيارات

لتلبية متطلباتك الفريدة

- شراء بدون ألم

لماذا تختار؟

حبل دوراكورديكس UHMWPE

- جودة فائقة: تضمن دوراكورديكس حبال UHMWPE عالية الجودة بعد اختبارات دقيقة. نفخر بمعدل رضا العملاء 96%، ونضع التميز في المقام الأول.

- الخبرة في المجال: مع سنوات من الخبرة في تصنيع حبال UHMWPE، فإننا نفهم بعمق احتياجات قطاعات السيارات والمعدات الثقيلة والعسكرية.

- إمكانيات التخصيص: إدراكًا لاحتياجات العملاء الفريدة، فإننا نقدم خيارات مخصصة للقطر والطول على 90% من منتجاتنا، مما يضمن الملاءمة المثالية.

- خدمة عملاء استثنائية: تركز Duracordix على الخدمة السريعة والفعالة مع وقت استجابة أقل من 4 ساعات، وحل 95% من الاستفسارات في يوم عمل واحد فقط.

- السلامة: مع إعطاء الأولوية لسلامة المستخدم، تم تصميم حبال UHMWPE الخاصة بنا لتحمل الظروف الصعبة، مما يقلل المخاطر ويضمن عمليات آمنة في كل مرة.

- أسعار تنافسية: من خلال موازنة الجودة العالية مع الأسعار التنافسية، تقدم Duracordix منتجات بأسعار أقل بمقدار 20% من العديد من المنافسين، دون التضحية بالموثوقية.

الأسئلة الشائعة

كل ما تحتاج لمعرفته حول حبل Duracordix UHMWPE

ما هو حبل UHMWPE وما هي فوائده؟

حبل البولي إيثيلين فائق الوزن الجزيئي (UHMWPE) هو حبل ألياف عالي الأداء، يتميز بقوته الاستثنائية وخفة وزنه ومتانته. ويتميز بمزايا مثل قوة الشد العالية، ومقاومة ممتازة للتآكل، وخصائص تمدد منخفضة، ومقاومة للمواد الكيميائية والأشعة فوق البنفسجية.

ما مدى قوة حبل UHMWPE مقارنة بأنواع الحبال الأخرى؟

حبل UHMWPE قويٌّ للغاية؛ بل إنه يتمتع بواحدة من أعلى نسب القوة إلى الوزن بين جميع الحبال الاصطناعية. يمكن أن يكون أقوى بخمس عشرة مرة من حبال الأسلاك الفولاذية من نفس القطر.

هل حبل UHMWPE مناسب للتطبيقات البحرية؟

بالتأكيد! بفضل نسبة قوتها إلى وزنها العالية وخصائصها المقاومة للماء، تُستخدم حبال UHMWPE على نطاق واسع في مختلف التطبيقات البحرية، بما في ذلك حبال الإرساء، وحبال القطر، وحبال الرافعات، والعمليات البحرية.

هل يمكنني استخدام حبل UHMWPE لعمليات الرفع الثقيلة؟

نعم! بفضل المتانة الفائقة لحبل UHMWPE، فهو مثالي لمهام الرفع الثقيلة التي تتطلب أداءً فائقًا. كما أن خفة وزنه تُخفف الضغط على المعدات أثناء عمليات الرفع.

ما هي بعض التطبيقات الشائعة لحبل UHMWPE؟

تجد حبال UHMWPE استخدامًا واسع النطاق في مجموعة واسعة من الصناعات والتطبيقات، بما في ذلك العمليات البحرية، وصيد الأسماك وتربية الأحياء المائية، والبناء، والتعدين، وزراعة الأشجار (رعاية الأشجار)، والتجهيز في الإنتاجات المسرحية/المسرحية، والأنشطة الترفيهية مثل التخييم والمشي لمسافات طويلة.

هل حبال UHWMPE مقاومة للمواد الكيميائية؟

بالتأكيد! من أهم مزايا حبل UHMWPE مقاومته الممتازة لمجموعة واسعة من المواد الكيميائية. فهو يتحمل التعرض للأحماض والقلويات والمذيبات والزيوت والوقود دون أي تدهور يُذكر.

كيف يجب أن أعتني بحبل UHMWPE الخاص بي لضمان طول عمره؟

لإطالة عمر حبل UHMWPE الخاص بك، يُنصح بفحصه بانتظام بحثًا عن أي تلف أو تآكل. كما يُنصح بالتنظيف الجيد عند الحاجة باستخدام محلول صابون خفيف/ماء. خزّنه جافًا بعيدًا عن أشعة الشمس المباشرة عند عدم استخدامه.

هل هناك أي معلومات سلامة محددة يجب أن أكون على دراية بها أثناء استخدام حبل UHMWPE؟

على الرغم من أنه من الآمن التعامل معه بشكل عام، إلا أنه يجب اتباع احتياطات السلامة القياسية مثل ارتداء القفازات الواقية أثناء التعامل أو تجنب الحواف الحادة التي يمكن أن تسبب التآكل على السطح.

هل يمكن لشركة Duracordix تقديم المواصفات الفنية لمجموعة حبال UHWMPE الخاصة بها؟

بالتأكيد! نوفر مواصفات فنية شاملة لحبال UHMWPE، بما في ذلك خيارات القطر، وقوة التحمل، وتفاصيل الوزن لكل متر/قدم. تواصل معنا لمزيد من المعلومات.

هل حبال UHWMPE من Duracordix متوافقة مع معايير الصناعة؟

بالتأكيد! منتجاتنا تخضع لإجراءات صارمة لمراقبة الجودة، وتتوافق مع معايير الصناعة ذات الصلة. مع شهادات مثل ISO وCE، نولي أهمية كبيرة لتقديم منتجات عالية الجودة تلبي توقعات عملائنا باستمرار.

هل يمكنني طلب عينة من حبل UHWMPE قبل تقديم طلب بالجملة؟

نعم! نحن ندرك أهمية تقييم جودة وملاءمة حبال UHMWPE التي نقدمها قبل اتخاذ أي قرار بشأن أي منتج. تواصل معنا، وسيسعدنا تزويدك بعينة.

هل تقدمون الدعم الفني أو المساعدة في اختيار حبل UHMWPE المناسب لتطبيقي؟

بالتأكيد! فريق خبرائنا جاهز لمساعدتك في اختيار حبل UHMWPE الأنسب لك بناءً على احتياجاتك الخاصة. نهدف إلى تقديم مساعدة شخصية مصممة خصيصًا لتلبية احتياجاتك.

هل هناك أي قيود أو احتياطات يجب أن أكون على علم بها أثناء استخدام حبل UHWMPE؟

على الرغم من متانة الحبل وقوته العالية، من المهم عدم تجاوز حد حمل العمل الموصى به (WLL) لكل قطر من أقطاره. بالإضافة إلى ذلك، تجنب تعريض الحبل للحواف الحادة أو الأسطح الكاشطة التي قد تؤثر على سلامته.

هل يمكنني استخدام الموصلات أو التركيبات مع حبال UHWMPE؟

نعم! يُمكن استخدام الموصلات والتجهيزات مع حبال UHWMPE وفقًا لمتطلبات التطبيق الخاصة. من الضروري اختيار الموصلات والتجهيزات المتوافقة لضمان الأداء الأمثل والسلامة.

هل يمكنني ربط أو ربط حبل UHWMPE بنفسي؟

يمكن ربط أو ربط حبال UHWMPE، ولكن يوصى بطلب التوجيه المهني أو استشارة فريق الدعم الفني لدينا للحصول على التقنيات المناسبة وأفضل الممارسات لضمان سلامة الحبل.

كيف تضمن شركة Duracordix جودة حبال UHMWPE الخاصة بها؟

في دوراكورديكس، نطبق إجراءات صارمة لمراقبة الجودة طوال عملية التصنيع. يشمل ذلك استخدام مواد عالية الجودة، وإجراء اختبارات دقيقة، والالتزام بالمعايير الدولية لتقديم منتجات عالية الجودة باستمرار.

هل تقدم شركة Duracordix تغطية الضمان لحبال UHMWPE الخاصة بها؟

نعم! نضمن جودة وأداء حبالنا المصنوعة من البولي إيثيلين عالي الكثافة (UHMWPE). نوفر ضمانًا ضد عيوب التصنيع لضمان راحتك وطمأنينتك عند الشراء.