AGRICULTURE

Homepage » Industries » Agriculture

AGRICULTURE

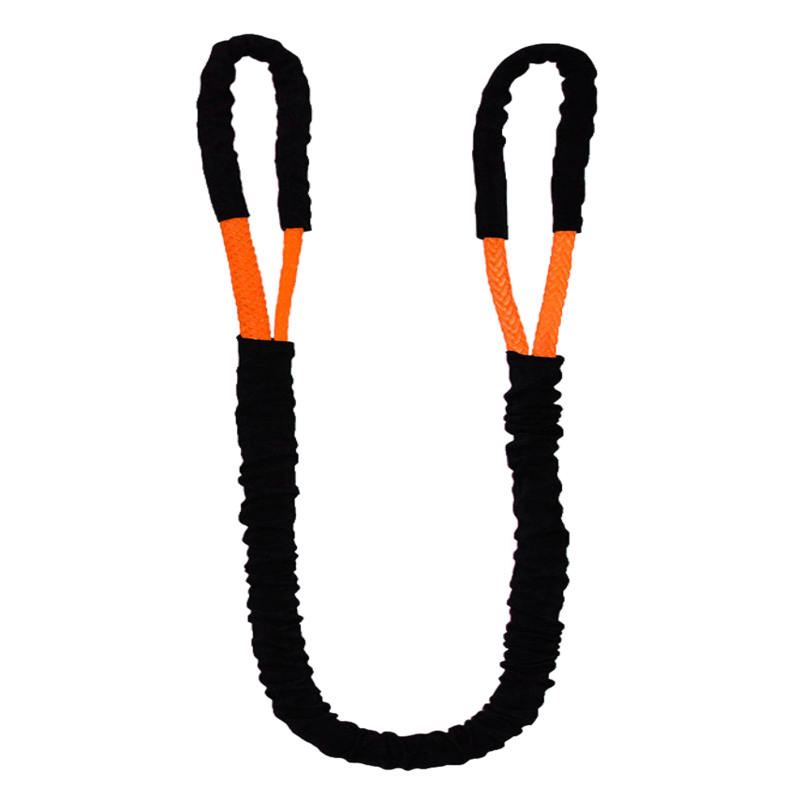

We offer a diverse array of premium-quality products tailored specifically for agricultural applications and challenges. Among our top-sellers are kinetic recovery rope, synthetic winch rope, synthetic lifting sling.

Additionally, we also provide other essential items that cater to your farming tasks like UHMWPE tow rope,tree trunk protector, log wrapper, tow strap, and rope-related accessories etc.

Eengineered to provide exceptional strength, durability, and reliability for your agricultural operations.

Eengineered to provide exceptional strength, durability, and reliability for your agricultural operations.

Designed to have high elasticity, strength, and durability for various heavy-duty recovery operations.

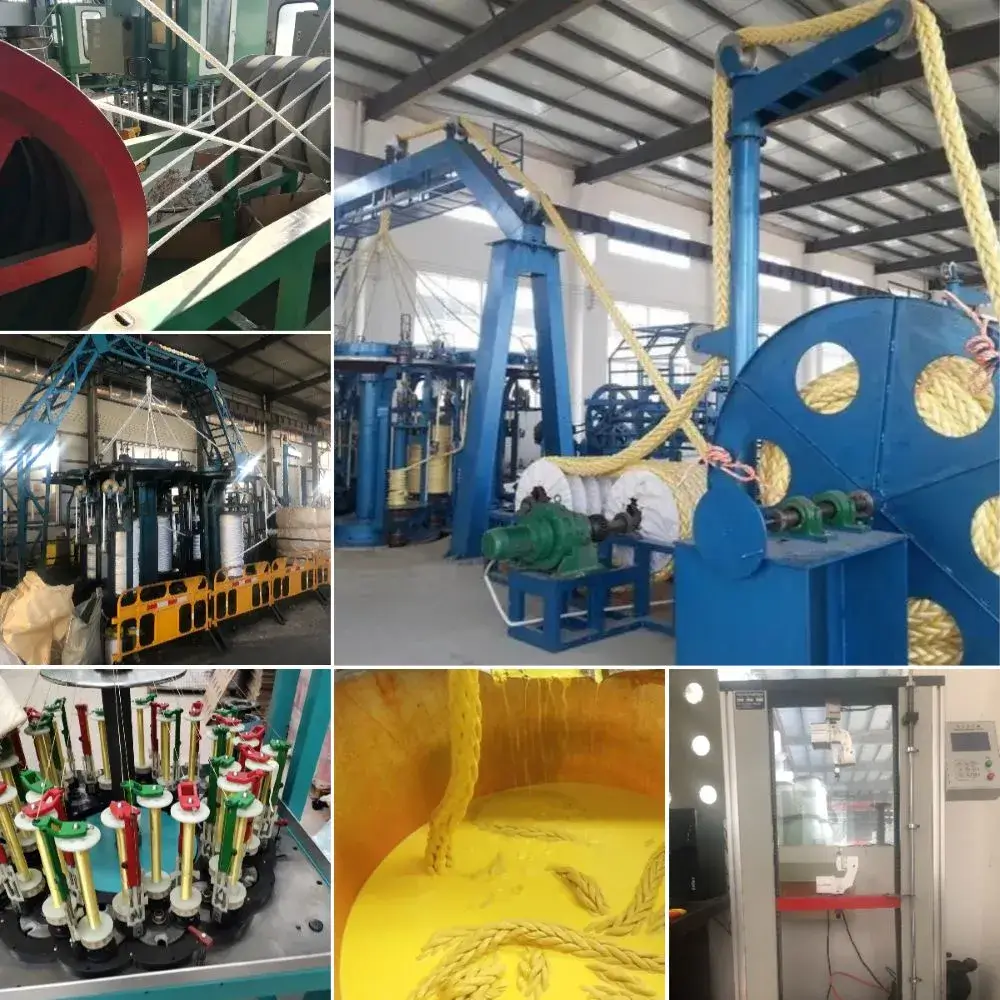

how to make

Discover Our Process of Producing High-Performance Agriculture Recovery Ropes.

Process 1

fiber selection

We carefully select high-quality synthetic fibers, such as nylon,polyester, or UHMWPE, to use in our ropes, ensuring strength and durability.

Process 2

Twisting and Forming

The selected fibers are twisted together to create yarns, which are then twisted together to create strands. The twisted strands are then formed into a rope-like structure.

Process 3

Laying and Braiding

The formed rope is laid into a braiding machine, which braids the rope together using specialized techniques and patterns to further increase strength and durability.

Process 4

Coating

A custom protective coating made of high-quality materials, such as PVC or polyurethane, is applied to enhance the rope’s durability and resistance to abrasion, water, and UV rays.

Process 5

Heat Treatment and Drying

The braided rope undergoes a specialized heat treatment process to set the braids and increase strength. The rope is then dried to remove any moisture.

Process 6

testing

Each Duracordix recovery rope is rigorously tested to ensure it meets our high standards for strength and stretch. Any rope that fails our testing process is discarded.

- Quality-Centric

. QUALITY CONTROL

Explore How We Ensure Unparalleled Excellence in Every Fiber Rope

1. Raw Materials

Our synthetic ropes are only made from raw materials that meet our strict quality standards. We work with trusted suppliers to ensure consistent quality and optimal performance in all our products.

2. In-House

By keeping our synthetic rope production in-house, we have full control over quality throughout the manufacturing process. This allows us to adhere to our high standards and provide reliable products to our customers.

3. Testing & Inspection

Our rigorous testing and inspection processes involve every stage of production, from raw materials to finished products. This ensures the consistent quality and safety of our synthetic ropes.

4. Automated Manufacturing

We integrate automated machinery and technology to ensure accuracy and consistency in our synthetic rope production. This reduces human error and ensures all products meet our strict quality standards.

5. Skilled Staff

Our highly skilled workforce undergoes ongoing training and continuing education to stay up-to-date with the latest techniques in synthetic rope production. This helps us uphold the highest level of quality and performance

- international standard

our certifications

easy & clear

Maximizing customer satisfaction with easy purchasing, minimizes communication and time costs.

Step 1: Solution Confirmation (3-5 days)

First, we’ll chat about your needs and recommend the best rope solution for you. Our expertise and experience will guarantee you get the best product possible.

Step 2: Sample Evaluation (7-14 days)

To ensure you’re happy with our product, we offer sample evaluations. Test our products before ordering to make sure they meet your requirements.

Step 3: Order Confirmation (within 3 day)

Once you’re satisfied with the sample evaluation, confirm your order with us. We’ll provide all necessary details, including pricing, lead times, and more, so you can be confident in your purchase.

Step 4: Bulk Manufacturing (30-45 days)

We offer bulk manufacturing options for larger orders. Our advanced production techniques and high-quality materials ensure consistency and reliability across all orders.

Step 5: Delivery (30-45 days)

We know timely delivery is important, so we’ll keep you updated on shipping progress and provide tracking information. Your order will arrive within the agreed timeframe.

Step 6: After-Sales Service

Our service doesn’t stop after your order is delivered. If you have any questions or concerns, our team is always available to assist you. We’re committed to providing excellent customer service and ensuring your satisfaction.

- Pain-Free Purchase

WHY CHOOSE

- UV Resistant: Our ropes are treated to resist 200% more UV radiation than others, ensuring durability even under the sun.

- Strength: Engineered with a tensile strength of 50,000 lbs. Whether towing or winching, our ropes won’t let you down.

- Security: Our custom rope has a proven record of securely tying down equipment for transportation and field use, giving you peace of mind.

- Cost-Effective: Expect savings of up to 30% compared to leading brands. Quality doesn’t always come at a premium.

- Dedicated Service: With 24/7 customer support, Duracrodix promises assistance in under 2 hours, always prioritizing your needs.

- Customizable: Whether you require custom length, diameter, color, or strength, our rope is tailored to meet your specific agricultural needs at a reasonable price.

FAQs

Frequently asked questions addressing customer concerns and pain points

What are agriculture ropes and straps used for?

Agriculture ropes and straps are used in agricultural applications for tasks such as securing crops, anchoring trees, pulling heavy equipment, and more.

Can agriculture ropes and straps be used interchangeably?

No, different types of ropes and straps have different strengths and uses, and it is important to choose the right product for each specific agricultural task.

What materials are agriculture ropes and straps made from?

Agriculture ropes and straps can be made from natural fibers such as cotton and sisal, or synthetic fibers such as nylon and polyester,uhmwpe etc.

Why are synthetic ropes preferred in agriculture?

Synthetic ropes offer several advantages in agriculture:

Durability: They resist environmental factors such as UV rays, rot, and mildew.

Strength: Especially those like UHMWPE, can bear heavy loads.

Cost-Effective: Longer lifespans mean fewer replacements.

Resistance: They repel water and most chemicals found in agricultural settings.

How do synthetic ropes compare to natural ropes in terms of strength?

While natural ropes, like manila or sisal, have been used historically for their inherent strength, modern synthetic ropes often surpass them in tensile strength and durability. UHMWPE ropes, for example, have a strength-to-weight ratio eight to fifteen times higher than steel.

Can synthetic ropes for agriculture be recycled?

Many synthetic ropes are recyclable, but the feasibility often hinges on the type of polymer and local recycling facilities. Always consult with the manufacturer or local waste management for proper recycling options.

How do you maintain synthetic ropes for agriculture?

Maintenance is key for longevity:

•Inspect regularly for wear, fraying, or damage.

•Clean periodically to remove dirt, chemicals, and moisture. Mild soap and water usually suffice.

•Store away from direct sunlight in a cool, dry place.

•Avoid contact with sharp or abrasive surfaces.

Are synthetic ropes for agriculture resistant to UV rays?

Many synthetic ropes, particularly nylon and polyester, have good UV resistance. However, over time and with prolonged exposure, UV rays can weaken any rope.

What's the lifespan of a synthetic rope used in agriculture?

Lifespan can vary based on use and environmental factors. With proper care, synthetic ropes can last several years. However, ropes used daily in heavy-duty tasks may need replacement sooner.

Can synthetic ropes handle heavy loads like bales or machinery in agriculture?

Yes. UHMWPE ropes, renowned for their high strength, are often used for heavy-lifting operations in agriculture, like moving large bales or machinery.

Are synthetic ropes safe for animal handling?

Synthetic ropes can be used safely for animal handling, be it as leads, tie-outs, or enclosures. Always ensure the rope is free from sharp or abrasive particles to prevent harm.

Do synthetic ropes for agriculture stretch?

Stretch varies by material. Nylon is elastic and has significant stretch, which can be useful for shock absorption. Polyester and UHMWPE, however, have minimal stretch, making them ideal for applications requiring stability.

How does moisture affect synthetic ropes for agriculture?

Synthetic ropes, especially polypropylene and polyethylene, are hydrophobic, meaning they resist water absorption. This resistance to moisture prevents rot, a common problem in natural ropes.

Can synthetic ropes for aguriculture be repaired if damaged?

For minor abrasions, it might be possible to mend or fuse the fibers. However, for significant wear, fraying, or if the structural integrity is compromised, it's safer to replace the rope.

Do synthetic ropes for agriculture come in different colors?

Absolutely. They're available in a wide range of colors, helpful for coding or aesthetic preferences. The color can also provide UV resistance or increased visibility.

Can synthetic ropes be used with pulleys and winches in agricultural settings?

Yes. High-strength ropes, like those made from UHMWPE, are particularly suited for pulley systems, winches, and other mechanical devices.

Is synthetic rope for agriculture resistant to oils and chemicals?

Synthetic ropes generally resist many chemicals and oils, but it varies by rope composition. For instance, polypropylene resists most acids but can be damaged by strong oxidizing agents. Always consult manufacturer guidelines when using ropes around chemicals.