بناء

الصفحة الرئيسية » الصناعات » بناء

بناء

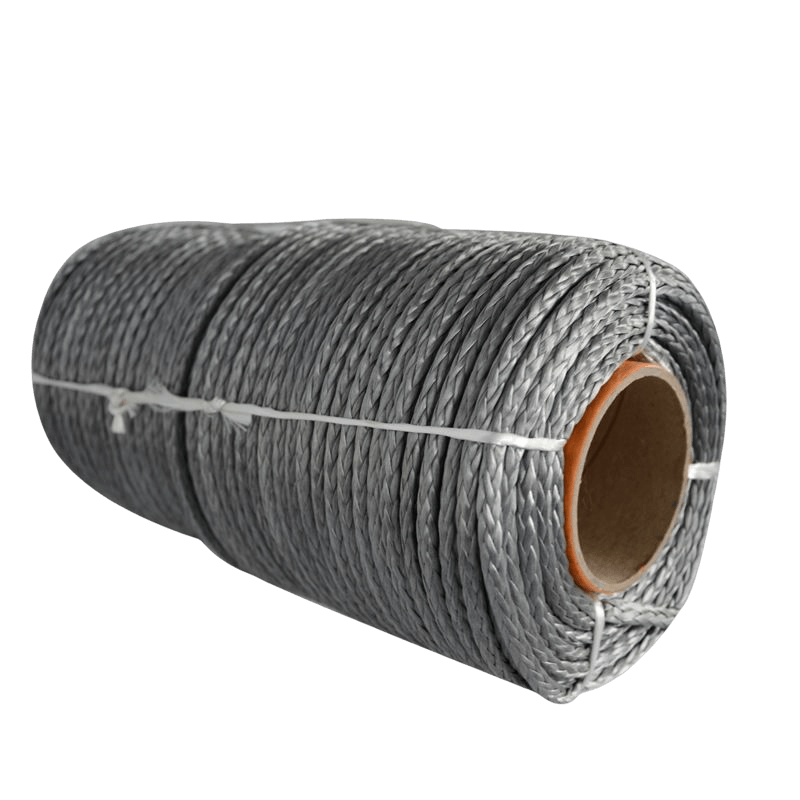

نقدم مجموعة واسعة من المنتجات عالية الجودة، المصممة خصيصًا لتطبيقات البناء ومهام الرفع الثقيلة. تشمل منتجاتنا الشهيرة: حبل الرافعة, حبال رفع ثقيلة و حزام حزام.

بالإضافة إلى ذلك، فإننا ننتج ونوفر أيضًا عناصر أخرى لا غنى عنها تلبي متطلبات البناء والرفع الثقيل مثل معادلات حبال الرافعة وشبكات الأمان في موقع البناء، حزام رفع ثقيل ومجموعة متنوعة من ملحقات الحبال والمعدات ذات الصلة.

كيفية صنع

حبل البناء

اكتشف عملية إنتاج حبال البناء عالية الأداء لدينا.

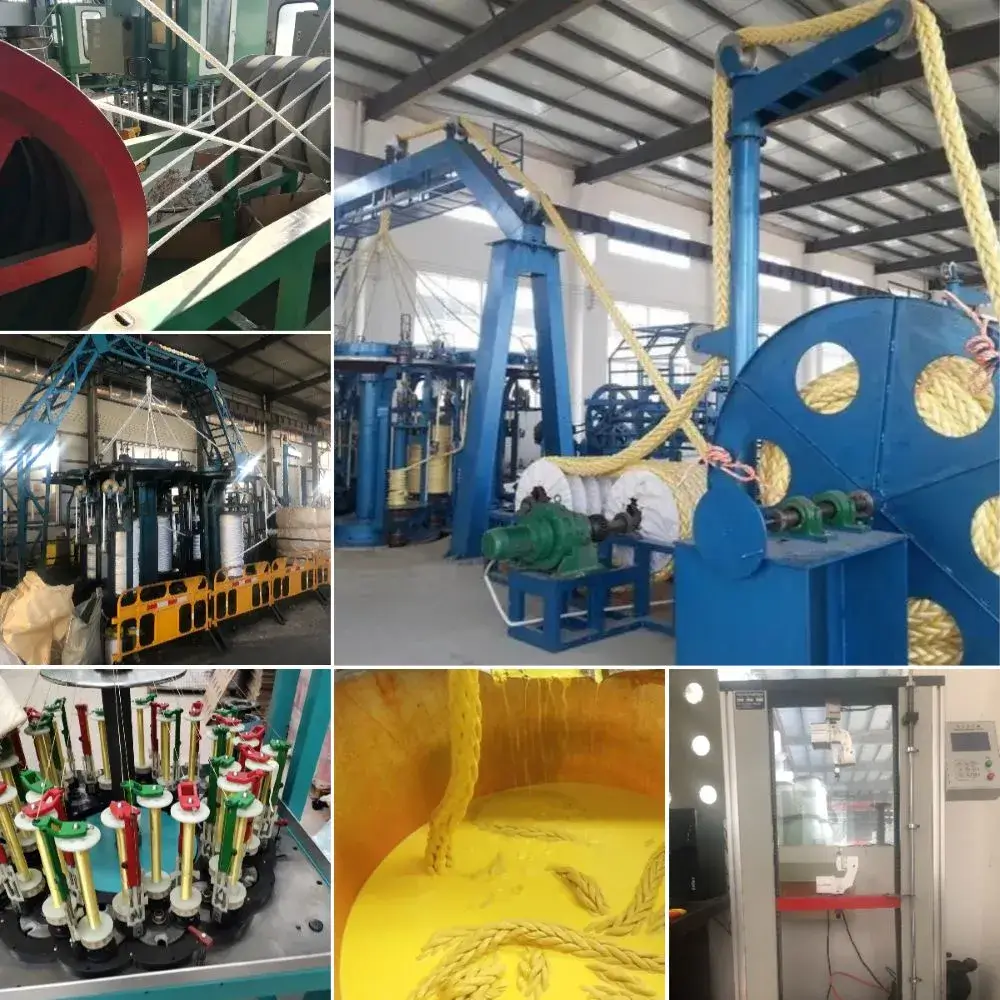

العملية 1

اختيار الألياف

نقوم بعناية باختيار الألياف الصناعية عالية الجودة، مثل النايلون، أو البوليستر، أو UHMWPE، لاستخدامها في حبالنا، مما يضمن القوة والمتانة.

العملية 2

الالتواء والتشكيل

تُلَفُّ الألياف المختارة معًا لتكوين خيوط، تُلَفُّ بدورها لتكوين خيوط. تُشكَّل الخيوط الملتوية بعد ذلك على شكل حبل.

العملية 3

وضع وتضفير

يتم وضع الحبل المشكل في آلة التضفير، والتي تقوم بضفر الحبل معًا باستخدام تقنيات وأنماط متخصصة لزيادة القوة والمتانة بشكل أكبر.

العملية 4

طلاء

يتم تطبيق طبقة حماية مخصصة مصنوعة من مواد عالية الجودة، مثل PVC أو البولي يوريثين، لتعزيز متانة الحبل ومقاومته للتآكل والماء والأشعة فوق البنفسجية.

العملية 5

المعالجة الحرارية والتجفيف

يخضع الحبل المضفر لعملية معالجة حرارية متخصصة لتثبيت الضفائر وزيادة قوتها. ثم يُجفف الحبل لإزالة أي رطوبة.

العملية 6

الاختبار

يخضع كل حبل استرداد من Duracordix لاختبارات دقيقة لضمان استيفائه لمعاييرنا العالية للقوة والمرونة. أي حبل لا يجتاز عملية الاختبار الخاصة بنا يتم التخلص منه.

- التركيز على الجودة

. ضبط الجودة

اكتشف كيف نضمن التميز الذي لا مثيل له في كل حبل من حبال الألياف

1. المواد الخام

حبال البناء الاصطناعية لدينا مصنوعة فقط من مواد خام مطابقة لمعايير الجودة الصارمة لدينا. نتعاون مع موردين موثوقين لضمان جودة ثابتة وأداء مثالي لجميع منتجاتنا.

2. داخليًا

بفضل إنتاجنا الداخلي للحبال الاصطناعية، نتمتع بتحكم كامل في الجودة طوال عملية التصنيع. هذا يسمح لنا بالالتزام بمعاييرنا العالية وتقديم منتجات موثوقة لعملائنا.

3. الاختبار والتفتيش

تشمل عمليات الاختبار والتفتيش الدقيقة لدينا كل مرحلة من مراحل الإنتاج، من المواد الخام إلى المنتجات النهائية. وهذا يضمن جودة وسلامة حبالنا الاصطناعية.

4. التصنيع الآلي

ندمج الآلات والتكنولوجيا الآلية لضمان الدقة والاتساق في إنتاج الحبال الاصطناعية. هذا يقلل من الأخطاء البشرية ويضمن استيفاء جميع المنتجات لمعايير الجودة الصارمة لدينا.

5. الموظفين المهرة

يخضع فريقنا من العمالة الماهرة لتدريب وتعليم مستمر لمواكبة أحدث التقنيات في إنتاج الحبال الصناعية، مما يساعدنا على الحفاظ على أعلى مستويات الجودة والأداء.

- المعيار الدولي

ملكنا الشهادات

سهل وواضح

تعظيم رضا العملاء من خلال سهولة الشراء، وتقليل تكاليف الاتصالات والوقت.

الخطوة 1: تأكيد الحل (3-5 أيام)

أولاً، سنناقش احتياجاتك ونقترح عليك أفضل حل للحبال. خبرتنا الواسعة تضمن لك الحصول على أفضل منتج ممكن.

الخطوة 2: تقييم العينة (7-14 يومًا)

لضمان رضاكم عن منتجاتنا، نقدم لكم تقييمات عينات. اختبروا منتجاتنا قبل الطلب للتأكد من أنها تلبي متطلباتكم.

الخطوة 3: تأكيد الطلب (خلال 3 أيام)

بعد رضاك عن تقييم العينة، أكّد طلبك معنا. سنزودك بجميع التفاصيل اللازمة، بما في ذلك السعر ومدة التسليم وغيرها، لتكون على ثقة تامة بشرائك.

الخطوة 4: التصنيع بالجملة (30-45 يومًا)

نوفر خيارات تصنيع بكميات كبيرة للطلبات الكبيرة. تقنياتنا الإنتاجية المتطورة وموادنا عالية الجودة تضمن الاتساق والموثوقية في جميع الطلبات.

الخطوة 5: التسليم (30-45 يومًا)

ندرك أهمية التسليم في الوقت المحدد، لذا سنُبقيك على اطلاع دائم بتقدم الشحنة ونزودك بمعلومات التتبع. سيصل طلبك في الموعد المحدد.

الخطوة 6: خدمة ما بعد البيع

خدمتنا مستمرة بعد توصيل طلبك. إذا كانت لديك أي أسئلة أو استفسارات، ففريقنا جاهز دائمًا لمساعدتك. نحن ملتزمون بتقديم خدمة عملاء ممتازة وضمان رضاكم.

- شراء بدون ألم

لماذا تختار؟

- المتانة: باستخدام مواد مبتكرة، تتحمل حبال Duracrodix التآكل والعوامل البيئية، مما يطيل عمرها بمقدار 50% مقارنة بالآخرين.

- القوة: بفضل قوة الشد التي تتجاوز المنافسين بـ 40%، تضمن Duracrodix قدرة تحمل لا مثيل لها لمهام البناء الصعبة.

- السلامة: يقلل الحبل الصناعي Duracrodix من مخاطر الإصابة بفضل مادة 80%، مما يزيل الارتداد الخطير للحبال التقليدية عند كسرها.

- خفيف الوزن: 60% أخف من البدائل الفولاذية، ويضمن حبلنا الاصطناعي التعامل دون عناء ويقلل من جهود العمل.

- بفضل توفير 30% مع صيانة أقل ومرونة دائمة، تتفوق حبال Duracrodix على الخيارات التقليدية من حيث الكفاءة من حيث التكلفة.

- التنوع: يلبي حبلنا متطلبات البناء المتنوعة، ويتميز بالتنوع، وهو مناسب للمهام من الرفع إلى التأمين.

الأسئلة الشائعة

الأسئلة الشائعة التي تتناول مخاوف العملاء ونقاط الألم

ما هو حبل البناء؟

حبل البناء هو حبل عالي القوة والمتانة مصمم للاستخدام في التطبيقات الشاقة، مثل بناء المباني والرفع والتجهيز.

كيفية اختيار القطر المناسب للحبل البناء لمشروعي؟

عند اختيار قطر حبل البناء، ضع في اعتبارك عوامل مثل سعة التحميل والاستخدام المقصود. استشر خبراء دوراكورديكس لاتخاذ قرار مدروس.

ما هو أفضل حبل للبناء؟

يعتمد اختيار أفضل حبل للبناء على التطبيق المحدد، ومتطلبات الحمل، والعوامل البيئية. من الخيارات الشائعة حبال النايلون، والبوليستر، والبولي بروبيلين، وUhmwpe، نظرًا لقوتها ومتانتها ومقاومتها للتآكل والعوامل البيئية.

ما هو نوع حبل الألياف الأنسب لتأمين الأحمال على الشاحنات أثناء النقل؟

يوفر حبل النايلون من Duracordix قوة شد ممتازة ومقاومة للتآكل، مما يجعله خيارًا مثاليًا لتأمين الأحمال على الشاحنات أثناء النقل.

هل لا تزال حبال الأسلاك الفولاذية مستخدمة على نطاق واسع في مشاريع البناء الحديثة؟

تستمر حبال الأسلاك الفولاذية في لعب دور حاسم في التطبيقات الثقيلة داخل صناعة البناء بسبب قوتها الشد ومتانتها الاستثنائية.

ما هو أفضل حبل بناء لرفع الأشياء الثقيلة؟

يوفر حبل UHMWPE من Duracordix قوة ومتانة استثنائية، مما يجعله مثاليًا للرفع الثقيل في مشاريع البناء.

هل حبل النايلون أو حبل UHMWPE أفضل لأغراض البناء العامة؟

يتمتع كل من حبال النايلون وحبال UHMWPE بمزاياها، ولكن تتميز حبال UHMWPE بنسبة القوة إلى الوزن المتفوقة، مما يجعلها الخيار المفضل للعديد من تطبيقات البناء.

هل يمكنني استخدام حبل كيفلر في البيئات ذات درجات الحرارة العالية أثناء البناء؟

نعم، تتميز حبال كيفلر بخصائص مقاومة الحرارة الممتازة، مما يجعلها مناسبة للبيئات ذات درجات الحرارة العالية التي تواجهها بعض أنشطة البناء.

ما هو نوع حبل الألياف الموصى به لخطوط أمان السقالات؟

تُستخدم الحبال النايلون عادةً كخطوط أمان في السقالات نظرًا لقدرتها الجيدة على امتصاص الصدمات وقوتها الشاملة.

هل هناك أي لائحة محددة بشأن الحد الأقصى للوزن الذي يمكن رفعه باستخدام الحبال الليفية؟

قد تختلف اللوائح حسب الولاية القضائية، ولكن بشكل عام، هناك عوامل مختلفة مثل قطر الحبل ونوع البناء واعتبارات السلامة الأخرى التي تلعب دورًا عند تحديد حدود الوزن لعمليات الرفع.

هل يمكن استخدام حبال UHMWPE في مشاريع البناء البحرية؟

بالتأكيد! تتميز حبال UHMWPE بمقاومة عالية لامتصاص الماء ومتانة ممتازة، مما يجعلها مناسبة لمختلف تطبيقات البناء البحري.

ما هو متوسط عمر حبل النايلون Duracordix المستخدم في عمليات صيانة المباني؟

يمكن أن يختلف عمر حبل النايلون Duracordix اعتمادًا على ظروف الاستخدام ولكن مع الرعاية والصيانة المناسبة، يمكن أن يستمر لعدة سنوات في عمليات صيانة المباني.

هل هناك أي شهادات أو معايير محددة يجب أن تلتزم بها حبال الألياف لاستخدامها في البناء؟

نعم، هناك شهادات معينة مثل شهادة ISO 9001 وشهادة CE تضمن أن حبال الألياف تلبي معايير الجودة المطلوبة للاستخدام الآمن في تطبيقات البناء.

كيف يعمل حبل UHMWPE مقارنة بالحبال السلكية التقليدية أثناء مهام الرفع الثقيلة؟

توفر حبال UHMWPE قوة مماثلة لحبال الأسلاك الفولاذية بينما تكون أخف وزناً بشكل كبير، مما يجعلها أكثر قابلية للإدارة أثناء مهام الرفع الثقيلة.

هل يمكن لحبل كيفلر أن يتحمل الظروف الجوية القاسية التي تواجهها عادة مواقع البناء؟

نعم، يتمتع الكيفلار بمقاومة ممتازة ضد الأشعة فوق البنفسجية وهو معروف بمتانته حتى في ظل الظروف الجوية القاسية الموجودة في مواقع البناء.

هل هناك أي فرق بين الهياكل المصنوعة من الألياف المضفرة والملتوية عندما يتعلق الأمر بالأداء في صناعة البناء؟

تميل الإنشاءات المدعمة إلى توفير قوة شد أعلى وامتصاص أفضل للصدمات مقارنة بالإنشاءات الملتوية التي تفضلها عمومًا الصناعات مثل التعدين أو قطع الأشجار حيث تكون المرونة أمرًا بالغ الأهمية

هل يمكن استخدام الحبال النايلون في أنظمة خطوط الحياة الرأسية في مشاريع البناء؟

نعم، تُستخدم الحبال النايلون عادةً كجزء من أنظمة خطوط الحياة الرأسية نظرًا لقوتها ومتانتها وقدرتها على امتصاص الطاقة أثناء السقوط.

هل يمكن لشركة Duracordix توفير أطوال مخصصة لحبال الألياف وفقًا لمتطلبات المشروع المحددة؟

بالتأكيد! تقدم دوراكورديكس خيارات تخصيص، بما في ذلك أطوال مُصممة خصيصًا لتلبية احتياجات مشروعك، مما يضمن حصولك على ما تحتاجه بدقة.

هل هناك فرق بين الأحمال الساكنة والديناميكية عند اختيار حبل البناء المناسب؟

نعم، الأحمال الساكنة تشير إلى الوزن الثابت، بينما الأحمال الديناميكية تنطوي على الحركة أو الاهتزاز. تُصبح اعتبارات مثل قابلية التمدد مهمة عند اختيار حبل البناء المناسب بناءً على نوع الحمل.