FISHING

Homepage » Industries » fishing

FISHING

SYNTHETIC ROPE & NET SUPPLIER

We offer an extensive selection of premium synthetic ropes and nets tailored for the fishing industry. Our top-selling products include durable fishing lines, trawl nets, synthetic anchor ropes, longlines, and UHMWPE fishing ropes.

Additionally, we manufacture and supply other indispensable items catering to your fishing requirements, such as net menders, float lines, purse seine ropes, and various fishing gear accessories. Trust in our expertise for all your fishing necessities.

Hot Selling Products

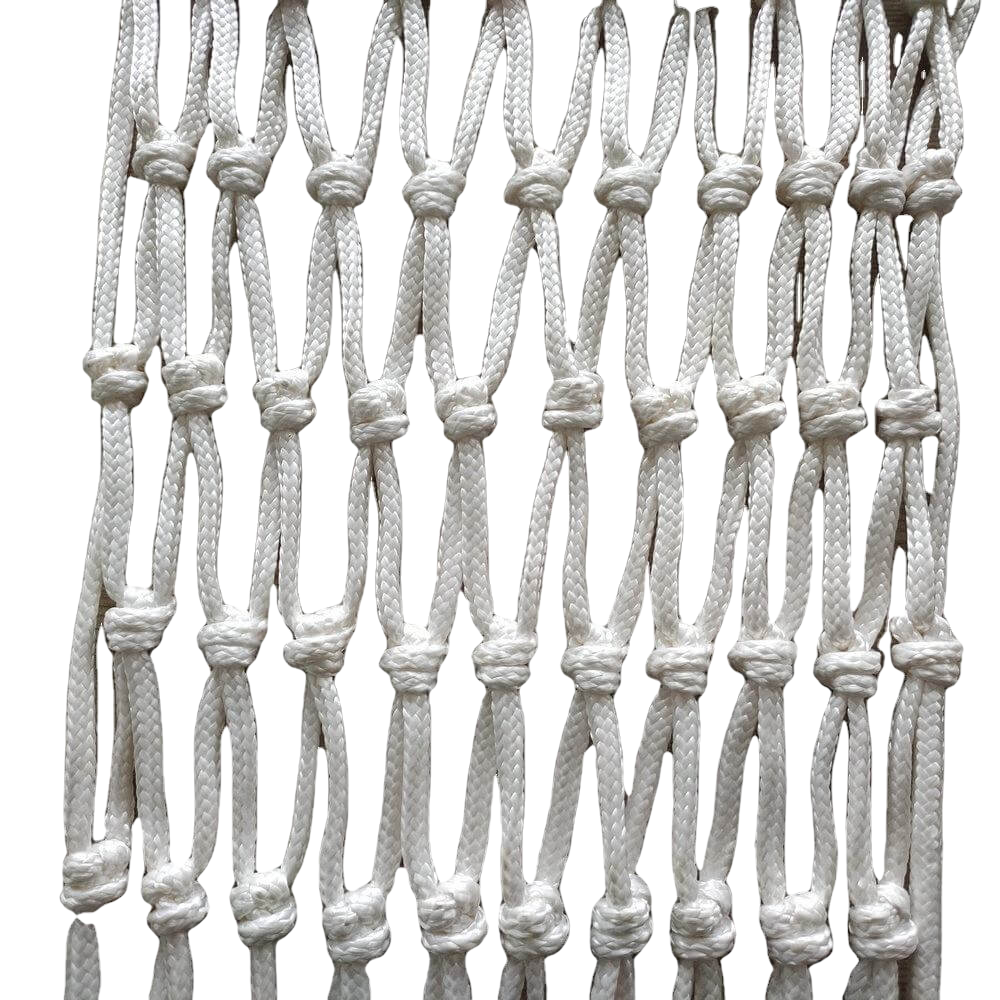

The fish farming cage, also known as an aquaculture net cage, is made from synthetic UHMWPE fibers

Strong, lightweight, and low-stretch, providing increased sensitivity for optimal catch rates.

how to make

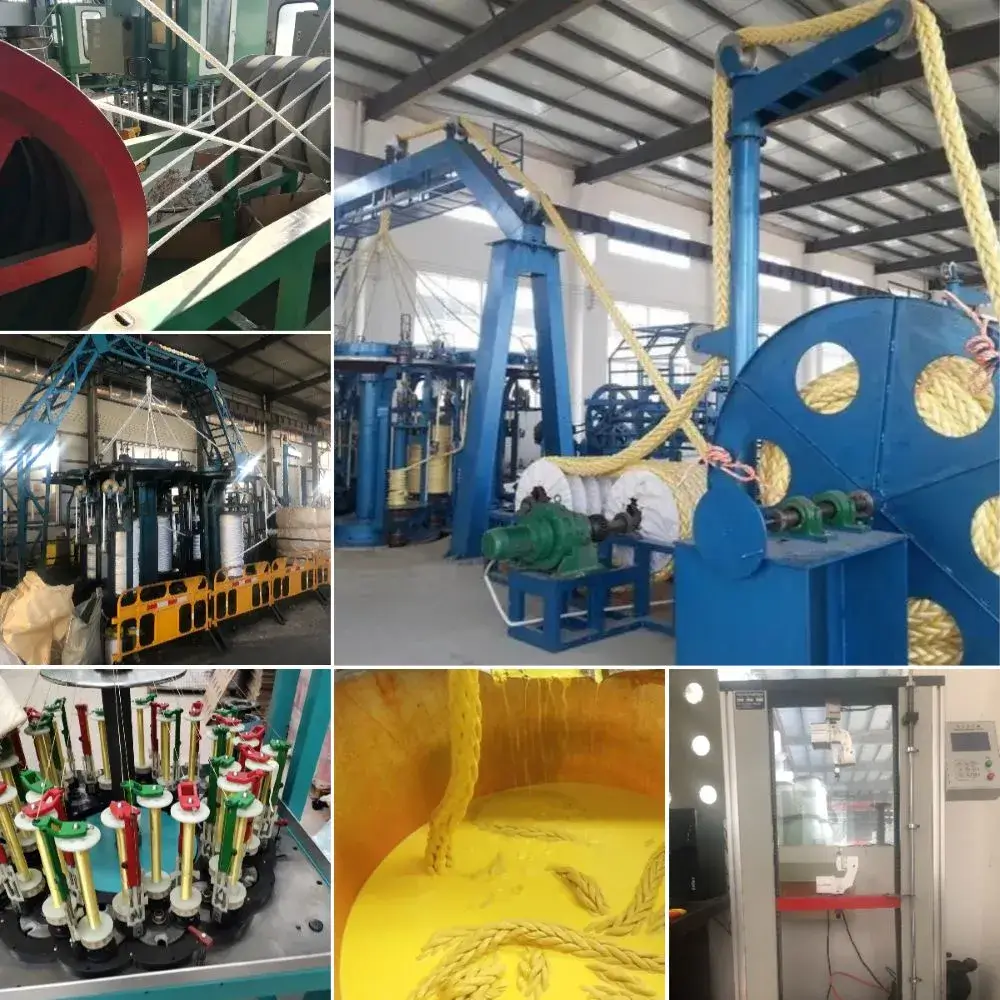

Discover Our Process of Producing High-Performance Fishing Ropes.

Process 1

fiber selection

We carefully select high-quality synthetic fibers, such as nylon,polyester, or UHMWPE, to use in our ropes, ensuring strength and durability.

Process 2

Twisting and Forming

The selected fibers are twisted together to create yarns, which are then twisted together to create strands. The twisted strands are then formed into a rope-like structure.

Process 3

Laying and Braiding

The formed rope is laid into a braiding machine, which braids the rope together using specialized techniques and patterns to further increase strength and durability.

Process 4

Coating

A custom protective coating made of high-quality materials, such as PVC or polyurethane, is applied to enhance the rope’s durability and resistance to abrasion, water, and UV rays.

Process 5

Heat Treatment and Drying

The braided rope undergoes a specialized heat treatment process to set the braids and increase strength. The rope is then dried to remove any moisture.

Process 6

testing

Each Duracordix recovery rope is rigorously tested to ensure it meets our high standards for strength and stretch. Any rope that fails our testing process is discarded.

- Quality-Centric

. QUALITY CONTROL

Explore How We Ensure Unparalleled Excellence in Every Fiber Rope

1. Raw Materials

Our synthetic ropes are only made from raw materials that meet our strict quality standards. We work with trusted suppliers to ensure consistent quality and optimal performance in all our products.

2. In-House

By keeping our synthetic rope production in-house, we have full control over quality throughout the manufacturing process. This allows us to adhere to our high standards and provide reliable products to our customers.

3. Testing & Inspection

Our rigorous testing and inspection processes involve every stage of production, from raw materials to finished products. This ensures the consistent quality and safety of our synthetic ropes.

4. Automated Manufacturing

We integrate automated machinery and technology to ensure accuracy and consistency in our synthetic rope production. This reduces human error and ensures all products meet our strict quality standards.

5. Skilled Staff

Our highly skilled workforce undergoes ongoing training and continuing education to stay up-to-date with the latest techniques in synthetic rope production. This helps us uphold the highest level of quality and performance

easy & clear

Maximizing customer satisfaction with easy purchasing, minimizes communication and time costs.

Step 1: Solution Confirmation (3-5 days)

First, we’ll chat about your needs and recommend the best rope solution for you. Our expertise and experience will guarantee you get the best product possible.

Step 2: Sample Evaluation (7-14 days)

To ensure you’re happy with our product, we offer sample evaluations. Test our products before ordering to make sure they meet your requirements.

Step 3: Order Confirmation (within 3 day)

Once you’re satisfied with the sample evaluation, confirm your order with us. We’ll provide all necessary details, including pricing, lead times, and more, so you can be confident in your purchase.

Step 4: Bulk Manufacturing (30-45 days)

We offer bulk manufacturing options for larger orders. Our advanced production techniques and high-quality materials ensure consistency and reliability across all orders.

Step 5: Delivery (30-45 days)

We know timely delivery is important, so we’ll keep you updated on shipping progress and provide tracking information. Your order will arrive within the agreed timeframe.

Step 6: After-Sales Service

Our service doesn’t stop after your order is delivered. If you have any questions or concerns, our team is always available to assist you. We’re committed to providing excellent customer service and ensuring your satisfaction.

- Pain-Free Purchase

WHY CHOOSE

DURACORDIX FISHING ROPE

- Durability: With 80% more resistance to UV, abrasion, and chemicals, our UHMWPE fishing ropes promise extended lifespan and 25% cost savings.

- Knot Strength: Even when wet, our ropes maintain 90% knot strength, outperforming others that weaken, ensuring consistent performance.

- Lightweight: Utilizing UHMWPE fibers, our ropes are 70% lighter, easing handling and reducing fatigue during prolonged fishing sessions.

- Floating: Our UHMWPE ropes naturally float, enhancing visibility by 60% and minimizing tangles compared to sinking alternatives.

- Reduced Friction: The rope's smooth surface offers a 40% decrease in friction, limiting wear on both rope and fishing gear.

- Cost-Effective: Though initial costs might be higher, the rope's longevity ensures a 30% cost reduction over its lifespan.

FAQs

Frequently asked questions addressing customer concerns and pain points

What is fishing rope?

Fishing rope is a type of strong, durable rope used in fishing applications. It is typically made from high-strength materials, such as nylon or polypropylene, and comes in various thicknesses and colors.

Why is UHMWPE becoming popular for fishing ropes?

UHMWPE ropes are favored due to their combination of light weight, incredible tensile strength, resistance to abrasions, and buoyancy in water. These properties make them efficient and durable for fishing applications.

What materials are commonly used for fishing ropes?

Popular materials include nylon for its stretchability, polyethylene for its lightweight nature, UHMWPE for exceptional strength and abrasion resistance, and polypropylene because it floats and is resistant to rot.

Are there environmental concerns with using fishing nets?

Absolutely. Abandoned or lost fishing nets, known as "ghost nets," can trap and kill marine life, causing environmental and ecological harm.

What is the main purpose of fishing nets?

Fishing nets are designed to efficiently capture and contain fish in larger quantities than individual fishing lines. Their design and mesh size cater to specific fishing needs and types of fish.

How often should fishing ropes be replaced?

The lifespan of fishing ropes depends on frequency of use and exposure to elements. However, routine inspections for signs of fraying, wear, or damage can guide replacement decisions.

What's the difference between braided and twisted fishing ropes?

Braided ropes consist of intertwined strands providing smoothness and flexibility, making them less prone to unraveling. Twisted ropes are made by coiling multiple strands, offering more grip but may untwist over time.

What are the advantages of nylon fishing ropes?

Nylon is favored for its elasticity, shock absorption, and abrasion resistance. This stretchability can prevent snapbacks during high-stress moments, like catching larger fish.

Why is proper net maintenance crucial?

Regular maintenance, including cleaning and mending, ensures nets function effectively. Proper care prolongs the net's lifespan, ensuring consistent and effective catches over time.

What's the best method to store fishing ropes?

To store fishing ropes properly, first clean them of salt and debris. Coil loosely to prevent kinks, and store in cool, dry areas away from sunlight. UV rays can weaken ropes. Regularly check for wear, mold, or damage to ensure safety and longevity.

What's the impact of synthetic nets on marine ecosystems?

Synthetic nets, if discarded irresponsibly, can persist in marine environments for years, trapping and killing marine life, which disrupts ecosystems and poses a threat to biodiversity.

How do drift nets work?

Drift nets, positioned vertically in water, serve as walls, trapping fish that swim into them. These nets, often spanning large areas, primarily ensnare fish by their gills, causing them to become entangled, ensuring a successful catch for fishermen without the need for active pursuit.

Are heavier ropes better for deep-sea fishing?

Weight isn't the sole determinant. While heavy ropes can resist deep-sea currents, lightweight UHMWPE ropes can be equally effective due to their inherent strength and resistance to underwater conditions.

How are fishing ropes and nets cleaned?

They should be cleaned with freshwater and mild detergents, followed by thorough drying. This prevents mold, rot, and maintains material integrity.

What are trawl warps in fishing?

Trawl warps are specialized ropes employed in trawling operations. They serve as crucial connectors between the trawl net and the fishing vessel, enabling the effective towing and maneuvering of the net as it captures fish during its aquatic journey.

How do synthetic and natural fishing ropes compare?

Synthetic fishing ropes, often made from materials like nylon or UHMWPE, excel in durability and marine condition resistance compared to natural fibers. They resist rot, maintain consistent strength, and generally outperform natural ropes in wet environments.

Why is color coding used in fishing nets?

Color coding in fishing nets assists fishermen in swiftly distinguishing between net types, mesh sizes, and specific uses. This system promotes streamlined operations, minimizes potential mistakes, and ensures the appropriate nets are deployed for targeted catches.

How do different mesh sizes impact the type of catch in fishing nets?

Mesh size directly influences the size and species of fish caught. Larger meshes target bigger fish, preventing juveniles from being captured, which promotes sustainable fishing practices.

Why are floating ropes essential for some fishing applications?

Floating ropes are vital in surface fishing methods like purse seining. Their buoyancy ensures nets stay at desired depths, optimizing catch efficiency and preventing bottom snags.