بعيدًا عن الشاطئ

الصفحة الرئيسية » الصناعات » بعيدًا عن الشاطئ

بعيدًا عن الشاطئ

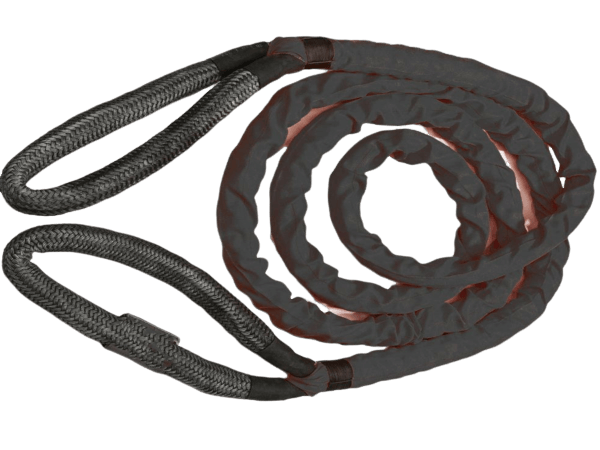

نقدم تشكيلة واسعة من المنتجات المتميزة المصممة خصيصًا لتلبية الاحتياجات الفريدة لصناعة النفط والغاز البحرية. من أبرز منتجاتنا حبال الرفع، وحبال الإرساء في أعماق البحار، وكابلات السحب البحرية المصنوعة من البولي إيثيلين عالي الكثافة (UHMWPE).

علاوة على ذلك، نقوم أيضًا بتصنيع وتوفير معدات حاسمة أخرى للعمليات البحرية، مثل خطوط المرساة، وحبال أمان منصات النفط، وملحقات التزوير المتخصصة المختلفة لضمان الأداء الأمثل في بيئة بحرية صعبة.

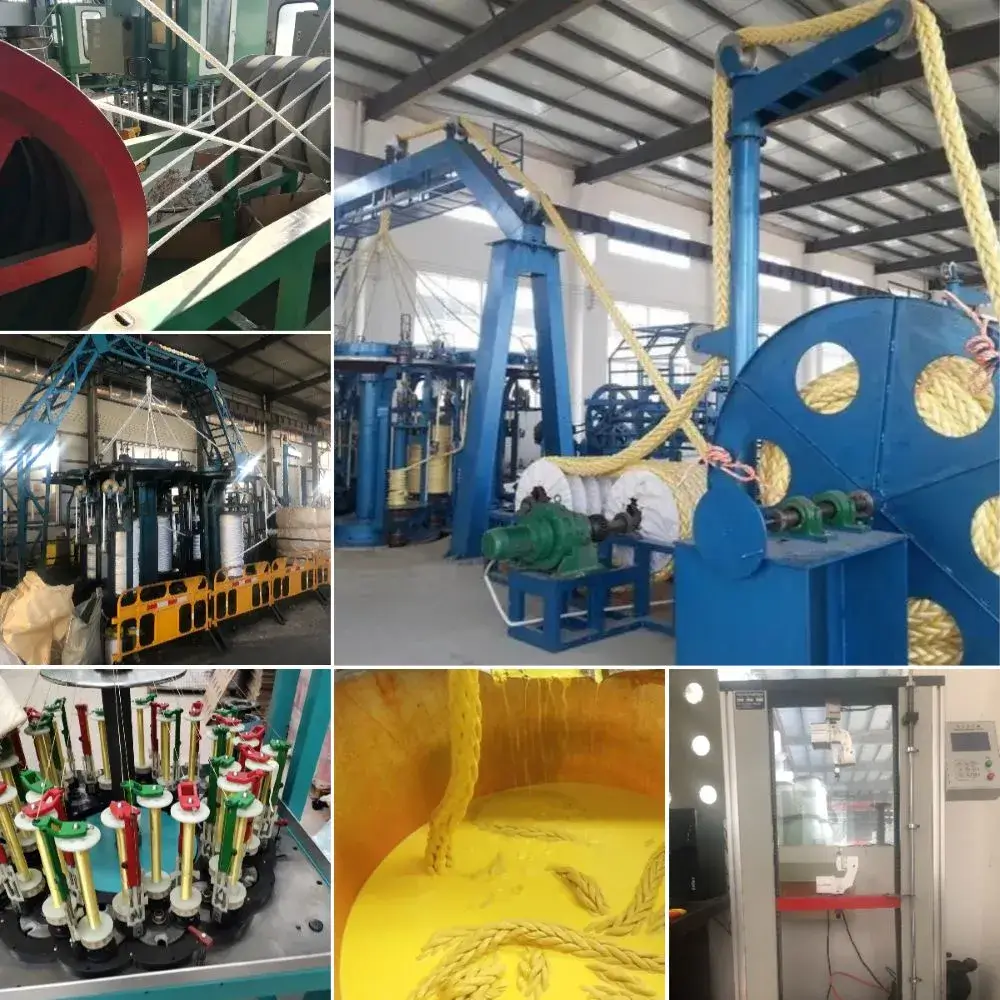

كيفية صنع

اكتشف عملية إنتاج الحبال البحرية عالية الأداء لدينا.

العملية 1

اختيار الألياف

نقوم بعناية باختيار الألياف الصناعية عالية الجودة، مثل النايلون، أو البوليستر، أو UHMWPE، لاستخدامها في حبالنا، مما يضمن القوة والمتانة.

العملية 2

الالتواء والتشكيل

تُلَفُّ الألياف المختارة معًا لتكوين خيوط، تُلَفُّ بدورها لتكوين خيوط. تُشكَّل الخيوط الملتوية بعد ذلك على شكل حبل.

العملية 3

وضع وتضفير

يتم وضع الحبل المشكل في آلة التضفير، والتي تقوم بضفر الحبل معًا باستخدام تقنيات وأنماط متخصصة لزيادة القوة والمتانة بشكل أكبر.

العملية 4

طلاء

يتم تطبيق طبقة حماية مخصصة مصنوعة من مواد عالية الجودة، مثل PVC أو البولي يوريثين، لتعزيز متانة الحبل ومقاومته للتآكل والماء والأشعة فوق البنفسجية.

العملية 5

المعالجة الحرارية والتجفيف

يخضع الحبل المضفر لعملية معالجة حرارية متخصصة لتثبيت الضفائر وزيادة قوتها. ثم يُجفف الحبل لإزالة أي رطوبة.

العملية 6

الاختبار

يخضع كل حبل استرداد من Duracordix لاختبارات دقيقة لضمان استيفائه لمعاييرنا العالية للقوة والمرونة. أي حبل لا يجتاز عملية الاختبار الخاصة بنا يتم التخلص منه.

- التركيز على الجودة

. ضبط الجودة

اكتشف كيف نضمن التميز الذي لا مثيل له في كل حبل من حبال الألياف

1. المواد الخام

حبالنا البحرية الاصطناعية مصنوعة فقط من مواد خام مطابقة لمعايير الجودة الصارمة لدينا. نتعاون مع موردين موثوقين لضمان جودة ثابتة وأداء مثالي لجميع منتجاتنا.

2. داخليًا

بفضل إنتاجنا الداخلي للحبال الاصطناعية، نتمتع بتحكم كامل في الجودة طوال عملية التصنيع. هذا يسمح لنا بالالتزام بمعاييرنا العالية وتقديم منتجات موثوقة لعملائنا.

3. الاختبار والتفتيش

تشمل عمليات الاختبار والتفتيش الدقيقة لدينا كل مرحلة من مراحل الإنتاج، من المواد الخام إلى المنتجات النهائية. وهذا يضمن جودة وسلامة حبالنا الاصطناعية.

4. التصنيع الآلي

ندمج الآلات والتكنولوجيا الآلية لضمان الدقة والاتساق في إنتاج الحبال الاصطناعية. هذا يقلل من الأخطاء البشرية ويضمن استيفاء جميع المنتجات لمعايير الجودة الصارمة لدينا.

5. الموظفين المهرة

يخضع فريقنا من العمالة الماهرة لتدريب وتعليم مستمر لمواكبة أحدث التقنيات في إنتاج الحبال الصناعية، مما يساعدنا على الحفاظ على أعلى مستويات الجودة والأداء.

- المعيار الدولي

ملكنا الشهادات

سهل وواضح

تعظيم رضا العملاء من خلال سهولة الشراء، وتقليل تكاليف الاتصالات والوقت.

الخطوة 1: تأكيد الحل (3-5 أيام)

أولاً، سنناقش احتياجاتك ونقترح عليك أفضل حل للحبال. خبرتنا الواسعة تضمن لك الحصول على أفضل منتج ممكن.

الخطوة 2: تقييم العينة (7-14 يومًا)

لضمان رضاكم عن منتجاتنا، نقدم لكم تقييمات عينات. اختبروا منتجاتنا قبل الطلب للتأكد من أنها تلبي متطلباتكم.

الخطوة 3: تأكيد الطلب (خلال 3 أيام)

بعد رضاك عن تقييم العينة، أكّد طلبك معنا. سنزودك بجميع التفاصيل اللازمة، بما في ذلك السعر ومدة التسليم وغيرها، لتكون على ثقة تامة بشرائك.

الخطوة 4: التصنيع بالجملة (30-45 يومًا)

نوفر خيارات تصنيع بكميات كبيرة للطلبات الكبيرة. تقنياتنا الإنتاجية المتطورة وموادنا عالية الجودة تضمن الاتساق والموثوقية في جميع الطلبات.

الخطوة 5: التسليم (30-45 يومًا)

ندرك أهمية التسليم في الوقت المحدد، لذا سنُبقيك على اطلاع دائم بتقدم الشحنة ونزودك بمعلومات التتبع. سيصل طلبك في الموعد المحدد.

الخطوة 6: خدمة ما بعد البيع

خدمتنا مستمرة بعد توصيل طلبك. إذا كانت لديك أي أسئلة أو استفسارات، ففريقنا جاهز دائمًا لمساعدتك. نحن ملتزمون بتقديم خدمة عملاء ممتازة وضمان رضاكم.

- شراء بدون ألم

لماذا تختار؟

- المتانة: تدوم حبال Duracrodix 40% لفترة أطول في الظروف البحرية القاسية، وتقاوم المياه المالحة والمواد الكيميائية والتدهور الناتج عن الأشعة فوق البنفسجية بشكل فعال.

- القدرة على تحمل التكاليف: توفر حبال Duracrodix 30% نسبة سعر إلى أداء أفضل، مما يزيد من عائد الاستثمار دون المساومة على الجودة.

- الابتكار: من خلال دمج التكنولوجيا المتطورة، تظهر حبالنا زيادة 30% في قوة الشد والمرونة، مما يعالج تحديات التجهيز بشكل مباشر.

- السلامة: تقليل المخاطر من خلال 60%، تعطي حبال Duracrodix الأولوية لسلامة الطاقم في البيئات البحرية الصعبة، وبناء الثقة.

- الدعم: خدمة عملاء على مدار الساعة طوال أيام الأسبوع، وحل 95% من التحديات الفنية في غضون ساعات، وضمان الحد الأدنى من الانقطاعات التشغيلية.

- صديق للبيئة: بفضل التأثير البيئي الأقل لـ 70%، تحمي حبالنا المستدامة الحياة البحرية مع تقديم أداء فائق.

الأسئلة الشائعة

الأسئلة الشائعة التي تتناول مخاوف العملاء ونقاط الألم

ما هو الحبل البحري؟

الحبل البحري هو حبل صناعي عالي القوة يوفر أداءً موثوقًا ودائمًا في العمليات البحرية المختلفة مثل الربط والسحب والرفع والمزيد.

ما هي المدة التي يستمر فيها الحبل الصناعي في الظروف البحرية؟

عادةً ما تدوم الحبال الاصطناعية من 3 إلى 5 سنوات في عرض البحر. تعتمد المتانة على الاستخدام والصيانة والتعرض البيئي. العناية الجيدة، كالشطف وتجنب الأشعة فوق البنفسجية، تُطيل عمرها الافتراضي.

لماذا يتم تفضيل الحبال الاصطناعية للعمليات البحرية؟

تتميز الحبال الاصطناعية بنسبة قوة إلى وزن ممتازة، ومقاومة ممتازة للتآكل، ومرونة عالية. هذا يجعلها مثالية لبيئة العمليات البحرية المتطلبة والديناميكية.

كيفية صيانة وتنظيف الحبال الصناعية في البيئات البحرية؟

تتضمن الصيانة فحص التآكل والتلف، والشطف بالماء العذب لإزالة الملح، وضمان التخزين المناسب في أماكن باردة وجافة للحماية من التدهور الناتج عن الأشعة فوق البنفسجية وإطالة العمر الافتراضي.

ما هو الحبل الاصطناعي الأفضل للأحمال البحرية الثقيلة؟

حبال UHMWPE الاصطناعية هي الخيار الأمثل للمهام البحرية الشاقة. فقوتها الاستثنائية في الشد، بالإضافة إلى خفة وزنها، تجعلها لا تُقدر بثمن للسحب والرفع في البيئات البحرية.

ما الذي يجعل الحبال الاصطناعية مثالية للحفر البحري؟

إن متانتها ضد العناصر البحرية المسببة للتآكل، إلى جانب قوة الشد والمرونة الفائقة، تضمن الأداء الأمثل والسلامة أثناء عمليات الحفر البحرية.

كيف يؤثر الماء المالح على متانة الحبال الاصطناعية؟

رغم أن الحبال الاصطناعية تقاوم المياه المالحة، إلا أن التعرض المستمر لها قد يُسبب التآكل. غسلها المتكرر بالمياه العذبة وتخزينها جافةً يُقلل بشكل كبير من احتمالية تدهورها.

هل الحبال الاصطناعية مناسبة لمهام القطر البحرية؟

بالتأكيد. نسبة قوتها إلى وزنها العالية ومرونتها تجعلها مثالية للقطر البحري. تتحمل الظروف البحرية المتغيرة والأحمال الثقيلة بكفاءة.

ما هي تدابير السلامة التي يجب اتخاذها عند استخدام الحبال الاصطناعية في الظروف البحرية؟

تأكد من إجراء عمليات تفتيش منتظمة بحثًا عن أي أضرار مرئية، واستخدم الحبال ضمن حدود حمولتها، وقم بالصيانة الروتينية، واستخدم دائمًا أجهزة متوافقة وعالية الجودة لتحقيق أقصى قدر من السلامة.

كيف تعمل الحبال الاصطناعية في درجات الحرارة البحرية القصوى؟

تحتفظ الحبال الاصطناعية عالية الجودة بقوتها في درجات حرارة مختلفة، مما يجعلها موثوقة في مختلف المناخات البحرية، من المياه الجليدية إلى الحرارة الاستوائية.

هل يمكن استخدام الحبال الاصطناعية لربط السفن في عرض البحر؟

بالتأكيد. تُفضّل الحبال الاصطناعية عالية القوة، مثل UHMWPE، للرسو والتثبيت نظرًا لمتانتها ومقاومتها للتحديات البحرية.

ما هي المدة التي يجب فيها فحص الحبال الاصطناعية في البيئات البحرية؟

في العمليات النشطة، تُعدّ عمليات التفتيش أو الفحوص الأسبوعية بعد الاستخدام المكثف أمرًا بالغ الأهمية. تضمن عمليات التفتيش في الوقت المناسب سلامة الحبال وسلامة المهام البحرية.

ما هي التأثيرات البيئية لاستخدام الحبال الاصطناعية في المحيط؟

على الرغم من أن الحبال الاصطناعية لا تطلق مواد كيميائية ضارة في الماء، فمن المهم التخلص من الحبال البالية بطريقة مسؤولة لمنع التلوث البحري وضمان السلامة البيئية.

كيف تتم مقارنة الحبال الاصطناعية بالكابلات الفولاذية للاستخدام البحري؟

تتميز الحبال الاصطناعية بخفة وزنها ومرونتها ومقاومتها للتآكل. وغالبًا ما تتفوق على الكابلات الفولاذية في التطبيقات البحرية بفضل هذه المزايا.

هل الحبال الاصطناعية مثالية للرياح البحرية؟

نعم، بفضل خفة وزنها وقوتها، تجعلها مستقرة في مواجهة الرياح البحرية القوية، مما يضمن الأداء الفعال والسلامة أثناء العمليات.

هل تستطيع الحبال الاصطناعية تحمل ضغوط أعماق البحار؟

تم تصميم الحبال الاصطناعية عالية الأداء لمقاومة ضغوط أعماق البحار، مما يضمن الموثوقية أثناء المهام والعمليات المكثفة تحت سطح البحر.

ما هي الخصائص التي تجعل الحبال الاصطناعية مثالية للتجهيز البحري؟

للتجهيزات البحرية، تتطلب الحبال قوة شد عالية، ومقاومة للتآكل، ومرونة. لذا، تُعدّ المواد التركيبية، بفضل هذه الخصائص، الخيار الأمثل.

كيف تؤثر الخصائص الحرارية على الحبال البحرية الاصطناعية أثناء الرفع البحري؟

تتمتع الحبال ذات الخصائص الحرارية الثابتة بمقاومة التآكل الناتج عن تقلبات درجات الحرارة، مما يضمن رفعًا آمنًا وفعالًا في درجات الحرارة البحرية المختلفة.