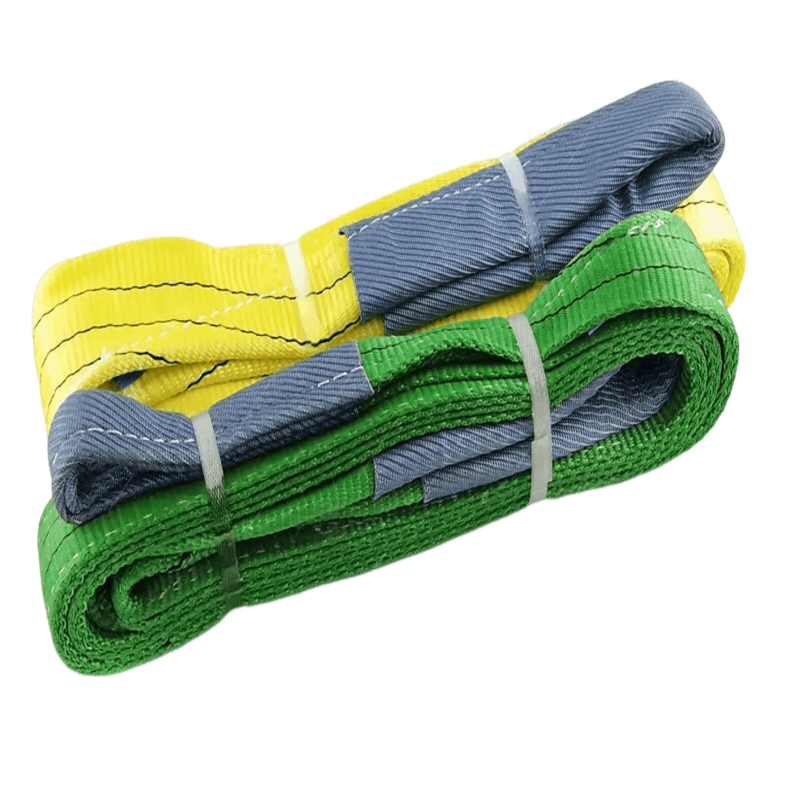

EYE & EYE LIFTING SLING

Strong. Reliable. Safe. The Lifting Solution For Your Demanding Applications

What Is the Eye & Eye Lifting Sling?

The Eye & Eye Lifting Sling, crafted from Ultra High Molecular Weight Polyethylene (UHMWPE), offers a practical solution for heavy lifting. Its dual loop ends ensure quick, secure attachment, adapting easily to different equipment. Unlike rigid wire ropes, it distributes weight evenly for smoother, safer handling across various tasks. Built to meet your toughest demands.

General Applications

Duracordix Provide Real-World Solutions, Can Be Engineered for Your Industry’s Needs

Shipping & Logistics

Our UHMWPE slings, with top-notch abrasion resistance, are perfect for frequent use in shipping

construction

Built for tough construction sites, our slings handle heavy loads smoothly, reducing wear on your equipment

oil & Gas

Made to handle chemicals and UV exposure, our slings deliver the durability needed in your oil and gas application.

- quality control

- sizes available

Specification

Find the Perfect Specifications for Your Unique Requirements!

| Rope Diameter mm | Rope Diameter inch | Working Load(UHMWPE)Vertical | Working Load(UHMWPE)Choker | Working Load(UHMWPE)Basket | Color |

|---|---|---|---|---|---|

| mm | inch | Vertical | Choker | Basket | |

| 11 | 7/16 | 3,260lbs(1.48t) | 2,600lbs(1.18t) | 6,520lbs(2.96t) | any |

| 14 | 9/16 | 4,850lbs(2.20t) | 3,880lbs(1.70t) | 9,700(4.40t) | any |

| 16 | 5/8 | 6,400lbs(2.90t) | 5,120lbs(2.30t) | 12,800lbs(5.80t) | any |

| 18 | 3/4 | 7,500lbs(3.40t) | 6,000lbs(2.72t) | 15,000lbs(6.8t) | any |

| 22 | 7/8 | 10,390lbs(4.70t) | 83,00lbls(3.76t) | 207,800lbs(9.4t) | any |

| 24 | 1 | 11,900lbs(5.40t) | 9,520lbs(4.32t) | 23,800lbs(10.80t) | any |

| 28 | 1 1/8 | 18,000lbs(8.16t) | 14,400lbs(6.50t) | 36,000lbs(16.32t) | any |

| 32 | 1 5/16 | 242,000lbs(11.00t) | 19,395lbs(8.80t) | 484,000lbs(22.00t) | any |

| 36 | 1 1/2 | 286,500lbs(13.00t) | 22,920lbs(10.50t) | 573,000lbs(26.00t) | any |

Vertical Lift: The sling holds the load directly underneath for a straightforward vertical lift.

Choker Lift: The sling wraps around the load, gripping it securely by “choking” it. This method provides extra hold but has a slightly lower capacity (about 70-80% of a vertical lift) due to the angle and pressure points.

Basket Lift: The sling supports the load like a cradle, with both ends attached to the lifting device, offering maximum stability and nearly double the capacity of a vertical lift.

Need other type of lifting? Just ask—custom options are available.

- OEM service

Customization Options

Duracordix provide custom options to meet your specific lifting needs

1. Tailored Lengths and Widths: Get the exact size you need—no more unsafe adjustments or compromises. Our slings come in a range of lengths and widths to fit your load perfectly.

2. Color Coding for Fast Identification: Make your workflow smoother with color-coded slings. Quickly grab the right sling every time, reducing mix-ups and boosting safety on site.

3. Custom Load Capacities: Match each sling to the specific weight of your lift. No more guessing or using “one-size-fits-all” slings that might not meet your needs.

4. Branded Slings for Easy Tracking: Add your logo for a professional look and easy identification of your gear on busy sites.

5. Extra Protection for Tough Conditions: For rough, chemical, or outdoor environments, choose added layers of protection. Our slings are built to last, even in extreme conditions.

- main features

Benefits Benefits Of Lifting Sling

Discover the Advantages of Synthetic Lifting Sling!

Lightweight

Synthetic slings are light, ensuring easy handling. This results in quicker setups and reduced manual effort, leading to enhanced efficiency and transport ease between job sites.

Durability

Resistant to UV rays, certain chemicals, and mildew, synthetic slings, with advanced materials, offer heightened abrasion resistance, ensuring extended lifespan even in tough environments.

Flexibility

Their flexible nature allows synthetic slings to conform to various load shapes, providing better grip, reducing load shifts, and minimizing operator strain or injury risks.

Non-marring Surface

Synthetic slings offer soft, non-abrasive surfaces that prevent damage to lifted items, safeguarding polished or delicate items and cutting down repair or refinishing costs.

- Happy Clients

Client Voice

Duracordix's heavy lifting sling has been a game-changer for our construction projects. It's not just strong; it's incredibly reliable. We trust Duracordix to keep our teams safe."

- Easy & Fast Decesion

Why to choose

Our synthetic lifting SLing

- Quality Assurance: With rigorous testing, our slings maintain a 99.8% defect-free rate, adhering to top international quality standards.

- Enhanced Durability: UHMWPE sling is inherently resistant to wear, tear, and environmental elements, offering a lifespan 30% longer than conventional materials.

- User-Centric: Our UHMWPE slings feature ergonomic grips and clear load indicators, maximizing safety and user-friendliness.

- Customization: Catering to varied needs, our UHMWPE slings offer 95% customization options, ensuring precision-fit for distinct projects.

- Customer Service: With 24/7 support, we're committed to swift query resolutions, ensuring uninterrupted and efficient client experiences.

- Cost-Effective: Balancing quality and cost, our UHMWPE slings are affordably priced without sacrificing performance, offering premium quality at competitive rates.

FAQs

Answers to Your Questions About Duracordix’s Durable and Versatile Soft Shackles.

What is a synthetic sling?

A synthetic sling is a lifting tool made from synthetic fibers like UHMWPE,nylon or polyester, designed for material handling and load bearing in lifting operations.

How to maintain a synthetic sling for durability?

To maintain its durability, store synthetic slings away from direct UV light, keep them clean, avoid chemical exposure, and routinely check for wear indicators and abrasion resistance.

Are synthetic slings better than wire rope slings?

Both have their advantages. Synthetic slings are lighter and more flexible, while wire rope slings are often more durable and resistant to heat.

What are the main applications of synthetic slings?

Synthetic slings are used in overhead lifting, heavy-duty lifting, and various lifting operations where load control and distribution are crucial.

What are the hazards of using a lifting sling?

Hazards include exceeding the sling's safe working load (SWL), UV degradation, chemical exposure, improper load distribution, and not following sling safety guidelines.

How often should a sling inspection take place?

Inspection frequency depends on usage, but before each use, look for wear indicators, abrasion resistance, and any visible damage.

What are wear protection and chafe guards in slings?

These are added protective materials to reduce wear and tear on the sling, especially when lifting objects with sharp edges.

Why is elongation an important factor in synthetic slings?

Elongation indicates the sling's stretchiness, impacting load control and the sling's reaction to sudden forces.

What do "eye and eye sling" and "endless sling" mean?

An "eye and eye sling" has loops at both ends. An "endless sling" is a loop without ends, often used in choker or basket hitch lifting methods.

How does UV degradation affect synthetic slings?

UV light can weaken synthetic fibers, reducing the sling's breaking strength and overall safety.

Why is chemical resistance vital for synthetic slings?

Certain chemicals can degrade synthetic fibers, compromising the sling's integrity and safety.

How should synthetic slings be stored?

Store in a cool, dry place away from UV light and chemicals. Proper sling storage extends the sling's lifespan.

Why is tagging and labeling important for synthetic slings?

Tags and labels provide crucial information about the sling, including load capacity, material type, and safety guidelines.

What criteria dictate the replacement of synthetic slings?

Replace slings if you find excessive wear, abrasion, UV degradation, chemical damage, or if the sling fails an inspection or certification check.

How does sling angle impact the lifting process?

The sling angle, or the angle between the horizontal and the sling leg, affects load distribution. Improper angles can reduce a sling's load-bearing capacity and risk breakage.

What role do sling accessories play in lifting operations?

Sling accessories, like hooks or connectors, enhance versatility and compatibility. They ensure secure attachments, aiding in load control and maximizing safety during lifts.

How do environmental conditions affect synthetic sling performance?

Temperature, moisture, and chemical exposure can degrade synthetic materials. A sling's performance may diminish if not suited to its working environment, emphasizing the importance of material choice.

Why are sling loops and spliced ends critical in lifting?

Sling loops and spliced ends are designed to distribute stress and prevent wear, offering secure attachment points and extending the sling's service life.

Why is training and safety paramount when using synthetic slings?

Proper training ensures users understand load limits, sling angles, and inspection criteria. It minimizes risks, promotes best practices, and guarantees that lifting operations remain accident-free.

How does "load balancing" impact the efficiency and safety of lifting operations using synthetic slings?

Load balancing ensures even weight distribution across the sling. It prevents undue stress on one section, reducing the risk of breakage and ensuring safer and more stable lifting.

- We Make More

Related products

Explore our Range of Related Products Of Lifting Sling for Enhanced Performance