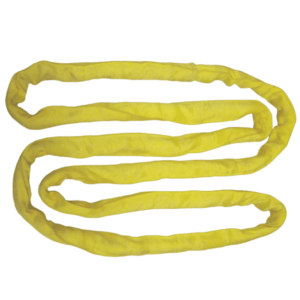

ما هو حبال الرفع الدائرية اللانهائية؟

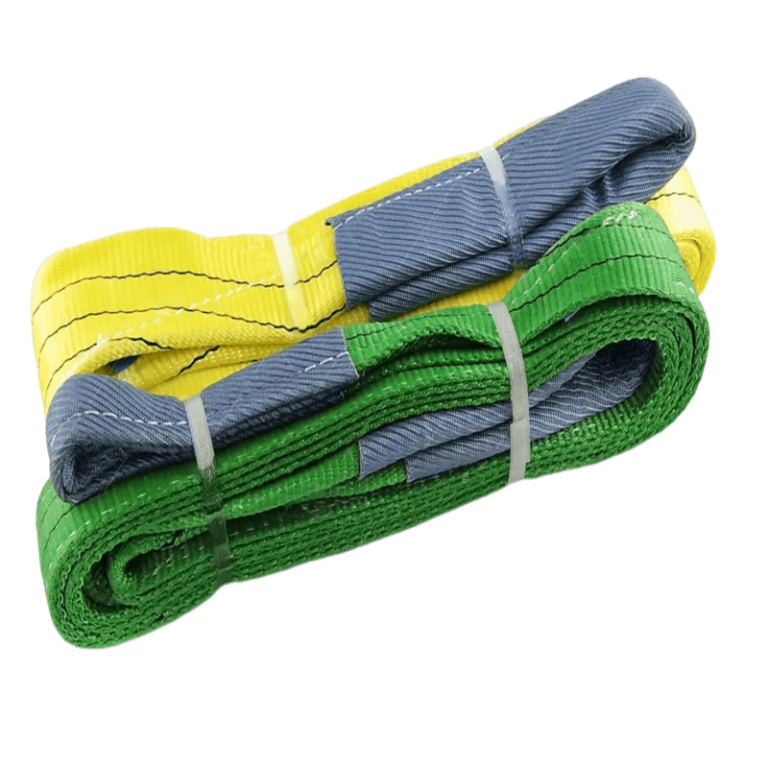

أحزمة الرفع الدائرية اللانهائية لدينا مصنوعة من ألياف صناعية عالية القوة، عادةً من البوليستر وUHMWPE. بفضل تصميمها الحلقي المستمر وبدون درزات، تتجنب هذه الأحزمة نقاط ضعف الأحزمة التقليدية. هذا يضمن توزيعًا أكثر توازنًا للحمل، ويطيل عمر الحزام، ويوفر لك عمليات رفع أكثر أمانًا وفعالية من حيث التكلفة.

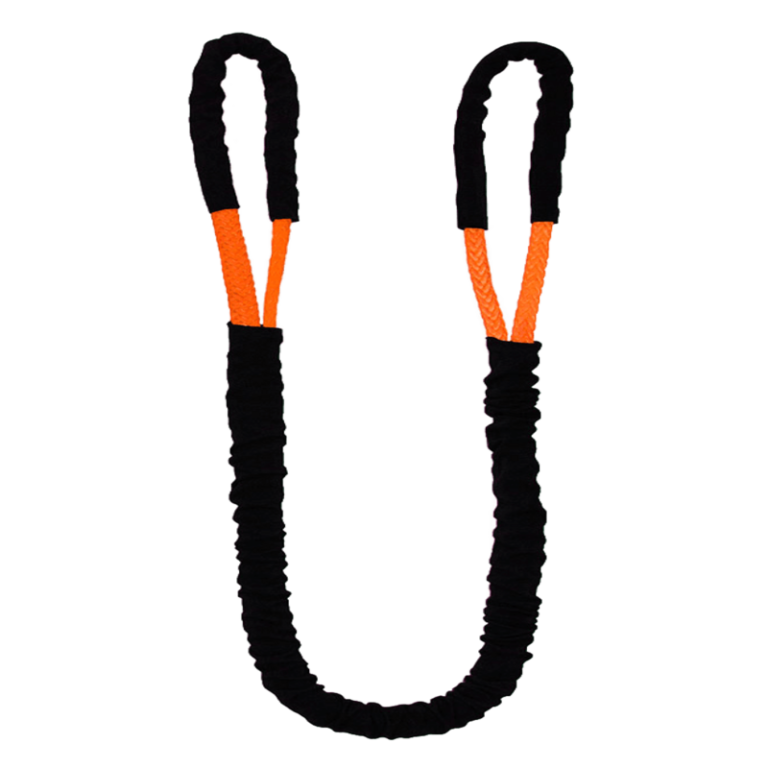

- قوة استثنائية

- خفيف الوزن للغاية

- متين للغاية

- سلامة فائقة