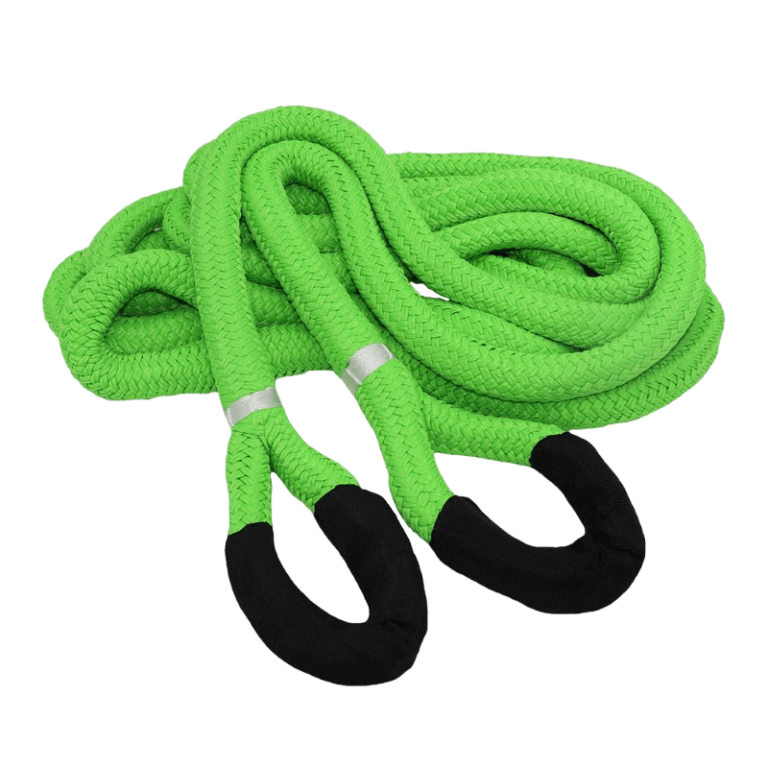

حبل سحب من مادة UHMWPE

بولي إيثيلين عالي الكثافة حبل السحب

حبل السحب UHMWPE من Duracordix — تم تصنيعه بعناية فائقة لتوفير قوة شد لا مثيل لها وموثوقية تشغيلية، متجاوزًا حبال السحب الفولاذية التقليدية في السيناريوهات الصناعية الصعبة.

- قوة فائقة

- أقصى درجات الأمان

- متانة طويلة الأمد

- مثالية للخدمة الشاقة

جدول محتويات هذه الصفحة

لضمان سهولة الوصول إلى المعلومات التي تحتاجها، قمنا بإنشاء جدول المحتويات هذا الذي سينقلك مباشرة إلى القسم ذي الصلة عند النقر فوقه

- الميزات الرئيسية

مبيعات ساخنة الأحجام

أفضل الاختيارات: الكشف عن أبعاد أحزمة الاسترداد المصنوعة من النايلون الأكثر شيوعًا

10 ملم

حبلنا خفيف الوزن ومتين، بسمك 10 مم، مثالي للمهام الزراعية. موثوق به للجرارات والمحاريث، ويضمن متانة عالية في الظروف الصعبة.

14 ملم

حبل 14 مم متعدد الاستخدامات ومتين، مثالي للاستخدام في التعدين والزراعة الثقيلة. يتميز بقوة فائقة، وهو مصمم للتضاريس الوعرة والموثوقية العالية.

22 ملم

حبلنا بقطر 22 مم، مصمم للاستخدام البحري والمهام الشاقة، يوفر قوة لا مثيل لها. مقاوم للتآكل والمياه المالحة، مما يضمن أداءً فائقًا.

Duracordix هو حبل سحب UHMWPE الشركة المصنعة والمورد في الصين.

نحن قادرون على الإنتاج أحجام مختلفة لتطبيقات مختلفة و مصنوع بطريقة مخصصة للمشاريع الخاصة.

بغض النظر عما إذا كنت تبحث عن مورد الجملة أو حزام الخطف المصنوع حسب الطلب، يمكننا جميعًا المساعدة. اتصل بـ Duracordix الآن.

- المقاسات المتوفرة

مواصفة

اكتشف مواصفات حبل القطر UHMWPE الخاص بنا لتطبيقك

| القطر | القطر | وزن | كيتكس | كيتكس | قوة الكسر | قوة الكسر |

|---|---|---|---|---|---|---|

| مم | بوصة | 100م(كجم) | معيار | خطأ | طن | كن |

| 12 | 1/2 | 8.8 | 87 | 5% | 12.12 | 121 |

| 14 | 9/16 | 12 | 119 | 5% | 15.4 | 153 |

| 16 | 5/8 | 15.5 | 151 | 5% | 20.6 | 205 |

| 18 | 3/4 | 19 | 190 | 5% | 23.9 | 238 |

| 20 | 13/16 | 23 | 225 | 5% | 28.99 | 289 |

| 22 | 7/8 | 28 | 276 | 5% | 33 | 322 |

| 24 | 1 | 37 | 368 | 5% | 38 | 371 |

| 28 | 1-1/8 | 50 | 490 | 5% | 57.5 | 562 |

| 32 | 1-5/16 | 62.5 | 621 | 5% | 68.5 | 671 |

| 36 | 1-1/2 | 77 | 767 | 5% | 80.4 | 789 |

| 40 | 1-5/8 | 87 | 868 | 5% | 98.2 | 964 |

| 44 | 1-3/4 | 96 | 955 | 5% | 118 | 1158 |

| 48 | 2 | 114 | 1137 | 5% | 139 | 1364 |

| 56 | 2-1/4 | 159 | 1547 | 5% | 184 | 1805 |

| 60 | 2-1/2 | 180 | 1784 | 5% | 199 | 1952 |

| 64 | 2-5/8 | 209 | 2021 | 5% | 222 | 2178 |

| 72 | 3 | 268 | 2598 | 5% | 274 | 2688 |

| 80 | 3-1/4 | 328 | 3195 | 5% | 333 | 3266 |

| 88 | 4 | 427 | 4170 | 5% | 390 | 3825 |

| 96 | 3-5/9 | 509 | 4970 | 5% | 455 | 4463 |

ملحوظة: أحجام أخرى متاحة عند الطلب.

- الميزات الرئيسية

المزايا المزايا من حبل القطر

اكتشف مزايا حبل القطر Duracordix UHMWPE

قوة فائقة

بفضل قوة الشد التي تتجاوز العديد من المواد بما يصل إلى 60%، يدعم هذا الحبل بثقة الأحمال التي تزيد عن 250000 رطل، مما يضمن أداءً ثابتًا في سيناريوهات السحب ذات الضغط العالي.

مقاومة التآكل

يتفوق UHMWPE الخاص بنا على الحبال التقليدية، حيث يتميز بزيادة ملحوظة في مقاومة التآكل بمقدار 45%، مما يؤدي إلى إطالة العمر المتوقع لمدة تتراوح بين 5 إلى 7 سنوات في البيئات الصعبة.

خفيف الوزن

حبل السحب الخاص بنا أخف وزنًا بشكل ملحوظ من نظرائه الفولاذيين، 72%. هذا الوزن الخفيف يُسهّل النشر السريع، ويُقلّل من إجهاد التشغيل، ويُعزز الكفاءة بفضل 42% المذهل.

المرونة الكيميائية/الأشعة فوق البنفسجية

يقاوم هذا المنتج كمية هائلة من المواد الكيميائية الصناعية الشائعة (99%). كما يتميز بآلية حماية فريدة من نوعها ضد الأشعة فوق البنفسجية، مما يضمن سلامة المادة لمدة أطول من معظم نظيراتها الاصطناعية بـ 3 إلى 5 سنوات.

- عملاء سعداء

ماذا قالو

شهادات العملاء: تقييمات رائعة لحبل السحب Duracordix UHMWPE

- شراء بدون ألم

لماذا تختار؟

حبل سحب DURACORIDX UHMWPE

- عمر افتراضي طويل: مصنوعة من ألياف UHMWPE المميزة من Duracordix، تتحدى حبال السحب الخاصة بنا التآكل، وتفتخر بعمر افتراضي أطول بمقدار 45%، حتى في ظل أقسى الظروف.

- إتقان الأداء: أطلق العنان لقدرات السحب الفائقة باستخدام حبل UHMWPE من Duracordix، وحقق كفاءة متزايدة تصل إلى 92% في عمليات الاسترداد، وذلك بفضل التوازن المثالي بين القوة والمرونة.

- خبرة متواصلة: ثق في دعم دوراكورديكس المتواصل على مدار الساعة. من الرحلات البحرية إلى التضاريس الوعرة، يضمن فريقنا تجربة سحب سلسة.

- دقة مخصصة: تصنع Duracordix حبال UHMWPE المصممة خصيصًا لتلبية احتياجات القطر المحددة، مما يضمن متانة وأداء لا مثيل لهما لكل تحدٍ فريد.

- أسعار تنافسية: اكتشف تميز دوراكورديكس القائم على القيمة. حبال السحب المصنوعة من البولي إيثيلين عالي الكثافة (UHMWPE) التي نقدمها، بجودة لا مثيل لها، متوفرة بسعر 28% أكثر تنافسية، مما يضمن لك عوائد استثمارية ممتازة.

- نحن نصنع المزيد

متعلق ب منتجات

اكتشف منتجات حبل السحب UHMWPE التكميلية لتحسين الأداء

يولد حبل الاسترداد الحركي طاقة حركية من خلال قدرته على التمدد، مما يؤدي إلى سحب المركبات من الأماكن الصعبة.

حبل صناعي خفيف الوزن وعالي القوة، مثالي لتطبيقات القطر والاسترداد، ومعروف بمتانته وقدرته على الصمود.

خفيف الوزن وقوي بشكل لا يصدق، هذا الحزام هو شريكك الموثوق به لرفع الأشياء الثقيلة والتعامل الآمن مع البضائع

الأسئلة الشائعة

الإجابة على جميع استفساراتك حول حبال السحب المصنوعة من البولي إيثيلين عالي الكثافة: رؤى الخبراء تكشف النقاب عنها

ما هو حبل القطر؟

حبل السحب نوع متخصص من الحبال، مصمم أساسًا لسحب أو جرّ المركبات والآلات وغيرها من الأحمال الثقيلة. صُممت حبال السحب لتكون متينة وقوية، وهي أدوات أساسية في قطاعات متنوعة، مثل السيارات والبحرية والزراعة والبناء.

كيف تعمل حبال القطر الاصطناعية في الظروف القاسية؟

حبال السحب الاصطناعية، وخاصةً المصنوعة من البولي إيثيلين عالي الكثافة (UHMWPE)، تتفوق في الظروف القاسية. فهي تقاوم الرطوبة والأشعة فوق البنفسجية والتآكل، وتحافظ على قوتها في البرد أو الحر، وتدوم لفترة أطول من البدائل الطبيعية، مما يجعلها مثالية للبيئات الصعبة.

ما هي نقاط البيع الرئيسية للحبال السحب الاصطناعية مقابل الحبال التقليدية؟

تتميز حبال السحب الاصطناعية، مقارنةً بالحبال التقليدية، بقوة فائقة ووزن أخف ومتانة أكبر. كما أنها مقاومة للرطوبة والتآكل الناتج عن الأشعة فوق البنفسجية، مما يضمن عمرًا افتراضيًا طويلًا وأداءً ثابتًا في الظروف الصعبة.

كيف أختار حبل القطر المناسب؟

لاختيار حبل القطر المناسب من دوراكورديكس، قيّم احتياجاتك الخاصة بناءً على الاستخدام، والقوة، والطول، والقطر المطلوب. تأكد من توافقه مع معايير المتانة والمقاومة المعروفة من دوراكورديكس.

هل هناك فرق بين حبال القطر وأشرطة السحب؟

نعم، هناك فرق. حبال السحب توفر سحبًا ثابتًا ومستمرًا، بينما أحزمة السحب مرنة ومصممة لتوليد تأثير "الاندفاع"، وهو مفيد لتحرير المركبات العالقة.

ما هو الطول المناسب لحبل السحب؟

يختلف طول حبل السحب المثالي باختلاف الاستخدام. يتراوح عادةً بين 15 و30 قدمًا. تستوعب الحبال الأطول الأحمال الأكبر أو المواقف التي تتطلب مسافة أكبر بين الأشياء.

هل يمكنني استخدام أي حبل للسحب؟

لا، ليس كل حبل مناسبًا للسحب. يتطلب السحب حبالًا مصممة خصيصًا لهذا الغرض، حيث توفر القوة والمتانة وميزات السلامة اللازمة لتحمل الحمل.

كيف أعتني بحبل القطر الخاص بي؟

للعناية بحبل السحب، حافظ عليه نظيفًا وخاليًا من الأوساخ والحطام. خزّنه في مكان بارد وجاف بعيدًا عن أشعة الشمس المباشرة والرطوبة. افحصه بانتظام بحثًا عن أي علامات تآكل أو تلف.

هل يمكن استخدام حبل السحب الواحد لتطبيقات متعددة؟

بعض حبال القطر متعددة الاستخدامات ومناسبة لتطبيقات متعددة. مع ذلك، يُفضل استخدام حبال مصممة لأغراض محددة لضمان السلامة والأداء الأمثل.

كم مرة يجب علي استبدال حبل القطر الخاص بي؟

يعتمد تكرار استبدال حبل السحب على استخدامه وحالته. افحصه بانتظام بحثًا عن أي تآكل أو تلف. استبدله عندما تؤثر أي من هذه المشكلات على سلامته أو سلامته.

لماذا يتم طلاء بعض حبال القطر؟

تُطلى حبال القطر لتعزيز متانتها وأدائها. توفر الطلاءات، مثل البولي يوريثان، حماية من التآكل والأشعة فوق البنفسجية والرطوبة والمواد الكيميائية، مما يُطيل عمر الحبل ويحافظ على قوته.

كيف يتم قياس قوة حبل القطر؟

تُقاس قوة حبال القطر عادةً بمدى قوة الشد أو الكسر. في دوراكورديكس، نُخضع حبالنا لاختبارات صارمة، ونحدد قوتها بتطبيق قوة متزايدة حتى تصل إلى نقطة الكسر. تشير أعلى قوة يتحملها حبلنا إلى قوة الشد أو الكسر المذهلة.

هل يمكنني ربط حبل سحب Uhmwpe؟

لا يُنصح عمومًا بربط حبل سحب مصنوع من البولي إيثيلين عالي الكثافة (UHMWPE). فالعقد قد تُضعف الحبل بشكل كبير وتُضعف متانته. يُفضل استخدام موصلات أو ملحقات مُخصصة للسحب.

كيف أقوم بربط حبل السحب الاصطناعي بمركبتي؟

التحقق من نقاط السحب: تأكد من أن سيارتك تحتوي على نقاط سحب مخصصة، وفقًا للدليل أو الإرشادات المهنية.

فحص الحبل: افحص حبل السحب Duracordix الخاص بك بحثًا عن التآكل أو التلف، واستبدله إذا لزم الأمر.

المرفق الآمن: استخدم موصلات مناسبة (أغلال أو خطافات أو حلقات) لتثبيت الحبل بشكل آمن على نقاط السحب.

محاذاة مستقيمة: تأكد من تثبيت الخط المستقيم دون التواءات أو عقد للحصول على القوة المثالية.

سحب آمن: اتبع إرشادات السلامة، واحتفظ بالمارة على مسافة، وقم بالسحب بثبات لمنع الهزات المفاجئة أو الصدمات.

لماذا هناك ألوان مختلفة من حبال السحب UHMWPE؟

التعريف والسلامة: تُعدّ الألوان المختلفة بمثابة مُعرّف بصري سريع لأغراض أو نقاط قوة مُختلفة. يُساعد هذا المستخدمين على اختيار الحبل المُناسب لاحتياجاتهم المُحددة، مما يُقلل من خطر استخدام حبل غير مُناسب أو ضعيف.

الجمالية والعلامة التجارية: يمكن استخدام الألوان للعلامات التجارية والجماليات، مما يسمح لمصنعين مثل دوراكورديكس بتمييز منتجاتهم في السوق. كما تُحسّن هذه الحبال الجذابة المظهر العام للمعدات والمركبات.

مؤشر المادة والأداء: قد تشير بعض رموز الألوان إلى خصائص المادة أو أداء الحبل. على سبيل المثال، قد يدل لون معين على مقاومة الحبل للأشعة فوق البنفسجية أو المواد الكيميائية أو التآكل، مما يساعد المستخدمين على اتخاذ خيارات مدروسة بناءً على الاستخدام المقصود.

هل يمكنني طلب علامة تجارية مخصصة أو تسمية خاصة لحبال السحب الاصطناعية؟

نعم، يمكنك طلب علامة تجارية مخصصة أو علامة خاصة لحبال السحب الاصطناعية. يتيح هذا الخيار للشركات إضافة شعاراتها وأسمائها وبيانات الاتصال الخاصة بها على الحبال، مما يعزز هوية علامتها التجارية. أما العلامة التجارية الخاصة فتتعدى ذلك، حيث تحمل اسم الموزع أو بائع التجزئة حصريًا على الحبال لخط إنتاج مميز.

ما هي سياسات الإرجاع للطلبات بالجملة أو المعيبة؟

للطلبات بالجملة أو المعيبة، توفر دوراكوردكس سياسات إرجاع شفافة. في حال استلامكم منتجًا معيبًا، نوفر لكم إرجاعًا سلسًا خلال فترة زمنية محددة. للطلبات بالجملة، فريق دعم العملاء لدينا جاهز لمساعدتكم في حل أي استفسارات، مما يضمن عملية حل سلسة.

هل يمكنني الحصول على خصومات بالجملة أو أطوال مخصصة للطلبات الكبيرة؟

بالتأكيد! للطلبات الكبيرة، تقدم دوراكورديكس خصومات مميزة ومرونة في توفير أطوال حبال مخصصة تناسب احتياجاتك بدقة.