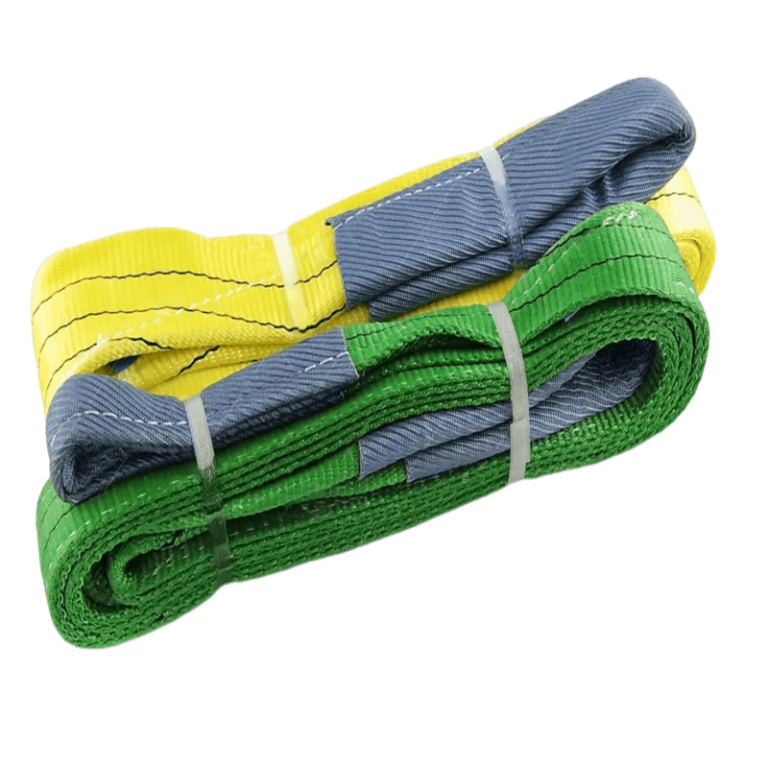

WEBBING SLING

A webbing sling is a piece of material made from woven fabric, typically polyester, nylon, or polypropylene, designed for lifting, hoisting, or securing loads. webbing slings are a popular and safer alternative to wire or chain slings in many lifting applications.

- High Load Capacity

- Lightweight & Flexible

- Damage-Reducing Surface

- Durable Woven Material

Table Of Contents For This Page

To ensure easy access to the information you need, we’ve created this table of contents that will take you directly to the relevant section when clicked

General Applications

Discover the Versatile Applications of Synthetic Webbing Slings

heavy lifting

Webbing slings ensure safe hoisting of heavy machinery like bulldozers and cranes. Their adaptability prevents damage during the lifting process.

construction

On sites, slings hoist materials like steel and concrete. Their damage-reducing surfaces protect delicate materials from scratches.

- customer's favourite

HOT SELLING SIZES

Discover our Synthetic Webbing Sling Options For Reliable Heavy Loading

3 Tons (6,000 lbs)

A reliable and durable solution for lifting heavy loads. Crafted with high-quality synthetic webbing, this sling ensures secure and efficient operations in various industrial applications.

5 Tons (10,000 lbs)

Designed to handle heavier loads with utmost safety and reliability. This synthetic webbing sling offers superior strength and durability, making it an ideal choice for demanding lifting tasks across multiple industries.

10 Tons (22,000 lbs)

Engineered for extreme weight capacities, ensuring exceptional performance. Crafted from top-grade materials, it guarantees optimal strength and longevity in heavy-duty lifting operations.

Duracordix is a synhtetic webbing sling manufacturer & Supplier in China.

we can produce various sizes for different applications and custom made for special projects.

No matter you’re looking for a wholesale supplier or custom made winch ropes, we can all help. contact us to get your solution now.

- sizes available

webbing sling VS WIRE ROPE

Comparing Webbing Sling to Steel Wire Rope

| Criteria | Material | Flexibility | Weight & Portability | Durability & Environment | Safety & Inspection | Applications |

|---|---|---|---|---|---|---|

| Webbing Sling | Woven fabric (polyester, nylon, or UHMWPE | Highly flexible; adapts to load shape; protects surfaces. | Lightweight; easy to transport & handle. | Susceptible to cuts, tears,& UV; avoid sharp objects & prolonged sun. | Regular inspection needed for wear, cuts, damage. Retire if damaged. | Suited for delicate or polished loads, irregular shapes, & minimal damage risk scenarios. |

| Wire Rope | Steel wires twisted into strands helically wound around a core. | Rigid; less adaptable to irregular shapes; may scratch/damage surfaces. | Heavier; cumbersome to handle, transport, and store. | Highly durable; resistant to harsh environments but can corrode. | Inspection for corrosion, broken wires, wear; replace if damaged. | Suited for heavy-duty lifting in challenging environments. |

- main features

Benefits Benefits OF webbing SLING

Discover the Advantages of Synthetic Webbing Sling!

Lightweight

Being made from woven fabric, webbing slings are lightweight and easy to handle, making them convenient for transport and reducing fatigue during usage.

Easy Inspection

Webbing slings, especially those with visible wear or damage, can be quickly inspected, ensuring safer operations as damaged slings can be identified and retired promptly.

Flexibility

Webbing slings are highly flexible and can easily adapt to the shape of the load, ensuring a snug fit and reducing the risk of slippage.

Surface Protection

Due to their soft fabric nature, webbing slings are less likely to cause damage, scratches, or marks on the items they are lifting, especially on delicate or finished surfaces.

- Happy Clients

What They Said

Real Stories, Real Success: Customer Testimonials on Duracordix Webbling Sling

The inconsistency in quality from various suppliers was a persistent issue for our business. With Duracordix, not only is the quality consistent, but their customer service is also top-notch. They've made our supply chain process so much smoother.

Elena Rodriguez Wholesale DistributorIn the marine industry, the slightest compromise in sling quality can have significant repercussions. Duracordix provides peace of mind with their impeccable quality. It's been a relief to find a supplier that understands our pain points so well.

Takashi Yamamoto Marine Equipment ManagerI was tired of the frequent replacements and the unpredictable quality from previous suppliers. Duracordix's webbing sling has proven to be a reliable solution, addressing the very pain points we've been grappling with for years

Aishah Binti Azman Operational Manager- paint-free purchase

why choose

Duracordix Webbing Sling

- Unparalleled Quality: With Duracordix, 95% of customers attest to our slings' superior durability, thanks to high-performance fibers defining top-tier craftsmanship.

- Professional Customization: Serving over 3,000 professionals from automotive to heavy equipment, our slings consistently exceed industry expectations.

- Value Pricing: Offering unmatched quality, 80% of our repeat customers appreciate the balance of cost-effectiveness and premium products.

- Customer First: Over 2,000 positive reviews highlight our commitment to seamless service, with a team always ready to elevate your experience.

- Safety Commitment: Every Duracordix sling undergoes rigorous testing and quality checks. Our commitment to safety ensures that you can execute your operations with peace of mind.

- we make more

Related products

Explore our Range of Related Products and lifting sling for Enhanced Performance and Versatility

FAQs

Answers to Your Questions About Duracordix’s Durable and Versatile Soft Shackles.

What is a webbing sling?

A webbing sling is a strong and versatile lifting tool made from nylon, polyester, or UHMWPE, designed to safely lift, lower, or hold loads.

How to Choose the Webbing Sling?

Material Composition:

- Polyester: Generally, good resistance to acid but vulnerable to alkalis.

- Nylon: Resistant to alkalis but can be degraded by acids.

- Always consider the type of environment and materials the sling will be exposed to.

Load Capacity:

- Check the Safe Working Load (SWL) or Rated Capacity. Ensure the sling can handle the maximum weight of the load.

- Remember: Overloading can lead to sling failure.

Length:

- Choose the appropriate length based on the lifting application. Too long can lead to inadequate lifting control; too short may not fit the purpose.

Width:

- Wider slings tend to distribute the load more evenly, which can help protect both the sling and the load.

Environmental Factors:

- Consider UV resistance if the sling will be used outdoors.

- Check for resistance against chemicals or abrasive surfaces if relevant.

Safety Factor:

- Typically, the industry standard is a 5:1 or 7:1 safety factor. This means the breaking strength is 5 or 7 times the SWL.

End Fittings and Attachments:

- Ensure any hardware or attachments are compatible with the sling and can support the intended load.

Which is better: nylon webbing sling or polyester webbing sling?

Both nylon and polyester have their advantages. Nylon is more elastic and resilient, while polyester is less stretchy but more resistant to acid damage. Your choice should depend on the specific application.

What are the primary uses of a webbing sling?

Webbing slings are predominantly used in the lifting and rigging industry for tasks such as moving heavy equipment, construction operations, and other industrial applications.

How do I inspect a webbing sling?

Regular inspection involves checking for wear and tear, cuts, frays, burns, or any deformities in the stitching. Any signs of damage should be taken seriously, and the sling should be retired if deemed unsafe.

What's the difference between a flat webbing sling and a round one?

Flat webbing slings are generally made from woven fabric and are flat in appearance. Round slings, however, are tubular and are often made from continuous loops of yarn inside a protective cover.

How often should webbing slings be inspected?

Webbing slings should be inspected before each use. Additionally, a thorough, periodic inspection by a competent professional should occur at least every 12 months, or more frequently depending on its usage.

How do I care for and store my webbing sling?

Keep webbing slings away from sharp edges, chemicals, and extreme temperatures. Store them in a cool, dry place, preferably hung up to prevent tangling.

Can a webbing sling stretch under load?

Yes, especially nylon slings, which have more elasticity compared to polyester. Always account for a little stretch when planning lifts.

Is it safe to use a webbing sling for lifting people?

No, unless explicitly designed for that purpose. Standard webbing slings are for material handling only.

What are the safety standards for webbing slings?

Various organizations, such as ISO and ASME, provide safety standards for webbing slings. Always ensure your sling meets the necessary standards for your region and application.

How long does a webbing sling last?

The lifespan of a webbing sling varies based on usage, care, and storage. With proper care, a sling can last several years, but it's essential to retire them at the first sign of damage.

Can I repair a damaged webbing sling?

No, damaged slings should never be repaired but instead should be immediately retired to ensure safety.

How do webbing slings compare to ropes in lifting applications?

While both can be used in lifting, webbing slings offer a broader contact surface which can help distribute the weight more evenly and reduce damage to the load.

What should I do if my webbing sling gets wet?

Dry it thoroughly in a shaded area. Avoid direct sunlight or extreme heat sources which can degrade the material.

Are there color codes for webbing slings indicating weight capacity?

Yes, different colors often represent various weight capacities. Always refer to the manufacturer's guidelines or the sling label.

Can I use multiple webbing slings together for heavier loads?

Yes, but it's essential to ensure they are used correctly and that the combined capacity is not exceeded.

What is the temperature resistance of webbing slings?

It varies based on the material. For instance, polyester might withstand up to 180°F, while nylon can handle up to 194°F. Always consult manufacturer guidelines.

What do I need to consider when choosing a webbing sling for my needs?

Consider factors like load weight, sling material, lifting environment, potential exposure to chemicals, and the specific type of lift (vertical, choker, or basket).

I've always found it challenging to source webbing slings that can handle the demanding weight requirements we deal with daily. Duracordix's webbing sling has truly been a game-changer for us. Superior strength and durability, every single time

Johnathan Williams Procurement Officer