حبل ربط السفن والقوارب البحرية

حبال إرساء قوية وموثوقة مصممة للحفاظ على سلامة وأمان سفينتك

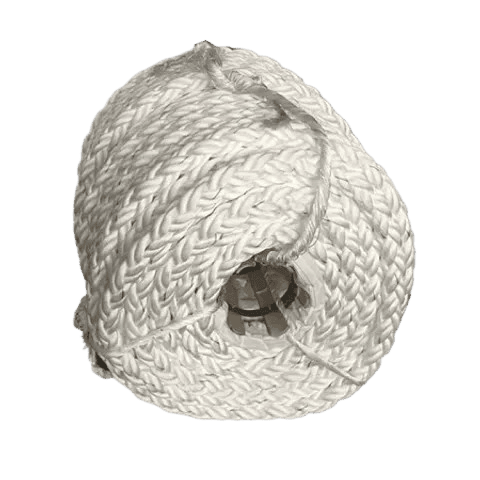

اصطناعي حبل الربط

الربط هو تثبيت القارب أو السفينة لمنعها من الانجراف. يتم ذلك بربطها إلى رصيف أو عوامة باستخدام حبال أو سلاسل، بحيث تبقى ثابتة حتى مع قوى الرياح أو التيارات أو المد والجزر.

تم تصميم حبل الربط الخاص بنا، المصنوع من ألياف صناعية عالية الجودة، لتوفير القوة والمتانة لربط السفن بشكل موثوق.

- قوة عالية: مسكة آمنة وموثوقة.

- مقاومة للأشعة فوق البنفسجية: يتحمل الظروف البحرية القاسية.

- خفيف الوزن: سهولة التعامل والربط.

- امتصاص الصدمات: يقلل من تأثير الأمواج

عام التطبيقات

استكشاف حبال الربط في التطبيقات البحرية المتنوعة

صناعة الشحن

حبل ربط السفن يسهل التعامل مع سفن الربط الخاصة بك ويجعلها آمنة في ظروف الشحن الصعبة.

الحفر البحري

حبل الربط خفيف الوزن، مما يجعل العمليات أسهل ويثبت معداتك البحرية بشكل آمن

البيئة البحرية

قوي وخفيف الوزن، مصمم لتحمل الظروف القاسية وتأمين سفن الرسو الخاصة بك في البيئات البحرية

ركوب القوارب

تم تصميم خط ربط القوارب لأنظمة ربط القوارب والتعامل السهل والرسو الآمن في القوارب واليخوت.

حبال الربط حسب المادة

As a mooring rope mufacturer, we provide you different types of mooring-ropes for choosen

حبل إرساء UHMWPE

وصف: مصنوع من البولي إيثيلين عالي الوزن الجزيئي (UHMWPE)، مما يوفر بديلاً أكثر أمانًا وعالي الأداء للحبال الاصطناعية التقليدية لربط السفن والرسو البحري.

الميزات الرئيسية: بفضل نسبة قوة إلى وزن رائعة، وتمدده البسيط، وطفوه الممتاز، يطفو هذا الحبل على الماء ويقاوم الأشعة فوق البنفسجية والمواد الكيميائية والتآكل. صُمم ليتحمل الظروف البحرية الصعبة بكفاءة.

التطبيقات: مثالية للرسو والقطر وخطوط المرساة والإبحار وللسفن التي تحتاج إلى حلول رسو متينة وخفيفة الوزن وموثوقة.

حبل ربط النايلون

وصف: Made from high-quality Nylon, also called elastic mooring-rope or mooring hawser, designed to handle the stress of marine environments while providing reliable, safe mooring.

الميزات الرئيسية: مرونة عالية تمتص الصدمات، مما يجعلها مثالية في البحار الهائجة. مقاومة للتآكل ومحمية من الأشعة فوق البنفسجية لضمان متانة طويلة الأمد.

التطبيقات: مثالية للرسو والرسو وخطوط المرساة، حيث توفر المرونة وامتصاص الصدمات القوية للحفاظ على السفن آمنة ومؤمنة.

حبل ربط من البوليستر

وصف: Strong and durable, our polyester mooring-rope is built to handle tough marine conditions with minimal stretch.3strand,8strand,12strand or double braided rope available.

الميزات الرئيسية: تضمن المقاومة الممتازة للأشعة فوق البنفسجية والتآكل أداءً يدوم طويلاً، بينما يوفر التمدد المنخفض تحكمًا واستقرارًا موثوقًا به.

التطبيقات: مثالية للرسو والرسو وخطوط المرساة حيث تعد المتانة والاستقرار أمرًا أساسيًا للحفاظ على أمان السفن.

حبل ربط من البولي بروبيلين

وصف: Lightweight and economical, our polypropylene mooring rope( also called floating mooring-rope) is perfect for marine use where buoyancy is essential.

الميزات الرئيسية: يتميز هذا الحبل بالطفو، ومقاومته للعفن والتلف، وسهل التعامل معه، مما يجعله مثاليًا للاستخدام المتكرر.

التطبيقات: أفضل ما يناسب عمليات الربط والقطر الخفيف وعوامات العلامات، حيث تكون هناك حاجة إلى حبل عائم وسهل الإدارة.

حبل ربط البولي إيثيلين

وصف: Durable and cost-effective, our polyethylene mooring-rope is built for reliable performance in harsh marine environments.

الميزات الرئيسية: تتميز بمقاومة عالية للتآكل والأشعة فوق البنفسجية مما يضمن طول العمر، في حين أن امتصاصها المنخفض للماء يجعلها خفيفة الوزن وسهلة التحكم.

التطبيقات: مثالية للرسو وصيد الأسماك وغيرها من الاستخدامات البحرية حيث تكون المتانة وسهولة التعامل ضرورية.

- خدمة صانعي القطع الأصلية

التخصيص

لتلبية مشاريعك الفريدة والخاصة

- الميزات الرئيسية

المزايا

اكتشف مزايا حبل الربط Duracordix!

قوة فائقة

يتميز حبل الربط البحري من Duracordix بقوة شد لا مثيل لها، مما يضمن عمليات ربط موثوقة وآمنة في البيئات البحرية الأكثر تطلبًا.

مقاومة الاحتكاك

بفضل خصائص الحبل الليفي، يتميز الحبل بتآكل أقل بسبب الاحتكاك، مما يطيل عمره ويضمن تجربة إرساء أكثر أمانًا وموثوقية.

خفيف الوزن

على الرغم من قوتها، فإن خطوط ربط Duracordix خفيفة الوزن بشكل لا يصدق، مما يسهل التعامل معها وتخزينها والعمليات، خاصة أثناء عمليات الربط الحرجة.

مرونة الطقس

تم تصميم هذا الحبل ليكون متينًا، فهو يقاوم الأشعة فوق البنفسجية والمياه المالحة وظروف الطقس القاسية، مما يضمن طول العمر والأداء المتسق طوال فترة استخدامه.

- عملاء سعداء

صوت العميل

يشارك المستخدمون تجاربهم ونجاحاتهم في ربط الحبال البحرية

- شراء بدون ألم

لماذا تختار

حبل ربط دوراكورديكس

- Built for Reliability: Many mooring-ropes fail under tough marine conditions. Duracordix’s HMPE mooring-rope rope offers unmatched strength, reducing breakage risks and keeping your vessel secure when it matters most.

- Built to Last: Typical ropes break down in harsh conditions. Duracordix’s mooring-rope resists UV and marine elements, offering long-lasting durability you can rely on.

- Quality Meets Affordability: With Duracordix’s UHMWPE mooring-rope, you get top-notch quality without breaking the bank—delivering real value and reliability.

- السلامة التي يمكنك الوثوق بها: يقاوم خط ربط Duracordix الانكسارات المفاجئة، مما يضمن الأمان الموثوق به وراحة البال في الظروف البحرية الصعبة.

- Low Maintenance, More Freedom: Duracordix’s mooring-rope requires minimal upkeep, letting you focus on what matters most—your time on the water, not rope care.

الأسئلة الشائعة

استكشاف تفاصيل حبل الربط واستخداماته

ما هو الربط؟

الربط هو عملية تثبيت القارب أو السفينة في نقطة ثابتة، كالرصيف أو العوامة، ليبقى في مكانه. ويتم ذلك عادةً باستخدام الحبال أو السلاسل أو الكابلات للحفاظ على ثبات السفينة، حتى في ظل تغيرات المد والجزر والرياح القوية، مما يضمن عدم انجرافها أو تحركها بشكل مفاجئ.

هل تعرف أنواع الربط؟

نعم، هناك عدة أنواع من الربط، كل منها يناسب مواقف مختلفة وأنواع مختلفة من السفن:

ربط نقطة واحدة (SPM): يُثبّت السفينة في نقطة واحدة، عادةً ما تكون عوامة، مما يسمح لها بالتحرك مع الرياح والمد والجزر. يُستخدم عادةً مع ناقلات النفط الكبيرة.

ربط متعدد النقاط: يستخدم عدة حبال ربط متصلة بنقاط ثابتة مختلفة، مثل العوامات أو قاع البحر، مما يزيد من أمان السفينة وثباتها. مثالي للحفر البحري أو السفن الثقيلة.

رسو تقليدي (رصيف): يربط السفينة مباشرةً بالرصيف باستخدام حبال من المقدمة والمؤخرة والجوانب. شائع في المراسي والموانئ للقوارب والسفن الصغيرة.

رسو البحر الأبيض المتوسط: تواجه مؤخرة السفينة الرصيف بينما تكون مقدمتها مثبتة، مما يسمح بدخول المزيد من القوارب إلى الرصيف. يُستخدم هذا النظام غالبًا في المراسي المزدحمة.

التموضع الديناميكي (DP): يستخدم نظامًا حاسوبيًا ودوافع لإبقاء السفينة ثابتة دون الحاجة إلى حبال إرساء مادية. يُستخدم عادةً في السفن البحرية التي تحتاج إلى تحديد مواقع دقيق.

ما هو أفضل حبل لخط الربط؟

تعتمد أفضل مادة لحبال الربط على الاستخدام والمتطلبات المحددة. يُعتبر البولي إيثيلين عالي الكثافة (UHMWPE) الأفضل عمومًا لخفة وزنه وقوته العالية ومتانته.

كيف تختار حجم حبل الربط المناسب؟

يعتمد قطر وطول حبل الإرساء على حجم سفينتك ووزنها والحمل الذي تتحمله. تأكد من قدرة رافعة الإرساء على تحمل حجم الحبل الذي تختاره. كقاعدة عامة، يجب ألا يقل طول الحبل عن مرة ونصف طول السفينة لضمان إرساء آمن ومرونة كافية لظروف التنقل.

ما هو الفرق بين حبال الربط الملتوية والمضفرة؟

تُصنع حبال الربط الملتوية بلف خيوط متعددة معًا، بينما تُصنع حبال الربط المضفرة بضفر الخيوط. تتميز الحبال المضفرة بقوتها ومتانتها، مما يجعلها خيارًا مثاليًا للربط الشاق.

هل تحتاج إلى غلاف حماية لحبل الربط؟

نعم، يُعدّ غلاف الحماية إضافةً ذكيةً لإطالة عمر حبل الربط. فهو يساعد على حماية الحبل من التآكل، والتلف الناتج عن الأشعة فوق البنفسجية، والتآكل الناتج عن الاحتكاك المستمر بالأرصفة أو المشابك. تُحدث هذه الطبقة الإضافية فرقًا كبيرًا، خاصةً في الظروف القاسية، حيث تحافظ على قوة حبلك وموثوقيته مع مرور الوقت.

ما هو حبل الربط الثقيل؟

حبل إرساء ثقيل مصمم لتأمين السفن الكبيرة في الظروف القاسية. مصنوع من مواد فائقة المتانة (مثل UHMWPE أو الداينيما)، ويوفر قوة موثوقة، ويقاوم التآكل والأضرار الناتجة عن الأشعة فوق البنفسجية، ويحافظ على ثبات سفينتك في التيارات والرياح القوية - مثالي للتطبيقات البحرية الشاقة.

كيفية ربط حبل الربط؟

يُعدّ ربط حبل الربط مهارةً مفيدةً لإنشاء حلقات قوية أو ربط حبلين. إليك دليلٌ بسيط:

فك الخيوط: ابدأ بفك الضفيرة أو فك نهاية الحبل بعناية، وفصلها إلى ثلاثة خيوط أو أكثر.

تشكيل حلقة: قم بطي الحبل للحصول على حجم الحلقة الذي تريده، مع ترك ذيل بالخيوط السائبة.

نسج الخيوط: خذ كل خصلة ونسجها عبر الحبل الرئيسي، مرورًا فوق وتحت خيوط جسم الحبل. كرر هذه العملية عدة مرات لتثبيت الوصلة.

شد الوصلة: اسحب كل خصلة بإحكام للتأكد من أن الوصلة آمنة، ثم قم بقص أي فائض للحصول على لمسة نهائية نظيفة.

مع الممارسة، يصبح الوصل أسهل، وهو طريقة رائعة للحفاظ على إعداد الربط الخاص بك قويًا وموثوقًا به.

ما هو الفرق بين حبل الرصيف وحبل الربط؟

حبل الرصيف هو حبل يستخدم لربط السفينة بالرصيف، بينما يستخدم حبل الربط لتأمين السفينة إلى مرساة أو عوامة.

كيفية ربط عقدة خط الربط بشكل صحيح؟

لتأمين سفينتك بأمان، استخدم وصلة ربط عقدة:

- لف الحبل حول قاعدة المشبك.

- اصنع شكل الرقم ثمانية عن طريق عبور الحبل فوق المشبك.

- قم بإنهاء العمل بنصف حلقة أسفل اللفة الأخيرة.

هذه العقدة قوية، وسهلة الفك، وتحافظ على قاربك آمنًا حتى في الظروف الصعبة.

ما هو الفرق بين حبل الربط المضفر المفرد والحبل المضفر المزدوج؟

تتكون حبال الربط ذات الضفيرة المفردة من حبل مضفر واحد، بينما تتكون حبال الربط ذات الضفيرتين من حبلين مضفرين - نواة داخلية وغلاف خارجي. عادةً ما تكون حبال الضفيرتين أقوى وأكثر متانة من حبال الضفيرة المفردة.

How do you inspect a mooring-rope for wear and damage?

لفحص حبل الربط بحثًا عن أي تآكل أو تلف، ابحث عن علامات تآكل أو قطع أو تغير في اللون أو تصلب. مرر يديك على الحبل للتحقق من أي تشوهات أو بقع خشنة. استبدل أي أجزاء تالفة أو مهترئة فورًا.

ما هو الفرق بين حبال الربط المصنوعة من مادة UHMWPE وحبال الربط المصنوعة من مادة البوليستر؟

حبال ربط UHMWPE أخف وزنًا وأقوى من حبال البوليستر، لكنها أغلى ثمنًا. حبال البوليستر أكثر مرونة ومقاومة للتآكل من حبال UHMWPE.

Why do mooring-ropes have a braided design?

زيادة القوة: يعمل التضفير على تعزيز قوة الشد، مما يساعد الحبال على تحمل قوى الربط الثقيلة.

متانة: تتمتع الضفائر المدمجة بمقاومة للتآكل، وتدوم لفترة أطول في البيئات البحرية القاسية.

المرونة: يتم التعامل مع الحبال المضفرة بسلاسة، مما يقلل من نقاط الضغط.

الحد الأدنى من التمدد: يضمن التمدد المنخفض الاستقرار ويقلل من مخاطر الانكسار تحت التوتر.

سهولة التعامل: يمنع السطح الأملس الالتواء ويقلل من إجهاد اليد.

حماية الغلاف الأساسي: يضيف اللب الداخلي القوة؛ بينما يحمي الغلاف الخارجي من التآكل والعناصر.

توفر خطوط الربط المضفرة أداءً موثوقًا به وطويل الأمد، وهي مصممة للحفاظ على سفينتك آمنة مع الحد الأدنى من المتاعب.

كيف تقوم بتنظيف حبل الربط؟

لتنظيف حبل الربط، اشطفه بالماء النظيف والصابون المعتدل، ثم علقه ليجف في مكان بارد وجاف بعيدًا عن أشعة الشمس المباشرة أو الرطوبة. تجنب استخدام المواد الكيميائية القاسية أو المنظفات الكاشطة التي قد تتلف الألياف.

What is the best mooring-rope for you?

يعتمد أفضل حبل ربط على نوع سفينتك، وظروف الربط، والاحتياجات المحددة.

للحصول على متانة عالية وطويلة الأمد، حبال النايلون تعتبر رائعة بسبب قوتها العالية وامتصاصها للصدمات.

حبال البوليستر توفر تمددًا منخفضًا ومقاومة للأشعة فوق البنفسجية، وهي مثالية للاستقرار المستمر.

حبال البولي بروبلين إنها خفيفة الوزن وتطفو، مما يجعلها مفيدة للرسو المؤقت.

حبال UHMWPE تتميز هذه المنتجات بأنها قوية للغاية ومقاومة للتآكل، وهي مثالية للبيئات الصعبة حيث تكون الموثوقية أمرًا بالغ الأهمية.

How often should you replace a mooring-rope?

يعتمد تكرار استبدال حبل الإرساء على المادة، والقطر، والتركيب، والاستخدام. استشر خبيرًا في الإرساء أو راجع إرشادات الصناعة لمعرفة فترات الاستبدال المناسبة.

ما هو الفرق بين حبل الربط المكون من 3 خيوط وحبل الربط المكون من 8 خيوط؟

يتكون حبل الربط المكون من 3 خيوط من ثلاثة خيوط ملتوية معًا، بينما يتكون حبل الربط المكون من 8 خيوط من ثمانية خيوط مضفرة معًا. عادةً ما تكون الحبال المكونة من 8 خيوط أقوى وأكثر متانة من الحبال المكونة من 3 خيوط.

How do you protect a mooring-rope from UV damage?

لحماية حبل الربط من أضرار الأشعة فوق البنفسجية، قم بتخزينه في مكان بارد وجاف بعيدًا عن أشعة الشمس المباشرة أو الرطوبة، أو قم بتغطيته بغطاء أو غلاف مقاوم للأشعة فوق البنفسجية.

What is the best mooring-rope for yacht mooring?

بالنسبة لليخوت، حبال ربط النايلون مثالية. فهي توفر قوة عالية ومرونة وامتصاصًا ممتازًا للصدمات، مما يجعلها مثالية لحماية يختك في ظل تقلبات المد والجزر والظروف القاسية. تضمن متانة النايلون ومقاومته للأشعة فوق البنفسجية أداءً طويل الأمد، مما يحافظ على سلامة يختك وأمانه مع الحد الأدنى من التآكل.

How to Avoid Mooring-Rope Accidents?

فحص بانتظام: افحص الحبال بحثًا عن أي تآكل أو تلف قبل كل استخدام. فالحبل الضعيف قد ينقطع تحت الحمل، مما يؤدي إلى حوادث خطيرة.

اختر الحبل المناسب: استخدم حبلًا قويًا بما يكفي لحجم ووزن سفينتك، مع طول وقطر كافيين لتحمل الحمل.

ابتعد عن الحبال المحملة: عندما يكون الحبل مشدودًا، ابتعد عنه. إذا انقطع، فقد يرتد بشكل خطير.

استخدم أكمام الحماية: يمكن لغلاف حماية الاحتكاك أن يحمي الحبل من التآكل، مما يطيل عمره ويقلل من تلف حبل الربط وخطر الانكسار المفاجئ.

مراقبة التوتر والطقس: راقب تغيرات المد والجزر، أو الرياح القوية، أو الظروف المتغيرة التي قد تضيف ضغطًا على إعدادات الربط الخاصة بك.

من خلال اتباع هذه الخطوات، يمكنك تقليل المخاطر والحفاظ على عمليات الربط آمنة لجميع المشاركين.

What is Regular Length of Your Mooring-Rope Reel?

تأتي بكرات حبل الربط لدينا عادةً بأطوال من 100 إلى 200 متريوفر حبلًا كافيًا لتلبية احتياجات الربط المختلفة. يضمن لك هذا الطول مرونة كافية لقص أطوال مخصصة، مما يساعدك على الحصول على المقاس المثالي لسفينتك.

- نحن نصنع المزيد

متعلق ب منتجات

اكتشف المزيد: المنتجات التكميلية للتطبيقات البحرية