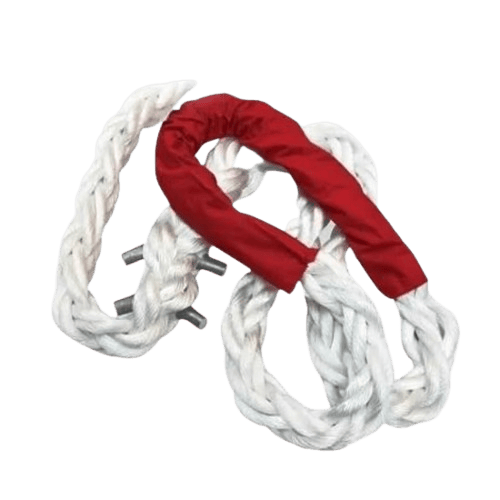

mooring Tail rope

Ensure the stability and safety of vessels, platforms, or offshore mooring systems

What Is Mooring Tail?

A mooring tail is typically made from synthetic fibers such as nylon or a blend of polyester and polypropylene fibers. It is primarily used in conjunction with our UHMWPE mooring ropes, serving as an extension of the main mooring rope.

Mooring Tail Rope is not only effectively cushions and protects the main mooring rope but also, due to its flexibility and ability to absorb some of the tension, reduces the load pressure on the main mooring line, thereby enhancing the overall stability and safety of the mooring system.

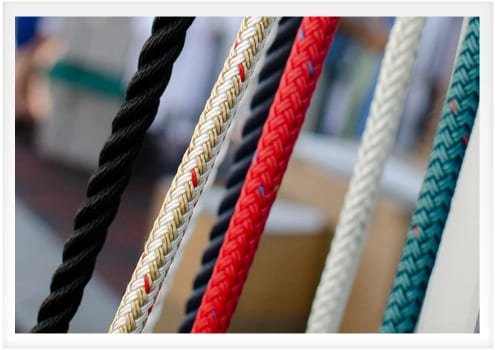

Mooring Tail Rope By Material

As a mooring tail rope mufacturer, we provide you several types of mooring tail for choosen

Description: made from 100% nylon (polyamide) with 8-strand or 12-strand designs and a double-twist technique. Thanks to nylon’s high elongation, they provide excellent elasticity and shock absorption, effectively handling the impact from strong winds and waves.

Application: Mooring systems for vessels, offshore platforms, and floating structures.

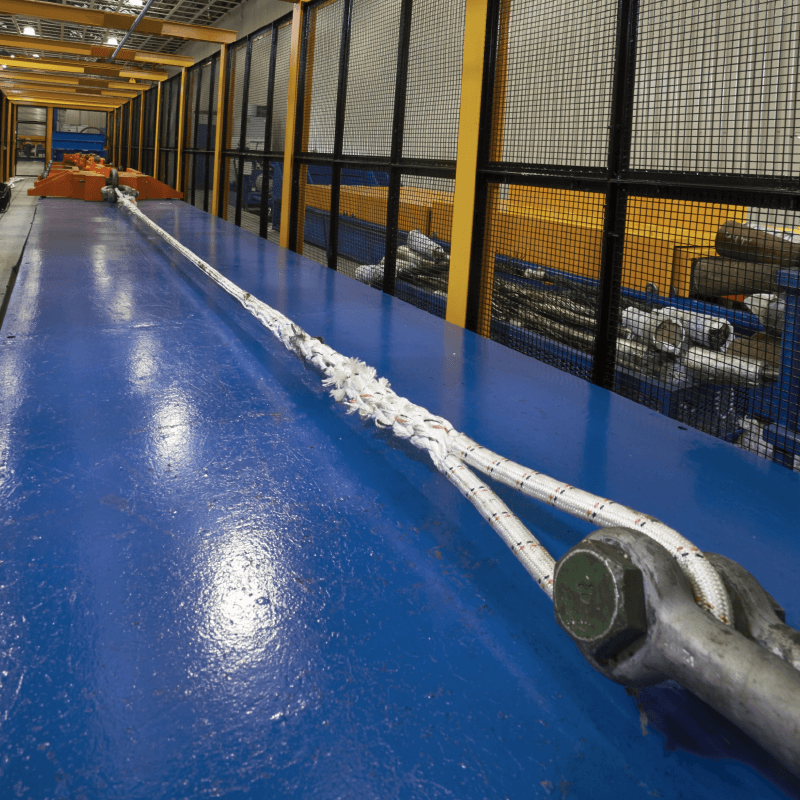

Regular Size: Diameter: 78mm and 80mm, common length:11m and 22m, splice eyes at both ends in 1m,1.5,2m or else.

Meets OCIMF MEG4 standards

Description: Made by combining polyester and polypropylene fibers, offering you the high strength, abrasion resistance, and chemical durability of polyester, along with the buoyancy of polypropylene. This helps prevent the mooring tails from sinking and entangling with obstacles, while also providing a lower cost compared to nylon.

- Specific Gravity: ~0.92 g/cm³

- Melting Point: 250-265°C

- Elongation at Break: 10-15%

- Water Absorption & Buoyancy: Moderate; good buoyancy

- UV Resistance: Moderate to Good

- Abrasion Resistance: High

- Chemical Corrosion Resistance: Good

- Rot Resistance: High

Application: Mooring systems for ports, docks, and floating storage facilities

Regular Size: Diameter: 78mm and 80mm, common length:11m and 22m, splice eyes at both ends in 1m,1.5,2m or else.

Meets OCIMF MEG4 standards

Customization

To Meet Your Unique and special projects