Synthetic fiber ropes are gaining popularity as a lightweight, easy-to-handle, and safer alternative to steel wire ropes. However, they come in various types. In this article, you will find the different types based on materials, structure, applications, strength, and color.

Table of Contents

ToggleWhat Is Synthetic Rope?

Synthetic rope(also called plastic rope) is a flexible, durable rope crafted from synthetic fibers. It’s commonly used for towing, lifting, mooring, and rigging. Compared to traditional natural fiber ropes, synthetic ropes offer superior strength, abrasion resistance, and corrosion resistance.

Types of Synthetic Rope Based on Material

Polyester Rope

Description: As the name suggests, polyester rope is a synthetic rope woven from polyester fibers, and is considered an all-around synthetic rope.

Properties:

Specific Gravity: 1.38g/cm3

High abrasion-resistant

Strong UV protection

Excellent chemical resistance

It doesn’t absorb water

High temperatures resistance: up to 265°C

Common uses: Marine Mooring, Towing, Fishing, Safety Line, Rigging and Sailing

Nylon Rope

Description: nylon rope is a type of synthetic rope made from nylon (polyamide) fibers, known for its high elasticity and strength, making it widely used in various applications.

Properties:

Gravity: 1.14g/cm3 it does not float

High Elongation up to 25%

Great heat resistance: 215°C(420°F)

Good UV resistance

Outstanding Wear resistance

Good chemical resistance

Common uses: marine, fishing, lifting, vehicle rescue, and climbing

Polypropylene Rope

Description: Polypropylene rope is a synthetic rope made from woven polypropylene fibers. Known for being a highly durable polymer, polypropylene makes this rope extremely tough and versatile, making it widely used in various applications

Properties:

Gravity: 0.91/cm3 it floats on water

Heat Resistance: 160°C (320°F)

Good wear resistance

Excellent Chemical Resistance

Good UV resistance

Common uses: marine mooring, fishing, leisure sport, construction.

Polyethylene Rope

Description: Polyethylene rope, made from polyethylene fibers, is known for its unique waxy texture. It typically comes in 3-strand, 6-strand, and 16-strand variations for various applications.

Properties:

Gravity: 0.91 g/cm³ (it floats on water)

Heat Resistance: 80°C (176°F)

Good Wear Resistance

Excellent Chemical Resistance

Good UV Resistance

Uses: marine, commercial fishing, construction, agriculture etc.

KEVLAR(ARAMID) Rope

Description: Kevlar rope is made from a fiber called Kevlar (an aramid fiber), known for its exceptional heat resistance and high strength, making it ideal for use in various specialized fields.

Properties:

Gravity: 1.44 g/cm3 immersed

Melting Point: 930°C

Elongation at break: 3~4%

Good UV resistance

Excellent Abrasion Resistance

Good Chemical Resistance

Uses: Sailing, Fire Mooring, Lifting, Safey line, Military and Tactical, fiber optic cables

UHMWPE (Ultra-High Molecular Weight Polyethylene) Rope

Description: UHMWPE rope is a synthetic rope made from ultra-high molecular weight polyethylene, typically consisting of 12 strands. Its lightweight and high strength provide better solutions for specific applications

Properties:

Gravity: 0.97g/cm3 floating

Melting point: 145°C

Elongation at break: 3.5%

None water absorption

Good UV Resistance

Good Wear resistance

Excellent Chemical Resistance

Uses: vehicle recovery, marine towing, mooring, offshore, telecom hauling, heavy lifting.

Comparison Table

| Rope Type | Material | Specific Gravity | Heat Resistance | UV Resistance | Abrasion Resistance | Chemical Resistance | Water Absorption | Common Uses | Strengths | Weaknesses |

| Polyester Rope | Rope Polyester Fibers | 1.38 g/cm³ | High (265°C) | Excellent | High | Excellent | No | Marine Mooring, Towing, Rigging | High UV and chemical resistance, no water absorption | Heavier, doesn’t float |

| Nylon Rope | Nylon Fibers | 1.14g/cm³ | Good (215°C) | Good | Outstanding | Good | Yes | Marine, Lifting, Climbing | High strength and elasticity, excellent wear resistance | Heavier, doesn’t float |

| Polypropylene Rope | Polypropylene Fibers | 0.91 g/cm³ | Moderate (160°C) | Good | Good | Excellent | No | Marine Mooring, Fishing, Construction | Lightweight, floats on water, excellent chemical resistance | Lower heat resistance, less durable under heavy loads |

| Polyethylene Rope | Polyethylene Fibers | 0.91 g/cm³ | Low (80°C) | Good | Good | Excellent | No | General Utility, Fishing, Nets | Floats on water, good chemical resistance | Lower heat and wear resistance |

| Kevlar (Aramid) Rope | Kevlar Fibers | 1.44 g/cm³ | Extremely High (930°C) | Good | Excellent | Good | No | Military, Tactical, Fire Mooring | Extremely high heat resistance, very strong | Higher cost, lower elongation |

| UHMWPE Rope | UHMWPE Fibers | 0.97 g/cm³ | Moderate (145°C) | Good | Good | Excellent | No | Vehicle Recovery, Offshore, Telecom | Lightweight, high strength, excellent chemical resistance | Moderate heat resistance |

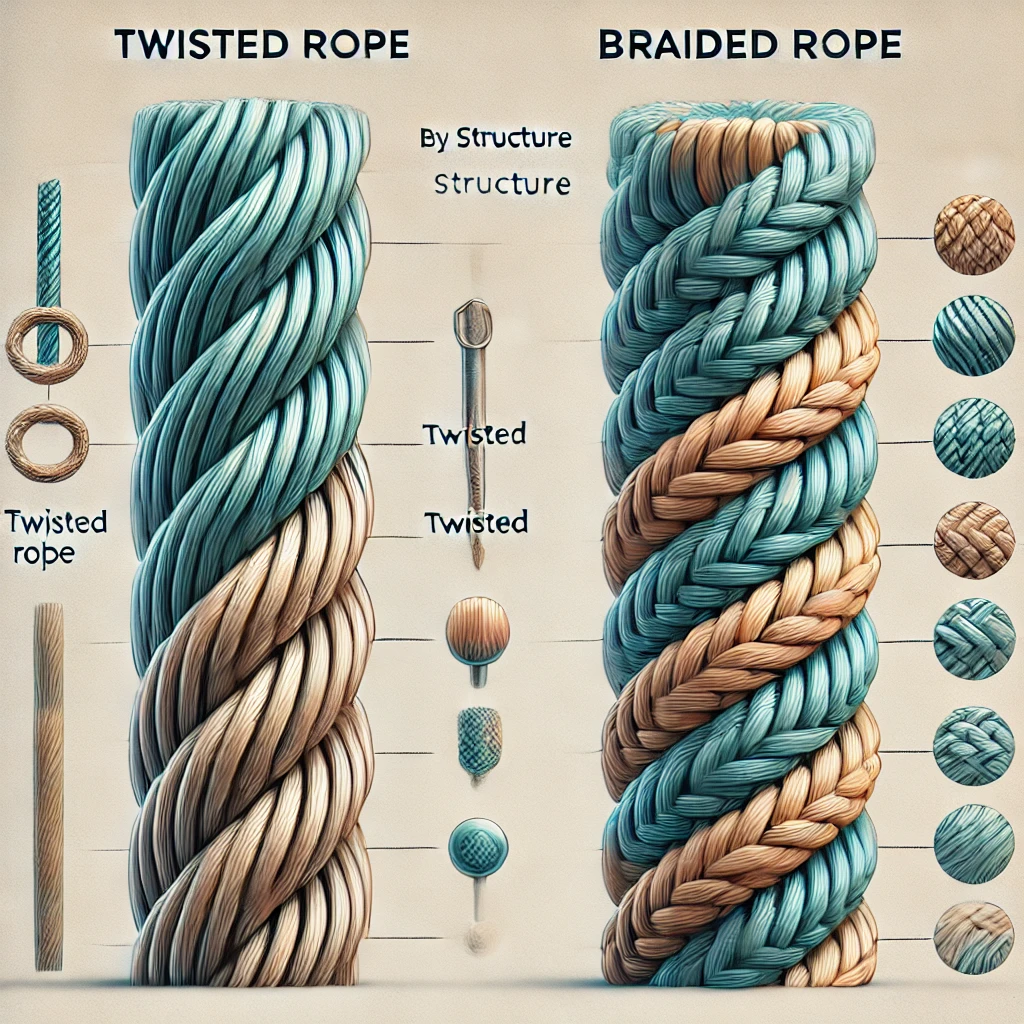

Types Of Synthetic Rope By Structure

Twisted Rope

Twisted rope is made by first spinning synthetic fibers into yarn. Then, a certain number of these yarns are twisted together to form a strand. Finally, multiple strands are twisted together to create a thicker rope. This results in a rope that has a spiral shape.

Twisted rope is not only cheaper and easier to splice than braided rope, but it also has greater elasticity. The most common type is made with three strands, and various synthetic fibers like nylon, polyester, polypropylene, Kevlar, and high-density polyethylene are widely used to make twisted rope.

Braided Rope

Braided ropes are created by intertwining strands of yarn to form a tubular braid. Typically, braided ropes have higher tensile strength, better flexibility, a smoother surface that reduces wear, and they are lighter and more durable.

The most common types include solid braid rope, diamond braid rope, hollow braid rope, double braid rope, kernmantle braid rope, plaited rope, and knit braid rope, among others.

Types Of Synthetic Rope By Application

Climbing Rope

Climbing ropes are specialized ropes used during climbing to absorb the impact of falls. They also provide effective safety measures for situations like rappelling and rescue descents, ensuring the safety of climbers and allowing climbing activities to proceed smoothly. Climbing ropes are typically categorized into dynamic ropes, static ropes, and waterproof ropes.

Tow Rope

A tow rope is specifically designed to pull or tow vehicles, boats, heavy equipments, or other objects. Common types of synthetic fiber tow ropes include nylon dynamic ropes, ultra-high molecular weight polyethylene tow ropes, Kevlar tow ropes, polypropylene (PP) tow ropes, and polyethylene (PE) tow ropes. When using a tow rope, it’s important not to exceed its load capacity to ensure safety

Cargo Rope

Cargo ropes are typically made from synthetic fibers like nylon, polypropylene, or polyester. They are designed to securely fasten goods during transportation and storage, preventing damage and potential safety hazards while ensuring the safety of personnel and minimizing cargo loss. Common types include braided cargo ropes, twisted cargo ropes, and elastic cargo ropes.

Lifting Rope

Lifting ropes (also called lifting sling) are typically made from high-performance synthetic fibers like UHMWPE, Kevlar, nylon, and polyester.

They are specifically designed for lifting and rigging tasks. Synthetic lifting ropes are lightweight, strong, and easy to handle, making them ideal for use in industries such as ports, logistics, transportation, marine applications, and rescue operations.

They also serve as a modern alternative to traditional steel wire lifting ropes, providing enhanced safety and efficiency for your lifting needs. By choosing synthetic lifting ropes, customers benefit from improved performance and reduced weight, ultimately making operations smoother and safer.

Fishing Rope

Fishing ropes, also known as trawl or net ropes, are specially designed synthetic fiber ropes for general and commercial fishing operations. Made primarily from nylon or high-density polyethylene, these ropes are lightweight, strong, and durable. They significantly enhance fishing efficiency and ensure the safety of personnel, focusing on meeting customer needs and delivering tangible benefits.

Agricultural Rope

Synthetic agriculture ropes are specifically designed for securing goods, bundling crops, towing, lifting, and storing agricultural products and livestock. Commonly used ropes include polypropylene, nylon, and UHMWPE ropes, which greatly enhance efficiency, safety, and cost-effectiveness in agricultural operations.

By using these ropes, you can improve productivity, ensure safer handling, and reduce operational costs.

Rescue Rope

Rescue ropes are synthetic fiber ropes specially designed for emergency rescue missions. Engineered to perform in extreme conditions like fire rescues, high-altitude operations, swift water rescues, and industrial rescues, these ropes are known for their high strength, lightweight, heat resistance, and visibility.

Typically made from Kevlar, nylon, or polyester, rescue ropes significantly enhance rescue efficiency and ensure the safety of personnel. These ropes offer reliable performance, ensuring your team can operate safely and effectively in the most challenging environments.

Sports Rope

Synthetic sports ropes are specifically designed for various activities and are made from materials like nylon, polyester, polypropylene, and UHMWPE. Common types include climbing ropes, jump ropes, water sports ropes, battle ropes, and winch ropes.

These ropes are lightweight, flexible, and safer alternatives to steel cables, making them ideal for meeting your needs in both performance and safety.

Types Of Synthetic Rope By Strength Class

Light Duty Rope

Light-duty synthetic ropes are made from materials like nylon, polyester, or polypropylene, designed for applications that don’t require high strength or durability. Typically ranging from 5 to 10 mm in diameter and with a strength of 200 to 3,000 pounds。

These ropes are perfect for lightweight tasks such as camping, gardening, DIY projects, transportation, and packaging. They offer flexibility and ease of use, making them a reliable choice for all your light-duty needs.

Medium Duty Rope

Medium-duty synthetic ropes strike a perfect balance between strength, durability, and versatility, filling the gap between lightweight and heavy-duty options. Made from materials like nylon, polyester, and polypropylene, they are perfect for applications such as anchoring small boats, lifting and towing cargo, and vehicle recovery.

With diameters ranging from 10mm to 20mm and strengths between 3,000 and 12,000 pounds, these ropes can be tailored to your specific needs. Choosing the right medium-duty rope ensures you get the reliability and performance essential for your tasks, enhancing safety and efficiency.

Heavy Duty Rope

Heavy-duty ropes are typically made from synthetic materials like UHMWPE, Kevlar, or nylon, offering exceptional strength, durability, and safety. They’re designed to withstand harsh environments and extreme forces, making them ideal for applications in marine, construction, mining, industrial, rescue, and military settings.

With diameters ranging from 20mm to over 200mm and strengths exceeding 12,000 pounds, these ropes deliver stable, long-lasting performance. Choosing heavy-duty rope ensures you have the reliability and safety needed for demanding tasks, helping you get the job done efficiently and securely.

Types Of Synthetic Rope By Color

Solid Color Rope

Solid color rope refers to synthetic fiber rope dyed in a single, uniform color without any variations. Its high visibility, durability, and safety make it ideal for a range of applications, including mooring boats, towing, outdoor sports, and industrial uses.

Common materials include nylon, polypropylene, polyester, and UHMWPE. This rope not only enhances safety but also ensures reliable performance in demanding environments.

Two-tone Rope

Two-tone rope is made from two colors of synthetic fibers woven or twisted together. This design enhances visibility, especially in low-light conditions.

Typically made from nylon, polyester, or polypropylene, it’s ideal for climbing, rescue operations, mooring, towing, and lifting. Its high visibility and strength make it a reliable choice for your safety and efficiency in various activities.

Multicolored Rope

Multicolored rope is a synthetic fiber rope dyed in three or more colors. Its vibrant colors allow for unique weaving and knotting, making it not only visually appealing but also highly visible. This rope is primarily used for decoration, entertainment, and safety signaling.

Common materials include nylon, polyester, and polypropylene, ensuring durability and strength for your various needs. Whether you’re enhancing your space or improving safety, multicolored rope offers both style and functionality.

FAQ

What type of rope is strongest?

The strongest rope is UHMWPE(also called dyneema or Spectra) rope, which is eight times stronger than traditional wire ropes of the same weight.

Made from Ultra-High Molecular Weight Polyethylene, it offers high strength, lightweight design, exceptional safety, and chemical resistance. This makes it ideal for maritime, military, vehicle rescue, climbing, and industrial applications, ensuring reliability and performance in demanding environments.

What type of rope does not stretch?

Most ropes stretch to some degree, but UHMWPE and Kevlar ropes have very limited stretch, around 2-3%. This makes them ideal for applications requiring precise control, such as lifting, cargo transport, towing, and marine docking.

Which type of rope consists of individual strands twisted together?

Made by twisting fibers into strands, then twisting those strands together to form the rope is twisted rope. It typically has a spiral pattern and is usually made with three strands.

What are the common types of rope materials and their uses?

The common rope materials in use are nylon, polyester, and polypropylene. They are cost-effective, perform well, and are versatile, making them ideal for a variety of applications like marine, Industrial, construction, arboricultureclimbing to meet your needs.

What are high-modulus materials?

High-modulus materials have a high elastic modulus, meaning they are extremely rigid and hard. Ropes made from these materials, like UHMWPE fiber (around 200 GPa) and Kevlar fiber (about 130 GPa), resist deformation under stress and offer excellent tensile strength and thermal stability.

They are perfect for demanding applications in marine, construction, military, and automotive sectors, providing customers with reliable performance and durability to meet their high standards.

Which type of synthetic rope floats on water?

There are several types of synthetic ropes, like polypropylene, polyethylene, and UHMWPE, float on water because their specific gravity is less than 1, making them lighter than water.

Polypropylene Rope Specific Gravity: 0.91 g/cm³ Polyethylene Rope Specific Gravity: 0.91 g/cm UHMWPE Rope Specific Gravity: 0.97 g/cm

What types of ropes used on ships?

Many types of synthetic fiber ropes can be used on boats, such as polyester, nylon, polypropylene, polyethylene, UHMWPE, and Kevlar (aramid) ropes. These can serve as mooring lines, tow ropes, rescue lines, winch lines, dock lines, and anchor lines.

Is braided rope stronger than twisted?

Yes, braided rope is stronger and more durable than twisted rope. Its construction interweaves multiple strands, allowing for even weight distribution. This means it can handle greater force and reduces the risk of wear and breakage.

In contrast, twisted rope can wear out and break more easily due to its bends and twists. Choose braided rope for enhanced strength and reliability in your applications!

What type of rope to tie a boat?

The most common ropes for tying up a boat are nylon and polyester rope. They are typically used for dock lines, mooring lines, and anchor lines.

What is best type of anchor rope?

For most standard anchoring needs, polyester rope is considered the best choice due to its low stretch, durability, and low cost. Its performance and affordability make it popular among customers.

Conclusion

With the information provided, you should have a solid understanding about the types of synthetic rope. We hope this helps you choose the right types of rope for your specific needs.

At Duracordix, as a provider of high-performance synthetic fiber rope solutions, we also offer customized and unique rope solutions to enhance your operational efficiency and safety, giving you peace of mind. Thank you!