Marin

Haute performance, robustesse et durabilité éprouvées pour les applications marines

Page d'accueil » Industries » marin

Qu'est-ce que la corde marine ?

Corde marine, Les cordages marins, souvent appelés cordages de bateau ou cordages de navire, sont spécialement conçus pour une utilisation en milieu marin. Les cordages marins Duracordix sont généralement fabriqués à partir de fibres synthétiques résistantes, tressées ou torsadées. On trouve couramment des cordages à trois torons, des cordages à simple tresse et des cordages à double tresse. Grâce à leur remarquable résistance, leur flottabilité, leur résistance à la corrosion et leur protection contre les UV, les cordages marins sont parfaitement adaptés aux environnements marins difficiles.

Solutions complètes pour la marine et les bateaux

Amarrage

Solution : Optez pour un cordage HMPE pour sa résistance et sa durabilité exceptionnelles, idéal pour sécuriser les grands navires. Associez-le à un cordage en polyester résistant aux UV pour une sécurité accrue et une résistance à l'abrasion accrue, notamment pour les quais fréquemment exposés au soleil.

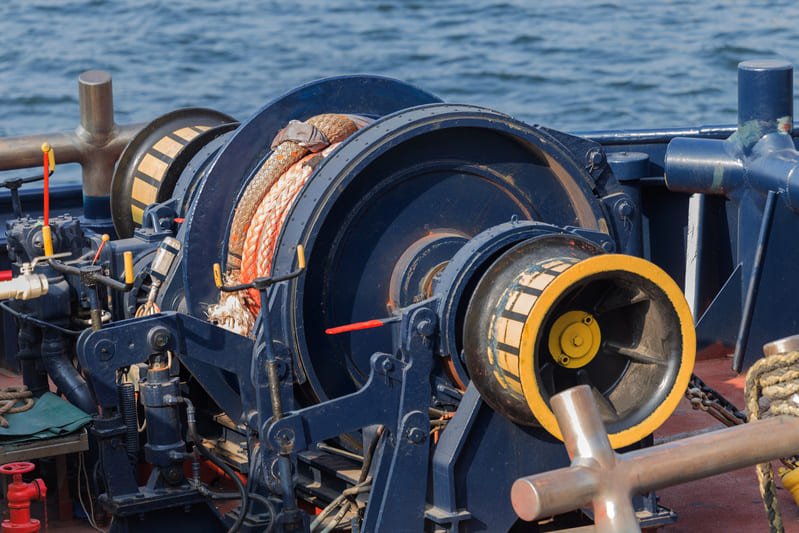

Remorquage

Solution : Pour le remorquage de charges lourdes, optez pour un câble HMPE : robuste et peu extensible, il est idéal pour les tâches exigeantes. Incorporez un câble en nylon élastique pour absorber efficacement les chocs et les vibrations lors de la navigation par mer agitée.

Levage et hissage

Solution : Pour le levage industriel lourd, pensez à utiliser un câble HMPE, car il offre une résistance et une efficacité exceptionnelles. Pour des opérations fréquentes, associez-le à un câble composé d'un mélange de polyester et de polypropylène, garantissant durabilité et facilité de manipulation.

Ancrage

Solution : Choisissez une corde HMPE pour sa résistance à la traction exceptionnelle afin de sécuriser des charges lourdes, et combinez-la avec une corde en polyester pour sa résistance à l'abrasion et une corde en nylon pour son élasticité, ce qui aidera à protéger contre les dommages pendant le transport.

Sécurisation et arrimage

Pour une solution fiable, optez pour un cordage en HMPE, pour sa résistance exceptionnelle, associé à un mélange de polyester et de polypropylène. Cette combinaison offre un choix léger et durable, idéal pour des manœuvres et un accostage en toute sécurité.

Sauvetage et sécurité

Pour une solution fiable, optez pour un cordage en HMPE, pour sa résistance exceptionnelle, associé à un mélange de polyester et de polypropylène. Cette combinaison offre un choix léger et durable, idéal pour des manœuvres et un accostage en toute sécurité.

Types de cordes marines par matériau

En tant que fabricant de cordages marins, Duracordix peut vous proposer différents types de cordages pour répondre à vos besoins maritimes.

La corde marine Duracordix UHMWPE est fabriquée en polyéthylène à ultra-haut poids moléculaire (UHMWPE) et bénéficie de notre revêtement DMX exclusif. Ce revêtement renforce la corde et améliore sa résistance à la corrosion, aux UV et à l'abrasion, la rendant idéale pour les environnements marins.

Corde haute performance, elle est devenue ces dernières années l'alternative idéale aux cordages en fibres et aux câbles en acier traditionnels. Elle peut être utilisée pour des applications telles que le remorquage, l'amarrage de navires, le mouillage et la navigation de plaisance.

La corde Duracordix en nylon de qualité marine est fabriquée à partir de fibres de nylon de haute qualité, reconnues pour leur élasticité exceptionnelle. Elle conserve sa forme initiale même après un étirement extrême, offrant ainsi une excellente absorption des chocs et une grande résistance aux impacts.

Grâce à son revêtement unique, Duracordix est parfaitement adapté à vos applications marines telles que l'amarrage, le mouillage, l'amarrage et la pêche, etc.

Le cordage Duracordix Kevlar de qualité marine est fabriqué à partir de fibres Kevlar haute performance importées, reconnues pour leur rapport résistance/poids exceptionnel et leur excellente résistance à la chaleur (jusqu'à 450 °C). Il offre également une grande résistance à la coupure, ce qui le rend idéal pour une utilisation dans des environnements extrêmes tels que les bouées d'amarrage, les pétroliers, les voiliers de course, le remorquage et les opérations de sauvetage.

La corde en polyester Duracordix de qualité marine est fabriquée à partir de fibres de polyester de haute qualité. Grâce à son excellente résistance à l'abrasion et à sa durabilité, elle conserve sa solidité même au contact de l'eau. Son prix abordable en fait un choix populaire pour les environnements marins. Cependant, en raison de sa densité élevée, elle ne flotte pas et coule. Elle peut être utilisée pour l'amarrage, le gréement de voiliers, le remorquage pour les sports nautiques, l'ancrage et la pêche.

Corde en polypropylène (PP)

La corde marine Duracordix PP est fabriquée à partir de fibres de polypropylène de haute qualité, conçues pour être légères et économiques. Sa flottabilité en fait un choix idéal pour les environnements marins où des cordes flottantes sont nécessaires. Vous pouvez l'utiliser comme ligne de sécurité, pour le remorquage de bateaux, comme ligne de défense, comme corde pour annexe ou pour la pêche.

La corde marine Duracordix PE est fabriquée à partir de fibres de polyéthylène (PE) de haute qualité. Bien que sa résistance soit inférieure à celle du nylon ou du polyester, elle est beaucoup plus légère et offre une excellente résistance à l'abrasion et aux UV, ce qui la rend idéale pour les environnements marins exposés. Elle peut être utilisée pour la pêche, la pose de filets, l'amarrage, les lignes de bouées et comme corde d'usage général.

Corde en polyéthylène (PE)

Produits les plus vendus

Comment choisir la bonne corde marine ?

1. En fonction de votre utilisation : vous devez connaître l'utilisation prévue de votre corde, que ce soit pour l'amarrage, le remorquage, le gréement de yacht, l'ancrage ou comme ligne de sécurité.

2. Choisissez par matériau : Les cordages marins sont disponibles dans des matériaux tels que l'UHMWPE, le nylon, le polyester, le Kevlar, le polypropylène et le polyéthylène. Pour une grande capacité d'allongement et une meilleure absorption des chocs, le nylon est le matériau idéal. Le polyester offre une excellente résistance à l'abrasion et à la corrosion. L'UHMWPE est un choix optimal pour une résistance élevée et une extrême légèreté. Les cordages en Kevlar sont la solution idéale pour une résistance aux hautes températures et aux coupures. Le polypropylène est un bon choix pour la flottabilité. Enfin, pour un usage général et économique, le polyéthylène est une option convenable.

3. Diamètre et résistance : Il est important de choisir un diamètre de câble adapté à la résistance requise pour votre tâche. Assurez-vous que le diamètre et la résistance à la traction du câble répondent à vos besoins opérationnels. En général, pour les tâches de remorquage, le câble doit avoir une résistance 1,5 à 2 fois supérieure à la charge maximale. En revanche, pour les tâches de levage, un facteur de sécurité de 5 à 7 fois la charge est nécessaire.

4. Longueur :Vous devez déterminer la longueur de votre corde en fonction du scénario d'application. Par exemple, les amarres mesurent généralement 1,5 à 2 fois la longueur du navire. Les exigences de longueur de corde varient selon l'application.

5. Coût : Bien que les cordes en PP et PE soient moins chères, leur résistance à la traction est également plus faible. Les cordes en UHMWPE et en Kevlar, bien que plus chères, offrent une résistance à la traction supérieure.

En tant que fournisseur professionnel de cordes marines, nous pouvons vous donner des suggestions plus spécifiques si nécessaire.

- témoignages

Voix du client

Certifications – Offre Duracordix

- Achat sans douleur

Pourquoi choisir

Corde marine Duracordix

- Durabilité : Les cordes marines Duracrodix, avec des fibres renforcées, offrent une longévité améliorée 50%, combattant la corrosion par l'eau salée et les dommages causés par le soleil.

- Rentable : Alliant qualité supérieure et prix abordable, Duracrodix promet des économies 20% par rapport à ses concurrents sans compromettre les performances maritimes.

- Légèreté : Malgré leur résistance, les cordes Duracrodix sont 30% plus légères, permettant des déploiements et des récupérations rapides dans les scénarios marins.

- Sécurité : Chaque corde Duracrodix est soumise à des tests complets, dépassant les normes de l'industrie maritime, garantissant des opérations en mer sûres 99%.

- Résistance : Bénéficiant d'une résistance à la traction supérieure de 20%, les cordages marins de qualité Duracrodix assurent la sécurité, notamment dans des conditions de mer turbulentes.

- Personnalisation : Que vous soyez une compagnie maritime, un exploitant de navire, une entreprise de pêche, une société d’exploitation portuaire, un club nautique ou une agence militaire, Duracordix peut personnaliser ses cordages marins pour répondre à vos besoins spécifiques : longueur, couleur, diamètre, revêtements spéciaux, protection contre l’abrasion ou épissures.

FAQ

Questions fréquemment posées répondant aux préoccupations et aux points faibles des clients

Les cordes synthétiques marines sont-elles intrinsèquement imperméables ?

Les cordages synthétiques Duracordix, notamment en nylon, polyester et UHMWPE, résistent naturellement à l'absorption d'eau. Cette propriété garantit leur légèreté même mouillés et leur résistance à la pourriture en milieu marin, un problème courant avec les fibres naturelles en milieu humide.

Quelle est la meilleure corde synthétique pour le remorquage marin ?

La corde synthétique Duracordix idéale pour le remorquage maritime est généralement une corde marine en nylon à double tresse. Elle offre une résistance à la traction et une élasticité exceptionnelles. En tant que corde marine à double tresse, elle offre également une résistance accrue à l'abrasion. Ses propriétés d'absorption des chocs la rendent parfaitement adaptée au milieu marin dynamique, notamment lors d'opérations de remorquage exigeantes.

Quelles cordes offrent la meilleure résistance à l’eau salée ?

Les cordages marins en UHMWPE et en nylon de Duracrodix sont conçus pour résister à la corrosion de l'eau salée. Vous bénéficiez ainsi d'une longue durée de vie et de performances constantes, même dans les environnements marins les plus exigeants.

Comment choisir la bonne corde pour les applications marines ?

Lors du choix d'une corde marine, tenez compte des facteurs suivants :

Il faut d'abord tenir compte de l'utilisation prévue de la corde. S'agit-il d'amarrage, de remorquage et de sauvetage, de gréement de voilier ou de sports nautiques ? Selon l'usage prévu, vous devrez choisir une corde aux propriétés appropriées.

Deuxièmement, vous devez déterminer la résistance requise du câble. Assurez-vous que sa résistance soit supérieure au poids de l'objet remorqué. Par mesure de sécurité, il est recommandé de prévoir une marge de sécurité de 50 à 100 tonnes.

Pour les applications nécessitant de l'élasticité, le Corde en nylon Duracordix de qualité marine Ce matériau est idéal car il offre un allongement de 20 à 251 TP3T. Cette élasticité assure un rebond lors de l'étirement, absorbant efficacement les chocs, ce qui le rend parfait pour les opérations de remorquage et de sauvetage.

Le Corde en polyester Duracordix de qualité marine Grâce à sa résistance naturelle aux UV, il constitue un excellent choix pour une exposition prolongée à un fort ensoleillement, ce qui le rend adapté aux applications exposées au soleil.

Dans des environnements tels que les opérations pétrolières et gazières en eaux profondes, Corde Duracordix UHMWPE de qualité marine Ce cordage se distingue par son exceptionnelle résistance à l'abrasion et aux produits chimiques. Il conserve une grande résistance dans le temps, même dans des conditions extrêmes.

Quelle doit être la longueur d’un câble de remorquage marin pour une performance optimale ?

Les câbles de remorquage pour bateaux mesurent généralement entre 23 et 30 mètres. La longueur idéale dépend de la taille du bateau, des conditions de remorquage et de la capacité d'étirement du câble, qui peut réduire les contraintes sur le bateau et le mécanisme de remorquage.

Est-il plus avantageux d’utiliser une longue corde pour tirer un bateau ?

Une corde plus longue offre davantage de flexibilité et d'élasticité lors des opérations de remorquage. Cela permet un remorquage plus fluide, réduisant les à-coups et les contraintes potentielles sur le bateau et la structure de remorquage.

Quel type de corde ne se dégrade pas dans l’eau ?

Les cordages marins Duracordix en polyéthylène UHMWPE et en polyester de qualité marine sont conçus pour résister à l'absorption d'eau et à la pourriture. Ils conservent leur résistance et leur intégrité même après une exposition prolongée à l'humidité marine.

Quel type de corde est généralement utilisé sur les remorqueurs ?

Les remorqueurs utilisent fréquemment les cordages HMPE de Duracordix en raison de leur haute résistance et de leur faible allongement. Ces propriétés garantissent d'excellentes performances lors des opérations de remorquage et d'accostage difficiles. Ce cordage de remorquage marin est léger, ce qui le rend facile à manipuler et à utiliser.

Quels types de nœuds de corde marine sont les plus utilisés ?

Les nœuds de corde marine que vous utiliserez le plus souvent incluent le Nœud de chaise, nœud de taquet et nœud de cabestanCes nœuds sont essentiels pour des tâches telles que l'amarrage, l'ancrage, l'arrimage des charges et le gréement des voiles. Ils garantissent une fixation solide et fiable de vos cordages sous tension, vous offrant ainsi une fixation fiable et sûre dans des conditions marines difficiles.

Connaissez-vous les applications des cordes marines ?

Les cordes marines sont essentielles pour vos différentes tâches telles que l'amarrage, l'ancrage, le remorquage, le gréement, la sécurisation des charges et la mise en place de lignes de sécurité, de défenses et plus encore.

Quels types de cordages marins flottent ?

Les cordages en polypropylène (PP), en polyéthylène (PE) et en HMPE de Duracordix ont une densité inférieure à celle de l'eau, ce qui leur permet de flotter à la surface. Ils peuvent donc être utilisés pour diverses applications telles que le sauvetage et la sécurité en mer, les sports nautiques, le balisage de filets de pêche, ainsi que pour l'assistance au chenal et le guidage des bateaux.

Comment dois-je nettoyer mes cordes marines synthétiques ?

Nettoyez les cordages marins synthétiques avec un mélange de détergent doux et d'eau tiède. Frottez délicatement pour éliminer le sel et les débris, en veillant à ne pas endommager les fibres. Après le nettoyage, rincez abondamment et laissez sécher à plat, de préférence à l'ombre pour éviter les dommages causés par les UV.

Quels sont les inconvénients de l’utilisation de cordes en polypropylène dans les environnements marins ?

Bien que le polypropylène soit flottant et rentable, il peut se dégrader en cas d'exposition prolongée aux rayons UV, présente une résistance à l'abrasion inférieure à celle d'autres matières synthétiques et peut s'affaiblir avec l'âge, en particulier sous de lourdes charges.

Comment la température affecte-t-elle les cordes marines synthétiques ?

Les cordages marins synthétiques résistent généralement à des températures variables. Cependant, à des températures extrêmement basses, ils peuvent devenir plus rigides, réduisant légèrement leur flexibilité. À l'inverse, une exposition prolongée à des températures très élevées peut potentiellement dégrader le matériau, affectant ainsi sa résistance et sa longévité.

Entre le nylon et le polypropylène, quelle corde offre la plus grande résistance ?

Le nylon surpasse généralement le polypropylène en termes de résistance à la traction et à l'abrasion. Sa capacité à s'étirer sous charge le rend également adapté aux applications marines dynamiques.

Comment le polyester se compare-t-il au polypropylène en termes de résistance ?

Le polyester a généralement une résistance à la traction supérieure à celle du polypropylène. De plus, il offre une meilleure résistance aux UV et une meilleure durabilité, ce qui le rend plus adapté à une utilisation marine prolongée.

Pourquoi les cordes synthétiques sont-elles préférées aux cordes naturelles pour une utilisation marine ?

Les cordes synthétiques offrent des avantages tels qu'une résistance accrue, une durabilité accrue, une résistance aux UV et une résistance à la pourriture. En revanche, les fibres naturelles peuvent se dégrader rapidement en milieu marin en raison de l'humidité et de l'exposition à l'eau salée.

Comment stocker les cordes marines synthétiques pour une meilleure longévité ?

Pour prolonger la durée de vie de votre corde, stockez-la dans un endroit frais et sec, idéalement dans un sac ou un contenant. Il est essentiel de la protéger des rayons UV directs. Enrouler la corde librement ou la suspendre évite la formation de nœuds, garantissant ainsi son bon fonctionnement et sa sécurité.

Quelle est la signification du code couleur dans les cordes marines ?

Le codage couleur des cordages marins simplifie leur identification. Il permet aux utilisateurs de déterminer rapidement le type, la taille ou la fonction des cordages sans prendre de mesures manuelles, améliorant ainsi l'efficacité des opérations maritimes tout en renforçant la sécurité grâce à la réduction des risques de confusion.