corde d'amarrage marine

Cordes d'amarrage solides et fiables conçues pour assurer la sécurité de votre navire

Marin corde d'amarrage

L'amarrage consiste à sécuriser un bateau ou un navire pour l'empêcher de dériver. On l'attache à un quai, une jetée ou une bouée à l'aide de cordes ou de chaînes, afin qu'il reste stable malgré le vent, les courants ou les marées.

Notre corde d'amarrage, fabriquée à partir de fibres synthétiques de haute qualité, est conçue pour offrir résistance et durabilité pour un amarrage fiable des navires.

- Haute résistance : Maintien sûr et fiable.

- Résistant aux UV : Résiste aux conditions marines difficiles.

- Léger: Manipulation et nouage faciles.

- Absorption des chocs : Réduit l'impact des vagues

Général Applications

Exploration des cordes d'amarrage dans diverses applications maritimes

industrie du transport maritime

Les cordes d'amarrage pour navires simplifient la manipulation et sécurisent l'amarrage de vos navires dans des conditions de navigation exigeantes.

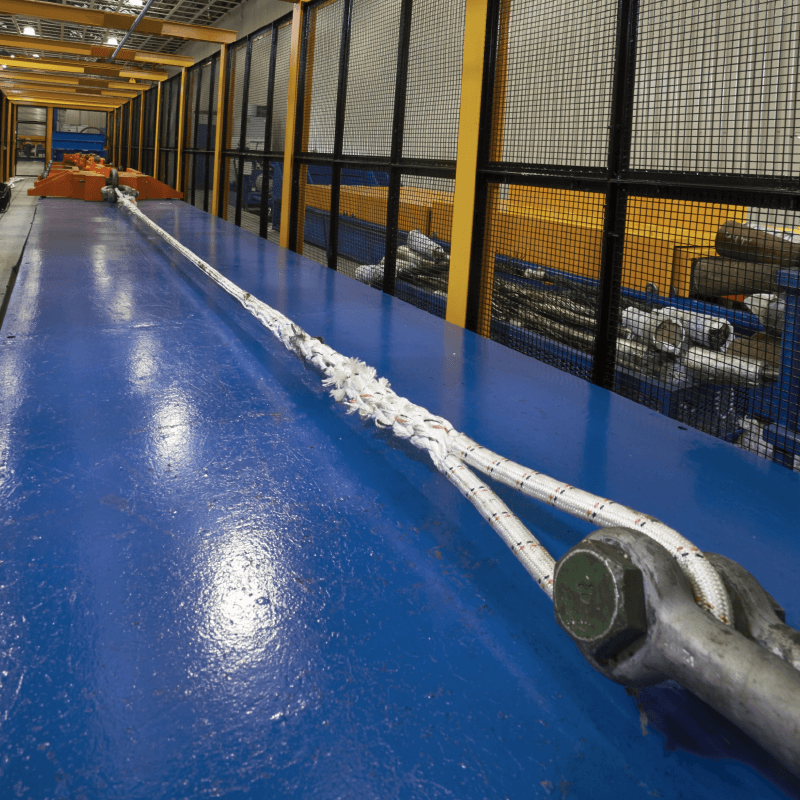

Forage en mer

Léger et facile à déployer, il simplifie les opérations et ancre en toute sécurité votre équipement offshore

environnement marin

Solide et léger, conçu pour résister aux conditions difficiles et amarrer vos navires en toute sécurité dans les environnements marins

navigation de plaisance

La corde d'amarrage pour bateau est conçue pour les systèmes d'amarrage de bateau, une manipulation facile et un amarrage sécurisé dans votre navigation de plaisance et de yachting.

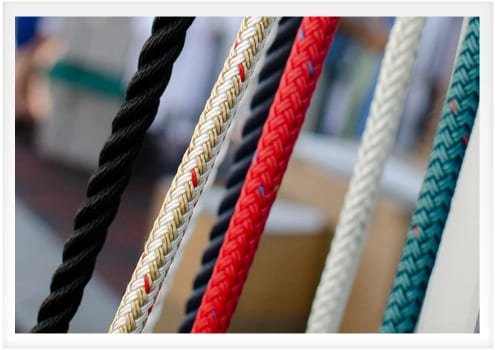

Cordes d'amarrage par matériau

En tant que fabricant de cordes d'amarrage, nous vous proposons différents types de cordes d'amarrage parmi lesquels choisir.

Corde d'amarrage UHMWPE

Description: Fabriqué à partir de polyéthylène à poids moléculaire ultra élevé (UHMWPE), offrant une alternative plus sûre et plus performante aux cordes synthétiques traditionnelles pour l'amarrage et l'accostage marins.

Caractéristiques principales : Dotée d'un rapport résistance/poids remarquable, d'un allongement minimal et d'une excellente flottabilité, cette corde flotte sur l'eau et résiste aux rayons UV, aux produits chimiques et à l'abrasion. Elle est conçue pour affronter avec fiabilité les conditions marines les plus exigeantes.

Applications : Idéal pour l'amarrage, le remorquage, les lignes d'ancrage et la navigation et pour les navires nécessitant des solutions d'amarrage durables, légères et fiables.

Corde d'amarrage en nylon

Description: Fabriqué en nylon de haute qualité, également appelé corde d'amarrage élastique, conçu pour gérer le stress des environnements marins tout en offrant un amarrage fiable et sûr.

Caractéristiques principales : Sa grande élasticité absorbe les chocs, ce qui le rend idéal par mer agitée. Résistant à l'abrasion et protégé contre les UV, il offre une durabilité accrue.

Applications : Parfait pour l'amarrage, l'accostage et les lignes d'ancrage, offrant flexibilité et forte absorption des chocs pour maintenir les navires en toute sécurité.

corde d'amarrage en polyester

Description: Solide et durable, notre corde d'amarrage en polyester est conçue pour résister aux conditions marines difficiles avec un étirement minimal. Corde à 3 brins, 8 brins, 12 brins ou double tresse disponible.

Caractéristiques principales : Une excellente résistance aux UV et à l'abrasion garantit des performances durables, tandis qu'une faible élasticité offre un contrôle et une stabilité fiables.

Applications : Idéal pour l'amarrage, l'accostage et les lignes d'ancrage où la durabilité et la stabilité sont essentielles pour assurer la sécurité des navires.

Corde d'amarrage en polypropylène

Description: Légère et économique, notre corde d'amarrage en polypropylène (également appelée corde d'amarrage flottante) est parfaite pour une utilisation marine où la flottabilité est essentielle.

Caractéristiques principales : Cette corde flotte, résiste à la moisissure et à la pourriture et est facile à manipuler, ce qui la rend idéale pour une utilisation fréquente.

Applications : Idéal pour l'amarrage, le remorquage léger et les bouées de marquage, où une corde flottante et facile à gérer est nécessaire.

Corde d'amarrage en polyéthylène

Description: Durable et économique, notre corde d'amarrage en polyéthylène est conçue pour des performances fiables dans des environnements marins difficiles.

Caractéristiques principales : Sa haute résistance à l'abrasion et aux rayons UV assure sa longévité, tandis que sa faible absorption d'eau le maintient léger et maniable.

Applications : Idéal pour l'amarrage, la pêche et d'autres utilisations marines où la durabilité et la facilité de manipulation sont essentielles.

- Service OEM

Personnalisation

Pour répondre à vos projets uniques et spéciaux

- caractéristiques principales

Avantages

Découvrez les avantages de la corde d'amarrage Duracordix !

Résistance supérieure

La corde d'amarrage marine de Duracordix offre une résistance à la traction inégalée, garantissant des opérations d'amarrage fiables et sûres dans les environnements marins les plus exigeants.

Résistance au frottement

Bénéficiant des propriétés de la corde en fibre, la corde présente une usure réduite par frottement, prolongeant sa durée de vie et garantissant une expérience d'amarrage plus sûre et plus fiable.

Léger

Malgré leur résistance, les lignes d'amarrage de Duracordix sont incroyablement légères, simplifiant la manipulation, le stockage et les opérations, en particulier pendant les processus d'amarrage critiques.

Résilience aux intempéries

Conçue pour durer, cette corde résiste aux rayons UV, à l'eau salée et aux conditions météorologiques extrêmes, garantissant une longévité et des performances constantes tout au long de sa vie.

- Clients satisfaits

Voix du client

Les utilisateurs partagent leurs expériences et leurs réussites en matière de cordes d'amarrage marines

- Achat sans douleur

Pourquoi choisir

Corde d'amarrage Duracordix

- Conçu pour la fiabilité : De nombreux amarres se détériorent dans des conditions marines difficiles. Le câble d'amarrage en HMPE de Duracordix offre une résistance inégalée, réduisant les risques de rupture et assurant la sécurité de votre navire au moment le plus critique.

- Conçu pour durer : les cordages classiques se détériorent dans des conditions difficiles. Le cordage d'amarrage Duracordix résiste aux UV et aux éléments marins, offrant une durabilité sur laquelle vous pouvez compter.

- La qualité rencontre l'abordabilité : avec la corde d'amarrage UHMWPE de Duracordix, vous obtenez une qualité de premier ordre sans vous ruiner, offrant une réelle valeur et une fiabilité.

- Une sécurité à laquelle vous pouvez faire confiance : la ligne d'amarrage de Duracordix résiste aux claquements soudains, garantissant une sécurité fiable et une tranquillité d'esprit dans des conditions marines difficiles.

- Faible entretien, plus de liberté : la corde d'amarrage de Duracordix nécessite un entretien minimal, vous permettant de vous concentrer sur ce qui compte le plus : votre temps sur l'eau, pas l'entretien de la corde.

FAQ

Exploration des détails et de l'utilisation des cordes d'amarrage

Qu'est-ce que l'amarrage ?

L'amarrage consiste à fixer un bateau ou un navire à un point fixe, comme un quai, une jetée ou une bouée, afin qu'il reste en place. Ce système utilise généralement des cordes, des chaînes ou des câbles pour maintenir le navire stable, même en cas de marées changeantes et de vents forts, et éviter ainsi toute dérive ou tout déplacement inattendu.

Connaissez-vous les types d'amarrage ?

Oui, il existe plusieurs types d'amarrage, chacun adapté à différentes situations et types de navires :

Amarrage à point unique (SPM) : Ancre un navire à un point, généralement une bouée, lui permettant de pivoter avec le vent et les marées. Souvent utilisé pour les grands pétroliers.

Amarrage multipoints : Utilise plusieurs amarres reliées à divers points fixes, comme des bouées ou le fond marin, pour une meilleure sécurité et stabilité du navire. Idéal pour le forage offshore ou les navires lourds.

Amarrage conventionnel (à quai) : Amarre le navire directement à un quai à l'aide de lignes reliant la proue, la poupe et les flancs. Ce système est courant dans les marinas et les ports pour les petits bateaux et navires.

Mouillage en Méditerranée : La poupe du navire est orientée vers le quai tandis que la proue est ancrée, ce qui permet à davantage de bateaux de s'y asseoir. Ce type de dispositif est souvent utilisé dans les marinas très fréquentées.

Positionnement dynamique (DP) : Utilise un système informatisé et des propulseurs pour maintenir un navire immobile sans amarres. Ce système est couramment utilisé sur les navires offshore nécessitant un positionnement précis.

Quelle est la meilleure corde pour l'amarrage ?

Le meilleur matériau pour les cordes d'amarrage dépend de l'application et des exigences spécifiques. L'UHMWPE est généralement considéré comme le meilleur pour sa légèreté, sa résistance élevée et sa durabilité.

Comment choisir la bonne taille de corde d'amarrage ?

Le diamètre et la longueur d'une amarre dépendent de la taille, du poids et de la charge de votre navire. Assurez-vous que votre treuil d'amarrage peut supporter la taille de corde choisie. En règle générale, la longueur de la corde doit être au moins égale à 1,5 fois celle du navire pour garantir un amarrage sûr et une flexibilité suffisante face aux conditions de changement de direction.

Quelle est la différence entre les amarres torsadées et tressées ?

Les amarres torsadées sont fabriquées en torsadant plusieurs torons, tandis que les amarres tressées sont obtenues par tressage de torons. Les amarres tressées sont généralement plus solides et plus durables, ce qui en fait un excellent choix pour les amarrages lourds.

Avez-vous besoin d'un manchon de protection pour corde d'amarrage ?

Oui, une gaine de protection est un ajout judicieux pour prolonger la durée de vie de votre amarre. Elle protège la corde de l'abrasion, des UV et de l'usure causée par le frottement constant contre les quais ou les taquets. Cette couche supplémentaire peut faire toute la différence, surtout dans des conditions difficiles, en garantissant la solidité et la fiabilité de votre corde au fil du temps.

Qu'est-ce qu'une corde d'amarrage lourde ?

Les amarres lourdes sont conçues pour sécuriser les grands navires dans des conditions difficiles. Fabriquées à partir de matériaux ultra-résistants (comme l'UHMWPE ou le Dyneema), elles offrent une solidité fiable, résistent à l'abrasion et aux UV, et maintiennent votre navire stable par vents et courants forts ; elles sont idéales pour les applications marines exigeantes.

Comment épisser une corde d'amarrage ?

Épisser un amarrage est une compétence pratique pour créer des boucles solides ou joindre deux cordages. Voici un guide simple :

Déroulez les mèches : Commencez par détordre ou détresser soigneusement l’extrémité de la corde, en la séparant en trois brins ou plus.

Former une boucle : Pliez la corde pour créer la taille de boucle souhaitée, en laissant une queue avec les brins lâches.

Tisser les brins : Prenez chaque brin et passez-le dans la corde principale, en passant par-dessus et en dessous des brins du corps de la corde. Répétez cette opération plusieurs fois pour sécuriser l'épissure.

Serrer l'épissure : Tirez fermement sur chaque brin pour vous assurer que l'épissure est bien fixée, puis coupez l'excédent pour une finition nette.

Avec la pratique, l'épissure devient plus facile et c'est un excellent moyen de garder votre installation d'amarrage solide et fiable.

Quelle est la différence entre une ligne d’amarrage et une corde d’amarrage ?

Une ligne d'amarrage est une corde utilisée pour attacher un navire à un quai, tandis qu'une corde d'amarrage est utilisée pour fixer un navire à une ancre ou à une bouée.

Comment faire un nœud d'amarrage approprié ?

Pour sécuriser votre navire en toute sécurité, utilisez le Taquet d'attelage noeud:

- Enroulez la corde autour de la base du taquet.

- Faites un huit en croisant la corde sur le taquet.

- Terminez par une demi-boucle sous le dernier tour.

Ce nœud est solide, facile à défaire et maintient votre bateau en sécurité même dans des conditions difficiles.

Quelle est la différence entre une corde d'amarrage à tresse simple et à tresse double ?

Les amarres à tresse simple sont constituées d'une seule corde tressée, tandis que les amarres à double tresse sont constituées de deux cordes tressées : une âme intérieure et une gaine extérieure. Les amarres à double tresse sont généralement plus solides et plus durables que les amarres à tresse simple.

Comment inspecter une corde d’amarrage pour détecter l’usure et les dommages ?

Pour inspecter une corde d'amarrage et détecter tout signe d'usure ou de dommage, recherchez des signes d'effilochage, de coupure, de décoloration ou de raideur. Passez vos mains le long de la corde pour détecter toute anomalie ou aspérité. Remplacez immédiatement toute section endommagée ou usée.

Quelle est la différence entre les cordes d’amarrage en UHMWPE et en polyester ?

Les cordes d'amarrage en UHMWPE sont plus légères et plus résistantes que les cordes en polyester, mais plus chères. Elles sont plus extensibles et offrent une meilleure résistance à l'abrasion que les cordes en UHMWPE.

Pourquoi les cordes d'amarrage ont-elles une conception tressée ?

Force accrue : Le tressage améliore la résistance à la traction, aidant les cordes à résister à de lourdes forces d'amarrage.

Durabilité: Les tresses compactes résistent à l'usure et durent plus longtemps dans les environnements marins difficiles.

Flexibilité: Les cordes tressées se manipulent en douceur, réduisant ainsi les points de tension.

Étirement minimal : La faible extensibilité assure la stabilité et réduit les risques de rupture sous tension.

Manipulation facile : La surface lisse empêche la torsion et réduit la fatigue de la main.

Protection noyau-gaine : Le noyau interne ajoute de la résistance ; la gaine extérieure protège contre l'abrasion et les éléments.

Les lignes d'amarrage tressées offrent des performances fiables et durables, conçues pour maintenir votre navire en sécurité avec un minimum de tracas.

Comment nettoyer une corde d'amarrage ?

Pour nettoyer une corde d'amarrage, rincez-la à l'eau claire et au savon doux, puis suspendez-la pour la faire sécher dans un endroit frais et sec, à l'abri de la lumière directe du soleil et de l'humidité. Évitez d'utiliser des produits chimiques agressifs ou des nettoyants abrasifs qui pourraient endommager les fibres.

Quelle est la meilleure corde d'amarrage pour vous ?

La meilleure corde d’amarrage dépend du type de votre navire, des conditions d’amarrage et des besoins spécifiques.

Pour une durabilité robuste et durable, cordes en nylon sont excellents en raison de leur grande résistance et de leur absorption des chocs.

Cordes en polyester offrent une faible élasticité et une résistance aux UV, idéales pour une stabilité constante.

Cordes en polypropylène sont légers et flottent, ce qui les rend pratiques pour les amarrages temporaires.

Cordes UHMWPE sont ultra-résistants et résistants à l'abrasion, parfaits pour les environnements difficiles où la fiabilité est essentielle.

À quelle fréquence faut-il remplacer une corde d’amarrage ?

La fréquence de remplacement des amarres dépend du matériau, du diamètre, de la construction et de l'utilisation. Consultez un expert en amarrage ou reportez-vous aux directives de l'industrie pour connaître les intervalles de remplacement appropriés.

Quelle est la différence entre une corde d'amarrage à 3 torons et à 8 torons ?

Une corde d'amarrage à 3 torons est composée de trois torons torsadés ensemble, tandis qu'une corde d'amarrage à 8 torons est composée de huit torons tressés ensemble. Les cordes à 8 torons sont généralement plus solides et plus durables que les cordes à 3 torons.

Comment protéger une corde d’amarrage des dommages causés par les UV ?

Pour protéger une corde d'amarrage des dommages causés par les UV, stockez-la dans un endroit frais et sec, à l'abri de la lumière directe du soleil ou de l'humidité, ou recouvrez-la d'un manchon ou d'une housse résistant aux UV.

Quelle est la meilleure corde d'amarrage pour l'amarrage d'un yacht ?

Pour les yachts, cordes d'amarrage en nylon Ils sont idéaux. Ils offrent une résistance élevée, une grande flexibilité et une excellente absorption des chocs, parfaits pour protéger votre yacht des fluctuations de marée et des conditions difficiles. La durabilité et la résistance aux UV du nylon garantissent des performances durables, assurant la sécurité de votre yacht avec une usure minimale.

Comment éviter les accidents de corde d’amarrage ?

Inspectez régulièrement : Vérifiez que les cordes ne sont pas usées, effilochées ou endommagées avant chaque utilisation. Une corde affaiblie peut se rompre sous la charge, entraînant de graves accidents.

Choisissez la bonne corde : Utilisez une corde suffisamment solide pour la taille et le poids de votre bateau, avec une longueur et un diamètre suffisants pour supporter la charge.

Restez à l'écart des cordes chargées : Lorsque la corde est sous tension, tenez-vous à l'écart. Si elle casse, elle peut reculer dangereusement.

Utiliser des manchons de protection : Un manchon de protection contre l'abrasion peut protéger la corde de l'abrasion, prolongeant ainsi sa durée de vie et réduisant les dommages à la corde d'amarrage et le risque de ruptures soudaines.

Surveiller la tension et la météo : Gardez un œil sur les marées changeantes, les vents forts ou les conditions changeantes qui peuvent ajouter de la pression à votre configuration d'amarrage.

En suivant ces étapes, vous pouvez réduire les risques et assurer la sécurité des opérations d’amarrage pour toutes les personnes impliquées.

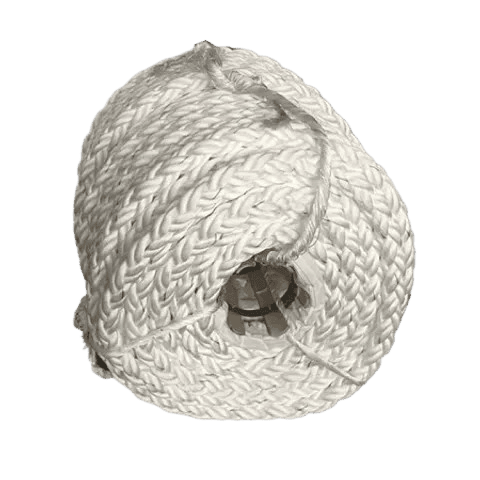

Quelle est la longueur normale de votre enrouleur de corde d'amarrage ?

Nos enrouleurs de corde d'amarrage sont généralement disponibles en longueurs de 100 à 200 mètres, offrant une longueur de corde suffisante pour répondre à divers besoins d'amarrage. Cette longueur vous permet de couper des longueurs sur mesure, vous permettant ainsi d'obtenir la longueur idéale pour votre navire.

- nous faisons plus

En rapport produits

En savoir plus : Produits complémentaires pour applications marines