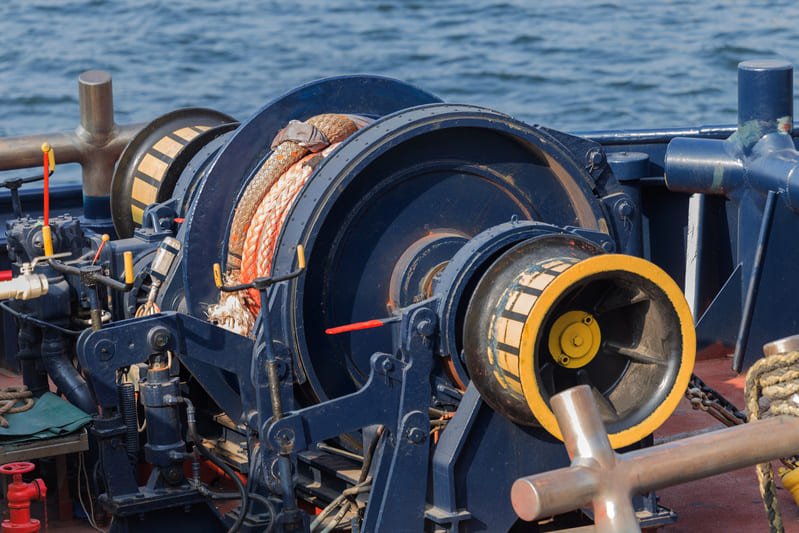

synthetic winch rope

Built for Tough Jobs: Strength, Durability, and Reliability When You Need It Most

Our synthetic winch rope made of UHMWPE fiber, the toughest material for winching. As an alternative to steel wire rope, engineered with cutting-edge technology and premium materials, our UHMWPE winch rope delivers unrivaled strength, durability, and safety.

- Lightweight: 80% lighter than steel cable.

- Low-stretch: Stretches less than 3%.

- Corrosion-resistant: Resistant to rust and corrosion

- Safer: Will not snap or recoil

General Applications

Duracordix synthetic winch lines offer versatility, making them perfect for all your lifting and towing tasks

Heavy Machinery Hauling

Built for heavy loads, our winch ropes support safe lifting and hauling, minimizing equipment wear and tear.

Port Operations

Ideal for port towing & mooring, lightweight, corrosion-resistant, handle heavy loads, ensuring efficiency.

Marine Towing & Rescue

our winch lines ensure safe, quick marine towing and rescue with strong, water-resistant durability for all conditions.

- popular sizes

Hot Selling sizes

Discover Our Synthetic Winch Rope For Reliable Recovery and Towing

3/8" (10mm)

Ideal for heavy-duty off-roading, towing, marine,construction etc; increased strength for demanding situations. increased strength for demanding situations.

5/8" (16mm)

Designed for heavy-duty commercial vessels, large yachts, and marine infrastructure projects, this size delivers maximum performance for the most demanding tasks.

1-1/2" (38mm)

Designed for the bigger ships and commercial vessels, this size offers unparalleled strength for anchoring, mooring, and towing in harsh marine environments.

Duracordix is a synhtetic winch rope manufacturer & Supplier in China.

we can produce various sizes for different applications and custom made for special projects.

No matter you’re looking for a wholesale supplier or custom made winch ropes, we can all help. contact us to get your solution now.

- strength chart

Specification

Find the Perfect Winch Rope Sizes for Your Unique Requirements!

| DIAMETER | DIAMETER | WEIGHT | KETX | KETX | BREAKING STRENGTH | BREAKING STRENGTH |

|---|---|---|---|---|---|---|

| mm | inch | 100m(kg) | standard | error | ton | kn |

| 5 | 3/16 | 1.7 | 16.62 | 5% | 2 | 19 |

| 6 | 1/4 | 2.3 | 23 | 5% | 3.18 | 31 |

| 8 | 5/16 | 4.1 | 40 | 5% | 6.35 | 63 |

| 9 | 23/64 | 5.1 | 50.5 | 5% | 7.83 | 78 |

| 9.5 | 3/8 | 5.6 | 55.75 | 5% | 8.32 | 83 |

| 10 | 13/32 | 6.1 | 61 | 5% | 9.32 | 93 |

| 11 | 7/16 | 7.5 | 74 | 5% | 10.4 | 103 |

| 12 | 1/2 | 8.8 | 87 | 5% | 12.12 | 121 |

| 14 | 9/16 | 12 | 119 | 5% | 15.4 | 153 |

| 16 | 5/8 | 15.5 | 151 | 5% | 20.6 | 205 |

| 18 | 3/4 | 19 | 190 | 5% | 23.9 | 238 |

| 20 | 13/16 | 23 | 225 | 5% | 28.99 | 289 |

| 22 | 7/8 | 28 | 276 | 5% | 33 | 322 |

| 24 | 1 | 37 | 368 | 5% | 38 | 371 |

| 28 | 1-1/8 | 50 | 490 | 5% | 57.5 | 562 |

| 32 | 1-5/16 | 62.5 | 621 | 5% | 68.5 | 671 |

| 36 | 1-1/2 | 77 | 767 | 5% | 80.4 | 789 |

| 40 | 1-5/8 | 87 | 868 | 5% | 98.2 | 964 |

| 44 | 1-3/4 | 96 | 955 | 5% | 118 | 1158 |

| 48 | 2 | 114 | 1137 | 5% | 139 | 1364 |

| 56 | 2-1/4 | 159 | 1547 | 5% | 184 | 1805 |

| 60 | 2-1/2 | 180 | 1784 | 5% | 199 | 1952 |

| 64 | 2-5/8 | 209 | 2021 | 5% | 222 | 2178 |

Note: other sizes are available upon request.

- main benefits

OUR ADVANTAGES

Durability, Safety, and Performance You Can Rely On, No Matter the Conditions

safter

No risk of dangerous snapback like steel cables. Keeps you safe during recovery tasks

Lighter

Easier to handle and spool, even with one person. It reduces fatigue on long operations.

stronger

High tensile strength, capable of handling heavy-duty recoveries, ensuring you’re ready for any challenge.

Durable

UV, water, and abrasion-resistant, built to last in tough environments, even after extended use

Flexible

Stays flexible in all weather conditions, making it easy to use in both hot summers and cold winters

Low Maintenance

Unlike steel ropes, no need to worry about rust or corrosion, keeping your rope in top condition longer

- Happy Clients

What They Said

Real Stories, Real Strength: Customer Testimonials on Our Synthetic Winch Rope

Duracordix's synthetic winch ropes have exceeded our expectations in our marine operations. They resist abrasion and UV damage, making them perfect for our mooring and towing needs.

Sarah JohnsonI've tried Duracordix synthetic winch ropes on my ATV for a while, and they're just amazing! They're so lightweight and strong, making my off-roading adventures way safer and way more fun!

David LeeOur emergency team started using Duracordix winch ropes and saw huge improvements in vehicle extractions and rescues. They're strong, reliable, and easy to handle – a real game-changer for us!

Eric Mitchell- Pain-Free Purchase

WHY CHOOSE

- Unmatched Quality:Duracordix offers the highest quality fiber ropes, undergoing strict testing, ensuring 99% customer satisfaction.

- Extensive Product Range:Duracordix provides a diverse range of fiber ropes, including UHMWPE, Kevlar, and nylon, with over 60 product variations to fulfill specific needs.

- Customization Capabilities: Duracordix offers customization, including diameter and length variations on 80% of products, catering to unique customer requirements for the perfect fit.

- Exceptional Customer Service: Duracordix emphasizes exceptional service, with a sales team responding in under 2 hours and resolving 95% of inquiries within one business day.

- Cost-effective: Duracordix offers superior quality ropes at competitive prices, up to 20% lower than competitors, ensuring savings without sacrificing performance, reliability, or safety.

FAQs

Answers to Your Questions About Duracordix’s Durable and Versatile Winch Rope.

Is synthetic winch rope worth it?

Synthetic winch rope is lighter, safer, and easier to handle than steel cable. It’s a smart investment that improves performance and safety during recovery and towing. Plus, its flexibility makes it more user-friendly, so you can get the job done with less hassle.

how to splice synthetinc winch rope?

Here’s a simple guide to splice your synthetic winch rope:

1. Prepare the Rope

- Cut the rope cleanly using a sharp knife. Tape or heat-shrink the ends to prevent fraying.

2. Unlay the Ends

- Gently separate the strands on both ends of the rope.

3. Weave the Rope Together

- Weave one end of the rope into the other, threading it through the strands 5-6 times.

4. Taper and Secure

- Trim the excess rope and taper the ends. Use heat-shrink tubing or tape to secure the splice.

5. Test the Splice

- Gently pull the rope to check the strength of the splice. If it holds, you’re good to go.

With these steps, your winch rope splice will be strong and ready for action!

synthetic winch rope vs steel cable, which is better?

Synthetic winch rope is lighter, safer, and easier to handle than steel cable. It doesn't kink or fray, and it floats, making it ideal for water crossings. Steel cable, while durable, is heavier, can rust, and is more prone to dangerous recoil if it snaps. Overall, synthetic rope offers better performance and safety for off-road recovery

Which sizes of synthetic rope for atv winch?

For ATVs, the ideal winch rope size is usually 3/16" to 1/4". These sizes are strong enough to handle typical ATV recovery tasks while staying light and easy to manage.

A 3/16" rope can pull around 4,000-5,000 lbs, while 1/4" can handle 6,000-7,000 lbs.

How to install synthetic winch rope?

Installing your synthetic winch rope is simple and ensures optimal performance. Here's how to do it:

- Prepare the Winch: Clean the winch drum to remove debris that could damage the rope.

- Attach the Rope: Secure the rope’s eyelet to the winch drum using a strong knot or fastener. Ensure it's tightly secured.

- Spool Evenly: Slowly spool the rope onto the drum, ensuring it layers neatly without overlapping or tangling. Keep tension on the rope to avoid twists.

- Test the Setup: Run the rope in and out a few times to check for smooth spooling and correct alignment.

Proper installation maximizes your rope's strength and lifespan, giving you the reliability you need during tough jobs.

Why put winch damper on a winch cable?

winch rope damper is used to reduce the risk of injury in case of a cable or rope failure by absorbing energy and reducing recoil.

How to do synthetic winch rope replacement?

- Unwind the old rope from the winch drum. Cut any knots or damaged sections.

2. Clean the Drum

- Wipe down the winch drum to remove dirt, debris, and old rope fragments.

3. Attach the New Rope

- Secure the new synthetic rope to the drum using a strong knot (like a figure-eight knot) or winch rope hook.

4. Wind the Rope onto the Drum

- Slowly wind the new rope onto the drum, keeping it tight and evenly spaced. Use a friend or vehicle to pull the rope while you guide it onto the drum.

5. Check and Test

- Ensure the rope is wound correctly and check for any twists. Test the winch with a light load before heavy use.

And you're done! A fresh, strong synthetic winch rope ready for your next adventure.

What are the most common dangers when handling synthetic rope?

While synthetic ropes are generally safer to handle than steel cables, users should still be cautious of sharp edges, abrasion, and proper tensioning to avoid accidents..

How to spool synthetic winch rope?

Spooling your synthetic winch rope correctly is key to maximizing its lifespan and performance. Here’s how:

- Clean the Drum: Start with a clean winch drum to avoid debris that can damage the rope.

- Ensure Even Layering: Slowly spool the rope onto the drum, ensuring it winds evenly without tangling or overlapping. This prevents knots and wear.

- Pull Tension: Keep slight tension on the rope as it spools. This helps maintain its shape and avoids twists.

- Avoid Overfilling: Leave space on the drum to allow for rope expansion when in use.

Proper spooling ensures your rope performs at its best and lasts longer—giving you reliable results every time.

ngth, making it an excellent choice for winch ropes.

What are the most common sizes for off-road recovery?

we have common sizes of synthetic rope like 1/4', 3/8',9/16' for 6000lb winch, 9500lb winch, 12000lb winch. used for atv,utv,mid-sized trucks & jeeps and full-sized trucks and SUVs.

What winch rope accessories do you need?

The essential winch rope accessories include shackles(steel shacke or soft shackle), recovery strap, winch hook, tube thimble,snatch block, winch fairlead, protective sleeve, Winch Rope Extension etc.

Having these accessories on hand makes your winching experience safer and more effective.

How to repair synthetic winch rope?

Repairing synthetic winch rope is simple and keeps your gear working like new. Here's how:

- Inspect the Damage: Check for frays, cuts, or worn-out sections. Identify the area that needs repair.

- Cut the Damaged Section: If there's a tear or fraying, cut the rope neatly just before the damage.

- Use a Splice or Knot: For small damages, a simple splice (braid repair) or a strong knot can restore the rope’s strength.

- Heat Sealing for Small Cuts: For minor frays or cuts, use a heat-sealing tool to melt and fuse the fibers back together.

- Test the Repair: Before using it again, gently pull the rope to make sure the repair is secure and reliable.

With Duracordix synthetic winch rope, even repairs are easy, extending the lifespan of your equipment and ensuring you're ready for your next job.

what is the best synthetic winch rope for you?

The best winch line depends on your specific application.

When picking the best synthetic winch rope, here’s what to look for:

Strength: If you need a rope that can handle heavy-duty towing or recovery, go with a high-tensile rope like Duracordix UHMWPE rope. It won’t let you down under pressure.

Durability: For tough environments, choose a rope with UV, water, and abrasion resistance. Duracordix ropes are built to last through harsh conditions.

Flexibility: A flexible rope makes spooling and handling much easier. Duracordix ropes stay flexible even in cold weather.

Safety: To avoid snapback or failure, you need a rope that has minimal stretch. Duracordix ropes are designed with low stretch for better control.

Duracordix gives you all this—strength, durability, easy handling, and safe performance. Perfect for tough jobs, every time.

What are the advantages and disadvantages of synthetic ropes?

Advantages include lighter weight, increased safety, and easier handling. Disadvantages may include susceptibility to UV damage, abrasion, and heat.

How do you wind a synthetic winch rope?

To wind synthetic winch rope, ensure it's clean and free of damage, then apply tension while spooling it evenly onto the drum, avoiding overlapping or bunching.

Can you use rollers with synthetic winch rope?

To avoid these potential problems, it's often recommended to use a hawse fairlead, specifically designed for synthetic ropes, instead of rollers. Hawse fairleads provide a smooth surface that minimizes friction and abrasion, ensuring the safe and effective use of synthetic winch ropes.

why do you need a winch rope extension?

A winch rope extension gives you extra length for tougher recoveries, allowing you to reach farther without moving your vehicle. It's perfect for situations where your rope isn’t long enough to reach the anchor point, ensuring you can handle more challenging terrain safely and efficiently

How to cut synthetic winch rope?

Cutting synthetic winch rope is simple and ensures clean edges for safe use. Here's how:

- Choose the Right Tool: Use a sharp pair of scissors or a rope cutter designed for synthetic fibers.

- Measure and Mark: Measure the length you need and mark the rope to avoid cutting too much.

- Cut Carefully: Cut slowly and evenly to avoid fraying. If needed, melt the ends with a heat source to prevent unraveling.

- Secure the Ends: For added security, tape the ends or use a heat-sealing tool to prevent further fraying.

With Duracordix synthetic winch rope, cutting and maintaining the rope is hassle-free, helping you keep your gear in top condition.

- we make more

Related products

Maximize your Duracordix winch rope experience with top-quality related products

I recently purchased Duracordix synthetic winch ropes for my off-road vehicle, and I'm genuinely impressed with their performance and durability. I've used other brands before, but Duracordix stands out as the best.

Mike Thompson