农业

农业

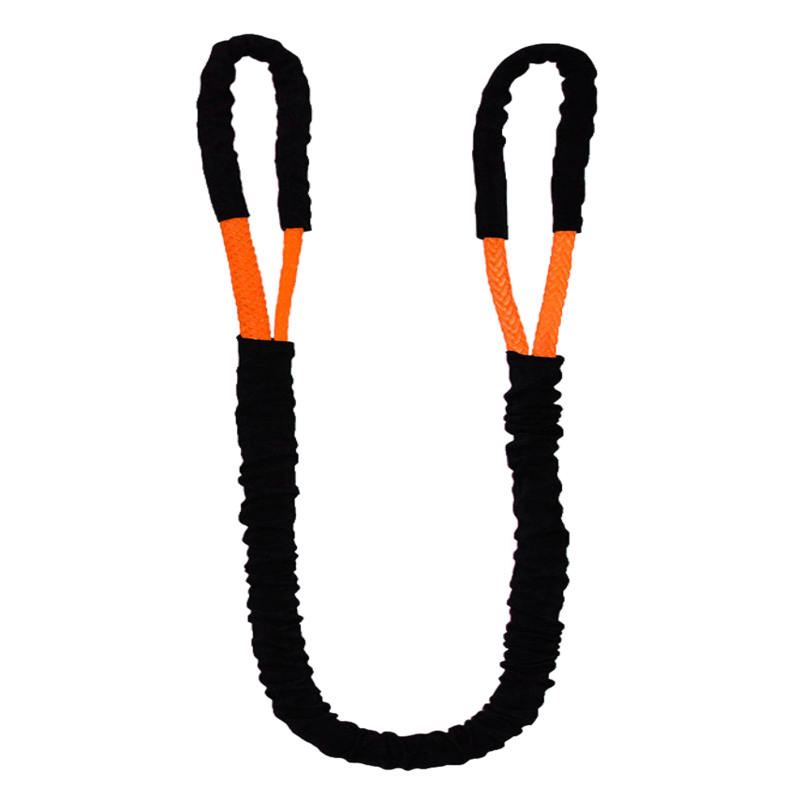

We offer a diverse array of premium-quality products tailored specifically for agricultural applications and challenges. Among our top-sellers are 动能恢复绳, 合成绞盘绳, synthetic lifting sling.

Additionally, we also provide other essential items that cater to your farming tasks like UHMWPE tow rope,tree trunk protector, log wrapper, tow strap, and rope-related accessories etc.

Eengineered to provide exceptional strength, durability, and reliability for your agricultural operations.

Eengineered to provide exceptional strength, durability, and reliability for your agricultural operations.

Designed to have high elasticity, strength, and durability for various heavy-duty recovery operations.

如何制作

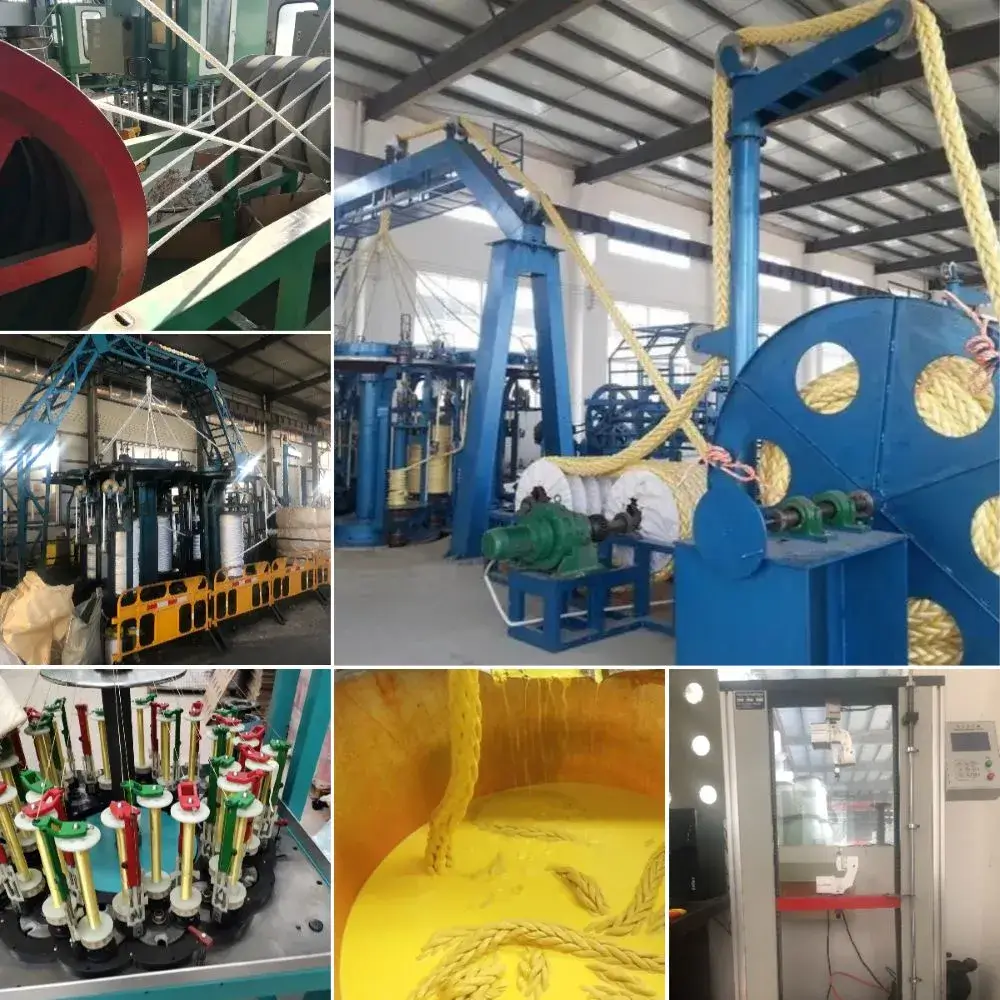

Discover Our Process of Producing High-Performance Agriculture Recovery Ropes.

流程 1

纤维选择

我们精心挑选高品质合成纤维,例如尼龙、聚酯或超高分子量聚乙烯,用于我们的绳索,确保强度和耐用性。

流程 2

扭曲和成型

将选定的纤维捻在一起制成纱线,再将纱线捻在一起制成股线。捻好的股线最终形成绳状结构。

流程 3

铺设和编织

成型的绳索被放入编织机,编织机采用专门的技术和图案将绳索编织在一起,以进一步提高强度和耐用性。

流程 4

涂层

采用 PVC 或聚氨酯等高品质材料制成的定制保护涂层,可增强绳索的耐用性和抗磨损、防水和抗紫外线能力。

流程 5

热处理和干燥

编织绳经过特殊的热处理工艺,使绳子定型并增强强度。之后,绳子会被烘干,以去除水分。

流程 6

测试

每条 Duracordix 救援绳都经过严格测试,以确保其符合我们对强度和延展性的高标准。任何未通过测试的绳索都将被丢弃。

- 以质量为中心

. 质量控制

探索我们如何确保每根纤维绳都具有无与伦比的卓越品质

1.原材料

Our synthetic ropes are only made from raw materials that meet our strict quality standards. We work with trusted suppliers to ensure consistent quality and optimal performance in all our products.

2. 内部

通过将合成绳索的生产保留在公司内部,我们可以完全控制整个生产流程的质量。这使我们能够坚持高标准,为客户提供可靠的产品。

3.测试与检验

我们严格的测试和检验流程涵盖从原材料到成品的每个生产阶段。这确保了我们合成绳索始终如一的质量和安全。

4.自动化制造

我们整合自动化机械和技术,以确保合成绳索生产的准确性和一致性。这减少了人为错误,并确保所有产品符合我们严格的质量标准。

5. 熟练的员工

我们拥有高技能的员工队伍,他们接受持续的培训和继续教育,以掌握最新的合成绳索生产技术。这有助于我们保持最高的质量和性能水平。

- 国际标准

我们的 认证

简单明了

通过轻松的购买最大限度地提高客户满意度,最大限度地减少沟通和时间成本。

第一步:方案确认(3-5天)

首先,我们会了解您的需求,并为您推荐最佳的绳索解决方案。我们的专业知识和经验将确保您获得最佳的产品。

第 2 步:样品评估(7-14 天)

为了确保您对我们的产品满意,我们提供样品评估。请在订购前测试我们的产品,以确保其符合您的要求。

步骤3:订单确认(3天内)

如果您对样品评估满意,请与我们确认订单。我们将提供所有必要的详细信息,包括价格、交货时间等,确保您购买安心。

步骤4:批量生产(30-45天)

我们为大宗订单提供批量生产服务。我们先进的生产技术和高品质的材料确保所有订单的一致性和可靠性。

第五步:发货(30-45天)

我们深知准时送达至关重要,因此我们会随时向您更新运输进度并提供追踪信息。您的订单将在约定时间内送达。

第六步:售后服务

您的订单送达后,我们的服务仍将继续。如果您有任何疑问或顾虑,我们的团队随时准备为您提供帮助。我们致力于提供卓越的客户服务,确保您满意。

- 轻松购物

为什么选择

- UV Resistant: Our ropes are treated to resist 200% more UV radiation than others, ensuring durability even under the sun.

- Strength: Engineered with a tensile strength of 50,000 lbs. Whether towing or winching, our ropes won’t let you down.

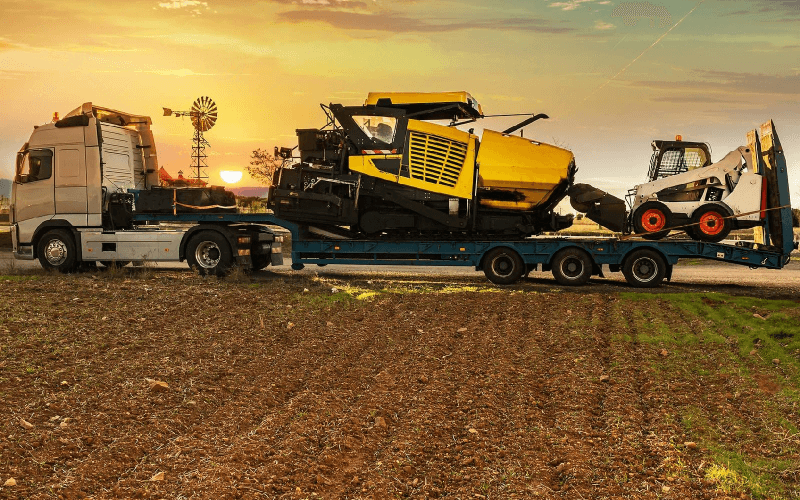

- Security: Our custom rope has a proven record of securely tying down equipment for transportation and field use, giving you peace of mind.

- Cost-Effective: Expect savings of up to 30% compared to leading brands. Quality doesn’t always come at a premium.

- Dedicated Service: With 24/7 customer support, Duracrodix promises assistance in under 2 hours, always prioritizing your needs.

- Customizable: Whether you require custom length, diameter, color, or strength, our rope is tailored to meet your specific agricultural needs at a reasonable price.

常见问题解答

解决客户顾虑和痛点的常见问题

What are agriculture ropes and straps used for?

Agriculture ropes and straps are used in agricultural applications for tasks such as securing crops, anchoring trees, pulling heavy equipment, and more.

Can agriculture ropes and straps be used interchangeably?

No, different types of ropes and straps have different strengths and uses, and it is important to choose the right product for each specific agricultural task.

What materials are agriculture ropes and straps made from?

Agriculture ropes and straps can be made from natural fibers such as cotton and sisal, or synthetic fibers such as nylon and polyester,uhmwpe etc.

Why are synthetic ropes preferred in agriculture?

Synthetic ropes offer several advantages in agriculture:

Durability: They resist environmental factors such as UV rays, rot, and mildew.

Strength: Especially those like UHMWPE, can bear heavy loads.

Cost-Effective: Longer lifespans mean fewer replacements.

Resistance: They repel water and most chemicals found in agricultural settings.

How do synthetic ropes compare to natural ropes in terms of strength?

While natural ropes, like manila or sisal, have been used historically for their inherent strength, modern synthetic ropes often surpass them in tensile strength and durability. UHMWPE ropes, for example, have a strength-to-weight ratio eight to fifteen times higher than steel.

Can synthetic ropes for agriculture be recycled?

Many synthetic ropes are recyclable, but the feasibility often hinges on the type of polymer and local recycling facilities. Always consult with the manufacturer or local waste management for proper recycling options.

How do you maintain synthetic ropes for agriculture?

Maintenance is key for longevity:

•Inspect regularly for wear, fraying, or damage.

•Clean periodically to remove dirt, chemicals, and moisture. Mild soap and water usually suffice.

•Store away from direct sunlight in a cool, dry place.

•Avoid contact with sharp or abrasive surfaces.

Are synthetic ropes for agriculture resistant to UV rays?

Many synthetic ropes, particularly nylon and polyester, have good UV resistance. However, over time and with prolonged exposure, UV rays can weaken any rope.

What's the lifespan of a synthetic rope used in agriculture?

Lifespan can vary based on use and environmental factors. With proper care, synthetic ropes can last several years. However, ropes used daily in heavy-duty tasks may need replacement sooner.

Can synthetic ropes handle heavy loads like bales or machinery in agriculture?

Yes. UHMWPE ropes, renowned for their high strength, are often used for heavy-lifting operations in agriculture, like moving large bales or machinery.

Are synthetic ropes safe for animal handling?

Synthetic ropes can be used safely for animal handling, be it as leads, tie-outs, or enclosures. Always ensure the rope is free from sharp or abrasive particles to prevent harm.

Do synthetic ropes for agriculture stretch?

Stretch varies by material. Nylon is elastic and has significant stretch, which can be useful for shock absorption. Polyester and UHMWPE, however, have minimal stretch, making them ideal for applications requiring stability.

How does moisture affect synthetic ropes for agriculture?

Synthetic ropes, especially polypropylene and polyethylene, are hydrophobic, meaning they resist water absorption. This resistance to moisture prevents rot, a common problem in natural ropes.

Can synthetic ropes for aguriculture be repaired if damaged?

For minor abrasions, it might be possible to mend or fuse the fibers. However, for significant wear, fraying, or if the structural integrity is compromised, it's safer to replace the rope.

Do synthetic ropes for agriculture come in different colors?

Absolutely. They're available in a wide range of colors, helpful for coding or aesthetic preferences. The color can also provide UV resistance or increased visibility.

Can synthetic ropes be used with pulleys and winches in agricultural settings?

Yes. High-strength ropes, like those made from UHMWPE, are particularly suited for pulley systems, winches, and other mechanical devices.

Is synthetic rope for agriculture resistant to oils and chemicals?

Synthetic ropes generally resist many chemicals and oils, but it varies by rope composition. For instance, polypropylene resists most acids but can be damaged by strong oxidizing agents. Always consult manufacturer guidelines when using ropes around chemicals.