军队

军队

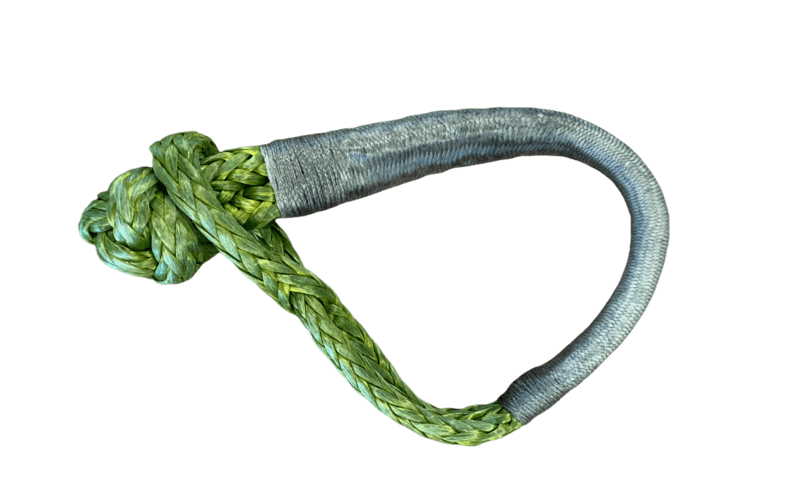

We provide an extensive array of top-notch products tailored specifically for military operations and tactical requirements. Our leading products include military-grade tow stap, shackle, tactical tow ropes, and durable winch ropes.

Furthermore, we also design and supply additional indispensable military gear, such as bridle equaliser cords, synthetic combat ropes, and a variety of tactical rope accessories, ensuring optimal preparedness for all defense scenarios.

如何制作

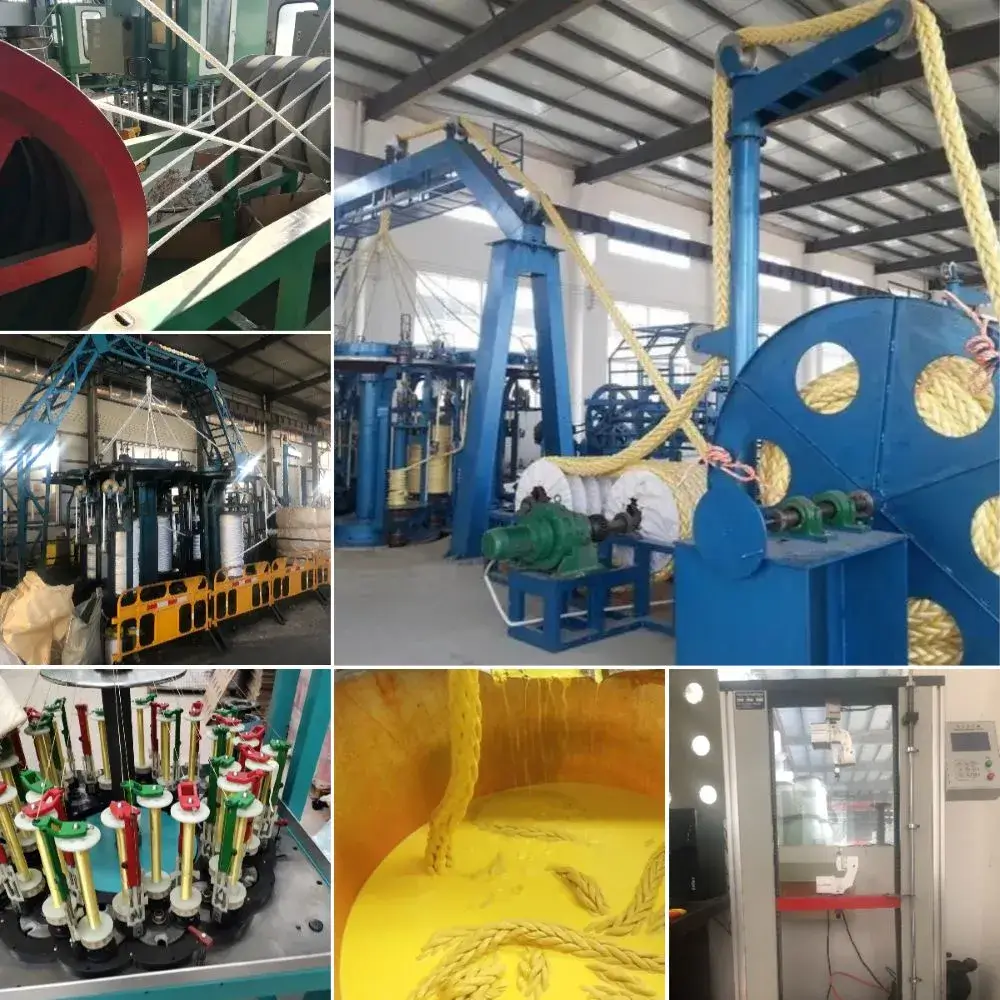

Discover Our Process of Producing High-Performance Military Ropes.

流程 1

纤维选择

我们精心挑选高品质合成纤维,例如尼龙、聚酯或超高分子量聚乙烯,用于我们的绳索,确保强度和耐用性。

流程 2

扭曲和成型

将选定的纤维捻在一起制成纱线,再将纱线捻在一起制成股线。捻好的股线最终形成绳状结构。

流程 3

铺设和编织

成型的绳索被放入编织机,编织机采用专门的技术和图案将绳索编织在一起,以进一步提高强度和耐用性。

流程 4

涂层

采用 PVC 或聚氨酯等高品质材料制成的定制保护涂层,可增强绳索的耐用性和抗磨损、防水和抗紫外线能力。

流程 5

热处理和干燥

编织绳经过特殊的热处理工艺,使绳子定型并增强强度。之后,绳子会被烘干,以去除水分。

流程 6

测试

每条 Duracordix 救援绳都经过严格测试,以确保其符合我们对强度和延展性的高标准。任何未通过测试的绳索都将被丢弃。

- 以质量为中心

. 质量控制

探索我们如何确保每根纤维绳都具有无与伦比的卓越品质

1.原材料

Our synthetic military ropes are only made from raw materials that meet our strict quality standards. We work with trusted suppliers to ensure consistent quality and optimal performance in all our products.

2. 内部

通过将合成绳索的生产保留在公司内部,我们可以完全控制整个生产流程的质量。这使我们能够坚持高标准,为客户提供可靠的产品。

3.测试与检验

我们严格的测试和检验流程涵盖从原材料到成品的每个生产阶段。这确保了我们合成绳索始终如一的质量和安全。

4.自动化制造

我们整合自动化机械和技术,以确保合成绳索生产的准确性和一致性。这减少了人为错误,并确保所有产品符合我们严格的质量标准。

5. 熟练的员工

我们拥有高技能的员工队伍,他们接受持续的培训和继续教育,以掌握最新的合成绳索生产技术。这有助于我们保持最高的质量和性能水平。

- 国际标准

我们的 认证

简单明了

通过轻松的购买最大限度地提高客户满意度,最大限度地减少沟通和时间成本。

第一步:方案确认(3-5天)

首先,我们会了解您的需求,并为您推荐最佳的绳索解决方案。我们的专业知识和经验将确保您获得最佳的产品。

第 2 步:样品评估(7-14 天)

为了确保您对我们的产品满意,我们提供样品评估。请在订购前测试我们的产品,以确保其符合您的要求。

步骤3:订单确认(3天内)

如果您对样品评估满意,请与我们确认订单。我们将提供所有必要的详细信息,包括价格、交货时间等,确保您购买安心。

步骤4:批量生产(30-45天)

我们为大宗订单提供批量生产服务。我们先进的生产技术和高品质的材料确保所有订单的一致性和可靠性。

第五步:发货(30-45天)

我们深知准时送达至关重要,因此我们会随时向您更新运输进度并提供追踪信息。您的订单将在约定时间内送达。

第六步:售后服务

您的订单送达后,我们的服务仍将继续。如果您有任何疑问或顾虑,我们的团队随时准备为您提供帮助。我们致力于提供卓越的客户服务,确保您满意。

- 轻松购物

为什么选择

- Strength: Despite being 70% lighter, Duracrodix ropes match or exceed the tensile strength of steel cables.

- Safety: if a Duracrodix rope snaps, it doesn't create dangerous whiplashes like steel, ensuring personnel safety.

- Lightweight: Duracrodix ropes are light, ensuring swift transportation and deployment, essential for rapid military response.

- Natural Buoyancy: Duracrodix synthetic ropes' buoyancy is invaluable in naval salvages and various aquatic operations.

- Flexibility: Offering 50% more flexibility than steel, Duracrodix ropes excel in challenging terrains and tight spaces.

- Color-Coded Convenience: Unique color-coding enables 90% quicker rope identification, enhancing operational efficiency and safety.

常见问题解答

解决客户顾虑和痛点的常见问题

What is military rope made of?

Military ropes are typically made from various materials, including UHMWPE (Ultra-High-Molecular-Weight Polyethylene), nylon, and polyester. These materials offer exceptional strength and durability, making them suitable for demanding military applications.

What is a strong rope-like material for military?

UHMWPE (Ultra-High-Molecular-Weight Polyethylene) is a strong rope-like material known for its incredible strength-to-weight ratio. It's often used in military ropes due to its exceptional tensile strength.

What types of military ropes are available?

There are several types of military ropes available, including static ropes for rappelling and climbing, dynamic ropes for activities like parachuting, and recovery ropes for vehicle extraction.

When should I use a military-grade recovery strap?

Military-grade recovery straps are used when a vehicle or equipment needs to be recovered from challenging terrain or obstacles. They provide a strong and controlled means of extraction.

What is the rope used by the military?

The military uses a variety of ropes depending on the specific application. UHMWPE ropes, nylon ropes, and static ropes are commonly used for tasks such as climbing, hoisting, towing, and more.

How thick is military climbing rope?

Military climbing ropes vary in thickness depending on the intended use. They can range from around 9mm to 11mm, providing a balance between strength and flexibility.

What is the strongest type of military rope?

UHMWPE ropes are often considered the strongest type of military rope due to their exceptional tensile strength, lightweight nature, and resistance to abrasion.

How do I choose the right military tow rope for my needs?

When choosing a military tow rope, consider factors like the weight of the vehicle, the terrain, and the desired level of stretch. Opt for a rope with sufficient strength and appropriate specifications for your towing needs.

What kind of rope is best for use in extreme temperatures?

When it comes to conquering the challenges posed by extreme temperatures, Kevlar Aramid rope emerges as the ultimate solution. Renowned for its exceptional thermal stability and durability, Kevlar Aramid rope is the go-to choice for applications that demand unwavering performance in both high and low temperature environments.

How to properly store military rope?

Store military rope in a cool, dry place away from direct sunlight to prevent degradation. Coiling or hanging the rope to avoid kinks is recommended.

what's the benefits of synthetic ropes in military applications

Synthetic ropes in military applications are lightweight, highly durable, and offer superior strength. They ensure safety, resist environmental damages, require minimal maintenance, and are cost-effective, making them ideal for diverse military operations.

What is a military winch rope?

A military winch rope is a strong, durable rope used with winch systems for various military applications, including vehicle recovery and equipment movement.

How to choose the right military rope for your needs?

Selecting the right military rope hinges on understanding your requirements. Assess the intended purpose, desired strength, material suitability, and environmental factors. Whether it's hoisting, towing, or climbing, this strategic evaluation ensures your choice aligns precisely with the demands of the task at hand.

synthetic vs steel rope for military, which is better?

Synthetic ropes are lightweight, safe upon breaking, and resist corrosion. Steel ropes are durable, UV and chemical resistant, and suitable for heavy lifting. The optimal choice between synthetic and steel ropes depends on the military application and environment.

Why is synthetic rope preferred in military applications?

Synthetic rope has become a favorite in military applications because of its unique combination of strength, flexibility, and lightweight nature. Additionally, these ropes are resistant to environmental degradation, ensuring a longer lifespan even under harsh conditions, which is imperative for military operations.

How do synthetic ropes compare in strength to steel cables?

While steel cables are inherently strong, synthetic ropes like UHMWPE can achieve a comparable strength-to-weight ratio, making them equally effective in many applications without the added weight.

What are the typical uses of synthetic ropes in the military?

In the military, synthetic ropes find their usage in a myriad of applications. They are commonly used for cargo slings, towing, helicopter external load operations, and as fast ropes for rapid deployment of troops. Their strength and resistance to wear make them suitable for demanding military applications.

Are there any safety concerns associated with the use of synthetic ropes in military contexts?

Synthetic ropes in military use have benefits but also safety concerns. They can store energy and may recoil dangerously if snapped. These ropes can degrade in extreme temperatures and shouldn't be exposed to flames. Always ensure they aren’t overloaded to guarantee safety.

How to clean and maintain military rope?

Military rope should be cleaned with mild soap and water, then air-dried. Avoid using harsh chemicals or machines for cleaning. It is recommended to inspect the rope regularly and replace it if any signs of damage are found.

which military divisions use synthetic ropes most?

Special Forces use synthetic ropes for rappelling and rescue. The Navy and Coast Guard employ them in marine tasks. Army Engineering Units utilize them for construction, and Airborne Divisions for cargo drops and extraction. Usage varies by country and operation.

Duracordix 能否根据项目特定要求提供定制长度的纤维绳?

当然!Duracordix 提供定制选项,包括根据您的具体项目需求定制长度,确保您获得所需的产品。