农业

如何制作

了解我们生产高性能农业回收绳索的流程。

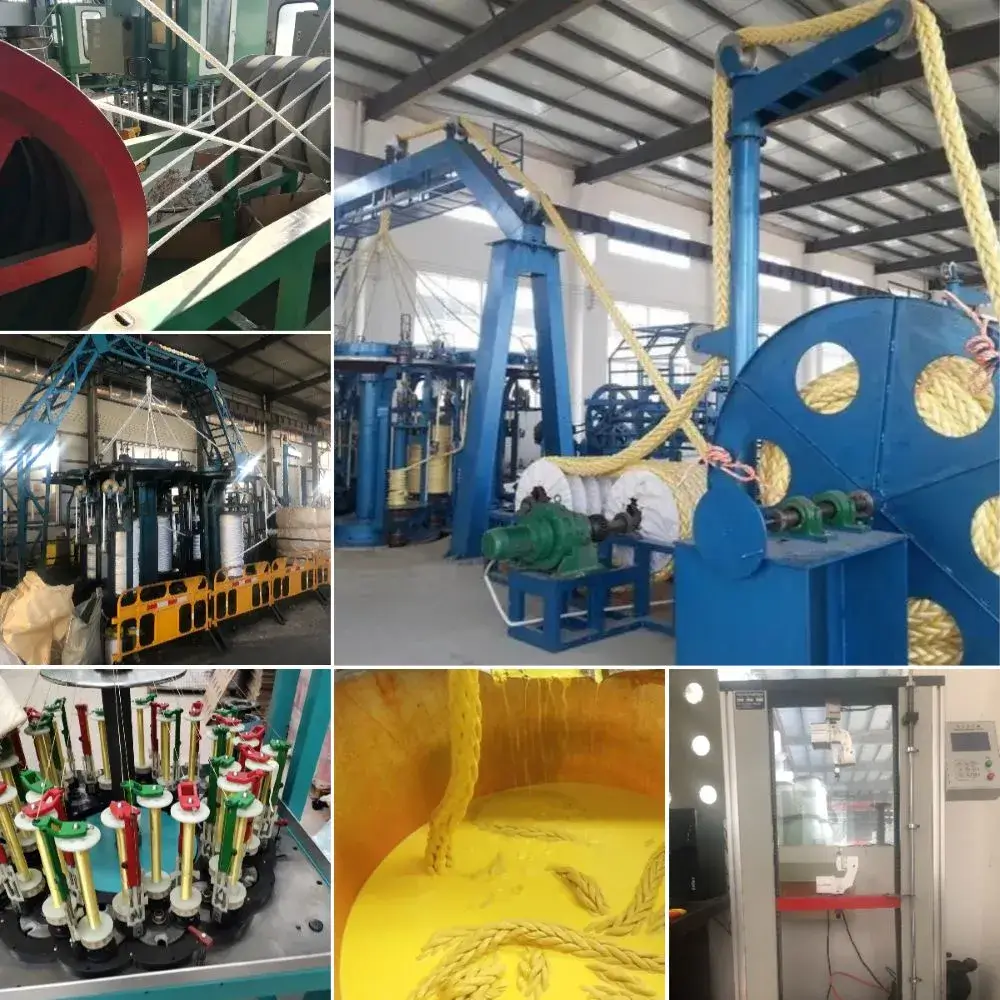

流程 1

纤维选择

我们精心挑选高品质合成纤维,例如尼龙、聚酯或超高分子量聚乙烯,用于我们的绳索,确保强度和耐用性。

流程 2

扭曲和成型

将选定的纤维捻在一起制成纱线,再将纱线捻在一起制成股线。捻好的股线最终形成绳状结构。

流程 3

铺设和编织

成型的绳索被放入编织机,编织机采用专门的技术和图案将绳索编织在一起,以进一步提高强度和耐用性。

流程 4

涂层

采用 PVC 或聚氨酯等高品质材料制成的定制保护涂层,可增强绳索的耐用性和抗磨损、防水和抗紫外线能力。

流程 5

热处理和干燥

编织绳经过特殊的热处理工艺,使绳子定型并增强强度。之后,绳子会被烘干,以去除水分。

流程 6

测试

每条 Duracordix 救援绳都经过严格测试,以确保其符合我们对强度和延展性的高标准。任何未通过测试的绳索都将被丢弃。

- 以质量为中心

. 质量控制

探索我们如何确保每根纤维绳都具有无与伦比的卓越品质

1.原材料

我们的合成绳索仅采用符合我们严格质量标准的原材料制成。我们与值得信赖的供应商合作,以确保所有产品均拥有始终如一的质量和最佳性能。

2. 内部

通过将合成绳索的生产保留在公司内部,我们可以完全控制整个生产流程的质量。这使我们能够坚持高标准,为客户提供可靠的产品。

3.测试与检验

我们严格的测试和检验流程涵盖从原材料到成品的每个生产阶段。这确保了我们合成绳索始终如一的质量和安全。

4.自动化制造

我们整合自动化机械和技术,以确保合成绳索生产的准确性和一致性。这减少了人为错误,并确保所有产品符合我们严格的质量标准。

5. 熟练的员工

我们拥有高技能的员工队伍,他们接受持续的培训和继续教育,以掌握最新的合成绳索生产技术。这有助于我们保持最高的质量和性能水平。

- 国际标准

我们的 认证

简单明了

通过轻松的购买最大限度地提高客户满意度,最大限度地减少沟通和时间成本。

第一步:方案确认(3-5天)

首先,我们会了解您的需求,并为您推荐最佳的绳索解决方案。我们的专业知识和经验将确保您获得最佳的产品。

第 2 步:样品评估(7-14 天)

为了确保您对我们的产品满意,我们提供样品评估。请在订购前测试我们的产品,以确保其符合您的要求。

步骤3:订单确认(3天内)

如果您对样品评估满意,请与我们确认订单。我们将提供所有必要的详细信息,包括价格、交货时间等,确保您购买安心。

步骤4:批量生产(30-45天)

我们为大宗订单提供批量生产服务。我们先进的生产技术和高品质的材料确保所有订单的一致性和可靠性。

第五步:发货(30-45天)

我们深知准时送达至关重要,因此我们会随时向您更新运输进度并提供追踪信息。您的订单将在约定时间内送达。

第六步:售后服务

您的订单送达后,我们的服务仍将继续。如果您有任何疑问或顾虑,我们的团队随时准备为您提供帮助。我们致力于提供卓越的客户服务,确保您满意。

- 轻松购物

为什么选择

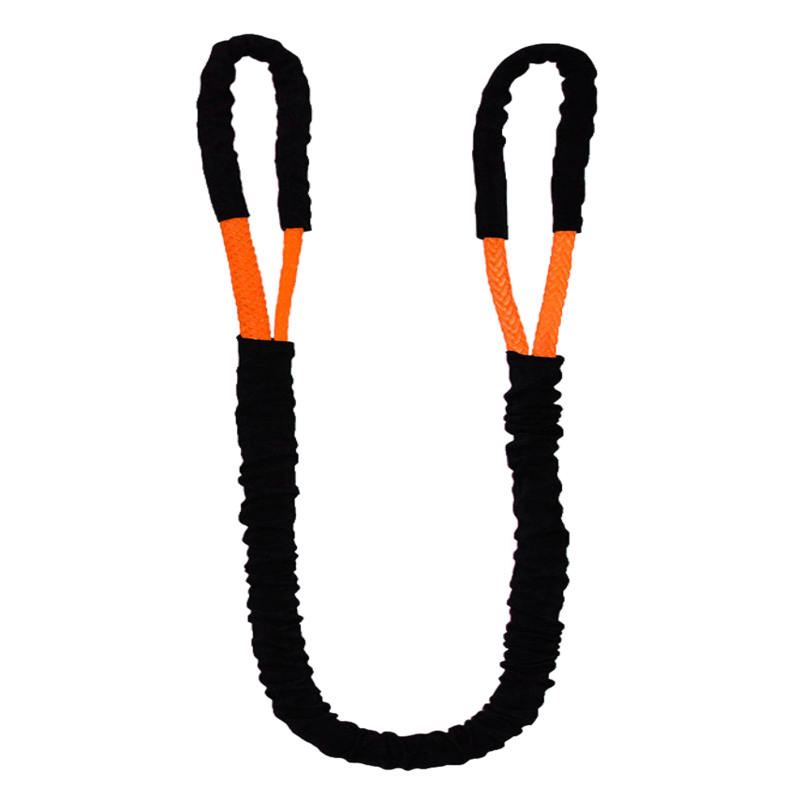

- 抗紫外线:我们的绳索经过特殊处理,可比其他绳索多抵抗 200% 的紫外线辐射,确保即使在阳光下也能持久耐用。

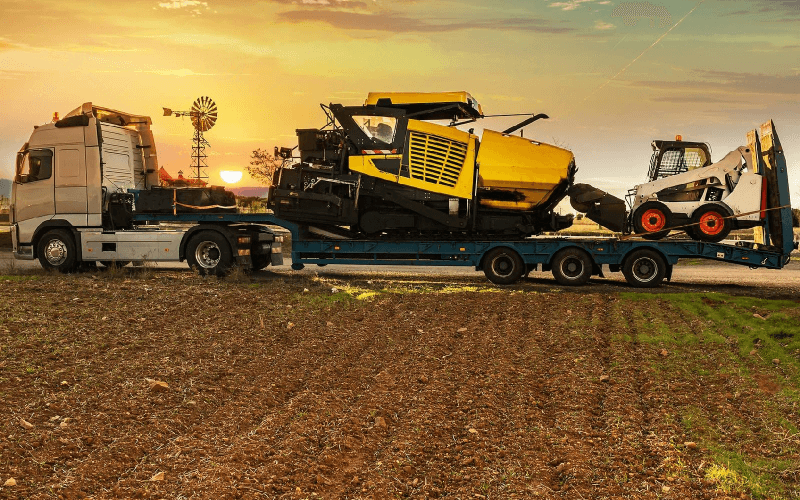

- 强度:抗拉强度高达 50,000 磅。无论是牵引还是绞盘,我们的绳索都不会让您失望。

- 安全性:我们的定制绳索具有可靠的记录,可以安全地固定运输和现场使用的设备,让您安心无忧。

- 经济实惠:与领先品牌相比,预计可节省高达 30%。品质并不总是意味着溢价。

- 专用服务:通过全天候客户支持,Duracrodix 承诺在 2 小时内提供帮助,始终优先考虑您的需求。

- 可定制:无论您需要定制长度、直径、颜色还是强度,我们的绳索都能以合理的价格满足您的特定农业需求。

常见问题解答

解决客户顾虑和痛点的常见问题

农业绳索和带子用于什么?

农业绳索和带子用于农业应用,例如固定农作物、锚固树木、牵引重型设备等。

农业绳索和带子可以互换使用吗?

不,不同类型的绳索和带子具有不同的强度和用途,对于每项特定的农业任务选择合适的产品非常重要。

农业绳索和带子由什么材料制成?

农业绳索和带子可以由棉和剑麻等天然纤维或尼龙和聚酯、超高分子量聚乙烯等合成纤维制成。

为什么农业领域更青睐合成绳索?

合成绳索在农业方面具有多种优势:

耐用性: 它们可以抵抗紫外线、腐烂和霉菌等环境因素。

力量: 特别是像超高分子量聚乙烯 (UHMWPE) 这样的材料,可以承受重载。

成本效益: 更长的使用寿命意味着更少的更换。

反抗: 它们可以防水并能抵御农业环境中的大多数化学物质。

合成绳索与天然绳索相比强度如何?

虽然马尼拉麻或剑麻等天然绳索历来因其固有强度而被广泛使用,但现代合成绳索的抗拉强度和耐用性往往超越它们。例如,超高分子量聚乙烯绳索的强度重量比是钢材的8到15倍。

农业用合成绳索可以回收吗?

许多合成绳索是可回收的,但其可行性通常取决于聚合物的类型和当地的回收设施。请务必咨询制造商或当地废物管理部门,了解合适的回收方案。

如何维护农业用合成绳索?

维护是延长使用寿命的关键:

•定期检查是否有磨损、磨损或损坏。

•定期清洁,去除污垢、化学物质和水分。通常用温和的肥皂和水即可。

•存放在阴凉干燥处,避免阳光直射。

•避免接触尖锐或粗糙的表面。

农业用合成绳索能抗紫外线吗?

许多合成绳索,尤其是尼龙和聚酯纤维,具有良好的抗紫外线性能。然而,随着时间的推移和长时间的暴露,紫外线会削弱任何绳索的强度。

农业中使用的合成绳索的寿命是多长?

使用寿命会因使用情况和环境因素而异。如果保养得当,合成绳索可以使用数年。然而,每天用于重型作业的绳索可能需要更早更换。

合成绳索可以承载诸如农业中的捆包或机械之类的重物吗?

是的。超高分子量聚乙烯绳索以其高强度而闻名,常用于农业领域的重型起重作业,例如搬运大捆货物或机械。

合成绳索对于处理动物来说是否安全?

合成绳索可以安全地用于动物处理,无论是用作牵引绳、拴绳还是围栏。务必确保绳索上没有尖锐或粗糙的颗粒,以防止造成伤害。

农业用合成绳索能拉伸吗?

拉伸因材料而异。尼龙富有弹性,拉伸性强,有助于减震。而聚酯纤维和超高分子量聚乙烯的拉伸性则相对较小,因此非常适合需要稳定性的应用。

湿度如何影响农业用合成绳索?

合成绳索,尤其是聚丙烯和聚乙烯,具有疏水性,这意味着它们不吸水。这种防潮性能防止了天然绳索常见的腐烂问题。

农业用合成绳索损坏后可以修复吗?

对于轻微的磨损,或许可以修补或熔接纤维。但是,如果磨损严重、磨损或结构完整性受损,则更安全的做法是更换绳索。

农业用合成绳索有不同的颜色吗?

当然。它们有多种颜色可供选择,方便您根据个人喜好进行编码或提升美观度。不同的颜色还能起到防紫外线或提高可见度的作用。

在农业环境中,合成绳索可以与滑轮和绞盘一起使用吗?

是的。高强度绳索,例如由超高分子量聚乙烯 (UHMWPE) 制成的绳索,特别适合滑轮系统、绞盘和其他机械设备。

农业用合成绳索是否耐油和化学品?

合成绳索通常能够抵抗多种化学品和油污,但具体情况因绳索成分而异。例如,聚丙烯能够抵抗大多数酸,但可能会被强氧化剂损坏。在化学品周围使用绳索时,请务必参考制造商的指南。