cuerda de grúa

Sintético cuerda de grúa

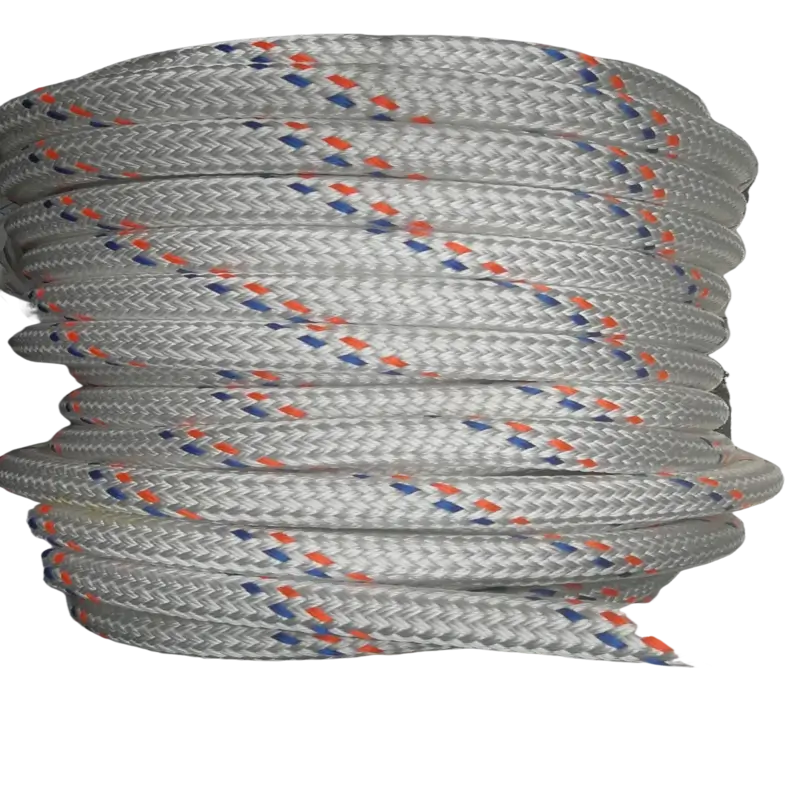

El cable sintético para grúas es un tipo de cable diseñado específicamente para grúas y aplicaciones de elevación. Está fabricado con fibras sintéticas de alto rendimiento: UHMWPE (polietileno de peso molecular ultraalto). Es una alternativa al cable de acero para grúas.

- Peso más ligero

- Mayor relación resistencia-peso

- Seguridad mejorada

- Requisitos de mantenimiento reducidos

Índice de contenidos de esta página

Para garantizar un acceso fácil a la información que necesita, hemos creado esta tabla de contenido que lo llevará directamente a la sección correspondiente cuando haga clic.

- El favorito del cliente

Venta caliente tamaños

Favoritos de la industria: Diámetros más populares de cables de grúa Duracordix

12 mm

Un tamaño versátil que ofrece un equilibrio entre resistencia y flexibilidad, lo que lo hace adecuado para una variedad de aplicaciones de elevación de servicio medio.

24 mm

Diseñado para aplicaciones de alta resistencia. Equilibra longitud y resistencia, ideal para vehículos grandes o situaciones que requieren mayor alcance.

32 mm

Diseñado para elevación extrema en construcción naval, construcción importante e industrias de extracción de minerales a gran escala.

Duracordix es una cuerda sintética para grúa. fabricante y proveedor En China.

podemos producir varios tamaños para diferentes aplicaciones y por encargo Para proyectos especiales.

No importa que estés buscando una proveedor mayorista o correa de arranque hecha a medida, todos podemos ayudar. comuníquese con Duracordix ahora.

- Tallas disponibles

ESPECIFICACIÓN

Explore las especificaciones de nuestro cable de grúa para su aplicación

| DIÁMETRO | DIÁMETRO | PESO | KETX | KETX | FUERZA DE ROMPIMIENTO | FUERZA DE ROMPIMIENTO |

|---|---|---|---|---|---|---|

| mm | pulgada | 100 m(kg) | estándar | error | tonelada | conocimiento |

| 6 | 1/4 | 1.7 | 23 | 5% | 3.1 | 31 |

| 8 | 5/16 | 4.1 | 40 | 5% | 6.35 | 63 |

| 10 | 13/32 | 6.1 | 61 | 5% | 9.3 | 93 |

| 12 | 1/2 | 8.8 | 87 | 5% | 12.12 | 121 |

| 14 | 9/16 | 12 | 119 | 5% | 15.4 | 153 |

| 16 | 5/8 | 15.5 | 151 | 5% | 20.6 | 205 |

| 18 | 3/4 | 19 | 190 | 5% | 23.9 | 238 |

| 20 | 13/16 | 23 | 225 | 5% | 28.99 | 289 |

| 22 | 7/8 | 28 | 276 | 5% | 33 | 322 |

| 24 | 1 | 37 | 368 | 5% | 38 | 371 |

| 28 | 1-1/8 | 50 | 490 | 5% | 57.5 | 562 |

| 32 | 1-5/16 | 62.5 | 621 | 5% | 68.5 | 671 |

Nota: Otros tamaños están disponibles bajo pedido.

- CABLE DE ACERO VS.

Ventajas Ventajas Cable de grúa OF

Descubra los beneficios del alambre sintético Duracordix sobre el alambre de acero tradicional

Reducción de peso

Los cables de grúa sintéticos Duracordix son significativamente más livianos que los cables de acero, lo que garantiza un manejo más fácil, menores costos de transporte y procesos de aparejo más rápidos.

Seguridad

Las cuerdas Duracordix tienen un tacto más suave y no hay riesgo de astillas de alambre, lo que reduce las lesiones en las manos y mejora la comodidad del usuario durante las operaciones.

Resistencia a la corrosión

A diferencia del acero, nuestras cuerdas sintéticas son inmunes al óxido y la corrosión, particularmente en ambientes marinos y hostiles, lo que garantiza una mayor vida útil y confiabilidad.

Flexibilidad y fuerza

Nuestras cuerdas sintéticas proporcionan una alta relación resistencia-peso, lo que garantiza una capacidad de carga superior al tiempo que siguen siendo flexibles, reduciendo el desgaste y maximizando la durabilidad.

- Clientes felices

Lo que dijeron

Voces de confianza: Experiencias reales con cuerdas Duracordix

- Compra sin dolor

¿POR QUÉ ELEGIR?

CABLE DE GRÚA DURACORIDX

- Alto rendimiento: el cable de grúa Duracordix garantiza una confiabilidad de 99.8%, brindando una resistencia a la tracción inigualable para elevaciones críticas y reduciendo los problemas de rotura.

- Resistente a la intemperie: diseñada para durar, nuestra cuerda resiste 95% de rayos UV y daños ambientales, lo que garantiza una vida útil prolongada incluso en condiciones difíciles.

- Rentable: Consiga una calidad superior sin gastar de más. Duracordix 20% ofrece una mejor rentabilidad de la inversión, combinando una durabilidad excepcional con un precio competitivo.

- Uso versátil: Adecuadas para diversos entornos, nuestras cuerdas cumplen con las necesidades de elevación específicas de la industria, lo que garantiza adaptabilidad y conveniencia.

- Soporte Inquebrantable: Benefíciese de nuestros 20 años de experiencia. Duracordix le brinda soporte continuo, lo que nos convierte en su socio de confianza para la elevación.

- Hacemos más

Relacionado productos

Más allá de lo básico: descubra más en nuestra gama de cables para grúas

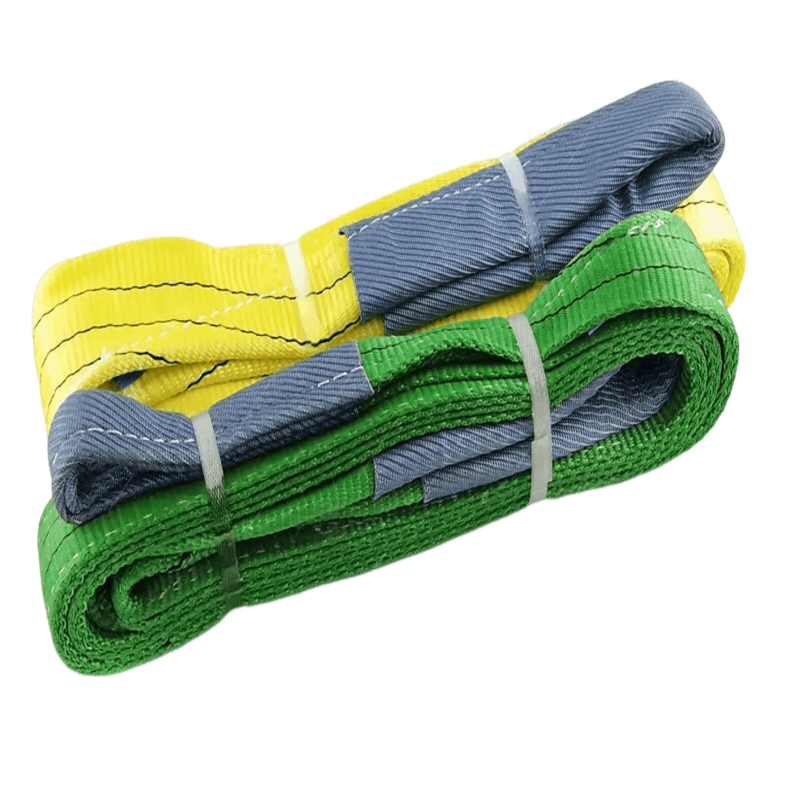

Ligeras pero resistentes, estas eslingas ofrecen durabilidad y flexibilidad, ideales para diversas aplicaciones de elevación.

De diseño circular, asegura una distribución uniforme del peso, optimizando la seguridad y la facilidad de manejo.

De tejido plano para mayor estabilidad, combina resistencia a la carga con una menor presión superficial sobre los objetos levantados.

Preguntas frecuentes

Abordando consultas comunes: información sobre cables sintéticos para grúas

¿Qué es la cuerda de grúa sintética?

Los cables sintéticos para grúas, fabricados con materiales como UHMWPE o nailon, son ligeros, resistentes a la corrosión y flexibles. Su fácil manejo y durabilidad los convierten en la opción preferida frente a los cables de acero tradicionales en las industrias de elevación pesada.

¿Cómo puedo inspeccionar el cable de mi grúa para detectar signos de desgaste o daños?

Las inspecciones de rutina son fundamentales. Busque daños externos como cortes, deshilachados o abrasiones. En el interior, revise si hay fibras rotas o irregularidades en la estructura de la cuerda. Documente todos los hallazgos y reemplace la cuerda si los daños parecen graves.

¿Cuál es la principal ventaja del cable de grúa sintético sobre el acero tradicional?

Los cables sintéticos para grúas son apreciados por su excelente relación resistencia-peso. Esto significa que pueden soportar cargas pesadas a la vez que son más ligeros, lo que reduce las dificultades de transporte y manipulación. Además, no se corroen como el acero y son resistentes a diversos factores ambientales.

¿Cuánto tiempo puedo esperar que dure mi cuerda de grúa sintética?

La vida útil de los cables sintéticos para grúas depende en gran medida de su frecuencia de uso, el entorno y el mantenimiento. Con el cuidado adecuado y en condiciones normales de funcionamiento, pueden durar varios años.

¿Existen pautas de mantenimiento específicas para los cables de grúa sintéticos?

Por supuesto. Asegúrese de almacenarlos adecuadamente, lejos de la luz solar directa y de productos químicos agresivos. La limpieza e inspección periódicas son cruciales. También es importante evitar la sobrecarga y utilizar técnicas de tensado correctas.

¿Cómo se comparan en resistencia los cables de grúa sintéticos con los cables de acero?

Los cables sintéticos para grúas, fabricados con materiales de alto rendimiento, ofrecen una resistencia a la tracción comparable, o incluso superior, a la del acero. Además, tienen la ventaja adicional de ser ligeros y resistentes a la corrosión.

¿Qué pautas de seguridad debo seguir al utilizar cables de grúa?

Respete siempre los límites de peso de la cuerda y sométala a inspecciones periódicas. Es fundamental tensarla correctamente. Seguir las instrucciones del fabricante sobre uso, almacenamiento y mantenimiento garantiza una seguridad óptima.

¿Cómo puedo determinar el diámetro correcto para el cable de mi grúa?

El diámetro ideal depende de la capacidad de la grúa, sus necesidades específicas de elevación y las recomendaciones del fabricante. Asegúrese siempre de cumplir con las normas de seguridad y del sector.

Cable de grúa de acero versus sintético: ¿cuál es más duradero?

Si bien el acero es intrínsecamente resistente, las cuerdas sintéticas ofrecen una mayor resistencia a la corrosión, los rayos UV y el desgaste ambiental. Las cuerdas sintéticas suelen ofrecer una mayor durabilidad funcional en diversas condiciones.

¿Qué precauciones son necesarias al manipular cables de grúa?

Es fundamental utilizar guantes, asegurarse de que las cuerdas no tengan nudos ni torceduras, mantener la tensión adecuada y almacenarlas en un lugar libre de posibles fuentes de daños, como objetos afilados o productos químicos.

¿Cómo se deben almacenar los cables de la grúa?

Un lugar fresco y seco es ideal. Evite zonas con luz solar directa, productos químicos agresivos u objetos afilados. Si se almacena al aire libre, utilice cubiertas protectoras y asegúrese de que haya una ventilación adecuada.

¿Qué técnicas se recomiendan para tensar el cable de la grúa?

Es fundamental seguir las instrucciones del fabricante. Asegúrese de que la carga sea uniforme, evite las cargas de impacto y siga siempre las mejores prácticas para garantizar la seguridad y la durabilidad de la cuerda.

¿Existen indicadores para comprobar el desgaste del cable de la grúa?

Sí, cualquier adelgazamiento visible, fibras rotas, estiramiento excesivo o desviación notable de la integridad estructural original de la cuerda deben abordarse de inmediato.

¿Cómo se mide el alargamiento del cable de la grúa?

Al comparar la longitud de la cuerda bajo una carga específica con su longitud original, se puede determinar el alargamiento. El monitoreo regular es clave para detectar niveles de alargamiento inseguros.

¿Qué problemas comunes están asociados con los cables de grúa?

Estos incluyen deshilachado, abrasiones, torceduras, falta de uniformidad en la tensión y daños causados por los rayos UV o productos químicos agresivos. Un cuidado y mantenimiento adecuados pueden mitigar muchos de estos problemas.

¿Existen métodos específicos para terminar o empalmar cables de grúa?

Existen diversos métodos, como el empalme trenzado, la unión adhesiva o el uso de terminaciones o accesorios especializados. La elección depende en gran medida del tipo de cable y la aplicación prevista.

¿Con qué frecuencia debo reemplazar mi cuerda de grúa sintética?

La frecuencia de reemplazo depende del desgaste. Si observa algún daño grave o una elongación notable que supere los límites aceptables, es momento de reemplazarlo.

¿Cuál es el impacto del agua salada en las cuerdas de grúa sintéticas?

Aunque muchos materiales sintéticos están diseñados para ser resistentes, la exposición prolongada al agua salada puede debilitar algunas fibras. Es fundamental limpiar e inspeccionar periódicamente las cuerdas utilizadas en entornos marinos.

¿Puedo obtener una cuerda de grúa sintética fabricada a medida de Duracordix?

- Coloca los vehículos: Asegúrate de que ambos vehículos estén en línea recta y uno frente al otro con una distancia mínima entre ellos.

- Coloque la correa de remolque: Pase un extremo de la correa por un punto de anclaje del Vehículo A y fíjela firmemente con conectores adecuados, como ganchos o anillos en D. Repita el procedimiento para el Vehículo B, asegurándose de que todas las conexiones estén seguras antes de comenzar a remolcar.

¿Cuáles son los beneficios de utilizar cuerdas de grúa sintéticas trenzadas?

Los diseños trenzados mejoran la resistencia y flexibilidad general de la cuerda. Además, ofrecen una resistencia superior a la abrasión y distribuyen el peso uniformemente, lo que las hace ideales para situaciones de levantamiento exigentes.