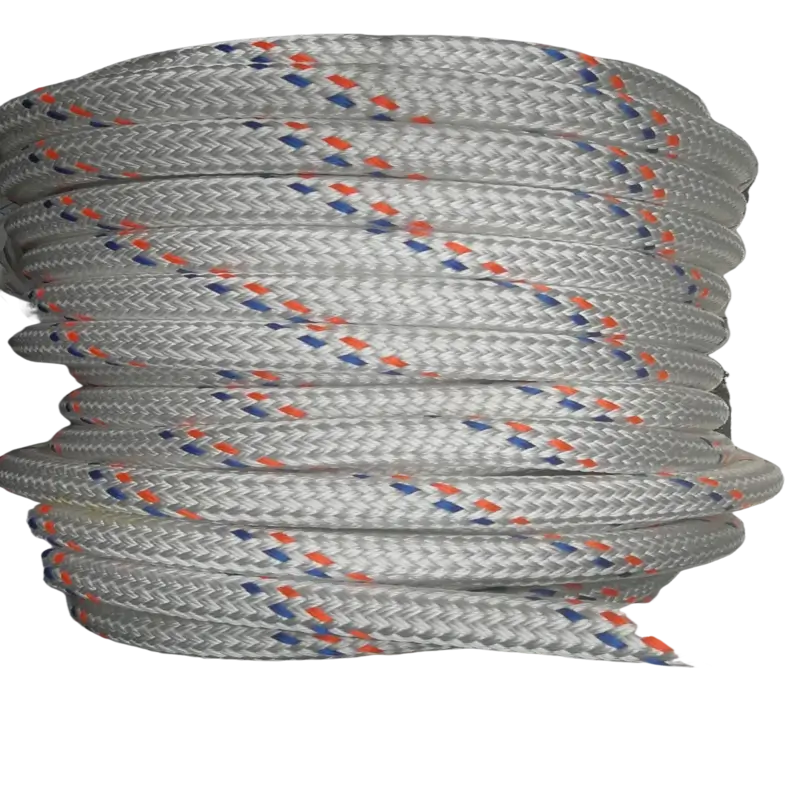

crane rope

Syntheitc crane rope

Synthetic crane rope is a type of rope specifically designed for use in cranes and lifting applications. It is made from high-performance synthetic fibers –UHMWPE (Ultra-High Molecular Weight Polyethylene). As an alternative to steel wire crane rope.

- Lighter Weight

- Higher Strength-To-Weight Ratio

- Improved Safety

- Reduced Maintenance Requirements

Table Of Contents For This Page

To ensure easy access to the information you need, we’ve created this table of contents that will take you directly to the relevant section when clicked

- Customer's favorite

Hot Selling sizes

Industry Favorites: Most-Popular Diameters of Duracordix Crane Ropes

12mm

A versatile size that offers a balance of strength and flexibility, making it suitable for a range of medium-duty lifting applications.

24mm

Designed for heavier-duty applications. Balances length and strength, suitable for larger vehicles or scenarios needing more reach.

32mm

Designed for extreme lifting in shipbuilding, major construction, and large-scale mineral extraction industries.

Duracordix is a synthetic crane rope manufacturer & Supplier in China.

we can produce various sizes for different applications and custom made for special projects.

No matter you’re looking for a wholesale supplier or custom made snatch strap, we can all help. contact Duracordix now.

- sizes available

SPECIFICATION

Explore the Specifications of our Crane Rope For Your Application

| DIAMETER | DIAMETER | WEIGHT | KETX | KETX | BREAKING STRENGTH | BREAKING STRENGTH |

|---|---|---|---|---|---|---|

| mm | inch | 100m(kg) | standard | error | ton | kn |

| 6 | 1/4 | 1.7 | 23 | 5% | 3.1 | 31 |

| 8 | 5/16 | 4.1 | 40 | 5% | 6.35 | 63 |

| 10 | 13/32 | 6.1 | 61 | 5% | 9.3 | 93 |

| 12 | 1/2 | 8.8 | 87 | 5% | 12.12 | 121 |

| 14 | 9/16 | 12 | 119 | 5% | 15.4 | 153 |

| 16 | 5/8 | 15.5 | 151 | 5% | 20.6 | 205 |

| 18 | 3/4 | 19 | 190 | 5% | 23.9 | 238 |

| 20 | 13/16 | 23 | 225 | 5% | 28.99 | 289 |

| 22 | 7/8 | 28 | 276 | 5% | 33 | 322 |

| 24 | 1 | 37 | 368 | 5% | 38 | 371 |

| 28 | 1-1/8 | 50 | 490 | 5% | 57.5 | 562 |

| 32 | 1-5/16 | 62.5 | 621 | 5% | 68.5 | 671 |

Note: other sizes are available upon request.

- VS STEEL WIRE ROPE

Advantages Advantages OF crane rope

Discover The Benifits of Duracordix Synthetic Over Traditional Steel Wire

Weight Reduction

Duracordix synthetic crane ropes are significantly lighter than steel wires, ensuring easier handling, reduced transportation costs, and faster rigging processes.

Safety

Duracordix ropes have a softer touch and no risk of wire splinters, reducing hand injuries and enhancing user comfort during operations.

Corrosion Resistance

Unlike steel, our synthetic ropes are immune to rust and corrosion, particularly in marine and harsh environments, ensuring extended lifespan and reliability.

Flexibility & Strength

Our synthetic ropes provide a high strength-to-weight ratio, ensuring superior load-bearing while remaining flexible, reducing wear and maximizing durability.

- Happy Clients

What They Said

Voices of Trust: Real Experiences with Duracordix Ropes

- Pain-free purchase

WHY CHOOSE

DURACORIDX CRANE ROPE

- High-Performance: Duracordix crane rope guarantees 99.8% reliability, providing unmatched tensile strength for critical lifts and reducing breakage concerns.

- Weather-Resistant: Built to endure, our rope resists 95% of UV and environmental damages, ensuring extended lifespan even in harsh conditions.

- Cost-Effective: Achieve top-tier quality without overspending. Duracordix offers a 20% better ROI, combining exceptional durability with competitive pricing.

- Versatile Use: Suitable for diverse environments, our ropes meet 90% of industry-specific lifting needs, ensuring adaptability and convenience.

- Unwavering Support: Benefit from our 20 years of expertise. Duracordix provides continuous support, making us your dependable lifting partner.

- we make more

Related products

Beyond the Basics: Discover More in Our Crane Rope Range

Lightweight yet strong, these slings offer durability and flexibility, ideal for varied lifting applications.

Circular in design, it ensures an even weight distribution, optimizing security and handling ease.

Flat-woven for stability, it combines load-bearing strength with reduced surface pressure on lifted items.

FAQs

Addressing Common Queries: Synthetic Crane Rope Insights

what is synthetic crane rope?

Synthetic crane ropes, made from materials like UHMWPE or nylon, are lightweight, corrosion-resistant, and flexible. Their ease of handling and longevity make them a preferred choice over traditional steel wires in heavy lifting industries.

How do I inspect my crane rope for signs of wear or damage?

Routine inspections are pivotal. Look for external damage like cuts, fraying, or abrasions. Internally, check for broken fibers or inconsistencies in the rope structure. Document all findings and replace the rope if damages seem severe.

What is the main advantage of synthetic crane rope over traditional steel?

Synthetic crane ropes are revered for their superior strength-to-weight ratio. This means they can handle heavy loads while being lighter, reducing transport and handling challenges. Additionally, they don't corrode like steel and are resistant to many environmental factors.

How long can I expect my synthetic crane rope to last?

Synthetic crane ropes' lifespan largely depends on their usage frequency, the environment, and maintenance. With proper care and under normal operating conditions, they can last several years.

Are there specific maintenance guidelines for synthetic crane ropes?

Absolutely. Ensure you store them properly away from direct sunlight and harsh chemicals. Regular cleaning and inspection are crucial. It's also important to avoid overloading and to use correct tensioning techniques.

How do synthetic crane ropes compare in strength to steel wires?

Synthetic crane ropes made from high-performance materials can offer comparable, if not superior, tensile strength than steel. Plus, they have the added benefit of being lightweight and non-corrosive.

What safety guidelines should I follow while using crane ropes?

Always respect the rope's weight limits and undergo regular inspections. Proper tensioning is a must. Adherence to the manufacturer's guidelines on usage, storage, and maintenance ensures optimal safety.

How do I determine the correct diameter for my crane rope?

The ideal diameter is influenced by the crane's capacity, your specific lifting needs, and the manufacturer's recommendations. Always ensure adherence to industry and safety standards.

Steel vs synthetic crane rope: which is more durable?

While steel is inherently strong, synthetic ropes have the advantage when considering resistance to corrosion, UV damage, and environmental wear. Synthetics often showcase longer functional durability in various conditions.

What precautions are necessary when handling crane ropes?

It's crucial to use gloves, ensure ropes are free from knots or kinks, maintain proper tensioning, and store in a location free from potential damage sources like sharp objects or chemicals.

How should crane ropes be stored?

A cool, dry place is ideal. Avoid areas with direct sunlight, harsh chemicals, or sharp objects. If storing outdoors, use protective covers and ensure adequate ventilation.

What techniques are recommended for crane rope tensioning?

Adherence to the manufacturer's guidelines is pivotal. Ensure even loading, avoid shock loads, and always follow best practices to ensure both safety and rope longevity.

Are there any indicators to check crane rope wear?

Yes, any visible thinning, broken fibers, excessive stretching, or notable deviations from the rope's original structural integrity should be addressed immediately.

How is crane rope elongation measured?

By comparing the rope's length under a specific load against its original length, one can determine elongation. Regular monitoring is key to detect unsafe elongation levels.

What common issues are associated with crane ropes?

These include fraying, abrasions, kinking, tension inconsistencies, and damage from UV rays or harsh chemicals. Proper care and maintenance can mitigate many of these issues.

Are there specific methods for terminating or splicing crane ropes?

Various methods exist, such as braided splicing, adhesive bonding, or utilizing specialized terminations or fittings. The choice largely depends on the rope type and intended application.

How often should I replace my synthetic crane rope?

Replacement frequency hinges on wear and tear signs. If you observe any severe damage or notable elongation beyond acceptable limits, it's time for a replacement.

What's the impact of saltwater on synthetic crane ropes?

Although many synthetic materials are designed to be resilient, prolonged exposure to saltwater can weaken some fibers. It's essential to clean and inspect ropes used in marine environments regularly.

Can I get a custom-fabricated synthetic crane rope from Duracordix?

- Position the vehicles: Ensure both vehicles are in a straight line and facing each other with minimal distance between them.

- Attach the tow strap: Loop one end of the strap through an anchor point on Vehicle A, secure it tightly using appropriate connectors like hooks or D-rings. Repeat for Vehicle B, ensuring all connections are secure before towing begins.

What are the benefits of using braided synthetic crane ropes?

Braided designs enhance the rope's overall strength and flexibility. They also provide superior resistance to abrasion and distribute weight evenly, making them optimal for challenging lifting scenarios.