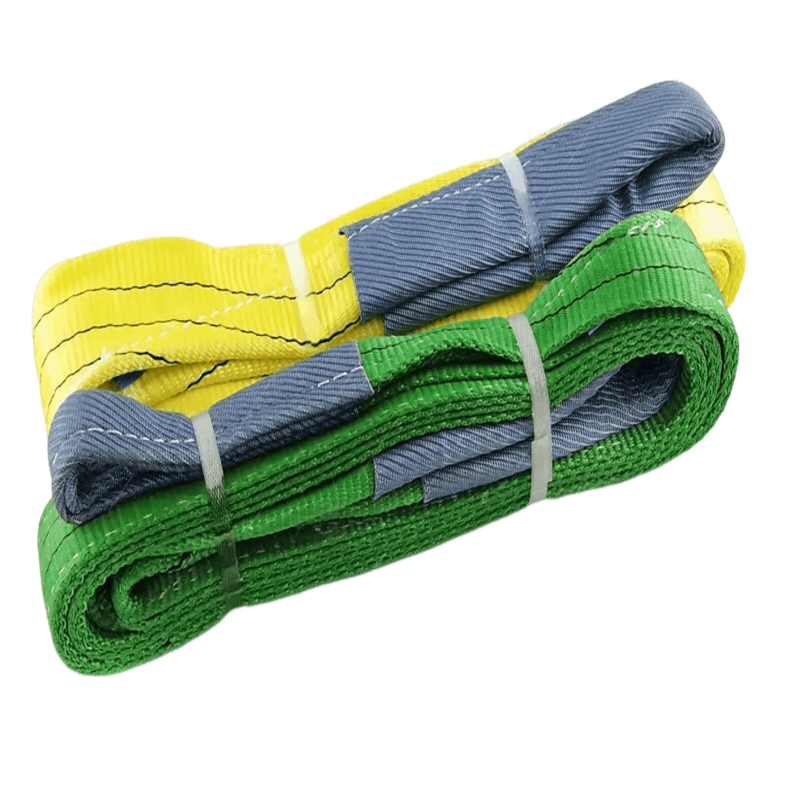

EYE & EYE LIFTING SLING

Strong. Reliable. Safe. UHMWPE Lifting Sling For Your Demanding Applications

What Is An Eye & Eye Lifting Sling?

Our Eye & Eye Lifting Sling is a high-performance lifting sling made from UHMWPE(ultra-high molecular weight polyethylene), typically covered with a abrasion-resistant polyester sheath or jacket. Each end has a reinforced eye, allowing it to connect with hooks, shackles, and the lifted objects.

It is widely used in cargo handling, mining, wind energy, offshore oil and gas, and construction industries for lifting your large, heavy equipments and irregular objects.

General Applications

Provide Real-World Solutions, Engineered for Your Industry’s Needs

- quality control

- sizes available

Sling Capacity Chart

Find The Perfect Sizes Of Lifting Sling for Your Unique Needs!

| Rope Diameter mm | Rope Diameter inch | Working Load(UHMWPE)Vertical | Working Load(UHMWPE)Choker | Working Load(UHMWPE)Basket | Color |

|---|---|---|---|---|---|

| mm | inch | Vertical | Choker | Basket | |

| 11 | 7/16 | 3,260lbs(1.48t) | 2,600lbs(1.18t) | 6,520lbs(2.96t) | any |

| 14 | 9/16 | 4,850lbs(2.20t) | 3,880lbs(1.70t) | 9,700(4.40t) | any |

| 16 | 5/8 | 6,400lbs(2.90t) | 5,120lbs(2.30t) | 12,800lbs(5.80t) | any |

| 18 | 3/4 | 7,500lbs(3.40t) | 6,000lbs(2.72t) | 15,000lbs(6.8t) | any |

| 22 | 7/8 | 10,390lbs(4.70t) | 83,00lbls(3.76t) | 207,800lbs(9.4t) | any |

| 24 | 1 | 11,900lbs(5.40t) | 9,520lbs(4.32t) | 23,800lbs(10.80t) | any |

| 28 | 1 1/8 | 18,000lbs(8.16t) | 14,400lbs(6.50t) | 36,000lbs(16.32t) | any |

| 32 | 1 5/16 | 242,000lbs(11.00t) | 19,395lbs(8.80t) | 484,000lbs(22.00t) | any |

| 36 | 1 1/2 | 286,500lbs(13.00t) | 22,920lbs(10.50t) | 573,000lbs(26.00t) | any |

Note: our slings can be custom-made with a Working Load Limit (WLL) up to 3000 tons or more

Vertical Lift: to suspending your object directly beneath the sling and lifting it vertically. Simple to for operate and provides high stability.

Choker Lift: involves passing one end of the sling through the other end of the load, creating a loop that tightly secures the load. Used for lifting irregularly shaped loads, but the sling’s load capacity is only 70% to 80% of that of a vertical lift due to the angle and pressure points

Basket Lift: it uses two slings attached to two points on the load, forming a basket-like structure. It provides better stability, reduces the risk of tilting, and is suitable for loads of various shapes and sizes. The lifting capacity can be up to twice that of a vertical lift.

- OEM service

Customization Options

Duracordix provide custom options to meet your unique lifting/rigging needs

1. Customized Lengths and Diameters: we can provide precise-sized HMPE/UHMWPE slings tailored to your load requirements based on your specific application, eliminating the need for unsafe adjustments or modifications.

2. Color Coding: we can customize colors for easy identification and apply special coatings tailored to your needs to enhance the sling’s performance in your unique application

3. Custom Load Capacities: we will produce custom slings based on your lifting weight, considering the safety factor, so you can use them directly.

4. Branding: we can create custom labels for you, including your logo, product information, safety warnings and else.

5. Extra Protection: for harsh, chemical, or outdoor environments, our custom-made corner guards(lifting sling protector) enhance wear resistance and are designed for long-lasting use.

6. Compatible with Accessories: the size of both eyes can be customized to ensure compatibility with hooks, shackles, or other lifting equipment connections.

Advantages

Main benefits compare to wire rope slings, chain slings, lifting straps and webbing sling

Lightweight

The weight of the UHMWPE lifting sling is only 1/8 or even lighter than traditional wire rope slings and chain slings, making it very easy to handle and operate in heavy-duty lifting tasks.

High Strength

Our lifting sling is not only lightweight but also offer higher lifting capacity than webbing slings and wire rope slings. Its increased strength reduces your need for labor and time, ensuring the safety of your operators as well

Flexibility

Our lifting sling offers you better flexibility compared to traditional polyester webbing slings and rigging straps, making it more adaptable to various scenarios, especially in your heavy-duty lifting and handling irregular objects.

Durability

Our UHMWPE slings, with a high-density polyester jacket, are resistant to rain and certain chemicals, Unlike chain sling and wire rope slings, it won't rust over time, offering enhanced durability & wear resistance in harsh environments

Improved Safety

Our lifting sling, compared to traditional wire rope and chain slings, is made from softer materials, reducing friction when in contact with equipment and other objects. This directly minimizes wear on the equipment and reduces the load during lifting

Higher Efficiency

Due to the lightweight construction and flexibility of the UHMWPE lifting sling, it allows for faster and easier setup and hook positioning compared to traditional slings, reducing pre-operation time, lowering costs, and improving overall lifting efficiency

Reduced Maintenance

Due to its excellent UV resistance and low elongation, the HMPE sling is more wear-resistant, durable, and rust-free in harsh working environments compared to wire rope sling & lifting sling strap. so it has a longer service life and lower maintenance costs

Sustainability

UHMWPE slings are eco-friendly, with a long lifespan and low carbon footprint, making them ideal for oil, gas, mining, and wind energy projects. Traditional synthetic materials have a greater environmental impact.

- Happy Clients

Client Voice

Duracordix's heavy lifting sling has been a game-changer for our construction projects. It's not just strong; it's incredibly reliable. We trust Duracordix to keep our teams safe."

- Easy & Fast Instruction

How To Use

1.Choose Right Size: Choose a lifting sling with the appropriate tonnage and length based on the working load requirements. Carefully inspect the label on the sling to confirm that its working load limit (WLL) can safely support the weight of the load being lifted

2. Check: Synthetic slings must be inspected for any tears or severe signs of wear. If any are found, stop using the sling and replace it. Check both ends of the eyes and hooks; the eyes should not have any tears, and the hooks should not be deformed or broken.

3. Choose the appropriate lifting method: Common lifting methods include Vertical Lift, Choker Lift, and Basket Lift. Select the most suitable lifting method based on your specific application.

4. Correctly position the sling: Attach the sling to the load-bearing object according to the required lifting method, ensuring even distribution of force and maintaining balance. The sling should not shift during the lift. For irregularly shaped loads, use clamps to secure the load.

5.Connect the sling to the lifting equipment: Attach the eye loops to the connection points of the lifting equipment. Ensure that the load is lifted in a straight line to prevent the sling from tangling or crossing during the lift.

6.Lifting and unloading: Conduct a test lift to ensure load stability. Once stable, slowly lift the load while maintaining balance. After reaching the desired position, unload the load slowly. Inspect the sling connection points and rope surface for cracks or damage, and perform necessary repairs or replacements

Warning: Never exceed the working load limit. Regularly inspect the sling to ensure its proper condition. Train operators and strictly follow the operating procedures. Unauthorized operations are prohibited.

FAQs

Answers to Your Questions About UHMWPE/HMPE Lifting Sling

What are the main types of lifting sling based on material?

Based on material, the lifting sling can be in polyester webbing sling, wire rope sling,chain sling,uhmwpe/dyneema sling( eye & eye lifting sling, endless round sling) etc

Do you have lifting sling identification tag on it?

Yes, we have inspection tags on our lifting slings. The tags display information such as our logo, manufacturer name, working load limit (WLL), length, warnings, and other relevant details.

can you make the lifting sling protector for it?

Yes, we can make protection sleeves for critical areas of the lifting sling, such as the eyes or wear-prone parts. Made from HD polyester, these sleeves can be customized to size based on requirements. They help prevent cuts and damage to the sling, extend its lifespan, and enhance safety during operations.

How To do the lifting sling storage?

Cleaning and Drying: Clean the sling to remove dirt, grease, or chemical residues, and dry it thoroughly to prevent mold growth.

Storage Environment: Store in a cool, dry place, avoiding direct sunlight or damp conditions to prevent damage to the fibers.

Proper Hanging and Storage: Hang the synthetic sling vertically on a dedicated rack, and if coiled, ensure it is loosely wound.

Regular Inspection: Inspect the sling every 3 to 5 months for any signs of damage or fraying to ensure safe use for the next operation.

What's the safety factor for lift sling?

According to international standards, ISO 10567: 2005, the safety factor for lifting slings is 7:1. The safety factor specified by the American ASME B30.9 is 5:1. According to European standards EN 1492-1 and EN 1492-2, the safety factor is 7:1. In Australia, AS 4497: 1997 specifies a safety factor of 6:1, while in China, GB/T 21659-2008 stipulates a safety factor of 5:1.

Can you make the lifting sling with hooks?

Yes, we can manufacture lifting slings with both eyes, as well as lifting slings with hooks or shackles (steel shackle or soft shackle) to suit your specific application needs.

how to shorten a lifting sling?

These are added protective materials to reduce wear and tear on the sling, especially when lifting objects with sharp edges.

What's the main applications for lifting sling?

The eye and eye lifting sling is versatile and can be used across various industries such as construction, shipping, warehousing, heavy industry, oil and gas, offshore operations, and mining. It is suitable for crane lifting, cargo handling, heavy equipment lifting,engine lifting sling, rigging for offshore applications, mining equipment lifting, boat lifting, wind turbine installation, and more

Can you also make slings with other material?

Yes, we can also manufacture slings made of nylon and polyester. Additionally, we offer other types such as flat lifting slings, webbing slings, shackle slings, and more.

what is the biggest WLL of your heavy duty lifting sling can you make?

We can manufacture heavy lifting slings using UHMWPE (also known as Dyneema or HMPE), the strongest fiber in the world. Our slings can achieve a maximum Working Load Limit (WLL) of 3000T or more

Why is chemical resistance vital for synthetic slings?

Certain chemicals can degrade synthetic fibers, compromising the sling's integrity and safety.

Lifting Sling or Rigging Strap:which one should I choose?

Our lifting sling is made of UHMWPE (Dyneema), offering extremely low elongation and strong corrosion resistance, making it ideal for precise heavy-duty lifting operations that require high safety standards, such as in construction and offshore oil and gas environments.

In contrast, rigging straps are typically made of polyester, which offers better elongation but lower strength. They are usually equipped with hooks and eyes at both ends and are commonly used for securing or stabilizing loads, but their load-bearing capacity is not as high as that of the HMPE lifting sling.

Can your synthetic fiber slings be compatible with other accessories?

Our synthetic fiber sling can be customized to fit various accessories based on your specific needs, such as steel shackles, hooks, protective sleeves for the eyes, soft shackles, thimbles, or rings.

rope round sling vs rope lifting sling, what's their difference?

A synthetic rope sling is made from high-performance synthetic fibers such as UHMWPE, typically using a double-braided construction or a single-braid with a protective sleeve. Its core structure is rope-based and usually features eye loops at both ends, allowing compatibility with various lifting accessories. This type of sling is particularly suited for lifting and securing large equipment and heavy objects.

In contrast, a rope round sling consists of a core made from high-strength fiber bundles such as UHMWPE, encased in a double-braided outer cover. It forms a continuous loop with a closed circular shape, where only the inner core bears the load. Extremely flexible, it is ideal for gentle lifting of cylindrical objects and delicate equipment that require surface protection.

What role do sling accessories play in lifting operations?

Sling accessories, like hooks or connectors, enhance versatility and compatibility. They ensure secure attachments, aiding in load control and maximizing safety during lifts.

How do environmental conditions affect synthetic sling performance?

Temperature, moisture, and chemical exposure can degrade synthetic materials. A sling's performance may diminish if not suited to its working environment, emphasizing the importance of material choice.

Why are sling loops and spliced ends critical in lifting?

Sling loops and spliced ends are designed to distribute stress and prevent wear, offering secure attachment points and extending the sling's service life.

Why is training and safety paramount when using synthetic slings?

Proper training ensures users understand load limits, sling angles, and inspection criteria. It minimizes risks, promotes best practices, and guarantees that lifting operations remain accident-free.

How does "load balancing" impact the efficiency and safety of lifting operations using synthetic slings?

Load balancing ensures even weight distribution across the sling. It prevents undue stress on one section, reducing the risk of breakage and ensuring safer and more stable lifting.

- We Make More

Related products

Explore our Range of Related Products Of Lifting Sling for Enhanced Performance