- Unique For Your application

Your High PerformanceSynthetic Rope & Nettingsupplier

Engineered High-Performance Synthetic Fiber Solutions to Replace Steel Wire

- what we focus

High-Performance Synthetic Rope & netting to meet your Need

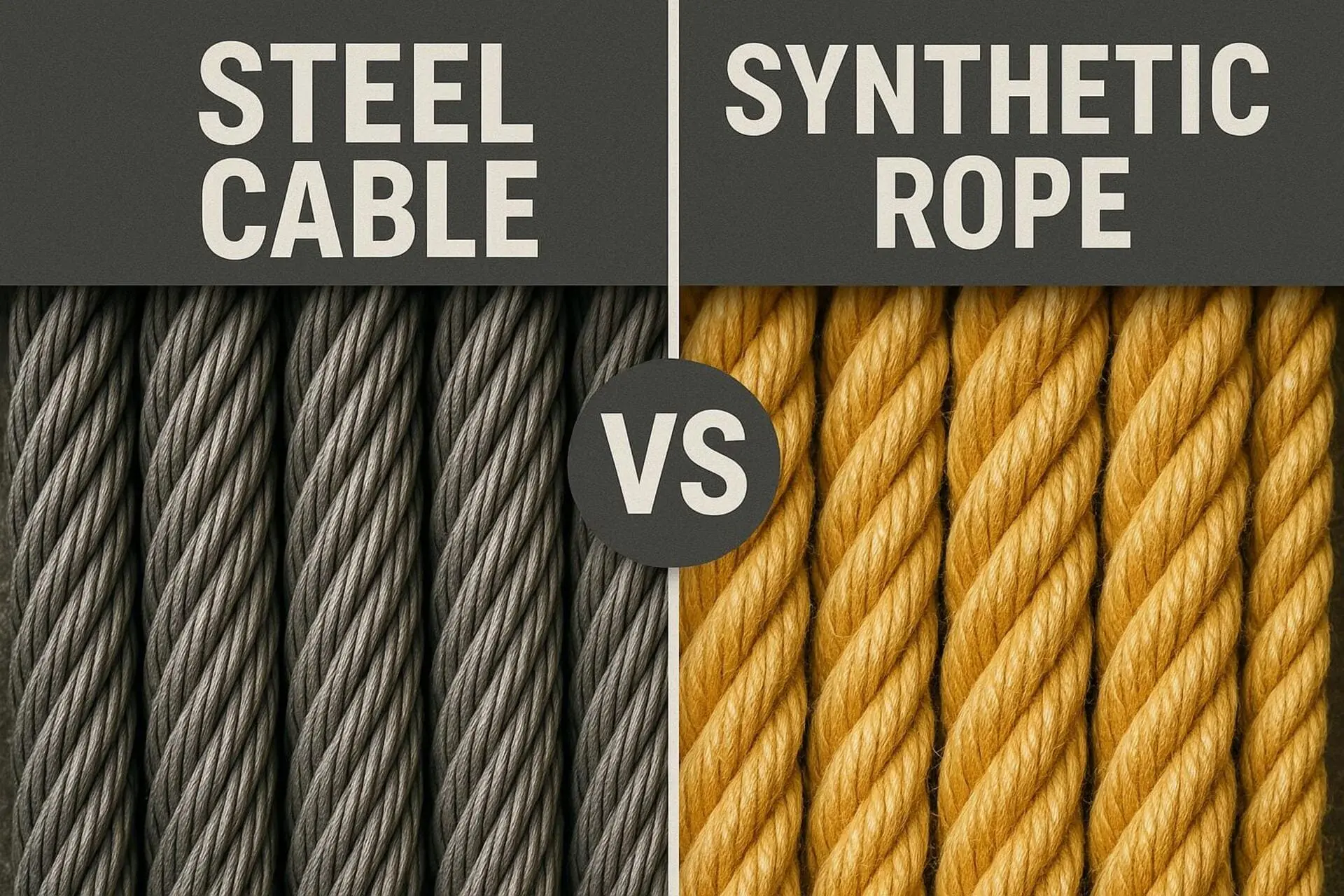

- VS Steel Wire Rope

why synthetic rope

Discover the Superior Advantages!

safer

Unlike steel wire rope, Duracordix synthetic rope reduces kinking and rebound by 80% and never rusts. It reduces hand injuries and rebound, thus improving safety, and you don't need to worry about corrosion.

lighter

Compare to steel wire, UHMWPE ropes are lighter 85% of steel wire in same diameter. It makes them easier to handle, transport, and store. Also, it increase your operation efficiency compared to steel wire.

stronger

At same material weight, HMPE rope has a tensile strength 10 times greater than steel wire. The high tensile strength makes it better suited for your lifting, towing, mooring & offshore operations, providing a safer solution.

- Solving Your Pain Points

Flexible Applications

Outdoor Sports

offroad,sail,camping

Construction

lifting ,hoisting and rigging

Agriculture

Equipment,machinery securing

Entertainment

Stage and theater rigging

OEM & Design

Custom solutions crafted for your unique applications and needs, ensuring peak performance every time.

- Customized Specs: Modify rope's length, diameter, strength to fit unique needs, optimizing application performance.

- Design for Use: Ropes specialized for off-road, marine, offshore, fishing, military, and construction applications.

- Color & Branding: Select diverse colors, embed your logo or brand for increased visibility.

- Packaging: Choose standard/custom packaging for safety, aligning with your brand ethos.

- Strand & Design Customization: Opt for varied strand configurations, eyes, loops, and unique accessories, ensuring ropes meet specific client needs flawlessly.

- Comprehensive Testing: OEM ropes undergo thorough tests, ensuring durability, strength, and global standards compliance.

Certifications-- Duracordix Offer

step inside Duracordix

Duracordix provides you engineered synthetic rope and netting solutions by integrating material expertise, rope design, and controlled manufacturing partnerships.

We‘re serving sectors like marine, offshore, off road recovery, fishing, military etc, we focus on performance where failure is not an option.

Rather than mass production, we emphasize application understanding, specification accuracy, and delivery accountability. Every product reflects our commitment to long-term reliability and real-world performance.

At Duracordix, we don’t position ourselves only by factory size — we are defined by the responsibility we take and the trust we build with you- our customers.

- Happy Clients

What They Said

Voices of Trust: Clients Share Their Experiences with Duracordix’s Ropes.

- Our Advantages

why duracrodix

Duracordix Excellence: The Gold Standard in Synthetic Rope & Netting Solutions

FAQS

Your Guide to Duracordix Products, Services, and Support

What is Duracordix?

Duracordix is a professional supplier and solution provider of high-performance synthetic ropes and nets. We work closely with qualified manufacturing partners and specialized factories to deliver products made from UHMWPE, Kevlar, nylon, polyester and more for you.

By focusing on your specific application requirements, we provide tailored rope and netting solutions that address real operational challenges. From material selection and customization to quality control and logistics, Duracordix acts as a reliable long-term partner—growing together with our customers and supporting their success.

What types of synthetic rope products does Duracordix offer?

Duracordix offers a wide range of high-performance synthetic ropes, including UHMWPE rope, Kevlar rope, nylon rope, polyester rope, and polypropylene rope etc. all designed to replace traditional steel wire ropes.

Based on your specific applications, Duracordix provides specialized ropes such as winch ropes, kinetic recovery ropes, mooring ropes, lifting slings, tug towing lines, dock ropes, and round slings. We also offer customization services to meet your individual needs and ensure the perfect fit for your application.

What are the advantages of Duracordix's synthetic ropes?

Duracordix's synthetic ropes offer several key advantages:

1.High Strength-to-Weight Ratio

For example, UHMWPE and Kevlar ropes not only have extremely high break strength but are up to 80~85% lighter than traditional steel ropes in same diameter, making them easier for you to handle.

2.Low Elongation

For instance, UHMWPE ropes have an elongation rate of only 3-5%, making them ideal for lifting and rescue applications that require precise control, providing you with greater accuracy and safety.

3.Corrosion Resistance

Synthetic ropes are highly resistant to corrosion, making them perfect for use in harsh environments. They do not rust and are more durable than steel ropes, offering you a longer lifespan and lower maintenance costs.

4.Flexibility and Safety

Compared to steel ropes, Duracordix's synthetic ropes, even when they break, do not produce dangerous recoil, significantly reducing the safety risk to operators. They are also soft, easy to handle, and highly flexible, which allows you to work more efficiently and safely.

5.Customization

We can customize the color of the ropes, provide special coatings, and offer different diameters and lengths based on your specific requirements. We also offer tailored solutions to meet your unique needs.

Do Duracordix products have any certifications?

Yes — Duracordix's products can be supplied with ISO and CE certifications.

We can also provide approval from various ship classification societies such as:

- China Classification Society (CCS)

- American Bureau of Shipping (ABS)

- Lloyd’s Register (LR)

- Bureau Veritas (BV)

- Korean Register of Shipping (KR)

- RINA – Registro Italiano Navale (RINA)

and others.

What types of fishing net does Duracordix provide?

Here are the types of fishing nets that Duracordix provides:

Ultra‑fishing nets made of UHMWPE (Ultra High Molecular Weight Polyethylene) fiber.

Traditional Netting like Nylon fishing netting, polyester fish netting, and polyethylene (PE) fishing net etc.

We also provide you knotted and knotless netting based on your specific needs.

How does Duracordix ensure product quality?

1. Incoming Inspection

Raw Materials Duracordix use the best high polymer raw materials from Beijing Tongyi, with monofilament denier reaching 1600D, which is rated at 35 or 36, while other suppliers' materials only reach 31 or 32. Our material offers 15% higher tensile strength than others. Its excellent color penetration increases the penetration rate by 20%, significantly improving the rope's overall performance. The denier of our raw materials is very precise, with no discrepancies, ensuring high-quality final products.

- Monofilament Testing

Each batch of monofilament is rigorously sampled, and a one-meter section is tested. If it does not meet standards, it is immediately returned. Our strict monofilament testing ensures consistent and excellent quality in the finished rope. Inspection Process

Duracordix production equipment is equipped with an automatic error-proofing and alarm system to ensure that any issues are immediately addressed by replacing defective strands. After the alarm is cleared, production resumes. Before coating, we ensure that the rope is free of burrs and broken strands, and we conduct a visual inspection to ensure the glue is evenly applied and there are no defects. Before packaging, we inspect the integrity of knots and the rope's appearance for any flaws. Only when everything is in perfect condition is the rope packaged, and the appropriate labels and shipping marks are applied.

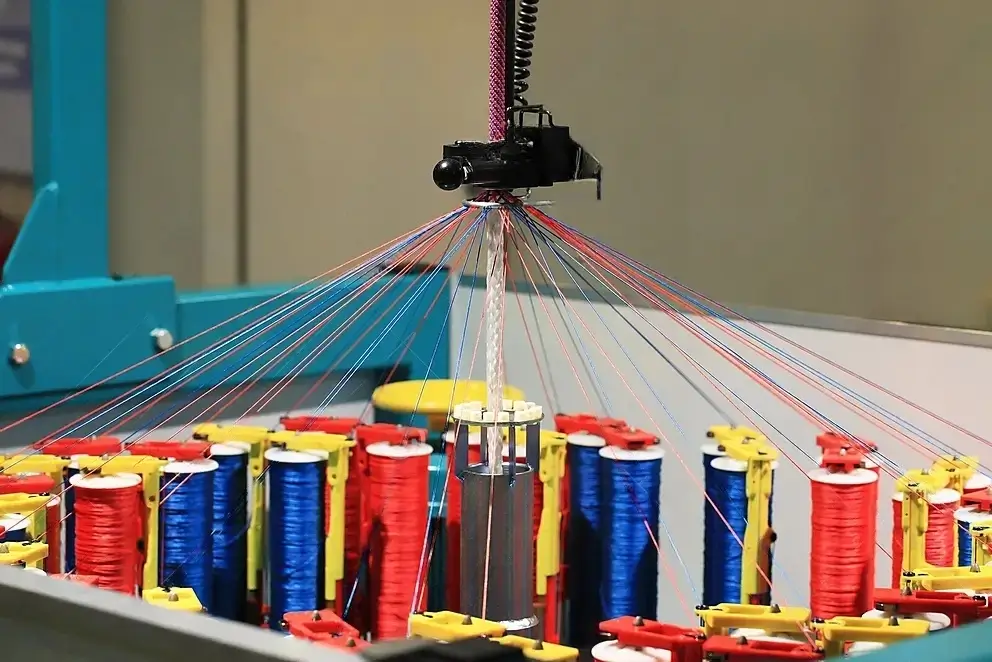

2. Rope Manufacturing Process

To optimize the manufacturing process, we’ve made several improvements that ensure the quality of the rope, particularly its tensile strength, corrosion resistance, and abrasion resistance. The specific improvements include:

Before the twisting process, each monofilament is passed through a tensioner to improve the uniformity of the rope under load and increase overall strength.

Prior to twisting, each monofilament is pre-stretched by 3~4%, which further enhances the final strength of the rope.

During rope production, we use a Programmable Logic Controller (PLC) to precisely control the twisting process, boosting the rope’s strength by 2~3%.

After the rope is formed, we apply a pre-stretch of 10~15% during the traction process to enhance tensile strength and flexibility.

3. Coating Process

We use a specially selected high-performance glue, which offers excellent penetration and adhesion, ensuring outstanding performance. Compared to other manufacturers, our glue has several advantages:

Extended Color Retention: The glue significantly slows down the fading process, maintaining the rope's brightness for a longer time.

Rope Brightness: The glue enhances the rope's gloss, ensuring a long-lasting shiny appearance.

Improved Abrasion Resistance: With superior penetration, the glue enhances the rope's durability, extending its service life.

Better Fatigue Resistance: The glue treatment improves the rope's resistance to fatigue, making it more durable and longer-lasting.

4. Rope Drying Process

Our rope drying process uses temperature-controlled drying technology to ensure uniform drying:

Uniform Drying: By using air-conditioned temperature-controlled drying, we ensure the rope dries evenly, enhancing its overall performance and quality.

Roller Drying Machine: We utilize roller drying machines to ensure that the glue is evenly adhered, the color is uniform, and the drying time is shortened, which boosts production efficiency.

5. Packaging Process

Duracordix offers differentiated packaging options that include:

Custom Logo and Labels: We provide personalized logo design and label printing services, enhancing brand recognition.

Color Box and Wooden Pallet Packaging: We offer high-end color box packaging or wooden pallet packaging, ensuring that products are well protected during transportation and storage, while also elevating the product's presentation.

These optimizations and detailed improvements ensure that Duracordix ropes excel in tensile strength, corrosion resistance, and abrasion resistance, ultimately enhancing product quality and improving your customer experience.

Is Duracordix a factory?

Duracordix is not a single factory. We are a professional synthetic rope and netting supplier and solution provider working closely with qualified manufacturing partners and specialized factories.

Our role is to integrate material expertise, application knowledge, quality control, and reliable delivery. It ensure you- our customers can receive the right rope or netting solution for their specific requirements. We take full responsibility for product selection, customization, quality control, inspection, and export coordination.

In this way, you can benefit from both professional manufacturing capabilities and a dedicated team focused on consistent quality and long-term partnership.

Which customization services do Duracordix provide?

Yes, we offer a variety of customization services.

For synthetic fiber ropes, we can customize different raw materials, diameters, lengths, colors, various protective Jacket, spliced eyes, and braiding methods (single braided or double braided), as well as coating formulas, to meet your specific needs in various industries.

For netting, we can customize different raw materials, colors, lengths, widths, strengths, mesh densities, braiding methods (knotted or knotless), and coating formulas, to fulfill your unique requirements.

Duracordix can also provide custom-made packaging with your own branding on it.

What are the features of Duracordix's fishing nets?

Duracordix purchase and uses higher-grade raw materials like UHMWPE and nylon fibers to produce fish nettings and netting cages. These high-performce nets offer not only high strength but also excellent tear and abrasion resistance. Their flexibility provides better protection for your fish and and they are particularly designed for harsh outdoor and marine environments.

They can effectively resist UV rays, saltwater, oil, and other chemicals. and also extend the overall lifespan of your fishing nets and aquaculture cages. It helps reduce both operational and replacement costs for you.

Do Duracordix products support global shipping?

Yes, we offer global shipping. Our products are already sold to over 50 countries and regions. Whether you're in Southeast Asia, Europe, North America, South America, Middle East or Australia, we can deliver your goods using sea freight, land transport, rail, or air shipping, ensuring timely delivery to your location.

How can I purchase Duracordix products?

You can submit an inquiry through our online form, contact us via WhatsApp for calls or messages, email us directly at info[@]duracordix.com, or send us your RFQ through our live chat tool.

What is the warranty period for Duracordix products?

Under normal usage conditions and with no human-induced damage, Duracordix provides a one-year quality warranty. However, for some custom products, we offer 3~5years warranty based on the materials used and the specific application scenario.

Blog & News

Introduction Do you need to securely moor your ship? You can find the right rope with this guide. We will talk about various mooring lines for ships. We explore different materials and how ropes are made. With this information, your vessel will stay safe, moreover, your crew will be secure during the entire mooring procedure. […]

Introduction A winch is a mechanical device widely used to pull,lift, or move objects. it rotates to wind or release the rope under force. A winch rope is the rope connected to your winch, and the main types of winch rope in use are steel wire ropes, often called winch wire, and synthetic ropes. But […]

Contact Duracordix

- Privacy is a top priority. We respect and safeguard our clients' confidential information.