軍隊

軍隊

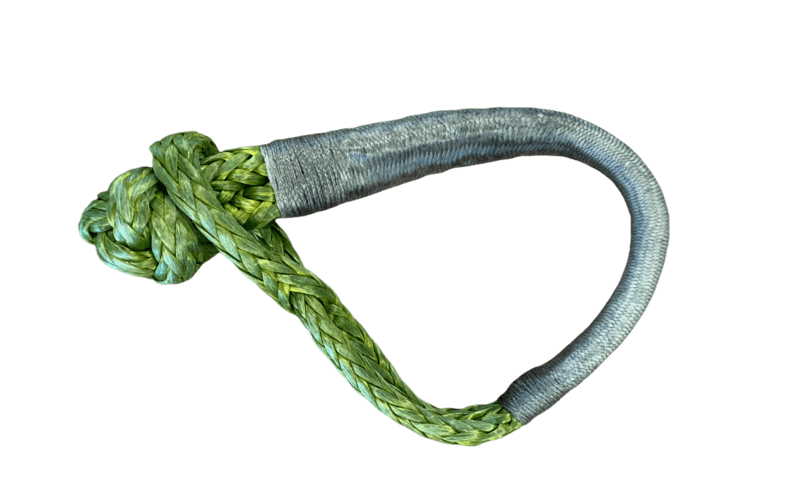

当社は、軍事作戦や戦術的要件に特化した最高級製品を幅広く提供しています。主力製品には、軍用グレードの牽引ストラップ、シャックル、タクティカルトウロープ、耐久性の高いウインチロープなどがあります。

さらに、当社は、ブライドルイコライザーコード、合成戦闘用ロープ、さまざまな戦術ロープアクセサリなど、追加の不可欠な軍事装備も設計・供給し、あらゆる防衛シナリオに最適な備えを確保します。

作り方

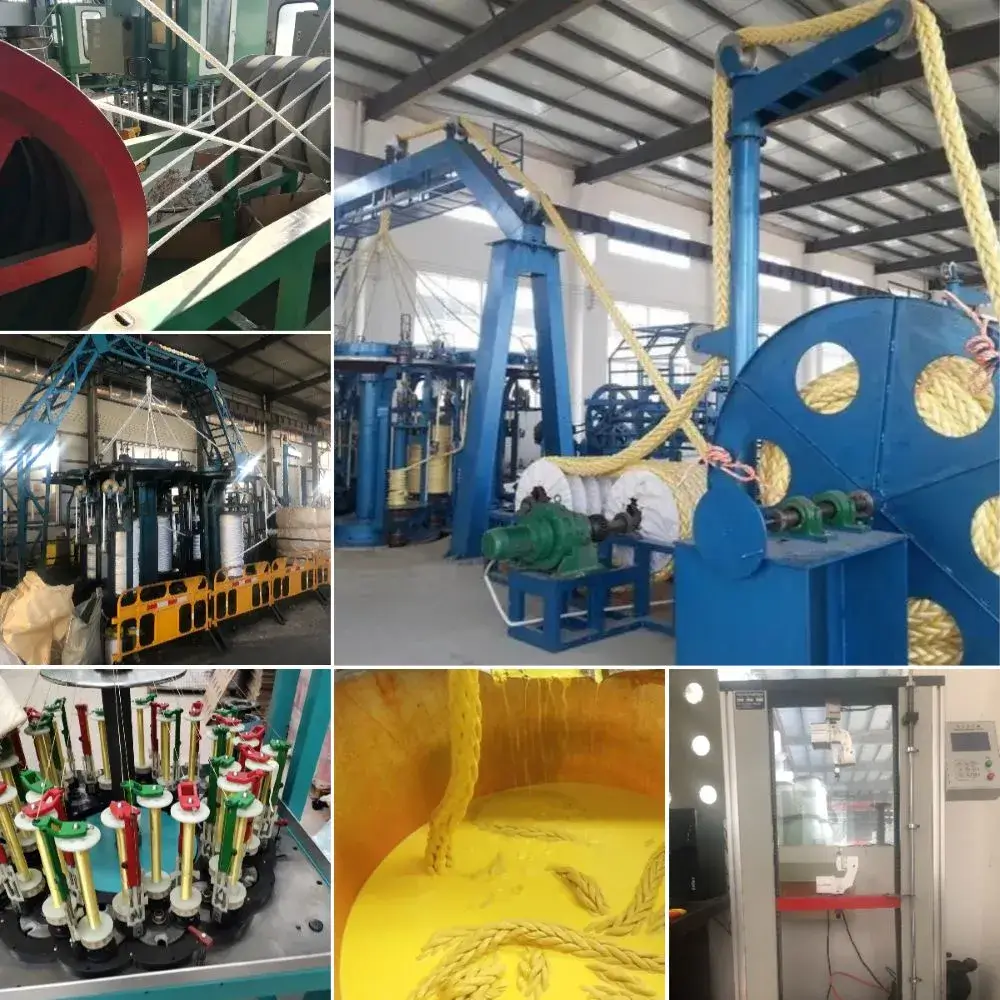

高性能な軍用ロープを製造する当社のプロセスをご覧ください。

プロセス1

繊維の選択

当社では、強度と耐久性を確保するために、ナイロン、ポリエステル、UHMWPE などの高品質の合成繊維を厳選してロープに使用しています。

プロセス2

ねじりと成形

選別された繊維を撚り合わせて糸を作り、さらに撚り合わせてストランドを作ります。そして、撚り合わされたストランドはロープのような構造に形成されます。

プロセス3

敷設と編み込み

形成されたロープは編組機に通され、特殊な技術とパターンを使用してロープが編まれ、強度と耐久性がさらに向上します。

プロセス4

コーティング

ロープの耐久性と摩耗、水、紫外線に対する耐性を高めるために、PVC やポリウレタンなどの高品質の材料で作られたカスタム保護コーティングが施されています。

プロセス5

熱処理と乾燥

編みロープは、編み目を固定し強度を高めるために特殊な熱処理工程を経ます。その後、ロープは乾燥され、水分が除去されます。

プロセス6

テスト

デュラコルディックスのリカバリーロープはすべて、強度と伸縮性に関する当社の高い基準を満たすよう、厳格なテストを受けています。テストプロセスに合格しなかったロープはすべて廃棄されます。

- 品質重視

. 品質管理

あらゆる繊維ロープにおいて比類のない卓越性を保証する方法をご覧ください

1. 原材料

当社の合成軍用ロープは、厳格な品質基準を満たした原材料のみを使用しています。信頼できるサプライヤーと協力することで、すべての製品において一貫した品質と最適な性能を確保しています。

2. 社内

合成ロープの生産を自社で行うことで、製造工程全体を通して品質を徹底的に管理しています。これにより、高い基準を維持し、お客様に信頼性の高い製品を提供することができます。

3. テストと検査

当社の厳格な試験・検査プロセスは、原材料から完成品に至るまで、製造のあらゆる段階に及んでいます。これにより、当社の合成繊維ロープの一貫した品質と安全性が保証されています。

4. 自動化製造

当社では、自動化された機械と技術を導入し、合成ロープ製造における精度と一貫性を確保しています。これにより人為的ミスが削減され、すべての製品が当社の厳格な品質基準を満たすことが保証されます。

5. 熟練したスタッフ

当社の熟練した従業員は、合成ロープ製造における最新技術を習得するため、継続的な研修と教育を受けています。これにより、最高レベルの品質と性能を維持することができます。

- 国際標準

私たちの 認定

簡単で明確

簡単な購入で顧客満足度を最大化し、コミュニケーションと時間のコストを最小限に抑えます。

ステップ1:ソリューションの確認(3~5日)

まず、お客様のニーズをお伺いし、最適なロープソリューションをご提案いたします。当社の専門知識と経験に基づき、最高の製品をお届けいたします。

ステップ2:サンプル評価(7~14日間)

お客様に製品にご満足いただけるよう、サンプル評価をご提供しております。ご注文前に製品をテストし、お客様のご要望を満たしているかご確認ください。

ステップ3:注文確認(3日以内)

サンプル評価にご満足いただけましたら、ご注文を確定してください。価格、納期など、必要な詳細情報をすべてご提供いたしますので、安心してご購入いただけます。

ステップ4:大量生産(30~45日)

大量注文には、一括製造オプションをご用意しております。高度な製造技術と高品質の材料により、すべてのご注文において一貫性と信頼性を確保いたします。

ステップ5: 配送(30~45日)

迅速な配送が重要であることを理解しておりますので、配送状況の最新情報を随時お知らせし、追跡情報をご提供いたします。ご注文の商品は、ご指定の期間内にお届けいたします。

ステップ6:アフターサービス

ご注文の商品が届いた後も、当社のサービスは続きます。ご質問やご不明な点がございましたら、いつでもお気軽にお問い合わせください。私たちは、お客様に最高のカスタマーサービスを提供し、ご満足いただけるよう尽力しております。

- 安心の購入

なぜ選ぶのか

- 強度: 70% よりも軽量であるにもかかわらず、Duracrodix ロープはスチール ケーブルの引張強度に匹敵するかそれを上回ります。

- 安全性: Duracrodix ロープが切れても、鋼鉄のように危険な鞭打ち現象は発生しないため、作業員の安全が確保されます。

- 軽量: Duracrodix ロープは軽量であるため、迅速な輸送と展開が可能で、迅速な軍事対応に不可欠です。

- 自然な浮力: Duracrodix 合成ロープの浮力は、海軍の引き揚げ作業やさまざまな水中作業で非常に貴重です。

- 柔軟性: スチールよりも優れた柔軟性を備えた Duracrodix ロープは、困難な地形や狭いスペースで優れた性能を発揮します。

- 色分けされた利便性: 独自の色分けにより、90% はロープをより素早く識別でき、操作の効率と安全性が向上します。

よくある質問

顧客の懸念や問題点に対応するよくある質問

軍用ロープは何でできていますか?

軍用ロープは通常、UHMWPE(超高分子量ポリエチレン)、ナイロン、ポリエステルなど、様々な素材で作られています。これらの素材は優れた強度と耐久性を備えており、要求の厳しい軍事用途に適しています。

軍用の丈夫なロープ状の素材は何ですか?

UHMWPE(超高分子量ポリエチレン)は、ロープのような強度を持つ素材で、その驚異的な強度対重量比で知られています。その優れた引張強度から、軍用ロープによく使用されています。

どのような種類の軍用ロープがありますか?

軍用ロープには、懸垂下降や登山用の静的ロープ、パラシュートなどの活動用の動的ロープ、車両からの回収用の回収ロープなど、いくつかの種類があります。

ミリタリーグレードのリカバリーストラップはいつ使用すればよいですか?

軍用グレードの回収ストラップは、車両や機器を困難な地形や障害物から回収する必要がある場合に使用されます。強力かつ制御された回収手段を提供します。

軍隊で使われるロープとは何ですか?

軍隊では、用途に応じて様々なロープを使用しています。UHMWPEロープ、ナイロンロープ、スタティックロープは、登山、吊り上げ、牽引などの作業によく使用されます。

軍用登山用ロープの太さはどのくらいですか?

軍用登山用ロープの太さは用途によって異なり、9mmから11mm程度までの範囲で強度と柔軟性のバランスが取れています。

最も強力な軍用ロープは何ですか?

UHMWPE ロープは、その優れた引張強度、軽量性、耐摩耗性により、軍用ロープの中で最も強力なタイプであると考えられています。

自分のニーズに合った適切な軍用牽引ロープを選択するにはどうすればよいでしょうか?

軍用牽引ロープを選ぶ際には、車両の重量、地形、必要な伸縮レベルなどの要素を考慮してください。十分な強度と牽引ニーズに適した仕様のロープをお選びください。

極端な気温で使用するのに最適なロープはどのようなものでしょうか?

極度の温度環境における課題を克服する上で、ケブラーアラミドロープは究極のソリューションとなります。卓越した熱安定性と耐久性で知られるケブラーアラミドロープは、高温環境と低温環境の両方で揺るぎない性能が求められる用途に最適です。

軍用ロープを適切に保管するにはどうすればいいですか?

軍用ロープは劣化を防ぐため、直射日光を避け、涼しく乾燥した場所に保管してください。ロープがねじれないように、巻き付けるか吊り下げることをお勧めします。

軍事用途における合成ロープの利点は何ですか?

軍事用途における合成繊維ロープは、軽量で耐久性が高く、優れた強度を備えています。安全性を確保し、環境による損傷に強く、メンテナンスが最小限で済むだけでなく、費用対効果も高いため、多様な軍事作戦に最適です。

軍用ウインチロープとは何ですか?

軍用ウインチ ロープは、車両の回収や装備の移動など、さまざまな軍事用途のウインチ システムで使用される強力で耐久性のあるロープです。

ニーズに合った適切な軍用ロープを選択するにはどうすればよいでしょうか?

適切な軍用ロープを選ぶには、お客様の要件を理解することが不可欠です。用途、必要な強度、材質の適合性、そして環境要因を評価しましょう。吊り上げ、牽引、登山など、用途が何であれ、この戦略的な評価により、お客様の選択がまさにその作業の要求に合致したものとなることが保証されます。

軍用には合成ロープとスチールロープのどちらが良いでしょうか?

合成繊維ロープは軽量で、破断時の安全性が高く、耐腐食性に優れています。スチールロープは耐久性、耐紫外線性、耐薬品性に優れ、重量物の吊り上げに適しています。合成繊維ロープとスチールロープの最適な選択は、軍事用途と環境によって異なります。

軍事用途ではなぜ合成ロープが好まれるのでしょうか?

合成繊維ロープは、その独自の強度、柔軟性、そして軽量性を兼ね備えているため、軍事用途で広く使用されています。さらに、環境劣化にも強いため、過酷な環境下でも長寿命を実現し、軍事作戦に不可欠な要素となっています。

合成ロープの強度はスチールケーブルと比べてどうですか?

スチールケーブルは本質的に強力ですが、UHMWPE などの合成ロープは同等の強度対重量比を実現できるため、重量を増やさずに多くの用途で同等の効果を発揮します。

軍隊における合成ロープの典型的な用途は何ですか?

軍事分野において、合成繊維ロープは様々な用途で使用されています。貨物用スリング、牽引、ヘリコプターの外部荷役作業、部隊の迅速な展開のためのファストロープなど、幅広く使用されています。その強度と耐摩耗性により、要求の厳しい軍事用途にも適しています。

軍事用途での合成ロープの使用に関して、安全上の懸念はありますか?

軍事用途の合成繊維ロープには利点がある一方で、安全上の懸念もあります。エネルギーを蓄え、切断された場合に危険な反動を引き起こす可能性があります。また、極度の温度下では劣化する可能性があるため、火気にさらしてはいけません。安全を確保するため、常に過負荷状態にならないようにしてください。

軍用ロープの洗浄とメンテナンス方法は?

軍用ロープは、中性洗剤と水で洗浄し、自然乾燥させてください。洗浄には、強力な化学薬品や機械の使用は避けてください。ロープは定期的に点検し、損傷の兆候が見られた場合は交換することをお勧めします。

どの軍隊部門が合成ロープを最も多く使用していますか?

特殊部隊は、懸垂下降や救助活動に合成繊維ロープを使用しています。海軍と沿岸警備隊は海上任務に使用しています。陸軍工兵部隊は建設作業に、空挺師団は物資の投下や回収に使用しています。用途は国や作戦によって異なります。

Duracordix は、プロジェクト固有の要件に応じて、ファイバーロープの長さをカスタマイズできますか?

もちろんです!Duracordix は、お客様の特定のプロジェクトのニーズに合わせて長さを調整するなど、カスタマイズ オプションを提供しており、必要なものを正確に手に入れることができます。