corda de guindaste

Sintético corda de guindaste

O cabo sintético para guindaste é um tipo de cabo projetado especificamente para uso em guindastes e aplicações de elevação. É feito de fibras sintéticas de alto desempenho – UHMWPE (Polietileno de Ultra-Alto Peso Molecular). É uma alternativa ao cabo de aço para guindaste.

- Peso mais leve

- Maior relação resistência-peso

- Segurança aprimorada

- Requisitos de manutenção reduzidos

Índice desta página

Para garantir fácil acesso às informações de que você precisa, criamos este índice que o levará diretamente à seção relevante quando clicado

- Favorito do cliente

Venda quente tamanhos

Favoritos da indústria: diâmetros mais populares dos cabos de guindaste Duracordix

12 mm

Um tamanho versátil que oferece equilíbrio entre resistência e flexibilidade, tornando-o adequado para uma variedade de aplicações de elevação de médio porte.

24 mm

Projetado para aplicações mais pesadas. Equilibra comprimento e resistência, adequado para veículos maiores ou cenários que exigem maior alcance.

32 mm

Projetado para elevação extrema em indústrias de construção naval, grandes obras e extração de minerais em larga escala.

Duracordix é uma corda de guindaste sintética fabricante e fornecedor na China.

nós podemos produzir vários tamanhos para diferentes aplicações e personalizado para projetos especiais.

Não importa o que você esteja procurando por um fornecedor atacadista ou uma cinta de segurança personalizada, todos nós podemos ajudar. Entre em contato com a Duracordix agora mesmo.

- tamanhos disponíveis

ESPECIFICAÇÃO

Explore as especificações do nosso cabo de guindaste para sua aplicação

| DIÂMETRO | DIÂMETRO | PESO | KETX | KETX | FORÇA DE RUPTURA | FORÇA DE RUPTURA |

|---|---|---|---|---|---|---|

| milímetros | polegada | 100m(kg) | padrão | erro | tonelada | kn |

| 6 | 1/4 | 1.7 | 23 | 5% | 3.1 | 31 |

| 8 | 5/16 | 4.1 | 40 | 5% | 6.35 | 63 |

| 10 | 13/32 | 6.1 | 61 | 5% | 9.3 | 93 |

| 12 | 1/2 | 8.8 | 87 | 5% | 12.12 | 121 |

| 14 | 9/16 | 12 | 119 | 5% | 15.4 | 153 |

| 16 | 5/8 | 15.5 | 151 | 5% | 20.6 | 205 |

| 18 | 3/4 | 19 | 190 | 5% | 23.9 | 238 |

| 20 | 13/16 | 23 | 225 | 5% | 28.99 | 289 |

| 22 | 7/8 | 28 | 276 | 5% | 33 | 322 |

| 24 | 1 | 37 | 368 | 5% | 38 | 371 |

| 28 | 1-1/8 | 50 | 490 | 5% | 57.5 | 562 |

| 32 | 1-5/16 | 62.5 | 621 | 5% | 68.5 | 671 |

Observação: outros tamanhos estão disponíveis mediante solicitação.

- VS CABO DE AÇO

Vantagens Vantagens DE corda de guindaste

Descubra os benefícios do Duracordix sintético em relação ao fio de aço tradicional

Redução de peso

Os cabos sintéticos para guindastes Duracordix são significativamente mais leves que os cabos de aço, garantindo manuseio mais fácil, custos de transporte reduzidos e processos de montagem mais rápidos.

Segurança

As cordas Duracordix têm um toque mais macio e não há risco de lascas de fio, reduzindo lesões nas mãos e aumentando o conforto do usuário durante as operações.

Resistência à corrosão

Ao contrário do aço, nossas cordas sintéticas são imunes à ferrugem e corrosão, principalmente em ambientes marinhos e adversos, garantindo maior vida útil e confiabilidade.

Flexibilidade e Força

Nossas cordas sintéticas oferecem uma alta relação resistência-peso, garantindo excelente capacidade de carga, permanecendo flexíveis, reduzindo o desgaste e maximizando a durabilidade.

- Clientes satisfeitos

O que eles disseram

Vozes de Confiança: Experiências Reais com Cordas Duracordix

- Compra sem dor

POR QUE ESCOLHER

CABO PARA GUINDASTE DURACORIDX

- Alto desempenho: o cabo para guindaste Duracordix garante confiabilidade de 99,8%, proporcionando resistência à tração incomparável para içamentos críticos e reduzindo preocupações com quebras.

- Resistente às intempéries: Feita para durar, nossa corda resiste a 95% de raios UV e danos ambientais, garantindo vida útil prolongada mesmo em condições adversas.

- Custo-benefício: Alcance a melhor qualidade sem gastar demais. A Duracordix oferece um retorno sobre o investimento 20% melhor, combinando durabilidade excepcional com preços competitivos.

- Uso versátil: adequadas para diversos ambientes, nossas cordas atendem à norma 90% de necessidades de elevação específicas do setor, garantindo adaptabilidade e conveniência.

- Suporte Inabalável: Beneficie-se dos nossos 20 anos de experiência. A Duracordix oferece suporte contínuo, tornando-nos o seu parceiro de elevação confiável.

- nós fazemos mais

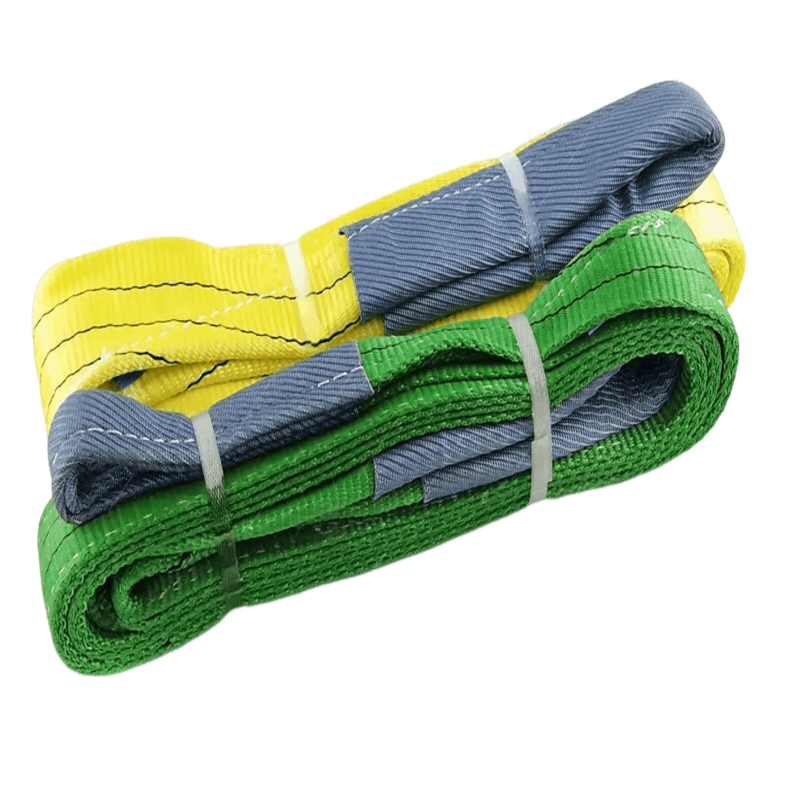

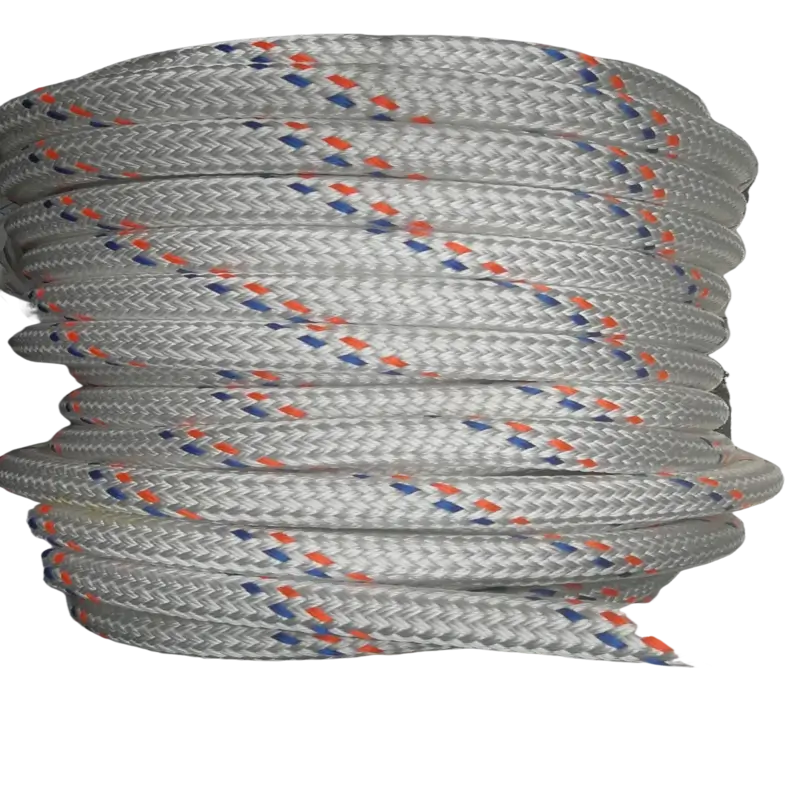

Relacionado produtos

Além do básico: descubra mais sobre nossa linha de cabos para guindaste

Leves, porém fortes, essas eslingas oferecem durabilidade e flexibilidade, ideais para diversas aplicações de elevação.

Com design circular, garante uma distribuição uniforme do peso, otimizando a segurança e a facilidade de manuseio.

Com trama plana para maior estabilidade, ele combina resistência de carga com pressão superficial reduzida sobre itens levantados.

Perguntas frequentes

Respondendo a perguntas comuns: Insights sobre cabos de guindaste sintéticos

o que é corda sintética para guindaste?

Cabos sintéticos para guindastes, feitos de materiais como UHMWPE ou nylon, são leves, resistentes à corrosão e flexíveis. Sua facilidade de manuseio e durabilidade os tornam a escolha preferida em relação aos cabos de aço tradicionais em indústrias de içamento pesado.

Como posso inspecionar o cabo do meu guindaste em busca de sinais de desgaste ou danos?

Inspeções de rotina são essenciais. Procure por danos externos, como cortes, desfiamentos ou abrasões. Internamente, verifique se há fibras quebradas ou inconsistências na estrutura do cabo. Documente todas as constatações e substitua o cabo se os danos parecerem graves.

Qual é a principal vantagem do cabo sintético para guindaste em relação ao aço tradicional?

Os cabos sintéticos para guindastes são reverenciados por sua excelente relação resistência-peso. Isso significa que podem suportar cargas pesadas e, ao mesmo tempo, serem mais leves, reduzindo os desafios de transporte e manuseio. Além disso, não corroem como o aço e são resistentes a diversos fatores ambientais.

Quanto tempo posso esperar que meu cabo sintético para guindaste dure?

A vida útil dos cabos sintéticos para guindastes depende em grande parte da frequência de uso, do ambiente e da manutenção. Com os devidos cuidados e em condições normais de operação, eles podem durar vários anos.

Existem diretrizes específicas de manutenção para cabos sintéticos de guindaste?

Com certeza. Certifique-se de armazená-los adequadamente, longe da luz solar direta e de produtos químicos agressivos. Limpeza e inspeção regulares são cruciais. Também é importante evitar sobrecarga e usar técnicas de tensionamento corretas.

Como os cabos sintéticos para guindastes se comparam em resistência aos fios de aço?

Cabos sintéticos para guindastes, feitos de materiais de alto desempenho, podem oferecer resistência à tração comparável, se não superior, à do aço. Além disso, têm a vantagem adicional de serem leves e não corrosivos.

Quais diretrizes de segurança devo seguir ao usar cabos de guindaste?

Respeite sempre os limites de peso da corda e faça inspeções regulares. O tensionamento adequado é essencial. O cumprimento das instruções do fabricante sobre uso, armazenamento e manutenção garante segurança ideal.

Como determino o diâmetro correto do cabo do meu guindaste?

O diâmetro ideal é influenciado pela capacidade do guindaste, suas necessidades específicas de elevação e as recomendações do fabricante. Garanta sempre o cumprimento das normas de segurança e do setor.

Cabo de aço ou sintético para guindaste: qual é mais durável?

Embora o aço seja inerentemente forte, as cordas sintéticas têm vantagem em termos de resistência à corrosão, danos UV e desgaste ambiental. As sintéticas geralmente apresentam maior durabilidade funcional em diversas condições.

Quais precauções são necessárias ao manusear cabos de guindaste?

É essencial usar luvas, garantir que as cordas não tenham nós ou dobras, manter a tensão adequada e armazená-las em um local livre de possíveis fontes de danos, como objetos pontiagudos ou produtos químicos.

Como os cabos do guindaste devem ser armazenados?

O ideal é um local fresco e seco. Evite áreas com luz solar direta, produtos químicos agressivos ou objetos cortantes. Se armazenar ao ar livre, use capas protetoras e garanta ventilação adequada.

Quais técnicas são recomendadas para tensionamento de cabos de guindaste?

O cumprimento das orientações do fabricante é fundamental. Garanta uma carga uniforme, evite impactos e siga sempre as melhores práticas para garantir a segurança e a durabilidade da corda.

Existem indicadores para verificar o desgaste do cabo do guindaste?

Sim, qualquer afinamento visível, fibras quebradas, alongamento excessivo ou desvios notáveis da integridade estrutural original da corda devem ser resolvidos imediatamente.

Como é medido o alongamento do cabo do guindaste?

Comparando o comprimento da corda sob uma carga específica com seu comprimento original, é possível determinar o alongamento. O monitoramento regular é fundamental para detectar níveis de alongamento inseguros.

Quais problemas comuns estão associados aos cabos de guindaste?

Isso inclui desfiamento, abrasões, torções, inconsistências de tensão e danos causados por raios UV ou produtos químicos agressivos. Cuidados e manutenção adequados podem atenuar muitos desses problemas.

Existem métodos específicos para terminar ou emendar cabos de guindaste?

Existem vários métodos, como emenda trançada, colagem adesiva ou utilização de terminações ou conexões especializadas. A escolha depende em grande parte do tipo de cabo e da aplicação pretendida.

Com que frequência devo substituir meu cabo sintético de guindaste?

A frequência de substituição depende dos sinais de desgaste. Se você observar algum dano grave ou alongamento notável além dos limites aceitáveis, é hora de substituí-lo.

Qual é o impacto da água salgada em cabos sintéticos de guindaste?

Embora muitos materiais sintéticos sejam projetados para serem resistentes, a exposição prolongada à água salgada pode enfraquecer algumas fibras. É essencial limpar e inspecionar regularmente as cordas usadas em ambientes marinhos.

Posso obter uma corda sintética para guindaste feita sob medida da Duracordix?

- Posicione os veículos: certifique-se de que ambos os veículos estejam em linha reta e de frente um para o outro, com distância mínima entre eles.

- Fixe a cinta de reboque: Passe uma ponta da cinta por um ponto de ancoragem no Veículo A e prenda-a firmemente com conectores apropriados, como ganchos ou argolas em D. Repita o procedimento para o Veículo B, certificando-se de que todas as conexões estejam firmes antes de iniciar o reboque.

Quais são os benefícios de usar cabos de guindaste sintéticos trançados?

Os designs trançados aumentam a resistência e a flexibilidade geral da corda. Eles também oferecem resistência superior à abrasão e distribuem o peso uniformemente, tornando-os ideais para cenários de elevação desafiadores.