In this article,it offers you a professional yet easy-to-understand guide to HMPE rope. You’ll discover its definition, key properties, and applications, along with advice on selecting and customizing the right rope for your needs, enhancing your understanding and helping you choose the best option.

Table of Contents

Toggle1.WHAT IS HMPE ROPE?

HMPE rope, High Modulus Polyethylene rope, means a high performance rope made from Ultra-high molecular weight polyethylene fibers(UHMWPE), characterized by high strength, lightweight, abrasion resistance etc. It is ideal for your use in harsh outdoor environments.

Applications you can use include off-roading, marine mooring, port towing, telecommunications, and lifting large precision objects etc. Its lighter weight, non-conductivity, and superior strength make it an alternative to steel wire rope.

2. THE KEY HMPE ROPE PROPERTIES

2.1 SPECIFIC GRAVITY: 0.97G/CM3 FLOATING

Because it is lighter than water, it can float, making it easier for you to observe and retrieve during water activities, and preventing entanglements underwater.

2.2 MELTING POINT:146℃

At high temperatures, it offers better thermal stability, meaning the rope maintains its performance and does not deform even when subjected to significant heat, enhancing your safety during use.

2.3 ELONGATION AT BREAK:AROUND 2%~3%

The low elongation rate not only ensures precision during your operations, with minimal stretch, but also allows it to withstand sudden shocks and pulls. This is especially important for your precise towing, mooring, and lifting tasks.

2.4 WATER ABSORPTION: NONE

Since it does not absorb water, the rope won’t become damp or swell, which preserves its strength. In your marine and outdoor activities, its lifespan isn’t compromised by water absorption, and it maintains its lightweight characteristic, making it easy for you to handle even when wet.

2.5 UV RESISTANCE: GOOD

The rope will not degrade due to prolonged exposure to the sun, which preserves its strength and performance. This can extend your rope’s lifespan and reduce the frequency of your rope replacements.

2.6 ABRASION RESISTANCE:GOOD

In off-roading, lifting, and mooring operations, good abrasion resistance allows your rope to better withstand frequent friction and contact with rough objects, thus preserving its strength and performance.

2.7 CHEMICAL RESISTANCE: GREAT

Excellent chemical resistance allows your rope to maintain its complete structure and stable performance in environments with chemicals, enhancing your rope’s reliability in corrosive settings and reducing the frequency of replacements.

3. THE UNMATCHED BENEFITS OF HMPE ROPE

3.1 HIGHER STRENGTH-TO-WEIGHT RATIO

Under the same diameter, HMPE rope has higher strength compared to steel wire rope and other fiber ropes like nylon, polyester, and polypropylene ropes. It offers you a smaller diameter at the same strength level and is lighter in weight, ensuring high strength while reducing overall weight.

3.2 LIGHTWEIGHT & SOFTNESS

Compared to steel wire rope and traditional fiber ropes like nylon and polyester, HMPE fiber rope is lighter and more flexible, which makes it easier for you to handle, operate, and install during your outdoor work. This significantly improves your work efficiency, saves labor time, and reduces costs.

3.3 HIGH SAFETY

As HMPE rope is buoyant and lightweight, it does not pose a risk of entanglement or sinking hazards in your marine operations. When you’re towing, its lower recoil if broken reduces your risk of injury compared to the high recoil impact of steel wire rope. Additionally, its softness and slight elasticity prevent injuries like cuts that can occur when handling steel wire rope, thus enhancing your safety.

3.4 EASY TO WORK

Due to its lightweight nature, HMPE rope is very easy for you to carry and handle. Its soft texture also prevents unnecessary injuries to personnel, enhancing efficiency and saving your time.

3.5 LONG SERVICE LIFE

Compared to traditional fiber ropes, HMPE fiber rope has a longer lifespan due to its superior abrasion resistance, corrosion resistance, UV protection, and fatigue resistance. These qualities allow it to better withstand harsh environments and external wear, resulting in an extended service life.And in some cases, it can be repaired and reused as well.

3.6 LOW COST

Although your initial cost of HMPE synthetic rope is higher than that of steel wire and traditional fiber ropes, its longer lifespan and higher safety reduce your long-term operational and safety costs. This increases your work efficiency and shortens your operation times, ultimately lowering your overall cost of use.

4. THE DISADVANTAGES Of HMPE ROPE

4.1 NOT HEAT-RESISTANT

Due to its relatively low melting point of around 146°C, HMPE fiber rope is not as heat-resistant as Kevlar aramid rope, which has a melting point of about 500°C. Therefore, it may deform or lose performance in your extremely high-temperature operations.

4.2 LIMITED SHOCK ABSORPTION

Due to its low elongation rate of only 2-3%, HMPE rope cannot absorb and mitigate sudden shocks or the energy produced under load as effectively as your nylon rope. Therefore, extra caution is needed in similar usage scenarios.

5. Versatile APPLICATIONS OF HMPE ROPE

5.1 VEHICLE RECOVERY & OTHER OUTDOOR SPORTS

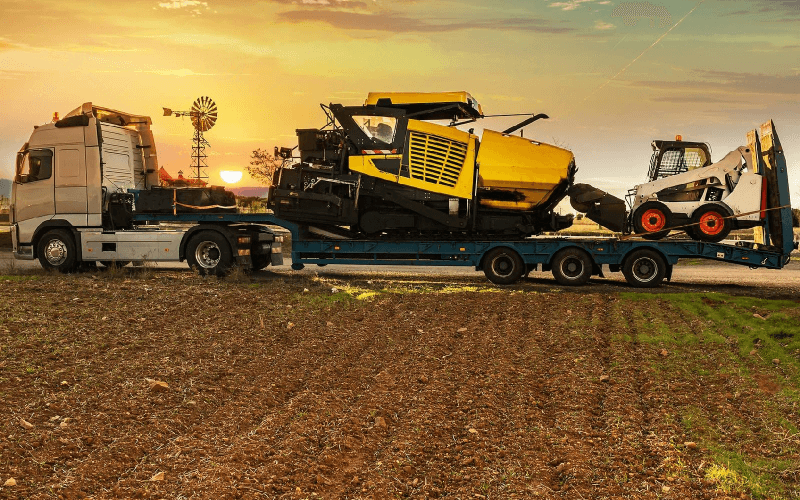

In your 4×4 off-road racing,transport and watersports, HMPE ropes are widely used for recovery ,rescue and towing. Specific applications include:

5.1.1 SYNTHETIC WINCH ROPE

During your off-roading, when a vehicle gets stuck in mud, sand, or snow and can’t free itself, a uhmwpe winch rope is used for your vehicle recovery to pull it out. This enhances the efficiency and your safety of off-roading or overlanding.

5.1.2 SOFT SHACKLE

During your vehicle recovery operations, a soft shackle serves as a connection point,linking tow straps, winch ropes, and kinetic ropes to your vehicle. Its lightweight design and high tensile strength make it very easy for you to use and it does not damage the vehicle’s paint or connection points.

5.1.3 WINCH EXTENSION ROPE

As the name suggests, a winch extension rope is used to extend your reach of the built-in synthetic winch rope when it’s not long enough to reach an anchor point. It is used for your recovery tasks where the anchor point is at a considerable distance.

5.1.4 EQUALIZER ROPE

The main function of equalizer rope during your vehicle recovery is to evenly distribute the load across two anchor points. This ensures the force is balanced, providing you maximum protection to vehicle.

5.1.5 CLIMBING ROPE

HMPE climbing ropes can withstand the strong forces generated during your falls. Thanks to their excellent abrasion resistance, they offer you superior stability against friction with rock surfaces, ensuring your efficiency and safety.

5.1.6 WATER SKIING TOW LINE

During water sports, it provides a secure connection between you and the boat. Its low weight and minimal stretch greatly ensure stability and responsiveness, guaranteeing you a good experience and safety.

5.2 MARINE/BOATING

Due to hmpe rope’s superior strength-to-weight ratio, low elongation, corrosion resistance, and abrasion resistance, HMPE marine ropes are particularly well-suited for your use in the harsh environments of marine and boating. Specific applications include:

5.2.1 MOORING LINE

HMPE Mooring Ropes are used to connect and secure your vessels to docks and other fixed points. They are widely used because of their high strength, water resistance, and lightweight properties.

5.2.2 TUG TOW LINE

In harsh marine and river environments, it is used to connect your tugboats and the vessels being towed, providing strong towing capabilities. Its ability to float and low elongation rate make it easier for you to use and allow for more precise operations.

5.2.3 ANCHOR LINE

It securely connects your ships to anchors, ensuring stability in harsh conditions and preventing external forces from shifting the ship’s position, keeping them firmly in place as intended.

5.2.4 DOCK LINE

It is used to secure your ships to docks and other mooring points, ensuring safety and stability of your vessels in maritime environments.

5.2.5 SAILING RIGGING ROPE

Sailing rigging rope can be used to rig and construct your sailboats, allowing for precise control and maneuverability of your vessel.

5.3 MINING

Due to its high strength and lightweight properties, synthetic HMPE rope allows for more efficient work and easier handling in your mining industry. Specific applications include:

5.3.1 HOSTING AND LIFTING ROPE

Its main function is to precisely hoist and lift your equipment, heavy objects, and materials in and out of mines and other chambers, ensuring your operational continuity.

5.3.2 WINCH ROPE

In mining operations, winch ropes are used to tow your equipment, vehicles, and other heavy loads. Due to their high tensile strength and lightweight nature, they can be operated by a single person, greatly enhancing the efficiency of your mining operations.

5.3.3 SAFETY LINE

It is to provide your workers with a strong and reliable lifeline, enabling safe tasks such as mine shaft ascent and descent, working at heights, and emergency evacuations in hazardous environments.

5.4 OFFSHORE OIL,GAS

The HMPE fiber rope makes your handling and operations on offshore platforms easier and safer. it is well-suited for the harsh marine environment, increasing its lifespan and reducing the frequency of replacements. Additionally, its low elongation rate makes it ideal for your precise lifting and towing tasks on platforms. specific applications include:

5.4.1 MOORING LINE

It is used to reduce the vertical load on your marine platforms, secure them in place, and maintain stability against drifting caused by ocean currents and other external forces.

5.4.2 TOW ROPE

Due to its high strength, excellent abrasion resistance, and corrosion resistance, HMPE tow rope is commonly used to tow your large structures such as oil platforms, ships, and buoys in marine environments.

5.4.3 LIFTING SLING

HMPE Lifting slings( also called plasma slings) are used for hoisting your heavy objects and mechanical equipment offshore. Compared to wire ropes, they are extremely light and flexible, which greatly facilitates handling and management, enhancing your safety and work efficiency.

5.4.4 RISER TETHERS

Riser tethers are primarily used to support and stabilize your risers, which are pipes that transport materials from the seabed to the surface. They help maintain the vertical and lateral position of your risers, preventing excessive movement that could lead to wear or failure.

5.4.5 ANCHOR LINE

It securely connects your ships or platforms to an anchor, ensuring stability under harsh conditions and limiting external forces from altering their position, keeping them securely in place.

5.5 FISHING

HMPE rope is especially suitable for fast and efficient operations in your fishing industry. Its excellent abrasion resistance allows it to maintain performance even when rubbing against rough surfaces. Additionally, it provides you better control and stability, while also ensuring your safety in case of breakage.Specific applications include:

5.5.1 FISHING LONGLINE

A fishing longline is a type of fishing gear used for your commercial and recreational fishing, widely used because of its lightweight, high strength, and corrosion resistance.

5.5.2 TRAWL WARP

Trawl warp is a crucial component of your fishing trawl systems, primarily used as the towing cable for nets. It is highly suitable for your use in harsh environments due to its performance and reliability.

5.5.3 PURSE SEINE LEAD LINE

It is a special type of fishing line used in the purse seine fishing method. This method involves surrounding fish with a large net and then closing the bottom of the net to capture them

5.5.4 GILL NETS

Gill nets are primarily used in your commercial and artisanal fishing. This type of fishing net allows only the fish’s head to pass through, after which the fish are caught by their gills.

5.5.5 AQUACULTURE NETS

It is primarily used in your aquaculture to confine farmed fish and organisms within a specific area, protecting them from other creatures and preventing escapes into the outside environment, even under harsh farming conditions.

5.6 MILITARY

The HMPE synthetic fiber rope ensures you the mobility and speed of military logistics and rapid deployment, as well as the lifespan and stability in unknown and unpredictable environments. This guarantees efficiency in your military activities such as vehicle recovery,towing, lifting, and securing materials and equipment.Specific applications include:

5.6.1 VEHICLE RECOVERY ROPE

It is specifically used for towing and recovery of your vehicles in military logistics and field operations. Its lightweight, high maneuverability, and corrosion resistance make it especially suitable for your use in harsh and challenging environments.

5.6.2 HELICOPTER LONGLINE

Helicopter longlines are primarily used in your military activities for transporting equipment, conducting rescue operations, and performing other aerial logistics tasks, enhancing you the precision and reliability of these operations.

5.6.3 PARACHUTING ROPE

Parachuting ropes are mainly used in your military activities for air drops, rescue missions, and activities involving parachute systems, significantly enhancing you the reliability and safety of operations.

5.6.4 MOORING/ANCHORING ROPE

Due to its outstanding strength and durability, it is used to securely moor and anchor your military vessels and is suitable for frequent and harsh military maritime activities.

5.6.5 FAST ROPE

Due to its outstanding performance and safety, it allows your troops to quickly descend into areas where traditional parachuting or landing is not possible, enabling you rapid military deployment.

5.6.6 LIFTING SLING

It is primarily used for moving and lifting your heavy military equipment such as vehicles, machinery, and other supplies, helping you to accomplish your demanding tasks in military logistics and operations.

5.7 CONSTRUCTION

The HMPE rope ensures you effective load handling, safety, and precise operations when lifting your heavy materials and equipment in tough outdoor construction projects. This reduces your operational costs and enhances work efficiency.Specific applications include:

5.7.1 HEAVY LIFTING ROPE

Heavy lifting rope is primarily used for lifting your building materials, equipment, and structural components, significantly enhancing safety and efficiency of operations.

5.7.2 CRANE ROPE

It is used in cranes for lifting and moving your heavy objects, and its excellent abrasion resistance, low weight, and high strength allow it to better accomplish your heavy lifting tasks.

5.7.3 LOAD SECURING ROPE

Load securing rope is used to secure your loads during transportation or lifting. It ensures your materials are firmly held in place, preventing any movement that could lead to damage or accidents, thereby enhancing the safety and stability of operations.

5.7.4 SAFETY ROPE

Safety ropes are essential for your tasks such as fall prevention, securing safety nets, and as part of emergency rescue equipment in construction. Their strength, durability, and resistance make them a reliable choice for maintaining safety standards on construction sites.

5.8 TELECOMMUNICATION

HMPE rope is non-conductive, lightweight and low elongation, making it particularly well-suited for areas with electrical hazards, significantly improving your work efficiency, reducing the need for frequent replacements, and decreasing the occurrence of safety incidents. Specific applications include:

5.8.1 CABLE PULLING LINE

They are used in your power, telecommunications, and communication operations for installing or maintaining fiber optic and power cables.

5.8.2 RIGGING ROPE

Specifically used in the telecommunications industry, it is used to efficiently support, lift, and secure your telecom equipment and cables during installation or maintenance.

5.8.3 SAFETY LINE

Used to ensure the safety of your operators during the installation, maintenance, and operation of telecommunications equipment and infrastructure, enhancing your work efficiency.

5.9 AGRICULTURE & FORESTRY

Due to the characteristics of HMPE fiber rope, it plays a crucial role in lifting and transporting your heavy items such as large timber, equipment, and agricultural machinery. It can withstand various outdoor weather changes, and ensures convenience, efficiency, and safety for you during operation. Specific applications include:

5.9.1 TOW RECOVERY ROPE

Used to tow and recover your stuck vehicles and machinery, and to clear fallen trees and other objects.

5.9.2 LIFTING SLING

Due to their durability and reliable performance, they are used for lifting and moving your heavy equipment, trees, and other objects in agriculture and forestry.

5.9.3 LOG WRAPPER

Used to secure and bundle your timber, its resistance to cutting and tearing makes it especially suitable for handling rough and heavy wood, enhancing your work efficiency and safety.

5.9.4 CARGO SECURING

Used to secure the transportation of your agricultural and forestry products as well as heavy equipment and machinery, preventing movement and potential damage during transit.

5.10 ENTERTAINMENT

When you’re handling heavy equipment like stage scenery and sound systems, or during film rigging, HMPE rope provides you stable and precise load support, ensuring your safety of performers and allowing for precise control. Its non-conductive properties also make it safer to use around wires and electrical equipment. Specific applications include:

5.10.1 STAGE RIGGING LINE

Used to safely support your stage equipment, scenery, and lighting, helping you to ensure the safe and efficient execution of performances and other entertainment events.

5.10.2 STUNT RIGGING ROPE

Used in your stunt and special effects scenarios, it ensures you the effectiveness of aerial performances and the safety of stunt performers.

6. HOW TO MAKE BEST HMPE ROPE

Here you can find how we craft high-quality HMPE rope at Duracordix, detailed step-by-step.

6.1 USE THE BEST RAW MATERIALS

We start with using the best raw materials to ensure you the performance and quality of the rope. At Duracordix, we use the finest UHMWPE raw materials available in China to guarantee you our product quality, and we conduct single fiber strength tests on every batch of raw materials.

6.2 TWISTING

Only UHMWPE fibers that pass quality control are used in the twisting process. Twisting tightly winds these strands together to form a strong rope. This process also alters the rope’s structure and strength, flexibility, and reliability, preparing it for the next stage of production. we use a Programmable Logic Controller (PLC) to control the twisting of the rope based on its size, which enhances the rope’s strength by 2-3%.

6.3 BRAIDING

The twisted fibers are then braided. During the braiding process, multiple strands of yarn are interlaced in a specific way. This braiding method differs from simple twisting; it actually allows the yarns to form interlocking layers with each other, which increases the rope’s flexibility and stretchability.

6.4 FINISHING

After HMPE fiber rope is braided, we apply a glue coating. Because we soak it for an hour longer than our competitors, combined with our specially formulated glue, not only is the glue’s penetration enhanced, but the rope’s abrasion resistance and fatigue resistance are also improved. Additionally, this process gives the rope a higher brightness and greater strength.

6.5 DRYING

After the HMPE rope is coated with glue, the drying process is very important. Once your rope is fully dried and cured, it enhances the adhesion between the fibers, thereby increasing the rope’s strength and durability, and extending its usage cycle and lifespan. This process also ensures that your rope’s brightness lasts longer.

6.6 TESTING & QUALITY CONTROL

We conduct tensile strength tests, abrasion resistance tests, and corrosion resistance tests on each batch of your rope to ensure consistent performance and quality. Only those that meet our standards undergo a final visual inspection before being packaged and sent to customers.

7.HOW TO CHOOSE THE RIGHT SIZE

Choosing the right size of UHMPWE rope for your needs not only depends on the intended use and required tensile strength but also on safety and compatibility with the equipment. Additionally, it’s important to ensure it meets international standards and to seek expert advice for specific applications to make your informed decision.

7.1 STRENGTH & DIAMETER

To determine the actual weight of your objects for towing and lifting, consider a safety factor to decide the required strength of your rope and choose the appropriate diameter.

7.2 SAFETY FACTOR

For safety, when selecting your rope sizes, a safety factor is typically added. For example, tow ropes generally have a 1:2 safety factor, and lifting ropes (vertical lifting) typically have a 1:5 safety factor. This means your rope’s breaking strength should be 2 and 5 times the weight of the object, respectively.

7.3 TYPE OF USE

When considering your rope applications, it’s important to specify the industry to meet the required diameter and strength standards. For instance, winches must not exceed a certain diameter to avoid impacting the length of rope needed. Additionally, the strength requirements for your lifting ropes differ from those used for the horizontal pulling.

7.4 COMPATIBILITY WITH EQUIPMENT

When choosing your ropes, it’s essential to consider compatibility with the equipment. If your rope’s tensile strength is insufficient, it cannot guarantee normal operation and safety. To enhance abrasion resistance, adding a protective cover is necessary, which also increases your rope’s diameter.

7.5 INTERNATIONAL STANDARDS

We need to ensure that your HMPE rope meets the standards of the relevant country and provide the necessary certifications to prove that your product complies with international standards and requirements, meeting yours procurement criteria.

7.6 EXPERT CONSULTATION

Considering safety, compliance, know-how, and customization, it’s best for you to consult with industry experts to ensure you choose HMPE ropes with the appropriate diameter, strength, and standard-compliant coatings.

8. HMPE ROPE Protection & MAINTENANCE

8.1 ROPE PROTECTION

8.1.1 AVOID DIRECT CONTACT WITH SHARP EDGES

When using your rope, avoid direct contact with sharp edges to prevent cuts that could render the rope unusable.

8.1.2 CLEAN THE ROPE AFTER USE

Always clean your rope after use to remove impurities like sand that can embed within the fibers, damaging the rope and reducing its tensile strength.

8.1.3 PROPER STORAGE AND COILING

After use, store your rope neatly coiled in a rope bag to prevent it from twisting or knotting, which can weaken its strength.

8.2 ROPE MAINTENANCE

8.2.1 REGULAR INSPECTIONS

Conduct regular inspections of your rope to assess wear, abrasion, and damage. If localized wear is observed, consider cutting out the worn section for repair to extend the overall lifespan.

8.2.2 IMMEDIATE REPAIRS

If minor repairable damage is found in your rope, perform a safety assessment and review standards before making necessary repairs of your rope.

8.3.3 STORAGE

Although your HMPE rope has good UV resistance and corrosion resistance, to extend its lifespan, store it in a cool, dry place away from moisture and heat sources.

FAQS

1. WHAT IS hmpe meaning?

HMPE is a type of polyethylene fiber known for its high-performance qualities. It is widely used in the production of ropes, fishing nets, and various fabrics.

2. Are there any alternative names for HMPE rope?

Yes, you can also call it Dyneema rope, Spectra rope, Plasma rope, UHMPWE rope, High-performance polyethylene (HPPE) rope.

3. Can you recommend any famous brands for HMPE rope?

Yes, there is famous brands like Samson Rope, Marlow Ropes, Cortland Rope, Duracordix Rope, Yale Cordage,Premiumropes, English Braids etc.

4. UHMPWE vs DYNEEMA, What is the difference?

They are fundamentally the same material. UHMWPE stands for Ultra-High-Molecular-Weight Polyethylene, which is the material’s name. Dyneema, on the other hand, is a well-known global brand of UHMWPE produced by DSM, renowned for its high-performance applications.

5. What is the HMPE rope price?

The price of HMPE rope depends on the diameter and length of the rope you choose. Contact Duracordix for an accurate quote.

6. Is HMPE rope the best non-stretch rope?

HMPE rope has the lowest stretch compared to common synthetic ropes like nylon rope, polyester rope, and polypropylene rope(PP rope). Nylon can stretch 20-30%, polyester 5-15%, and polypropylene 15-25%, while HMPE only stretches 1-3%. This makes HMPE ideal for applications requiring minimal stretch and precise control.

9. CONCLUSION

We hope this article has given you a comprehensive and deep understanding of HMPE ropes. As a provider of HMPE rope solutions, Duracordix is ready to offer you specialized advice and custom solutions. If you have any needs or questions, please contact us. Thank you!

About The Author

Moses Xu

Hi, I’m Moses Xu, VP and Marketing Director at Duracordix. With 10+ years in high-performance synthetic ropes and netting, I specialize in export trade and marketing. Whether it’s HMPE, Kevlar, or nylon ropes, I’m happy to share insights and connect!