Table of Contents

ToggleIntroduction

Do you need to secure a large vessel during dangerous offshore operations? When a mooring hawser system fails, the safety of the entire crew is compromised immediately. This guide breaks down the mechanics, materials, and load limits you need to know. Continue reading to learn the critical details of securing your ship safely.

What Is Single Type Mooring Hawser?

A mooring hawser acts as a large diameter rope that connects an oil tanker to a single point mooring buoy. The rope functions as a large spring that absorbs the kinetic energy of the moving boat in the water. We manufacture these ropes to survive extreme marine conditions found in the ocean environment. High tenacity nylon gives the rope elasticity needed for heavy work.

The rope stretches at high tensions, which decreases the peak load placed on the deck hardware. Standard Hawsers are rated to handle loads up to the 1140kN MBL limit. The rope is used to keep the tanker in place while the transfer operation is being completed. All of our hawsers are built to meet the strict OCIMF MEG4 standards.

The mooring hawsers are designed to negate the harmful effects of cyclic fatigue over time. Engineers use specific water depths to design the assembly, which includes chafe chains and shackles. It acts as a vital link to offshore safety during transfer operations. We are pleased to say that all of our hawsers are built to the required international standards. The quality of the hawser rope is of high importance as crews rely on it daily.

Understanding How A Mooring Hawser System Works!

This system handles safe load transfer from a moving vessel while it sits in rough water. An explanation of the mechanics is provided below to clarify how the parts work together.

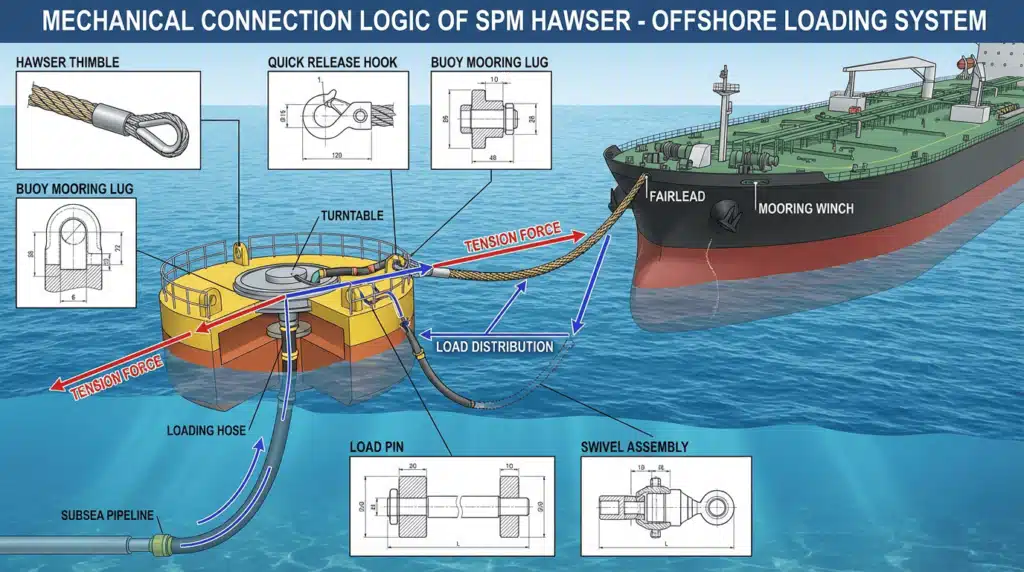

A. Mechanical Connection Logic

Hardware fastens the thick rope directly to the boat structure to ensure a secure hold. We will examine the important contact points for these mechanical connections in detail.

1. Buoy Attachment

Galvanized Thimble

A metal hood protects the rope loop from damage during heavy operation. We use hot-dip galvanizing to help the metal withstand rust from the ocean. Its shape matches the shackle pin to ensure a secure fit. It prevents the fiber from crushing under high tension loads. The mooring hawser assembly is manufactured to withstand the test of time. The zinc coating fights corrosion from saltwater very effectively.

SPM Buoy

This acts as the floating anchor point for the entire system. The mooring hawser in ship operations connects here to hold the vessel. It rotates with the tanker so it does not allow the rope to twist. The buoy handles the extreme weight of the chain in the water. We have engineered ropes accordingly for this specific movement.

Shackle Link

Steel shackles join the thimble directly to the buoy connection point. We ensure to use high-grade alloy steel for maximum durability. The pin must be secured with a cotter pin as it is the critical weak link. We suggest that this mooring hawser reel component be inspected regularly for safety. Holloway Houston warns to “discard the shackle immediately” if you see “nicks, gouges, and cracks.” Safety is highly dependent on this specific piece of hardware.

Thimble Eyes

The rope loop is what holds the thimble firmly in place. We splice this eye with extra care to ensure it holds. It bears the complete load of the ship during the transfer. Textiles cover this section to protect it from internal abrasions and wear. This strong termination point is what the mooring winch hawser drum depends on.

2. Tanker Interface

Bow Connection

This is one of the most perilous activities of the tanker ship operation. Operators must connect the hawser to the standard brackets designed for quick release. This is one of the most dangerous areas due to the movement and difficult weather.

Chafe Chain

There is a steel chain that passes through the fairlead to protect the mooring hardware. The rope stays outside the ship and only the chain touches the metal chock. We supply chains with a high breaking strength to prepare for potential rope failure.

Bow Cleats

Heavy cleats hold the chain stopper and transfer the load to the hull. This is heavily relied on in offshore design for stability. We calculate the forces so the cleats withstand the Safe Working Load. The deck can suffer serious and costly damage if the vessel becomes unsecured.

Fairlead Chocks

There is an opening that the chain passes through during the connection. This allows you to easily guide the line off the bow of the ship. The smoothness of the surfaces must be monitored as rough spots stop the line. These are the standards we must hold ourselves to for safety. We check for burrs as they quickly destroy the protective chain.

3. End Termination

Spliced Eye

Self-weaving ramps up the efficiency of splice maintenance and creates a secure loop. This loop retains 90% of the rope’s strength during operation. Mazzella Companies notes “an Eye Splice… can be considered 100% efficient,” unlike weaker knots. Skilled riggers are used, and the splice itself acts as the primary anchor point.

6mm Cover

The load-bearing core is protected by an abrasion-resistant, polyester jacket cover. This jacket shields the sensitive fibers from harmful UV light. Covers are tightly fitted to prevent core debris contamination from entering. External damage is mitigated by this thick layer.

Splice Protector

Heavy cloth acts as a wrap for the splice area. This serves as a secondary protection measure for areas that endure high friction. The protector fabric is constructed from high quality, tear, and cut resistant polyurethane. The protector improves the splice functional lifespan and simplifies visual inspection.

Protective Sleeve

Entire rope lengths are covered with floating, oil resistant, protective sleeves. These sleeves are constructed from durable synthetic fibers to prevent snagging on the deck. Design considerations for the sleeve focus on user friendly removal for maintenance. Maintenance crews inspect the core, which is essential for sleeve longevity.

4. Hardware Interaction

15:1 Ratio: Correct diameter eliminates stress on the rope fibers.

Steel Friction: Metal fibers wear down the rope over time.

Contact Points: Monitor these danger zones for signs of wear.

B. Load Transfer Dynamics

When a ship is secured using a rope, the ship exerts tremendous tension in storms. We look at how the force moves through the mooring hawser systemduring use.

1. Tension Management

1140kN MBL

MWL is a standard defensive mooring system hawser rating. We rate ropes at Minimum Breaking Load for safety. This rating makes the rope storm resistant. Every batch is tested at Duracordix to ensure quality. The tandem mooring hawser cannot fail during operation. Operators rely on this number to define the limits of the system.

Axial Force

The pull must be straight to avoid damaging the rope. If the hawser ropes get twisted, it weakens the rope fibers significantly. We purpose the hawser design for linear tension applications. The SPM mooring hawser aligns directly with the load. We instruct gap guides to prevent losing side loads to the system. Alignment is critical to the safe use of the mooring hawser.

Peak Load

The sudden force of a storm puts stress on the rope. Moving a ship in a storm requires the rope to stretch to handle the load. We call this sudden force the peak load. The single point mooring hawser dampens shock loads effectively. The system calculates safety for the hardware involved. The rope stretches and recovers after hard use to defeat peak loads.

Working Load

This is the tension level that we run the system at daily. It must be 50% of the MBL to remain safe. This is the SPM mooring hawser operational zone for the crew. We suggest recording this information for safety records. Safe operations stay within the operational zone of the mooring hawser.

2. Stress Distribution

Core Bearing

The inner fibers are load bearing, while the cover is merely protective. We ensure solid cores as this is critical to the mooring line hawser. We use a parallel strand construction method to maximize tensile strength. We focus on core strength during inspections to ensure safety.

Even Loading

All strands must pull as a unit to work effectively. Loose strands create unwanted internal friction within the rope. We achieve a balance of the overall twist to prevent this issue. The towing hawser performs as a single unit during the pull. Manufacturing is known for this uniformity in the rope structure. Early failure can happen due to uneven loading in the rope.

Strand Tension

Each yarn of the hawser has a specific tension level that we monitor. The comparison with steel hawser highlights the weight savings found here. We ensure no shock waves are formed inside the rope due to tension. The structure remains stable under load during the operation.

Load Sharing

Double leg systems share the force evenly between both ropes in the system. We ensure they are the same length for balance. The mooring requirements mandate this symmetry for safety reasons. We pair hawsers for tandem use to ensure safety. A rope can break if it is overloaded during use.

3. Fatigue Resistance

Cyclic Loading

As waves push and pull the rope, it cycles through tension. It is important that the rope remain elastic during this process. We test how many cycles it can withstand before failure. Ropes are elastic enough to withstand millions of cycles. We monitor cycles to prevent unexpected parting of the line.

Tension Fatigue

Continuous loading pulls the rope like a spring over time. Internally, polymer chains weaken from this constant stress.

Internal Heat

During constant loading, the rope heats up from friction. For long, slow pulls, heat resistant fibers are used to prevent damage. We design heat resistant fibers for long slow pulls.

Rope Recovery

The rope regains its length, but it happens slowly. This lacking of recovery comes from thermal hysteresis in the fibers. For this reason, long cooling periods are vitally needed for the rope.

Bend Fatigue

Over flexing fairlead bends causes external sheathing fatigue to occur. Over flexing is less harmful than internal filament fatigue, which breaks the rope. Large flex radius practices are recommended for longevity.

Structural Integrity

The importance of a rope remaining whole is galvanizing for the crew. Impulses tire cuts which propagate under tension during the pull.

4. Breaking Limits

105% MBLsd: The Critical Danger Line where the rope will fail.

Break Force: When the rope snaps, rope breaking occurs.

Safety Factor: Built-in safety buffer to prevent accidents.

Overload Risk: Overdriving pulls excess tension until the rope breaks.

C. Elastic Energy Absorption

The hawser acts like a shock absorber for the ship. We look at how it dampens the ocean forces below.

1. Elongation Mechanics

20% Stretch

Nylon is a type of rope that elongates under load. This elongation dampens the force of the waves. We engineer for 20% stretch in the line. Ropes protect the deck from damage. During mooring, chafing prevention of the mooring hawser is vital. Flexibility helps in absorbing sudden shock loads from the water.

Elastic Recovery

The rope must return to its original length after use. This is a sign of the fibers being healthy and strong. Recovery is measured to ensure quality. The line mooring hawser acts like a spring during use. Materials resist permanent deformation from heavy loads. Loss of bounce means replacement is needed.

Elongation Limit

Stretching too much results in damage of some kind to the rope. We must define the safe limit for the crew. The rope mooring hawser breaks past this point of tension. We mark the danger zone on the rope. The operators watch the extension length during the operation.

Fiber Extension

Under heavy tension, molecules will align within the fibers. This provides the incredible strength of the rope. We use long-chain polymers for this purpose. What is single point mooring without elasticity in the line? We choose 6.6 nylon, a high grade that stretches.

2. Shock Mitigation

Dynamic Loads

In moving ships, a number of different variable forces come into play. For example, the waves crashing against the ship’s hull cause impacts. The rope helps smooth rough spikes in tension. We make sure the load transferred is conducted smoothly. This is considered for procedures involving single mooring point installations.

Surge Dampening

When a ship is docked, it can surge back and forth violently. The hawser uses gentle control of this movement. To better achieve control, we calculate the spring constant carefully. This can be seen on the single point mooring diagram. To avoid sharp and dangerous jerks, we use quality materials.

Wave Impact

Even the largest of tankers can be lifted by ocean swells. Once the tanker is lifted, gravity exerts a downward force. The rope absorbs the strain of this drop. The hawser on the calm buoy mooring system absorbs vertical movement. The system sails smoothly over the sea.

Energy Absorption

When kinetic energy is transferred, a ship’s momentum absorbs as heat. With this technology, we can manage internal melting effectively. The hawser is used as an energy sink for the ship. Energy is absorbed in order to prevent a ship from breaking free.

3. Recoil Control

80% Lower

Synthetic recoil is dangerous for the crew on deck. We design to minimize snapback in our ropes. Broken rope reduces the injury risk significantly. Standard nylon snaps back and is violent when it breaks. We alter the structure of the fiber for safety.

Snapback Arrest

We integrate a safety core which absorbs the snapback energy. The broken rope does not whip back at the crew. Crews in the snapback zone are safer during operations. Snapback causes severe injuries on the deck. Our technology significantly reduces this risk for everyone.

Energy Dissipation

The recoil energy from a broken rope must go somewhere safely. Ropes dampen the break to protect the crew. The fiber structure internally collapses during the break. This prevents the slingshot effect from occurring. Dissipation is a safety feature on our rope.

Recoil Reduction

Reducing the whip on a rope is essential for safety. We use specific braid angles to lower recoil speed. Tests determine safer decks for the crew. High-stretch ropes are dangerous to use on a break. We balance stretch with safety to reduce the whip.

4. Material Behavior

Nylon 66: The golden standard and most common nylon is 66 for ropes. It is known for its stretch properties. Dutest Industries notes “Nylon rope is basically used for absorbing shock loads” due to elasticity.

30% Extension: Extreme stretching capabilities for heavy loads.

Hysteresis Loss: Internal loss of energy during the cycle.

Fiber Memory: The rope retains its shape after use.

D. Buoyancy And Flotation

To avoid damage, the rope must stay afloat on the water. We explain how flotation gear works for the rope.

1. Float Installation

Tubular Floats

Foam tubes wrap the rope to provide buoyancy. They provide the necessary lift for the line. We use closed-cell foam for the floats. The mooring hawser SPM stays on the surface. We secure them with straps to hold them. They resist water absorption to stay light.

Lace-on Floats

Jackets containing foam lace onto the rope easily. They are easy to replace when they wear out. We supply durable outer shells for the floats. The single buoy mooring line uses these for safety. We design them for visibility on the water.

Float Spacing

The distance between floats matters for the rope. Too far allows sagging in the water. We calculate the optimal pitch for the floats. The single buoy mooring SBM requires flat lines. We specify the exact spacing for the best results.

Buoy Markers

Reflective strips are used on floats to signify visibility. We ensure night detection for the ships. Captains see the line clearly in the dark. Avoidance prevents accidental cutting of the line. Visibility defines the safe zone for the vessel.

2. Water Interaction

Surface Floating

Securing a floatable line is hugely beneficial for the crew. Moored buoy systems depend on Positively Buoyant lines. Submerged mooring line systems leave ropes at the bottom. Surface lines allow easier surface retrieval for the crew.

Zero Absorption

It is a constant debate, single buoy mooring vs single point mooring. Heavy ropes are hard to pull and absorb water. To combat this, we coat the fibers to provide hydrophobic properties. Lines remain dry, so the rope stays light.

Hydrophobic Core

Your core has to repel water to avoid rot. Trapped water causes inner rot in the rope. Sub-ropes will always stay sealed with moisture inside. We guarantee water resistance within the core of the rope. No salt crystals will form, extending the lifetime.

Water Repellent

The water, marine tape, and spray adhesion clip harmful growth. The line stays clean so algae cannot grip. Heavy ropes are hard to pull for the crew. This repellent feature absorbs water, reducing drag for a better line.

3. Specific Gravity

0.91 Gravity

It is simple, we are under 0.91 specific gravity. Polypro is lighter than water, so it is buoyant. To allow for the blending of fibers, we engage science. 0.91 SG is naturally supporting in the water. No extra buoyancy is needed for the rope.

1.14 Sinking

Nylon is heavier than water, so it sinks. Thus, it sinks without foam floats to help it. We add external flotation gear to the rope. We calculate the required lift for the line. Sinking lines foul propellers on the ship.

0.97 Floating

HMPE floats cut naturally on the water surface. It is also lighter than seawater, so we use it. We prefer naturally floating ropes, as they are safer. No external floats are needed for this rope. Gravity works on our side in this case.

Positive Buoyancy

The physics of floating matters for the rope. We ensure the rope pushes up in the water. We engineer the density for this purpose. Positive buoyancy prevents snagging on the bottom. The rope rides the waves easily.

4. Subsea Avoidance

Propeller Clearance: Keep rope away from blades to avoid cuts.

Seabed Drag: Rocks cut the rope on the bottom.

Line Visibility: Orange color helps visibility for the crew.

Tangle Prevention: Floats stop underwater knots from forming.

E. Structural Wear Defense

The ocean environment destroys weak equipment over time. We detail how to stop the wear on the rope.

1. Abrasion Resistance

6mm Jacket

A thick skin protects the core from damage. It takes the physical abuse during the operation. We tightly weave it to show maximum thickness. The jacket sacrifices itself for the core. The core remains untouched inside the jacket. The used hawser rope for sale shows wear here.

Polyester Cover

Polyester is resistant to cut and rub damage. Also, it is the best armor for the rope. In the products, it is combined with nylon fibers. In the hawser rope for sale, this combination works well. We choose high tenacity yarn for the cover.

Friction Coefficient

Prevention of heat build-up is key for longevity. The slickness of the rope determines how long it lasts. To make it last, we apply a marine finish. The mooring hawser for sale is made with high friction materials. We minimize surface friction to save the rope.

Wear Resistance

We want the rope to last longer for you. To test this, we wear it down on rough drums. Ropes outlast the average rope on the market. The mooring rules surround inspection of the rope. Resistance to wear saves you money over time.

2. Internal Friction

Core Chafing

Strands rub against one another inside the rope. They get sand inside which wears it down. The outer jacket is sealed to prevent this. Mooring instructions include cleaning the shaft regularly. We prevent the ingress of particles into the rope.

Fiber Lubrication

We oil the internal fibers to reduce heat friction. This takes the form of a marine coating inside. It is long-lasting for internal fibers to survive. The PA6 ULTRALINE SPM mooring hawser uses this technology. Best of all, it is vital for elasticity.

Inter-strand Wear

Strands overlap and intersect within the rope structure. Tension causes pressure on these points. We design loose weaves to help this issue. We decrease crossover points in the design. Wear occurs at contact points in the rope.

Yarn Friction

The smallest amount of wear happens here. Damage occurs from micro-movements in the rope. We utilize smooth filaments to stop this. We track the quality of each yarn used. Friction can create harmful heat inside.

3. UV Protection

300 Hours

We assess extreme sunlight exposure on the rope. UV light causes plastic to degrade quickly. We ensure UV protection for the fibers. The rope stays strong in the sun. Ropes without protection become brittle and break. We test to prove durability in the sun.

UV Stabilized

Sunscreen for the rope fibers protects them. We incorporate chemical stabilizers in the plastic. We treat each yarn for protection. The rope does not fade in the sun. UV radiation breaks polymer chains in the rope. Boyuan Rope states “UV rays… results in… a significant loss of tensile strength.”

Sun Shield

The cover protects the core from the rays. The core stays in the dark safely. We use opaque jacket materials for the cover. We design for exposure to the elements. The shield takes the damage for the core.

Fiber Degradation

The sun makes plastic brittle over time. It cracks under load during use. We monitor strength loss in the rope. We choose plastic that withstands the sun. Degradation leads to failure on the deck.

4. Heat Management

215°C Melt: Nylon melts at high temp during use.

Friction Heat: Fast rubbing burns rope fibers quickly.

Thermal Stability: Staying strong when hot is essential.

Heat Dissipation: Letting the heat out saves the rope.

F. Operational Vessel Control

The hawser keeps the ship in position during transfer. We control the dynamic explained below for you.

1. Position Holding

Bow Secure

The front of the ship stays put during transfer. It pivots around the buoy securely. We ensure a solid hold for the ship. Single handed mooring pick up is tricky to do. Ropes hold fast to the buoy. Security prevents collision risks at sea.

Drift Limit

How far can it move safely? We define the safe circle for the ship. The what is a mooring point defines the center. We calculate the excursion limit for safety. Limits prevent hose rupture during transfer. Drifting puts strain on hoses.

Yaw Control

Stopping the side-to-side swing is vital. The ship fishtails in current if unchecked. We use shorter lines to stop this. The what is a single point sling helps here. We advise on length for control. Yawing creates wear on the system.

Station Keeping

Staying in the pumping zone is required. The tanker must align with the buoy. We provide the tether for this. The what is a mooring pole comparison applies here. We ensure station keeping for the ship. Proper tension maintains position during transfer.

2. Environmental Response

Wind Force

The wind pushes the tanker during operations. The rope fights back hard against the wind. We calculate wind load on the ship. The what is a mooring slip is different. We design for typhoons and storms. Wind creates constant tension on the line.

Current Drag

The water pushes the hull of the ship. This force is massive in the ocean. We use drag coefficients to calculate this. Single point mooring manufacturers model this force. We build for high currents in the water. Drag adds to the load on the rope.

Tide Changes

Up and down water levels affect the rope. The scope changes constantly with the tide. We allow for tidal range in the design. Ropes handle the angles of the tide. Tides change the tension vector on the line.

Sea States

Rough seas versus calm water make a difference. Waves create shock loads on the rope. We test for high sea states for safety. We ensure storm survival for the ship. Calm water is easy for the rope.

3. Safety Zones

Snapback Zone

Kill Zone Deck Safety Lines should be painted red. Full warning is needed for the crew. We advocate for deck safety at all times. Do not walk in the danger zone. If the line breaks, it will kill. Lives are lost due to a lack of awareness. West of England P&I advises considering “the entire mooring deck” a potential snap-back zone.

Recoil Path

To where the broken rope will fly on deck. It will fly out at the speed of sound. We can even predict the trajectory path. We work at minimizing the energy of the recoil. Knowing the path the rope will take is vital.

Crew Clearance

Off the deck is where all personnel should be. We always prioritize safety of all personnel on board. Training always emphasizes this safety rule. The deck is clear to help prevent accidents. Only the necessary crew are allowed to stay.

Deck Safety

Everyone knows that skids, slips, trips, and falls happen. To prevent that, the deck must stay clear. We offer our customers the ability to organize their reels. Deck Management is what we offer you. Loose, un-stowed ropes are dangers.

4. Emergency Release

Release Hook: Emergency Panic Button for the crew.

Load Shedding: Quickly dropping the line saves the ship.

Parting Point: Intentionally designed weak link that will break.

Quick Disconnect: Rapid separation to avoid a catastrophe.

What Materials Make The Best Mooring Hawser?

The right material also significantly determines the price of the mooring hawser. The right material also needs to be balanced against performance, cost, and safety. We will assist in determining the best fiber to use for your specific offshore needs.

Polyamide 66

This is the most accepted nylon in the industry. It has great elasticity meaning it can absorb shocks. It is used in most of our operations. The mooring hawsers we have come in different sizes based on the tonnage of the vessel. It’s on the cheaper side of the spectrum but absorbs water. We make it water resistant.

HMPE SK78

This fiber provides the highest strength to weight ratio. It has the advantage of floating on water. It is used in the most demanding applications. The mooring hawser of this class is expensive but lasts longer. We advise using it for the most heavy-duty usage.

Nylon 6.6

This is the classic fiber used for deep water. It has a safe stretch of up to 20%. Double braids is our style of weaving. The mooring hawser HS code classifies this as a synthetic. It has the downside of sinking in water but we counteract this by adding floats.

Tenacity Polyester

Polyester has high strength with low stretch. It stays just as strong even when wet. For Position Keeping we used this strength. A comparable product is the BEXCO mooring hawser. It is heavy compared to nylon. For the jackets we use it.

UHMWPE Fiber

Ultra-high molecular weight polyethylene is extremely strong and withstands chemicals. It is utilized for extreme durability requirements. The mooring hawser manufacturer USA market has this need. It is slippery and needs special splicing. We handle the fabrication with utmost care.

Kevlar Aramid

Kevlar has extreme heat and tension resistance. It has low stretch properties. We use it in high-temperature work environments. The BRIDON mooring hawser competes in this area. It fails with abrupt bending stress. We use it for straight line pulls only.

Mixed Fibers

We use a blend of polyester and polypropylene for strength. This allows for the creation of a fiber capable of floating. This is the best of both worlds. The single point mooring hawser price is at a moderate level. It has a good resistance to fatigue.

Polysteel Rope

This is a high strength polypropylene material. It is inexpensive and has a capability of floating. We put it to use in non-critical lines. Single point mooring hawser manufacturers distribute this extensively. It has less resistance to abrasion. It degrades rapidly when exposed to sunlight.

Polypropylene PP

This is the least expensive alternative option. Polypropylene floats, although it decays in the sunlight. We caution users about UV damage. This is also included in the single point mooring hawser on our site. It has a low melt point.

| Material | Specific Gravity | Elongation (%) | Melting Point (°C) | Abrasion Resistance | UV Resistance |

| Polyamide 66 (Nylon 66) | 1.14 | 20-30% | 250 | Good | Good |

| HMPE SK78 | 0.97 | 3-4% | 145 | Excellent | Excellent |

| Tenacity Polyester | 1.38 | 10-15% | 260 | Very Good | Excellent |

| UHMWPE Fiber | 0.97 | 3-5% | 145 | Excellent | Excellent |

| Kevlar Aramid | 1.44 | <4% | 500 (Decomp) | Good | Poor |

| Mixed Fibers (Poly/PP) | 0.99 | 15-18% | 165/260 | Good | Good |

| Polysteel (High Strength PP) | 0.91 | 18-22% | 165 | Fair | Fair |

| Polypropylene (PP) | 0.91 | 18-25% | 165 | Poor | Poor |

Comparison of Mooring Hawser Material Specifications!

How To Calculate Proper Mooring Hawser Diameter?

When it comes to safety and compliance, making mooring calculations of hawser size is crucial. You have to consider the ship size and environmental conditions. We take the experience, and a single point mooring hawser is calculated and specified to the final detail.

Ship Tonnage

The load is determined by the ship size. Bigger vessels mean need for thicker lines. We work with Deadweight Tonnage (DWT) for our mooring. This is where the mooring calculation example begins. We align the diameter to the DWT.

Bollard Pull

The Pulling capacity of the tug is important. We assess the strength of the ropes against this factor. Moorings Hawaii often requires ropes with high strength. We ensure the rope is greater than the tug’s maximum pull.

MBLsd Calculation

We work with something called the Minimum Breaking Load for Ship Design. This establishes a base for safety. This is what the mooring harness must fit. We adhere to class society regulations.

Safety Factor

A 50% safety factor is a must. We don’t design for the limit. Mooring charges meaning relates to equipment grade. Wear and tear happen so we apply a 1.5 to 2.0 safety factor.

ISO 2307

An international testing standard in ISO 2307 is defined. This dictates how we measure diameter. As defined by ISO, this standard “specifies a method for the determination of the physical properties of fibre ropes.” The towing hawser navy specs are a standard to guide us. Compliance ensures the standard is accepted worldwide.

Break Force

This is the limit for the rope. The rope parts at this load. Mooring hawsers for sale state this clearly. We validate this on test beds. Knowing the limit is crucial to avoid accidents.

5:1 Ratio

Working load limit regulation is a rule of thumb. 20% of MBL is the upper limit to avoid fatigue failure. This is advised to users by operators. Lower is better and extends rope life.

Safe Working

These are the daily operational limits. The operations stay in this green zone. This is also on the certs. Safe Working Load emphasizes on this. Damaging the fibers occurs if you exceed SWL.

Load Limits

Know When to Stop Pulling immediately. Load Limits are more than just a theoretical concept to us. Knowing the red zone is crucial to be able to mitigate its danger.

Why Is OCIMF MEG4 Compliance Vital?

Safety Comes First! Across the maritime sector, the OCIMF MEG4 guidelines are the standard when it comes to safety within the industry. We respect these guidelines when it comes to OCIMF SPM mooring hawsers. Compliance with these guidelines is required if you want to be insured.

Failure to follow the guidelines put the deck crew in danger. We make hawsers to these guidelines. We test our hawsers to ensure they can withstand a fatigue test with a specified residual strength. In our industry, the guidelines set the retirement criteria.

Operators must track the usage hours over a time span. Single point mooring hawsers are abused over time. MEG4 makes sure they are fit for purpose. Management of the line must be in accordance with the instructions. We issue the safety certificates for each hawser.

Safety documentation is used when submitting to the port authority for approval. Safety Officers must have these certificates in their possession. Compliance with the guidelines mitigates risk of catastrophic failures within the terminal.

HMPE Vs Nylon: Which Fits Your Needs?

Deciding whether to use HMPE or Nyloncomes down to requirements from your 3 point mooring hawser manufacturer. You need to find the balance between stiffness and elasticity. For operational budget and technical needs, we offer both solutions.

3% Elongation

HMPE is extremely rigid and precise. It only stretches 3% at the point of break. For tight control usage, we use it. For positioning, the mooring hawser manufacturer recommends this.

15x Steel

HMPE is stronger than steel wire. It is able to manage enormous loads with ease. Because of this, we rarely use steel cables. Single point mooring hawser manufacturer’s preference is this strength. Dynamica Ropes confirms Dyneema is “up to 15 times stronger than steel by weight.”

Floating Core

HMPE is unique in that it floats. It floats on water by itself and does not require foam collars. For us, this is a promoted safety feature. Sinking lines pose a danger to the ship.

Zero Water

The fact that Zero Water HMPE stays wet makes it lightweight. It does not soak water weight. For crew safety we appreciate this. Ropes stay manageable for the crew.

High Cost

HMPE hits the pocket hard at first. It is costly raw material. We advise on total life cycle cost. We demonstrate the long-term worth. It outlasts nylon significantly.

0.97 Gravity

The specific gravity is less than 1. It floats by itself on the water. We measure density for quality. We prioritize positive buoyancy. This speeds up retrieval for the crew.

Low Recoil

HMPE is preferable in safety due to snapback. It falls down when it breaks. We choose it for safety zones. We lean greatly on crew safety. High energy recoil is fatal.

Snapback Safety

Unlike snaps that have deadly force, HMPE falls flat on the deck. We highlight this difference for safety. We focus on risk mitigation. The main hazard is snapback.

Creep Resistance

HMPE can stretch permanently over time. So, we use low-creep grades. We select SK78 fiber for this reason. It protects against load elongation. Standard PE creeps and fails.

FAQs!

We respond to multiple queries for hawser specifications. Duracordix has the knowledge to assist you.

What Is The Specific Gravity Of Nylon Hawsers?

Nylon has a specific gravity of 1.14. It is denser than water, so it sinks unassisted. We put foam collars to give it buoyancy. The mooring hawser HS code classifies it. We guarantee the line won’t sink. Sinking lines are a safety hazard.

Does OCIMF MEG4 Require Line Management Plans?

Yes, for sure. MEG4 requires a Line Management Plan (LMP). You have to document the use & the inspections. We supply these templates. It guarantees the line is retired before it fails. It is a requirement for terminals. Safety relies on the records.

What Is The Melting Point Of Polyamide 66?

Polyamide 66 has a melting point of 250°C (482°F). It softens before it gets to that temperature. Friction creates heat, and it can get dangerous. We lubricate the fibers to reduce the heat. The mooring mast meaning is at high tension. Heat must be controlled.

How Much Strength Does Wet Nylon Lose?

Wet nylon loses a percentage of roughly from 10 to 15 of its strength. Water molecules act as a lubricant to the internal bonds. This loss is factored in. We rate the ropes for wet strength. This reduction is known in the industry. Wilhelmsen states “strength of polyamide (Nylon) ropes decreases by 10-20% in wet condition.”

Is HMPE Stronger Than Steel Wire Rope?

Yes, more than wire steel. It is 15 times stronger than steel. We replace heavy wires with high-modulus fibers. It is the modern standard as it floats and does not rust. Kennedy Wire Rope notes HMPE is “86% lighter than steel wire rope” and remarkably durable.

What Is The Standard Safety Factor For Mooring?

The standard safety factor, 1.8 to 2.0, is the norm. We design for a factor of 50 of the MBL. Point loads on mooring vary. We advise to never exceed SWL. For lifting, the factor is higher. Mooring has lower factor allowance.

Do Single Point Mooring Hawsers Float?

Yes, as they should to avoid propellers. The multi-point mooring also requires this. We use float kits or buoyant fibers. We design for full visibility. Sinking hawsers get cut. Floatation is a requirement.

What Is The MBL Of 40mm HMPE?

About 40mm HMPE rope varies by construction type, but it breaks around 1400kN. We test every produced batch, and we certify the breaking load. It is very strong for its size, and certificates should always be checked.

Does Polyester Rope Absorb Water?

No, polyester does not absorb water significantly, but it retains full strength when wet. We suggest it for jackets due to its durability. It stays lightweight in the rain, but water absorption is negligible.

What Is The Elongation Of Dyneema At Break?

Dyneema only elongates about 3 to 4% at its break, but it is very stiff. We use it for precision, but we pull away in the case of shock loaded situations where there is no elastic buffer. Systems need dampeners.

How Often Should Hawsers Undergo Visual Inspection?

Hawsers should be visually inspected before every single operation. Look for cuts and abrasion. We provide inspection checklists for detailed inspections that occur monthly. Safety cannot be compromised, and catching damage early saves lives. As CLAIRVOYANTUAE states, “Regular inspection is the single most important factor in preventing rope failure.”

What Defines The Snap-Back Zone On Deck?

Snap-back zones are spaces where broken ropes recoil and fly. These areas are painted red, and training emphasizes the need to stay clear of these areas. Under tension, it is a lethal area.

Is 15:1 The Correct D/D Bend Ratio?

The correct ratio is 15:1, yes. The ratio of the hardware diameter to the rope diameter must be 15:1. This is the design we use to make the eyes. We prevent tight bends, which can weaken the rope. Arizona Wire Rope warns “strength is decreased” depending on “the severity of the bend.”

What Covers Protect The Hawser Eye Splice?

The covers offered for eye splice protection are a petroleum and polyurethane both used for protection against chafe and durability. We also add eye protection to avoid splices from wearing down. Protection on the splice also used to add durability to the eye and prolongs the splice’s service life.

Does UV Light Degrade Polypropylene Fibers Quickly?

Yes, sunlight is very damaging to polypropylene fibers and causes them to become brittle. To protect against sunlight damage, we use UV stabilizers and our jackets protect the core. Ropes should be stored covered to protect from sunlight damage.

Conclusion

Now you understand why choosing high-quality ropes is critical for operational safety at sea. We help you secure your vessels against the harsh elements with the right mooring hawser. DURACORDIX can assist you in securing your fleet today. To find the best gear for heavy ocean use, visit us to get started immediately.

About The Author

Moses Xu

Hi, I’m Moses Xu, VP and Marketing Director at Duracordix. With 10+ years in high-performance synthetic ropes and netting, I specialize in export trade and marketing. Whether it’s HMPE, Kevlar, or nylon ropes, I’m happy to share insights and connect!