Marine & Ship mooring rope

Strong, Reliable Mooring Ropes Built to Keep Your Vessel Safe and Secure

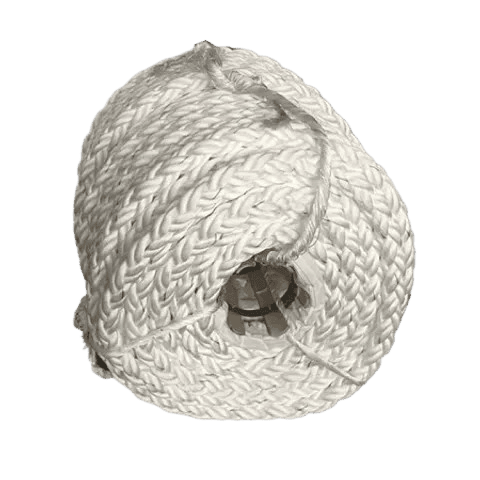

Synthetic mooring Rope

Duracordix mooring lines are designed to secure vessels to docks, mooring points, or buoys, preventing your vessel from drifting due to wind, waves, and tides. Our mooring lines are made of high-quality synthetic fibers such as UHMWPE, nylon, polyester, and polypropylene, or blends thereof.

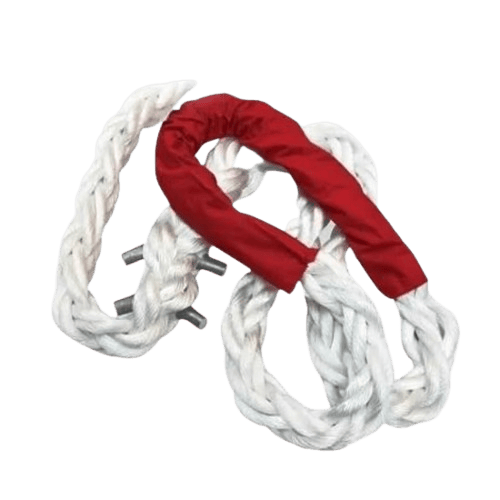

Duracordix designs our mooring rope in 3-strand, 8-strand, 12-strand, and double-braided structures to meet your needs. Combined with our ultra-durable chafe protection, they ensure the smooth operation of your mooring system.

Duracordix is not just a mooring rope supplier, but also a provider of comprehensive mooring solutions for your system

General Applications

Exploring Mooring Rope in Diverse Maritime Applications

shipping Industry

Mooring rope for ships simplify handling & securely your mooring vessels in demanding shipping conditions.

Offshore Drilling

Mooring hawser line is lightweight, making operations easier and securely anchoring your offshore equipment

marine environment

Strong and lightweight, built to withstand harsh conditions and securely your moor vessels in marine environments

Aquaculture

Used to secure fishing boats to the dock or to secure aquaculture fishing cages, maintaining the stability of aquaculture equipment.

Towing and Rescue

Our mooring line can connect a tugboat to a vessel that needs to be towed to a designated location, and in rescue situations, it can tow a distressed vessel to a safe area for rescue.

Yacht Mooring

Mmooring line for boat is designed for yacht and boat mooring systems, easy handling and secure mooring in your boating and yachting.

Types Of Mooring Rope

As a mooring rope manufacturer, we provide you different types of mooring ropes

Nylon Mooring Rope

polyester Mooring Rope

Polypropylene Mooring Rope

Polyethylene mooring Rope

Mooring Ropes Construction

Duracordix can offer you various rope construction to meet your special needs.

3 Strand Mooring Rope

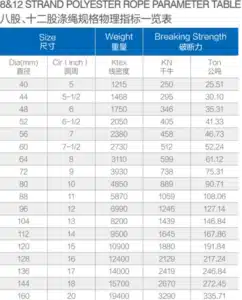

8 Strand Mooring Rope

12 Strand Mooring Rope

Double Braided Mooring Rope

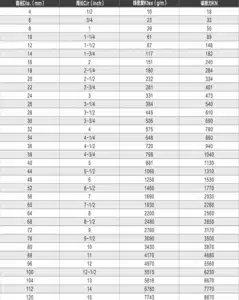

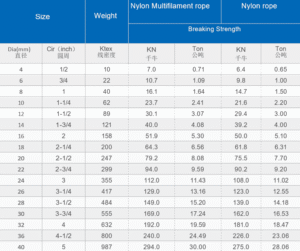

Mooring Rope Size Chart

Advantage of Our Mooring Rope

OEM & Custom Made Service

- Length & Diameter: Duracordix can provide mooring ropes of different diameters to suit your strength requirements, and also offer different lengths depending on your specific application, such as 50m, 100m, 220m, 500m, or other lengths.

- Color Options: Duracordix understands your color needs in different scenarios. We can customize eye-catching colors such as yellow, blue, orange, and red, as well as more subtle colors like gray and black.

- Construction: we can make you the braided mooring rope or twisted mooring rope as requested, we can also provide you the mooring lines in 3strand, 8strand, 12strand or double braided for your unique needs.

- Material:Whether you need HMPE mooring rope, nylon mooring rope, polyester, PP or PE, or mooring ropes made of mixed materials, we can customize them for you.

- Chafe Protection:Duracordix understands that protecting mooring ropes is crucial throughout the entire mooring system. so Duracordix has developed a series of chafe protection products, such as choke protection, Dura Guard, and PR wear protection, to prolong the service life of your mooring lines.

Client Voice

Our customers share their marine mooring rope experiences and successes

Certifications-- Duracordix Offer

Why Choose Duracordix

- Proven Quality: Duracordix mooring lines are exported to 30 countries, our quality is recognized by customers.We also provide third-party international quality certifications such as CCS, ABS, LR, RINA, BV, and DNV GL and MEG4 certfication.

- Safety: Due to its properties, Duracordix mooring line does not recoil with the same force as steel wire ropes. Additionly, we also have anti snap backn mooring rope minimizes recoil,it can ensure the safety of your personnel and equipment.

- Cost Effective: Duracordix has optimized the UV resistance and fatigue resistance of our mooring ropes through improviness of the rope manufacturing process, Our mooring line can last for over 6 months longer than others, it reduceg replacement frequency and lowering the total life cycle cost.

- Customer Service: Duracordix's sales and technical personnel will work together to customize your mooring solution based on your needs, ensuring 24/7 online communication and providing prompt responses and solutions to your questions.

FAQs

You Can Find More Details About Mooring Systerm and Mooring Rope

What is mooring?

Mooring is the process of securing a boat or ship to a fixed point, like a dock, pier, or buoy, so it stays in place. This is typically done using ropes, chains, or cables to keep the vessel steady, even in changing tides and strong winds, ensuring it doesn’t drift or move unexpectedly.

Do you know the types of mooring?

Yes, there are several types of mooring, each suited to different situations and vessel types:

Single-Point Mooring (SPM): Anchors a vessel to one point, typically a buoy, allowing it to pivot with the wind and tides. Often used for large tankers.

Multiple-Point Mooring: Uses several mooring lines connected to various fixed points, like buoys or the seabed, keeping the vessel more secure and stable. Ideal for offshore drilling or heavy vessels.

Conventional (Dock) Mooring: Ties the vessel directly to a dock using lines from the bow, stern, and sides. Common in marinas and ports for smaller boats and ships.

Mediterranean Mooring: The vessel’s stern faces the dock while the bow is anchored, allowing more boats to fit along a dock. Often used in crowded marinas.

Dynamic Positioning (DP): Uses a computerized system and thrusters to keep a vessel stationary without physical mooring lines. Commonly used on offshore vessels needing precise positioning.

Should a synthetic mooring rope in use ever be knotted?

A synthetic mooring rope in use should never be knotted, because knotting can reduce the rope's breaking strength by at least 50% and it also create a weak point in the entire rope.

This makes the rope susceptible to creep under normal operating conditions due to reduced strength, it may lead to insufficient tensile strength and eventual ropefailure.

What is the best rope for mooring line?

The best material for mooring ropes depends on the specific application and requirements. UHMWPE is generally considered the best for their lightweight, high strength and durability.

How do you choose the right mooring rope size?

The diameter and length of a mooring rope depend on your vessel’s size, weight, and the load it’ll need to handle. Be sure your mooring winch can support the rope size you choose. As a rule of thumb, the rope length should be at least 1.5 times the vessel's length to ensure secure mooring and enough flexibility for shifting conditions.

What is the difference between twisted and braided mooring ropes?

Twisted mooring ropes are made by twisting multiple strands together, while braided mooring ropes are created by braiding strands. Braided ropes tend to be stronger and more durable, making them a great choice for heavy-duty mooring.

Do you need mooring rope protection sleeve?

Yes, a protection sleeve is a smart addition to extend the life of your mooring rope. It helps shield the rope from abrasion, UV damage, and wear caused by constant rubbing against docks or cleats. This added layer can make a big difference, especially in rough conditions, keeping your rope stronger and more reliable over time.

What is Heavy Mooring Rope?

Heavy mooring rope is designed for securing large vessels in tough conditions. Made from ultra-durable materials(like UHMWPE or dyneema), it provides reliable strength, resists abrasion and UV damage, and keeps your vessel steady in strong currents and winds—ideal for demanding marine applications.

How to splice mooring rope?

Splicing a mooring rope is a handy skill to create strong loops or join two ropes. Here’s a simple guide:

Unwind the Strands: Start by carefully unbraiding or untwisting the end of the rope, separating it into three or more strands.

Form a Loop: Fold the rope to create the size of loop you want, leaving a tail with the loose strands.

Weave the Strands: Take each strand and weave it through the main rope, going over and under the strands in the rope body. Repeat this several times to secure the splice.

Tighten the Splice: Pull each strand tightly to make sure the splice is secure, then trim any excess for a clean finish.

With practice, splicing becomes easier, and it’s a great way to keep your mooring setup strong and reliable.

What is the difference between a dock line and a mooring rope?

A dock line is a rope used to tie a vessel to a dock, while a mooring rope is used to secure a vessel to an anchor or buoy.

How to Tie a Proper Mooring Line Knot?

To secure your vessel safely, use the Cleat Hitch knot:

- Wrap the rope around the cleat’s base.

- Make a figure-eight by crossing the rope over the cleat.

- Finish with a half-loop under the last wrap.

This knot is strong, easy to undo, and keeps your boat secure even in rough conditions.

What is the difference between single braided and double braided mooring rope?

Single braid mooring ropes are made up of a single braided rope, while double braid mooring ropes are made up of two braided ropes - an inner core and an outer sheath. Double braid ropes are typically stronger and more durable than single braid ropes.

How do you inspect a mooring-rope for wear and damage?

To inspect a mooring rope for wear and damage, look for signs of fraying, cuts, discoloration, or stiffness. Run your hands along the rope to feel for any abnormalities or rough spots. Replace any damaged or worn sections immediately.

What is Atlas Mooing Rope and Can you make it?

Atlas mooring rope is made from high-strength nylon, combining monofilament and multifilament yarns in a braided structure. typically with a 6-strand cross weave. It is primarily used for mooring large vessels in extreme marine environments.

Its high elasticity(also called elastic mooring rope) effectively absorbs the impact caused by waves and currents.

It can be used in conjunction with a mooring winch, it helps maintain the stability of your vessel. Duracordix has extensive experience in manufacturing Atlas mooring ropes; please contact us.

What is the difference between UHMWPE and polyester mooring ropes?

UHMWPE mooring ropes are lighter and stronger than polyester ropes, but are more expensive. Polyester ropes are more stretchy and have better abrasion resistance than UHMWPE ropes.

Why do mooring-ropes have a braided design?

Increased Strength: Braiding enhances tensile strength, helping ropes withstand heavy mooring forces.

Durability: Compact braids resist wear, lasting longer in harsh marine environments.

Flexibility: Braided ropes handle smoothly, reducing stress points.

Minimal Stretch: Low stretch ensures stability and lowers snap risks under tension.

Easy Handling: Smooth surface prevents twisting and reduces hand strain.

Core-Sheath Protection: Inner core adds strength; outer sheath protects against abrasion and the elements.

Braided mooring lines offer reliable, long-lasting performance, designed to keep your vessel secure with minimal hassle.

How do you clean a mooring rope?

To clean a mooring rope, rinse it with clean water and mild soap, and hang it up to dry in a cool, dry place away from direct sunlight or moisture. Avoid using harsh chemicals or abrasive cleaners that can damage the fibers.

What is the best mooring-rope for you?

The best mooring rope depends on your vessel type, mooring conditions, and specific needs.

For heavy-duty and long-lasting durability, nylon ropes are great due to their high strength and shock absorption.

Polyester ropes offer low stretch and UV resistance, ideal for consistent stability.

Polypropylene ropes are lightweight and float, which makes them handy for temporary moorings.

UHMWPE ropes are ultra-strong and abrasion-resistant, perfect for tough environments where reliability is critical.

How often should you replace a mooring-rope?

The frequency of mooring rope replacement depends on the material, diameter, construction, and usage. Consult with a mooring expert or refer to industry guidelines for proper replacement intervals.

What is the difference between a 3-strand and 8-strand mooring rope?

A 3-strand mooring rope is made up of three strands twisted together, while an 8-strand mooring rope is made up of eight strands braided together. 8-strand ropes are typically stronger and more durable than 3-strand ropes.

How do you protect a mooring-rope from UV damage?

To protect a mooring rope from UV damage, store it in a cool, dry place away from direct sunlight or moisture, or cover it with a UV-resistant sleeve or cover.

What is the best mooring-rope for yacht mooring?

For yachts, nylon mooring ropes are ideal. They offer high strength, flexibility, and excellent shock absorption—perfect for protecting your yacht in changing tides and rough conditions. Nylon’s durability and UV resistance ensure long-lasting performance, keeping your yacht safe and secure with minimal wear.

How to Avoid Mooring-Rope Accidents?

Inspect Regularly: Check ropes for wear, frays, or damage before each use. A weakened rope can snap under load, leading to serious accidents.

Choose the Right Rope: Use a rope that’s strong enough for your vessel’s size and weight, with enough length and diameter to handle the load.

Stay Clear of Loaded Ropes: When the rope is under tension, stand clear. If it snaps, it can recoil dangerously.

Use Protection Sleeves: A chafe protection sleeve can care the rope from abrasion, extending its life and reducing the mooring rope damage and the risk of sudden breaks.

Monitor Tension and Weather: Keep an eye on changing tides, strong winds, or shifting conditions that may add strain to your mooring setup.

By following these steps, you can reduce the risks and keep mooring operations safe for everyone involved.

What is Regular Length of Your Mooring-Rope Reel?

Our mooring rope reels typically come in lengths of 100 to 200 meters, providing ample rope for various mooring needs. This length ensures you have enough flexibility to cut custom lengths, helping you get the perfect fit for your vessel.

Related products

Duracordix also offer other related products to meet your mooring operation