CONSTRUCTION

Homepage » Industries » construction

CONSTRUCTION

We offer a broad spectrum of premium-quality products crafted specifically for construction applications and heavy-duty lifting tasks. Our popular products include crane rope, heavy-duty lifting sling and webbing sling.

In addition, we also produce and provide other indispensable items catering to your construction and heavy-lifting requirements such as crane rope equalizers, building site safety nets, heavy lifting strap and a diverse range of rope accessories and related gear.

Webbing Sling is flexible, durable, and lightweight, ensuring safe and efficient lifting across various applications.

UHMWPE Lifting Sling is ultra-strong, lightweight, surpassing traditional materials for efficient lifting

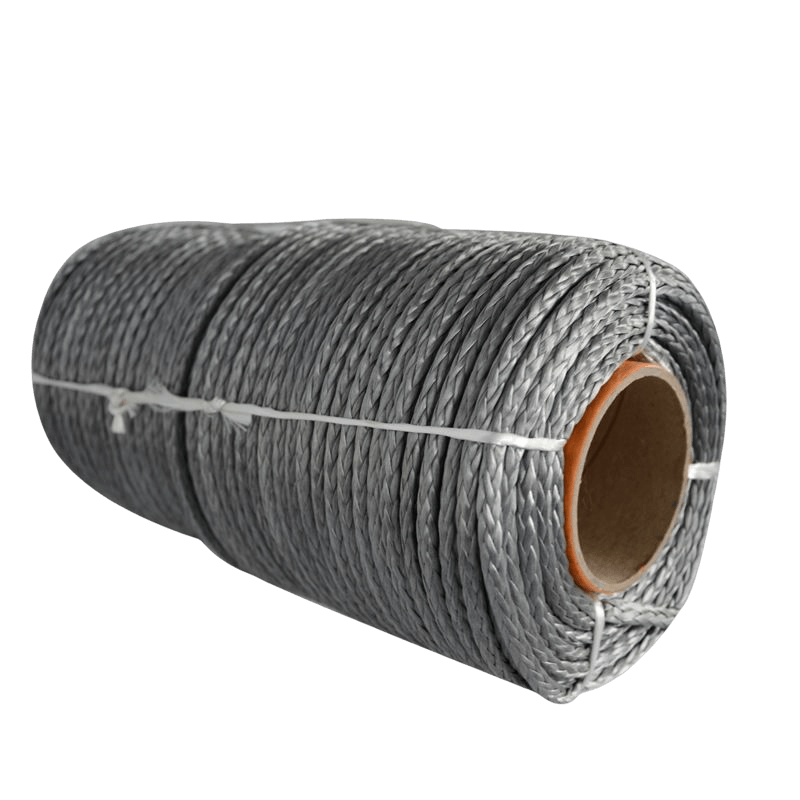

UHMWPE Crane Rope is strong, lightweight, and durable, transforming modern crane operations.

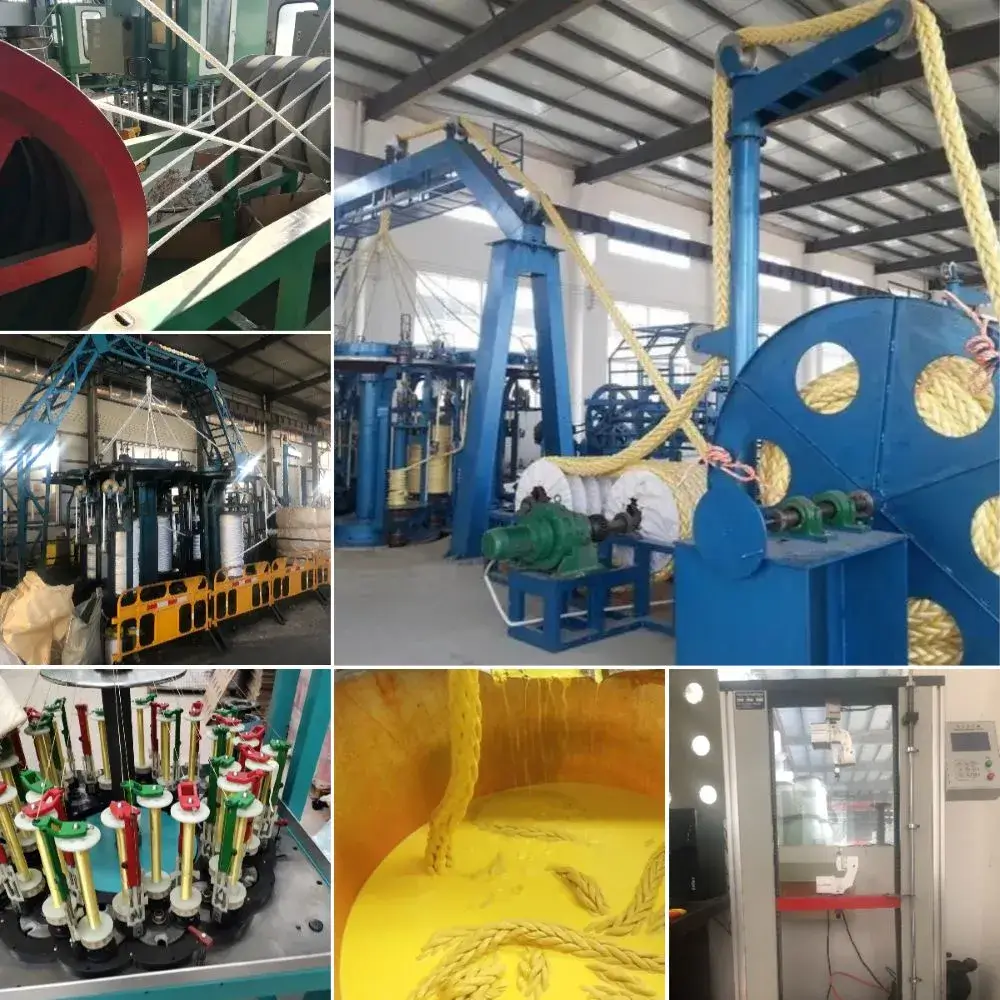

how to make

construction rope

Discover Our Process of Producing High-Performance Construction Ropes.

Process 1

fiber selection

We carefully select high-quality synthetic fibers, such as nylon,polyester, or UHMWPE, to use in our ropes, ensuring strength and durability.

Process 2

Twisting and Forming

The selected fibers are twisted together to create yarns, which are then twisted together to create strands. The twisted strands are then formed into a rope-like structure.

Process 3

Laying and Braiding

The formed rope is laid into a braiding machine, which braids the rope together using specialized techniques and patterns to further increase strength and durability.

Process 4

Coating

A custom protective coating made of high-quality materials, such as PVC or polyurethane, is applied to enhance the rope’s durability and resistance to abrasion, water, and UV rays.

Process 5

Heat Treatment and Drying

The braided rope undergoes a specialized heat treatment process to set the braids and increase strength. The rope is then dried to remove any moisture.

Process 6

testing

Each Duracordix recovery rope is rigorously tested to ensure it meets our high standards for strength and stretch. Any rope that fails our testing process is discarded.

- Quality-Centric

. QUALITY CONTROL

Explore How We Ensure Unparalleled Excellence in Every Fiber Rope

1. Raw Materials

Our synthetic construction ropes are only made from raw materials that meet our strict quality standards. We work with trusted suppliers to ensure consistent quality and optimal performance in all our products.

2. In-House

By keeping our synthetic rope production in-house, we have full control over quality throughout the manufacturing process. This allows us to adhere to our high standards and provide reliable products to our customers.

3. Testing & Inspection

Our rigorous testing and inspection processes involve every stage of production, from raw materials to finished products. This ensures the consistent quality and safety of our synthetic ropes.

4. Automated Manufacturing

We integrate automated machinery and technology to ensure accuracy and consistency in our synthetic rope production. This reduces human error and ensures all products meet our strict quality standards.

5. Skilled Staff

Our highly skilled workforce undergoes ongoing training and continuing education to stay up-to-date with the latest techniques in synthetic rope production. This helps us uphold the highest level of quality and performance

- international standard

our certifications

easy & clear

Maximizing customer satisfaction with easy purchasing, minimizes communication and time costs.

Step 1: Solution Confirmation (3-5 days)

First, we’ll chat about your needs and recommend the best rope solution for you. Our expertise and experience will guarantee you get the best product possible.

Step 2: Sample Evaluation (7-14 days)

To ensure you’re happy with our product, we offer sample evaluations. Test our products before ordering to make sure they meet your requirements.

Step 3: Order Confirmation (within 3 day)

Once you’re satisfied with the sample evaluation, confirm your order with us. We’ll provide all necessary details, including pricing, lead times, and more, so you can be confident in your purchase.

Step 4: Bulk Manufacturing (30-45 days)

We offer bulk manufacturing options for larger orders. Our advanced production techniques and high-quality materials ensure consistency and reliability across all orders.

Step 5: Delivery (30-45 days)

We know timely delivery is important, so we’ll keep you updated on shipping progress and provide tracking information. Your order will arrive within the agreed timeframe.

Step 6: After-Sales Service

Our service doesn’t stop after your order is delivered. If you have any questions or concerns, our team is always available to assist you. We’re committed to providing excellent customer service and ensuring your satisfaction.

- Pain-Free Purchase

WHY CHOOSE

- Durability: Using innovative materials, Duracrodix ropes withstand wear and environmental factors, extending lifespan by 50% compared to others.

- Strength: With a tensile strength surpassing competitors by 40%, Duracrodix ensures unmatched load-bearing for demanding construction tasks.

- Safety: Duracrodix synthetic rope reduces injury risks by 80%, eliminating the dangerous recoil of traditional ropes when broken.

- Lightweight: 60% lighter than steel alternatives, our synthetic rope guarantees effortless handling and reduces labor efforts.

- Offering 30% savings with lower maintenance and durable resilience, Duracrodix ropes outshine conventional options in cost-efficiency.

- Versatility: Catering to diverse construction demands, our rope excels in versatility, suitable for tasks from hoisting to securing.

FAQs

Frequently asked questions addressing customer concerns and pain points

What is construction rope?

Construction rope is a high-strength, durable rope designed for use in heavy-duty applications, such as building construction, lifting, and rigging.

How to choose the right diameter of construction rope for my project?

Consider factors such as load capacity and intended use when selecting the diameter of a construction rope. Consult with experts at Duracordix to make an informed decision.

What is the best rope for construction?

The best rope for construction depends on the specific application, load requirements, and environmental factors. Popular choices include nylon, polyester,polypropylene and uhmwpe ropes due to their strength, durability, and resistance to abrasion and environmental factors.

What type of fiber rope is best suited for securing loads on trucks during transportation?

Duracordix's nylon rope offers excellent tensile strength and abrasion resistance, making it an ideal choice for securing loads on trucks during transportation.

Are steel wire ropes still widely used in modern-day construction projects?

Steel wire ropes continue to play a crucial role in heavy-duty applications within the construction industry due to their exceptional tensile strength and durability.

What is the best construction rope for heavy lifting?

Duracordix's UHMWPE rope offers exceptional strength and durability, making it ideal for heavy lifting in construction projects.

Is nylon or UHMWPE rope better for general construction purposes?

Both nylon and UHMWPE ropes have their advantages, but UHMWPE stands out with its superior strength-to-weight ratio, making it a preferred choice for many construction applications.

Can I use Kevlar rope in high-temperature environments during construction?

Yes, Kevlar ropes are known for their excellent heat resistance properties, making them suitable for high-temperature environments encountered in certain construction activities.

Which type of fiber rope is recommended for scaffolding safety lines?

Nylon ropes are commonly used as safety lines in scaffolding due to their good shock absorption capabilities and overall strength.

Is there any specific regulation regarding the maximum weight limit that can be lifted using fiber ropes?

Regulations may vary by jurisdiction, but generally speaking, various factors such as rope diameter, construction type, and other safety considerations come into play when determining weight limits for lifting operations.

Can UHMWPE ropes be used in marine construction projects?

Absolutely! UHMWPE ropes have high resistance to water absorption and excellent strength, making them suitable for various marine construction applications.

What is the average lifespan of a Duracordix nylon rope used in building maintenance operations?

The lifespan of a Duracordix nylon rope can vary depending on usage conditions but with proper care and maintenance, it can last several years in building maintenance operations.

Are there any specific certifications or standards that fiber ropes should comply with for use in construction?

Yes, certain certifications such as ISO 9001 and CE certification ensure that the fiber ropes meet quality standards required for safe usage in construction applications.

How does UHMWPE rope perform compared to traditional wire ropes during heavy-duty lifting tasks?

UHMWPE ropes offer comparable strength to steel wire ropes while being significantly lighter, which makes them more manageable during heavy-duty lifting tasks.

Can Kevlar rope withstand harsh weather conditions commonly encountered on construction sites?

Yes, Kevlar has excellent resistance against UV radiation and is known for its durability even under extreme weather conditions found on construction sites.

Is there any difference between braided and twisted fiber constructions when it comes to performance in the construction industry?

raided constructions tend to offer higher tensile strength and better shock absorption compared to twisted constructions generally preferred by industries like mining or logging where flexibility is critical

Can nylon ropes be used for vertical lifeline systems in construction projects?

Yes, nylon ropes are commonly used as part of vertical lifeline systems due to their strength, durability, and ability to absorb energy during falls.

Can Duracordix provide customized lengths for fiber ropes according to project-specific requirements?

Absolutely! Duracordix offers customization options including tailored lengths for your specific project needs ensuring you get precisely what you require.

Is there any difference between static and dynamic loads when selecting the appropriate construction rope?

Yes, static loads refer to stationary weight while dynamic loads involve movement or vibration. Considerations like stretchability become important while choosing the right construction rope based on load type.