MARINe

High Performance, Trusted Strength and Durability for Marine Applications

Homepage » Industries » marine

What is Marine Rope?

Marine rope, often referred to as boat rope or ship rope, is crafted specifically for use in marine settings. Duracordix marine ropes are usually made from durable synthetic fibers, employing braiding or twisting methods. Common types include three-strand ropes, single-braid ropes, and double-braid ropes. Thanks to their remarkable strength, buoyancy, resistance to corrosion, and protection against UV rays, marine ropes are ideal for enduring tough marine environments.

Complete Marine & boat Solutions

Mooring

Solution: Opt for HMPE rope due to its exceptional strength and durability, making it ideal for securing large vessels. Combine it with UV-resistant polyester rope to enhance safety and provide abrasion resistance, particularly for docks that are frequently exposed to sunlight.

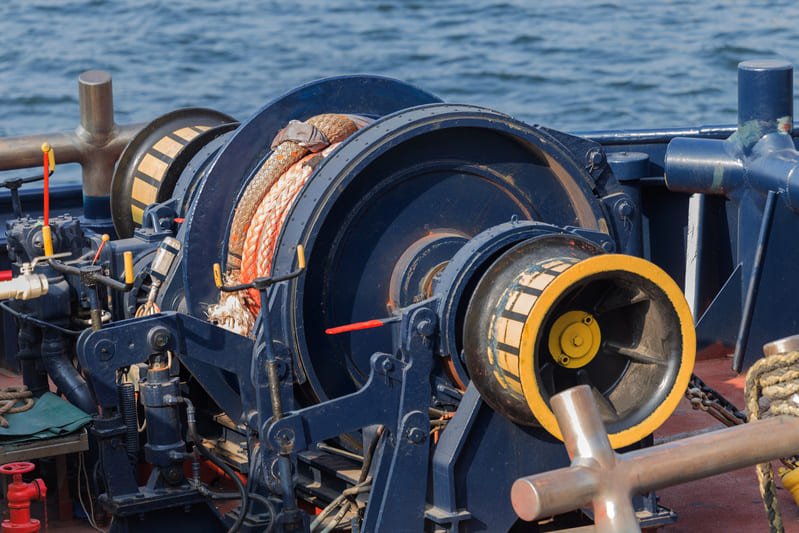

Tug Towing

Solution: For high-load towing, opt for HMPE rope—it's robust and has minimal stretch, making it ideal for demanding tasks. Incorporate elastic nylon rope to effectively absorb shocks and vibrations when navigating rough seas.

Lifting and Hoisting

Solution: For heavy industrial lifting, consider using HMPE rope, as it offers exceptional strength and efficiency. To enhance frequent operations, combine it with a rope made from a blend of polyester and polypropylene, ensuring durability and ease of handling.

Anchoring

Solution: Select HMPE rope for its exceptional tensile strength to secure heavy loads, and combine it with polyester rope for its abrasion resistance and nylon rope for its elasticity, which will help safeguard against damage during transport.

Securing & Lashing

To achieve a reliable solution, use HMPE rope for its outstanding strength when mooring large ships, paired with a blend of polyester and polypropylene. This combination offers a lightweight and durable choice, ideal for safe maneuvering and docking.

Rescue and Safety

To achieve a reliable solution, use HMPE rope for its outstanding strength when mooring large ships, paired with a blend of polyester and polypropylene. This combination offers a lightweight and durable choice, ideal for safe maneuvering and docking.

Types of marine Rope By Material

As a marine rope manufacturer,Duracordix can offer you different types of ropes for marine needs.

Duracordix UHMWPE Marine Grade Rope is made from Ultra-High Molecular Weight Polyethylene (UHMWPE) and features our unique DMX coating formula. This enhances the rope’s strength, corrosion resistance, UV resistance, and abrasion resistance, making it perfect for marine environments.

As a high-performance rope, it has become your ideal alternative to traditional fiber ropes and steel cables in recent years. you can use it in applications like tug towing, ship mooring, anchoring and yachting.

Duracordix Nylon Marine Grade Rope is made from high-quality nylon fiber, known for its exceptional elasticity. It can rebound when subjected to extreme stretching, providing you excellent shock absorption and impact resistance.

With Duracordix’s unique coating, it is perfectly suited for your marine applications like docking, anchoring, mooring and fishing etc.

Duracordix Kevlar Marine Grade Rope is made from imported high-performance Kevlar fibers, renowned for their exceptional strength-to-weight ratio and excellent heat resistance (up to 450°C). It also offers great cut resistance, making it perfect for your use in extreme environments such as mooring buoys, tankers, racing yachts, towing, and rescue operations.

Duracordix Marine grade Polyester Rope is made from high-quality polyester fibers. Thanks to its excellent abrasion resistance and durability, it maintains its strength even when exposed to water. Its moderate price makes it a popular choice for marine environments. However, due to its higher density, it does not float and will sink when in water. You can use it for mooring and docking, sailboat rigging, water sports towing, anchoring, and fishing

Polypropylene (PP) Rope

Duracordix PP marine rope is made from high-quality polypropylene fiber, designed to be lightweight and cost-effective. Its buoyant properties make it an ideal choice for marine environments where floating ropes are necessary. you can use it like safety line, boat towing, fender lines, dinghy rope, fishing

Duracordix PE Marine Rope is made from quality Polyethylene (PE) fiber. While it has a lower strength compared to nylon or polyester, it is much lighter and offers good abrasion resistance and UV stability, making it suitable for exposed marine environments. you can use it for fishing,netting,mooring,buoy lines,general-purpose ropes

Polyethylene (PE) Rope

Hot Selling Products

how to choose Right marine rope?

1. Based on your use: you need to know the intended use of your rope, whether it’s for mooring, tug towing, yacht rigging, anchoring, or as a safety line.

2. Choose By Material: Marine grade ropes come in materials such as UHMWPE, nylon, polyester, kevlar, polypropylene, and polyethylene. When you need higher elongation to absorb shock loads, nylon is the best choice. When you need abrasion resistance and corrosion resistance, polyester is a great. For high strength and extreme lightweight, UHMWPE is an excellent choice. for high-temperature resistance, cut resistance, kevlar ropes are the optimal choice. If you’re considering buoyancy, polypropylene is a good choice. For low-cost, general-purpose, polyethylene rope is a suitable option.

3. Diameter and Strength: it’s important to select the right rope diameter that aligns with the strength needed for your specific task. Make sure that both the diameter and tensile strength of the rope fulfill your operational needs. Generally, for towing tasks, the rope should have a strength that is 1.5 to 2 times greater than the maximum load. In contrast, for lifting tasks, a safety factor of 5 to 7 times the load is necessary.

4. Length:You need to determine the length of your rope based on the application scenario. For example, mooring lines are typically 1.5 to 2 times the length of the vessel. Different applications will have different length requirements for the rope.

5. Cost: while PP and PE ropes are cheaper, they also have lower tensile strength. UHMWPE and Kevlar ropes, although more expensive, offer superior tensile strength.

As a professional marine rope supplier, we can give you more specific suggestions if needed.

- testimonials

Client Voice

Certifications-- Duracordix Offer

- Pain-Free Purchase

Why Choose

Duracordix marine Rope

- Durability: Duracrodix marine ropes, with fortified fibers, offer 50% enhanced longevity, combatting saltwater corrosion and sun damage.

- Cost-Effective: Merging premier quality with affordability, Duracrodix promises 20% savings over competitors without compromising maritime performance.

- Lightweight: Despite their strength, Duracrodix ropes are 30% lighter, enabling swift deployments and recoveries in marine scenarios.

- Safety: Every Duracrodix rope undergoes comprehensive testing, surpassing marine industry standards, ensuring 99% safe sea operations.

- Strength: Boasting a 20% higher tensile strength, Duracrodix quality marine ropes ensure safety, especially during turbulent sea conditions.

- Customization: Whether you're a shipping company, vessel operator, fishing company, port or dock operations, yacht club, or military agency, Duracordix can customize Marine Grade Ropes to meet your specific needs. like length, color, diameter, special coatings, chafe protection, or spliced eyes

FAQs

Frequently asked questions addressing customer concerns and pain points

Are marine synthetic ropes inherently waterproof?

Duracordix's synthetic ropes, including nylon, polyester, and UHMWPE, naturally resist water absorption. This property ensures that your ropes stay lightweight even when wet and remain resistant to rotting in marine environments, a common issue with natural fibers in damp conditions.

What is the best synthetic rope for marine towing?

The ideal Duracordix synthetic rope for marine towing is typically double-braided nylon grade marine rope. it offers you exceptional tensile strength and elasticity. As double-braided marine rope, it also provide you with added abrasion resistance. Their shock-absorbing capabilities make them well-suited for the dynamic marine environment, especially during challenging towing operations.

Which ropes offer the best resistance to saltwater?

Duracrodix's UHMWPE marine rope and and nylon marine rope are designed to resist the corrosive effects of saltwater. This ensures you longevity and consistent performance even in your challenging marine environments.

How should I choose the right rope for marine applications?

When selecting a marine rope, consider factors like below:

First, you need to consider the intended use of the rope. Are you using it for mooring, towing and rescue, sailboat rigging, or water sports? Depending on your application, you will need to select a rope with the appropriate properties.

Second, you should determine the required strength of the rope. Ensure that the rope's strength exceeds the weight of the object you are towing. For safety, it is recommended to leave a safety margin of 50% to 100%.

For applications requiring elasticity, the Duracordix Nylon Marine Grade Rope is ideal, as it offers an elongation rate of 20-25%. This elasticity provides rebound when stretched, effectively absorbing shock, making it perfect for towing and rescue operations.

The Duracordix Polyester Marine Grade Rope is a great choice for long-term exposure to harsh sunlight due to its natural UV resistance, making it suitable for applications exposed to the sun.

For environments such as deep-sea oil and gas operations, the Duracordix UHMWPE Marine Grade Rope excels with its outstanding abrasion and chemical resistance. This rope maintains high strength over time, even in extreme conditions.

How long should a marine tow rope be for optimum performance?

Tow ropes for boats typically range between 75 to 100 feet. The ideal length depends on the boat's size, towing conditions, and whether the rope allows for some stretch, which can reduce stress on both the boat and the towing mechanism.

Is it more advantageous to use a long rope for pulling a boat?

A longer rope can provide added flexibility and stretch during towing operations. This results in a smoother towing experience, reducing potential jerks and stress on the boat and towing structure.

Which type of rope doesn't degrade in water?

Duracordix UHMWPE marine ropes and polyester marine grade ropes, are designed to resist water absorption and prevent rot. They retain their strength and integrity even after prolonged exposure to damp marine conditions.

What kind of rope is commonly used on tugboats?

Tugboats often use Duracordix's HMPE ropes because of their high strength and low stretch characteristics. These properties ensure excellent performance during challenging towing and berthing operations. This marine tow rope is lightweight, making it easy for you to handle and operate.

which types of marine rope knots used most?

The marine rope knots you’ll use most often include the Bowline Knot, Cleat Hitch, and Clove Hitch. These knots are crucial for tasks like mooring, anchoring, securing loads, and rigging sails. They help ensure that your ropes stay securely fastened under tension, giving you reliable and safe fastening in challenging marine conditions.

Do you know the marine rope applications?

Marine ropes are essential for your various tasks such as mooring, anchoring, towing, rigging, securing loads, and setting up safety lines, fenders and more

what types of marine rope float?

Duracordix's polypropylene (PP) ropes, polyethylene (PE) ropes, and HMPE ropes all have a density lower than water, allowing them to float on the surface. Therefore, you can use these ropes for applications such as water rescue and safety operations, water sports, fishing/net marking lines, as well as for channel/buoy assistance and boat guidance.

How should I clean my synthetic marine ropes?

Clean synthetic marine ropes using a mixture of mild detergent and lukewarm water. Gently scrub to remove salt and debris, ensuring no damage to fibers. After cleaning, rinse thoroughly and lay them flat to air dry, preferably in shaded areas to prevent UV damage.

What are the drawbacks of using polypropylene ropes in marine settings?

While polypropylene is buoyant and cost-effective, it can degrade under prolonged UV light exposure, has a lower abrasion resistance compared to other synthetics, and can weaken with age, especially under heavy loads.

How does temperature affect synthetic marine ropes?

Synthetic marine ropes generally withstand varying temperatures. However, at extremely low temperatures, they may become stiffer, slightly reducing flexibility. In contrast, prolonged exposure to very high temperatures can potentially degrade the material, impacting strength and longevity.

Between nylon and polypropylene, which rope offers more strength?

Nylon generally surpasses polypropylene in tensile strength and abrasion resistance. Its ability to stretch under load also makes it suitable for dynamic marine applications.

How does polyester compare to polypropylene in terms of strength?

Polyester tends to have a higher tensile strength than polypropylene. Additionally, it possesses better UV resistance and durability, making it more suited for prolonged marine use.

Why are synthetic ropes preferred over natural ones for marine use?

Synthetic ropes offer benefits such as enhanced strength, durability, UV resistance, and rot prevention. In contrast, natural fibers can degrade quickly in marine settings due to moisture and saltwater exposure.

How should synthetic marine ropes be stored for longevity?

For prolonged rope life, store them in a cool, dry location, ideally in a storage bag or container. It's crucial to shield ropes from direct UV exposure. Coiling loosely or hanging prevents the formation of kinks, ensuring they remain functional and safe.

What is the significance of color-coding in marine ropes?

Color-coding in marine ropes simplifies identification. It allows users to quickly determine rope types, sizes, or designated functions without manual measurements, enhancing efficiency in marine operations while also bolstering safety through reduced mix-up risks.