military

Homepage » Industries » Military

military

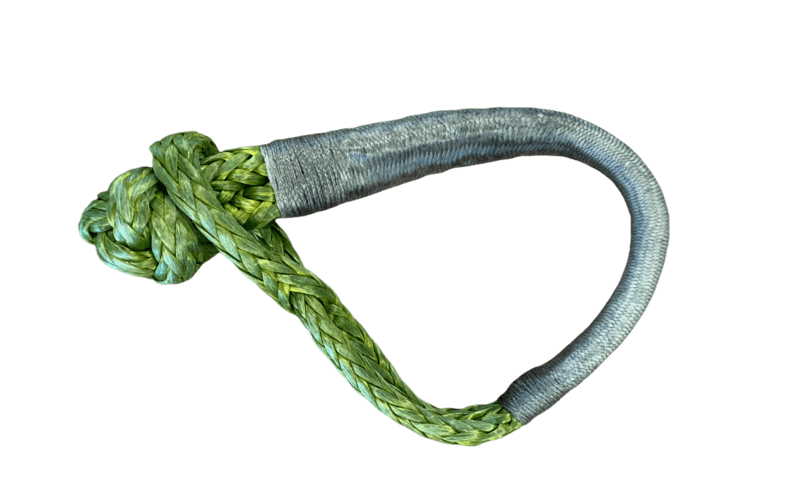

We provide an extensive array of top-notch products tailored specifically for military operations and tactical requirements. Our leading products include military-grade tow stap, shackle, tactical tow ropes, and durable winch ropes.

Furthermore, we also design and supply additional indispensable military gear, such as bridle equaliser cords, synthetic combat ropes, and a variety of tactical rope accessories, ensuring optimal preparedness for all defense scenarios.

Engineered for extreme conditions, ensuring strength and durability in towing operations.

how to make

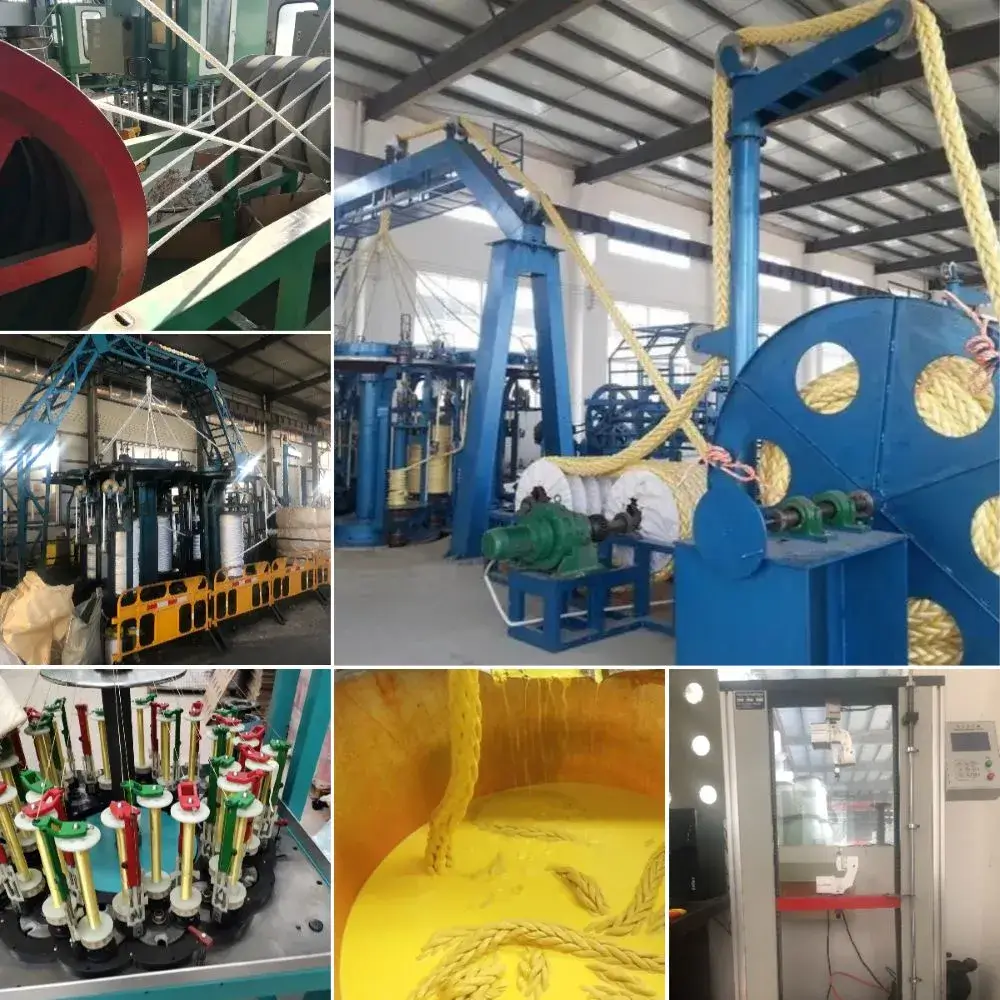

Discover Our Process of Producing High-Performance Military Ropes.

Process 1

fiber selection

We carefully select high-quality synthetic fibers, such as nylon,polyester, or UHMWPE, to use in our ropes, ensuring strength and durability.

Process 2

Twisting and Forming

The selected fibers are twisted together to create yarns, which are then twisted together to create strands. The twisted strands are then formed into a rope-like structure.

Process 3

Laying and Braiding

The formed rope is laid into a braiding machine, which braids the rope together using specialized techniques and patterns to further increase strength and durability.

Process 4

Coating

A custom protective coating made of high-quality materials, such as PVC or polyurethane, is applied to enhance the rope’s durability and resistance to abrasion, water, and UV rays.

Process 5

Heat Treatment and Drying

The braided rope undergoes a specialized heat treatment process to set the braids and increase strength. The rope is then dried to remove any moisture.

Process 6

testing

Each Duracordix recovery rope is rigorously tested to ensure it meets our high standards for strength and stretch. Any rope that fails our testing process is discarded.

- Quality-Centric

. QUALITY CONTROL

Explore How We Ensure Unparalleled Excellence in Every Fiber Rope

1. Raw Materials

Our synthetic military ropes are only made from raw materials that meet our strict quality standards. We work with trusted suppliers to ensure consistent quality and optimal performance in all our products.

2. In-House

By keeping our synthetic rope production in-house, we have full control over quality throughout the manufacturing process. This allows us to adhere to our high standards and provide reliable products to our customers.

3. Testing & Inspection

Our rigorous testing and inspection processes involve every stage of production, from raw materials to finished products. This ensures the consistent quality and safety of our synthetic ropes.

4. Automated Manufacturing

We integrate automated machinery and technology to ensure accuracy and consistency in our synthetic rope production. This reduces human error and ensures all products meet our strict quality standards.

5. Skilled Staff

Our highly skilled workforce undergoes ongoing training and continuing education to stay up-to-date with the latest techniques in synthetic rope production. This helps us uphold the highest level of quality and performance

- international standard

our certifications

easy & clear

Maximizing customer satisfaction with easy purchasing, minimizes communication and time costs.

Step 1: Solution Confirmation (3-5 days)

First, we’ll chat about your needs and recommend the best rope solution for you. Our expertise and experience will guarantee you get the best product possible.

Step 2: Sample Evaluation (7-14 days)

To ensure you’re happy with our product, we offer sample evaluations. Test our products before ordering to make sure they meet your requirements.

Step 3: Order Confirmation (within 3 day)

Once you’re satisfied with the sample evaluation, confirm your order with us. We’ll provide all necessary details, including pricing, lead times, and more, so you can be confident in your purchase.

Step 4: Bulk Manufacturing (30-45 days)

We offer bulk manufacturing options for larger orders. Our advanced production techniques and high-quality materials ensure consistency and reliability across all orders.

Step 5: Delivery (30-45 days)

We know timely delivery is important, so we’ll keep you updated on shipping progress and provide tracking information. Your order will arrive within the agreed timeframe.

Step 6: After-Sales Service

Our service doesn’t stop after your order is delivered. If you have any questions or concerns, our team is always available to assist you. We’re committed to providing excellent customer service and ensuring your satisfaction.

- Pain-Free Purchase

WHY CHOOSE

- Strength: Despite being 70% lighter, Duracrodix ropes match or exceed the tensile strength of steel cables.

- Safety: if a Duracrodix rope snaps, it doesn't create dangerous whiplashes like steel, ensuring personnel safety.

- Lightweight: Duracrodix ropes are light, ensuring swift transportation and deployment, essential for rapid military response.

- Natural Buoyancy: Duracrodix synthetic ropes' buoyancy is invaluable in naval salvages and various aquatic operations.

- Flexibility: Offering 50% more flexibility than steel, Duracrodix ropes excel in challenging terrains and tight spaces.

- Color-Coded Convenience: Unique color-coding enables 90% quicker rope identification, enhancing operational efficiency and safety.

FAQs

Frequently asked questions addressing customer concerns and pain points

What is military rope made of?

Military ropes are typically made from various materials, including UHMWPE (Ultra-High-Molecular-Weight Polyethylene), nylon, and polyester. These materials offer exceptional strength and durability, making them suitable for demanding military applications.

What is a strong rope-like material for military?

UHMWPE (Ultra-High-Molecular-Weight Polyethylene) is a strong rope-like material known for its incredible strength-to-weight ratio. It's often used in military ropes due to its exceptional tensile strength.

What types of military ropes are available?

There are several types of military ropes available, including static ropes for rappelling and climbing, dynamic ropes for activities like parachuting, and recovery ropes for vehicle extraction.

When should I use a military-grade recovery strap?

Military-grade recovery straps are used when a vehicle or equipment needs to be recovered from challenging terrain or obstacles. They provide a strong and controlled means of extraction.

What is the rope used by the military?

The military uses a variety of ropes depending on the specific application. UHMWPE ropes, nylon ropes, and static ropes are commonly used for tasks such as climbing, hoisting, towing, and more.

How thick is military climbing rope?

Military climbing ropes vary in thickness depending on the intended use. They can range from around 9mm to 11mm, providing a balance between strength and flexibility.

What is the strongest type of military rope?

UHMWPE ropes are often considered the strongest type of military rope due to their exceptional tensile strength, lightweight nature, and resistance to abrasion.

How do I choose the right military tow rope for my needs?

When choosing a military tow rope, consider factors like the weight of the vehicle, the terrain, and the desired level of stretch. Opt for a rope with sufficient strength and appropriate specifications for your towing needs.

What kind of rope is best for use in extreme temperatures?

When it comes to conquering the challenges posed by extreme temperatures, Kevlar Aramid rope emerges as the ultimate solution. Renowned for its exceptional thermal stability and durability, Kevlar Aramid rope is the go-to choice for applications that demand unwavering performance in both high and low temperature environments.

How to properly store military rope?

Store military rope in a cool, dry place away from direct sunlight to prevent degradation. Coiling or hanging the rope to avoid kinks is recommended.

what's the benefits of synthetic ropes in military applications

Synthetic ropes in military applications are lightweight, highly durable, and offer superior strength. They ensure safety, resist environmental damages, require minimal maintenance, and are cost-effective, making them ideal for diverse military operations.

What is a military winch rope?

A military winch rope is a strong, durable rope used with winch systems for various military applications, including vehicle recovery and equipment movement.

How to choose the right military rope for your needs?

Selecting the right military rope hinges on understanding your requirements. Assess the intended purpose, desired strength, material suitability, and environmental factors. Whether it's hoisting, towing, or climbing, this strategic evaluation ensures your choice aligns precisely with the demands of the task at hand.

synthetic vs steel rope for military, which is better?

Synthetic ropes are lightweight, safe upon breaking, and resist corrosion. Steel ropes are durable, UV and chemical resistant, and suitable for heavy lifting. The optimal choice between synthetic and steel ropes depends on the military application and environment.

Why is synthetic rope preferred in military applications?

Synthetic rope has become a favorite in military applications because of its unique combination of strength, flexibility, and lightweight nature. Additionally, these ropes are resistant to environmental degradation, ensuring a longer lifespan even under harsh conditions, which is imperative for military operations.

How do synthetic ropes compare in strength to steel cables?

While steel cables are inherently strong, synthetic ropes like UHMWPE can achieve a comparable strength-to-weight ratio, making them equally effective in many applications without the added weight.

What are the typical uses of synthetic ropes in the military?

In the military, synthetic ropes find their usage in a myriad of applications. They are commonly used for cargo slings, towing, helicopter external load operations, and as fast ropes for rapid deployment of troops. Their strength and resistance to wear make them suitable for demanding military applications.

Are there any safety concerns associated with the use of synthetic ropes in military contexts?

Synthetic ropes in military use have benefits but also safety concerns. They can store energy and may recoil dangerously if snapped. These ropes can degrade in extreme temperatures and shouldn't be exposed to flames. Always ensure they aren’t overloaded to guarantee safety.

How to clean and maintain military rope?

Military rope should be cleaned with mild soap and water, then air-dried. Avoid using harsh chemicals or machines for cleaning. It is recommended to inspect the rope regularly and replace it if any signs of damage are found.

which military divisions use synthetic ropes most?

Special Forces use synthetic ropes for rappelling and rescue. The Navy and Coast Guard employ them in marine tasks. Army Engineering Units utilize them for construction, and Airborne Divisions for cargo drops and extraction. Usage varies by country and operation.

Can Duracordix provide customized lengths for fiber ropes according to project-specific requirements?

Absolutely! Duracordix offers customization options including tailored lengths for your specific project needs ensuring you get precisely what you require.