offshore

Homepage » Industries » offshore

offshore

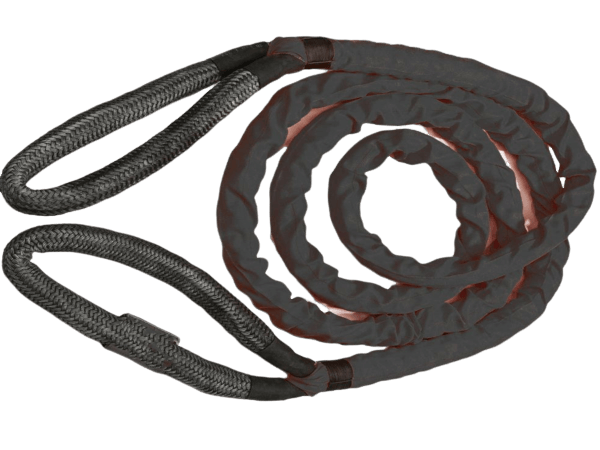

We offer an extensive selection of premium products tailored for the offshore oil & gas industry’s unique demands. Our top-sellers include lifting sling, deep-sea mooring ropes, and UHMWPE offshore tow cables.

Furthermore, we also manufacture and provide other crucial equipment for offshore operations, such as anchor lines, oil rig safety ropes, and various specialized rigging accessories to ensure optimal performance in the challenging offshore environment.

Offer superior strength, lightweight handling, and reliable performance for offshore anchoring.

Offer superior strength, lightweight handling, and exceptional durability for critical lifts.

Offer superior strength, durability, and lightweight performance for efficient towing

how to make

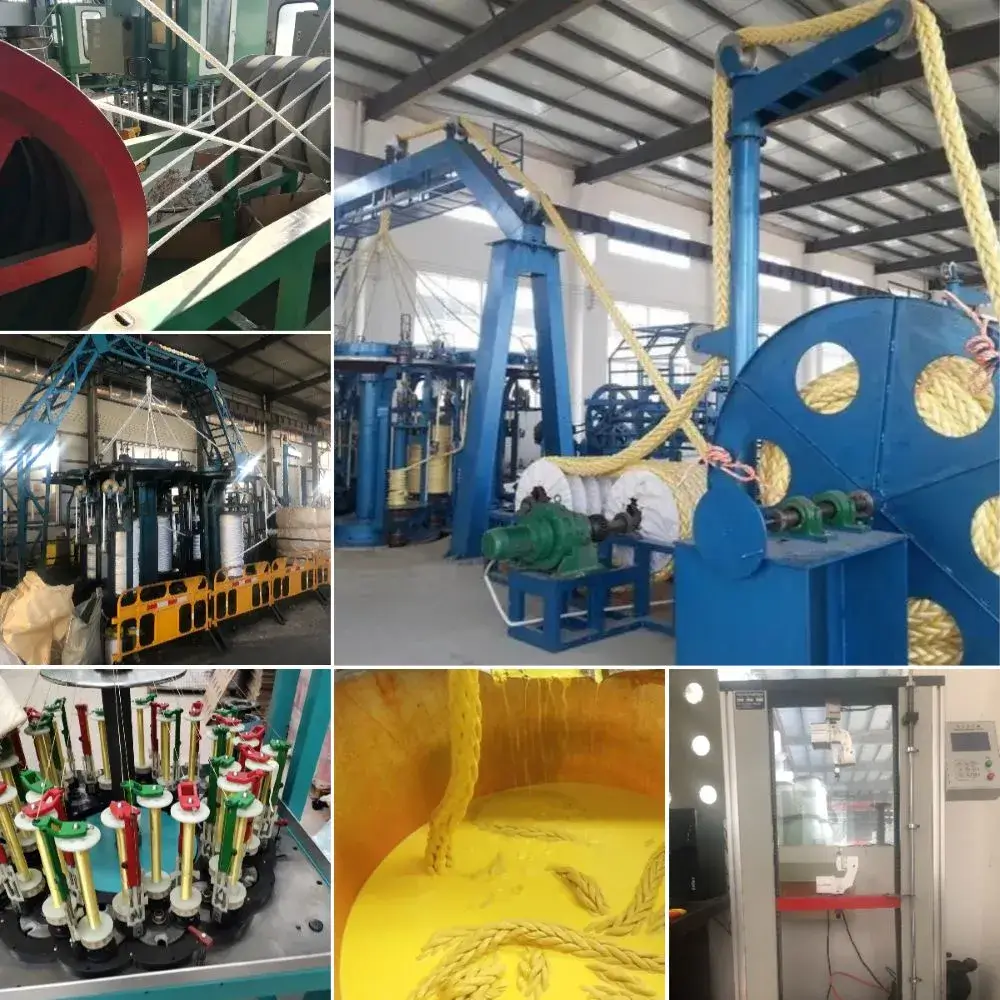

Discover Our Process of Producing High-Performance Offshore Ropes.

Process 1

fiber selection

We carefully select high-quality synthetic fibers, such as nylon,polyester, or UHMWPE, to use in our ropes, ensuring strength and durability.

Process 2

Twisting and Forming

The selected fibers are twisted together to create yarns, which are then twisted together to create strands. The twisted strands are then formed into a rope-like structure.

Process 3

Laying and Braiding

The formed rope is laid into a braiding machine, which braids the rope together using specialized techniques and patterns to further increase strength and durability.

Process 4

Coating

A custom protective coating made of high-quality materials, such as PVC or polyurethane, is applied to enhance the rope’s durability and resistance to abrasion, water, and UV rays.

Process 5

Heat Treatment and Drying

The braided rope undergoes a specialized heat treatment process to set the braids and increase strength. The rope is then dried to remove any moisture.

Process 6

testing

Each Duracordix recovery rope is rigorously tested to ensure it meets our high standards for strength and stretch. Any rope that fails our testing process is discarded.

- Quality-Centric

. QUALITY CONTROL

Explore How We Ensure Unparalleled Excellence in Every Fiber Rope

1. Raw Materials

Our synthetic offshore ropes are only made from raw materials that meet our strict quality standards. We work with trusted suppliers to ensure consistent quality and optimal performance in all our products.

2. In-House

By keeping our synthetic rope production in-house, we have full control over quality throughout the manufacturing process. This allows us to adhere to our high standards and provide reliable products to our customers.

3. Testing & Inspection

Our rigorous testing and inspection processes involve every stage of production, from raw materials to finished products. This ensures the consistent quality and safety of our synthetic ropes.

4. Automated Manufacturing

We integrate automated machinery and technology to ensure accuracy and consistency in our synthetic rope production. This reduces human error and ensures all products meet our strict quality standards.

5. Skilled Staff

Our highly skilled workforce undergoes ongoing training and continuing education to stay up-to-date with the latest techniques in synthetic rope production. This helps us uphold the highest level of quality and performance

- international standard

our certifications

easy & clear

Maximizing customer satisfaction with easy purchasing, minimizes communication and time costs.

Step 1: Solution Confirmation (3-5 days)

First, we’ll chat about your needs and recommend the best rope solution for you. Our expertise and experience will guarantee you get the best product possible.

Step 2: Sample Evaluation (7-14 days)

To ensure you’re happy with our product, we offer sample evaluations. Test our products before ordering to make sure they meet your requirements.

Step 3: Order Confirmation (within 3 day)

Once you’re satisfied with the sample evaluation, confirm your order with us. We’ll provide all necessary details, including pricing, lead times, and more, so you can be confident in your purchase.

Step 4: Bulk Manufacturing (30-45 days)

We offer bulk manufacturing options for larger orders. Our advanced production techniques and high-quality materials ensure consistency and reliability across all orders.

Step 5: Delivery (30-45 days)

We know timely delivery is important, so we’ll keep you updated on shipping progress and provide tracking information. Your order will arrive within the agreed timeframe.

Step 6: After-Sales Service

Our service doesn’t stop after your order is delivered. If you have any questions or concerns, our team is always available to assist you. We’re committed to providing excellent customer service and ensuring your satisfaction.

- Pain-Free Purchase

WHY CHOOSE

- Durability: Duracrodix ropes last 40% longer in extreme offshore conditions, resisting saltwater, chemicals, and UV degradation effectively.

- Affordability: Offering 30% better price-performance ratio, Duracrodix ropes maximize ROI without compromising on quality.

- Innovation: Incorporating cutting-edge technology, our ropes demonstrate a 30% increase in tensile strength and flexibility, addressing rigging challenges head-on.

- Safety: Reducing risks by 60%, Duracrodix ropes prioritize crew safety in demanding offshore environments, building trust.

- Support: 24/7 customer service, resolving 95% of technical challenges within hours, ensuring minimal operational interruptions.

- Eco-Friendly: With 70% less ecological impact, our sustainable ropes protect marine life while delivering superior performance.

FAQs

Frequently asked questions addressing customer concerns and pain points

What is offshore rope?

An offshore rope is a high-strength synthetic rope that provides reliable and durable performance in various marine operations such as mooring, towing, lifting, and more.

How long does synthetic rope last in offshore conditions?

Synthetic ropes typically last 3-5 years offshore. Durability depends on usage, maintenance, and environmental exposure. Proper care, such as rinsing and avoiding UV rays, can extend their lifespan.

Why are synthetic ropes preferred for offshore operations?

Synthetic ropes offer a superior strength-to-weight ratio, impressive corrosion resistance, and great flexibility. This makes them ideal for the demanding and dynamic environment of offshore operations.

How to maintain and clean synthetic ropes in marine environments?

Maintenance involves inspecting for wear and damage, rinsing with freshwater to remove salt, and ensuring proper storage in cool, dry places to protect from UV degradation and prolong lifespan.

Which synthetic rope is best for heavy offshore loads?

UHMWPE synthetic ropes are top-tier for heavy offshore tasks. Their exceptional tensile strength, combined with lightness, make them invaluable for towing and lifting in marine environments.

What makes synthetic ropes ideal for offshore drilling?

Their durability against corrosive marine elements, combined with superior tensile strength and elasticity, ensures optimal performance and safety during offshore drilling operations.

How does saltwater affect the durability of synthetic ropes?

While synthetic ropes resist saltwater, continuous exposure can cause wear. Frequent freshwater rinsing and storing them dry significantly reduces potential degradation.

Are synthetic ropes suitable for offshore towing tasks?

Absolutely. Their high strength-to-weight ratio and resilience make them prime for offshore towing. They handle dynamic marine conditions and heavy loads efficiently.

What safety measures should be taken when using synthetic ropes in offshore conditions?

Ensure regular inspections for visible damage, use ropes within their load limits, engage in routine maintenance, and always employ compatible, high-quality hardware for optimal safety.

How do synthetic ropes perform in extreme offshore temperatures?

Quality synthetic ropes retain their strength in varied temperatures, making them reliable across diverse offshore climates, from icy waters to tropical heat.

Can synthetic ropes be used for offshore anchoring and mooring?

Certainly. High-strength synthetic ropes like UHMWPE are favored for anchoring and mooring due to their robustness and resistance to marine challenges.

How frequently should synthetic ropes be inspected in marine environments?

For active operations, weekly inspections or checks after intensive use are vital. Timely inspections ensure rope integrity and the safety of marine tasks.

What are the environmental impacts of using synthetic ropes in the ocean?

While synthetic ropes don't release harmful chemicals in water, it's crucial to dispose of worn-out ropes responsibly to prevent marine pollution and ensure environmental safety.

How do synthetic ropes compare to steel cables for offshore use?

Synthetic ropes boast lightness, flexibility, and resistance to corrosion. Often, they outperform steel cables in offshore applications due to these advantages.

Are synthetic ropes ideal for offshore winds?

Yes, their lightweight and strong characteristics make them stable in strong offshore winds, ensuring efficient performance and safety during operations.

Can synthetic ropes handle deep-sea pressures?

High-performance synthetic ropes are crafted to resist deep-sea pressures, ensuring reliability during intense subsea tasks and operations.

What properties make synthetic ropes ideal for offshore rigging?

For offshore rigging, ropes need high tensile strength, corrosion resistance, and flexibility. Synthetics, with these properties, are thus a preferred choice.

How do thermal properties influence marine synthetic ropes during offshore lifting?

Ropes with consistent thermal properties resist wear from temperature fluctuations, ensuring safe and efficient lifting in varying offshore temperatures.