Single Point Mooring Hawser

Single Point Mooring Hawser

Used to securely moor oil tankers to a Single Point Mooring (SPM) buoy or offshore floating storage and offloading unit (FSO), allowing oil to be transferred through subsea pipelines to the buoy and then onto the tanker.

Duracordix SPM hawser rope is made from polyamide (nylon 66) along with an innovative circular double-braided structure. Compared to traditional designs, this structure provides better abrasion and wear resistance, while also giving the mooring hawser higher strength and fatigue resistance, which helps extend its service life.

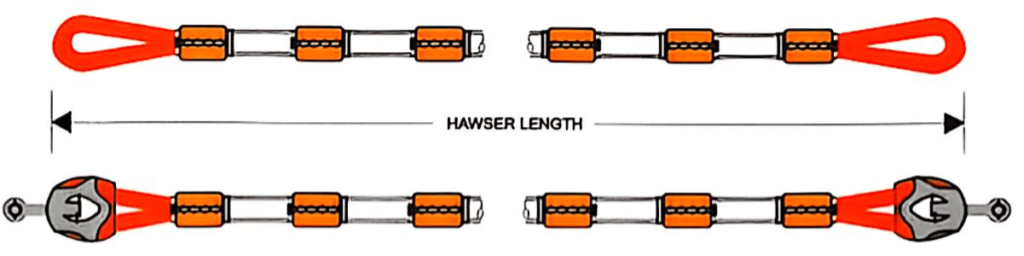

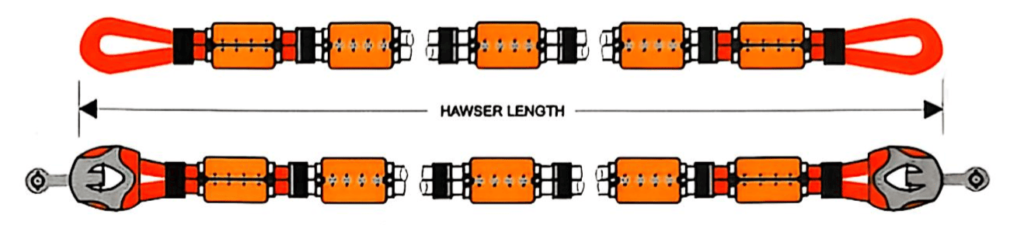

Both ends are equipped with galvanized SPM-type thimbles and are protected with a 6mm thick polyester cover. In addition, tubular floats are installed along the rope at specified distances to ensure the mooring hawser floats on the water.

All SPM mooring hawsers comply with the OCIMF 2000 standards.

main performance

- Material: Polyamide (nylon 66)

- Construction: Load-bearing cores with a protective cover of polyamide.

- Application: Marine fishing & Oil & Gas Industry

- Colour: White with green marker.

- Specific Gravity: 1.14 non-floating.

- Melting Point: 215°C.

- Abrasion Resistance: Excellent.

- U.V. Resistance: Excellent.

- Temperature Resistance: 80°C max continuous.

- Chemical Resistance: Reasonable; acids, oxidisers & solvents will affect nylon.

- Dry & Wet Conditions: Wet strength 5% lower than dry strength.

- Weight: ±5% Tolerance.

- SPM Polyamide Mooring Hawsers are manufactured in accordance with OCIMF 2000 regulations.

Single Type Mooring Hawser

Grommet Type Mooring Hawser

Mooring hawser Rope Sepecification

| DIA (MM) | DIA (INCH) | CIR (INCH) | WT (KGS/100M) | Single Leg MBL (TON) | Single Leg MBL (KN) | Grommet MBL (TON) | Grommet MBL (KN) | |

|---|---|---|---|---|---|---|---|---|

| 80 | 3-5/32 | 10 | 406 | 132 | 1290 | 237 | 2320 | |

| 88 | 3-7/16 | 11 | 506 | 167 | 1630 | 300 | 2940 | |

| 96 | 3-13/16 | 12 | 585 | 191 | 1870 | 344 | 3370 | |

| 104 | 4-1/8 | 13 | 699 | 222 | 2180 | 410 | 4020 | |

| 112 | 4-7/16 | 14 | 798 | 263 | 2580 | 473 | 4640 | |

| 120 | 4-3/4 | 15 | 914 | 298 | 2920 | 537 | 5260 | |

| 128 | 5-1/16 | 16 | 1031 | 335 | 3280 | 603 | 5910 | |

| 136 | 5-3/8 | 17 | 1164 | 382 | 3750 | 688 | 6740 | |

| 144 | 5-11/16 | 18 | 1316 | 429 | 4210 | 773 | 7580 | |

| 152 | 6 | 19 | 1490 | 478 | 4680 | 860 | 8430 | |

| 160 | 6-5/16 | 20 | 1624 | 526 | 5160 | 947 | 9280 | |

| 168 | 6-5/8 | 21 | 1785 | 574 | 5620 | 1033 | 10120 | |

| 176 | 6-15/16 | 22 | 1986 | 641 | 6280 | 1153 | 11300 | |

| 184 | 7-1/4 | 23 | 2165 | 693 | 6790 | 1248 | 12230 | |

| 192 | 7-9/16 | 24 | 2351 | 741 | 7260 | 1334 | 13070 | |

| 200 | 7-7/8 | 25 | 2554 | 811 | 7940 | 1459 | 14300 | |

| 208 | 8-3/16 | 26 | 2756 | 884 | 8670 | 1592 | 15600 | |

| 216 | 8-1/2 | 27 | 2957 | 952 | 9330 | 1714 | 16800 | |

| 224 | 8-13/16 | 28 | 3161 | 1026 | 10050 | 1846 | 18090 | |

| 232 | 9-1/8 | 29 | 3390 | 1094 | 10720 | 1969 | 19300 | |

| 240 | 9-7/16 | 30 | 3628 | 1173 | 11500 | 2112 | 20700 | |

| 248 | 9-3/4 | 31 | 3874 | 1257 | 12320 | 2262 | 22170 | |

| 256 | 10-1/16 | 32 | 4128 | 1340 | 13130 | 2411 | 23630 |

FAQs

Answers to Your SPM Hawser Rope Questions – Get Informed!

What is Single Point Mooring Systerm?

The Single Point Mooring (SPM) system, functioning as an offshore mooring buoy, operates like a floating dock at sea. When the water depth is insufficient to dock at a port terminal for loading or unloading, you can connect the tanker to the buoy via a single point mooring hawser, with the buoy securely anchored to the seabed using chains. This setup allows large tankers to rotate 360 degrees through a swivel joint on the buoy, effectively preventing safety risks caused by rough seas and waves. The floating hose connected to the swivel joint enables the transfer of oil and gas from subsea pipelines to the tanker or from the tanker to the subsea pipelines at the terminal.

The main types of SPM systems are: Single Anchor Leg Mooring (SALM), Catenary Anchor Leg Mooring (CALM), and Articulated Column Systems.

How long do Duracordix Single Point Mooring Hawsers typically last?

The lifespan of Duracordix Single Point Mooring hawsers varies depending on weather conditions, usage frequency, and offshore conditions. With proper maintenance, they typically last 5 to 7 years. However, if used frequently or exposed to harsh marine environments, the lifespan may be reduced to around 3 to 5 years.

What size of Duracordix Single Point Mooring Hawser do I need?

When you choose a Duracordix SPM mooring hawser, the first step is to calculate the required working load (WLL) of the rope. The working load can be estimated using the following formula:

WLL≈Maximum Expected Load×1.0–1.25

Typically, the Minimum Breaking Load (MBL) of the rope should be 2–3 times the working load to ensure a sufficient safety margin. For example, if your working load is 20 tons, the rope’s MBL should be between 40 and 60 tons.

Once you know the required MBL, you select the rope diameter based on the material:

Nylon mooring hawsers

High elongation, which helps absorb shock loads

Suitable for operations where dynamic load cushioning is needed

UHMWPE (Dyneema-grade) ropes

Extremely high strength-to-weight ratio

Low elongation

Much smaller diameter than a nylon rope of equivalent MBL

Very light and does not absorb water, so it won’t gain weight like nylon

By choosing the appropriate material and diameter based on your vessel and operational requirements, you ensure that your mooring hawser is both safe and easy to handle.

How do I maintain Duracordix Single Point Mooring Hawser Line?

The maintenance and care of Duracordix SPM mooring hawser ropes shall comply with OCIMF requirements. You can follow the procedures below:

1. Routine visual inspection (before each use)

Before every berthing operation, you should carry out a visual inspection of the hawser. Check the rope surface for broken yarns, abrasion, cuts, or other visible damage. You should pay particular attention to high-wear areas such as fairleads, chocks, and other contact points where abrasion is most likely to occur.

2. Periodic condition and internal integrity assessment

At intervals of 3 to 6 months, you should measure and monitor the hawser diameter. If you observe a diameter change exceeding 10–15%, this may indicate internal damage, and you should remove the rope from service and replace it.

You should also flex the hawser repeatedly by hand to check for signs of internal hardening or fiber fusion. If any of these conditions are detected, the rope must be replaced.

3. Inspection of terminations and protection systems

You should carefully inspect all termination areas, including the hawser eyes and thimbles, for cracks, deformation, or other structural damage.

To improve abrasion resistance, you should regularly check and replace protective sleeves at the eye sections and at fairlead contact points. This helps prevent localized wear that could otherwise lead to premature failure of the entire mooring rope.

4. Cleaning and protection after use

After each operation, you should clean the hawser with fresh water to remove seawater, sand, and debris. If oil contamination is present, you may use a neutral detergent. You must not use acidic or alkaline cleaning agents.

After cleaning, you should allow the rope to air-dry in a well-ventilated, shaded area and avoid prolonged exposure to direct sunlight.

5. Storage and record keeping

When the hawser is not in use, you should store it on pallets without any applied load, in a dry, well-ventilated, and shaded environment.

You should maintain a detailed log recording the rope condition, number of berthing operations, maximum loads experienced, inspection results, and service life, in order to support safe operation and timely replacement.

Can I customize the length and diameter of Duracordix Single Point Mooring Hawser?

Yes, Duracordix can customize a Single Point Mooring Hawser with the exact diameter and length required to meet your specific project needs. Based on your required working load, and considering a safety factor of 2.0–2.5, we will determine the final rope diameter and select the most suitable material—such as nylon or UHMWPE. We then manufacture the hawser to your specified length.

Contact our technical team today and let us know your detailed requirements

What is the difference between Duracordix Single Point Mooring Hawsers and conventional mooring lines?

1

How do Single Point Mooring Hawsers handle dynamic loads?

Duracordix's Single Point Mooring (SPM) hawsers are typically made from flexible materials such as nylon and UHMWPE. Particularly nylon, due to its high elongation, offers excellent elasticity, effectively cushioning the impacts caused by waves, wind, and currents, while maintaining the stability of your entire mooring system. These mooring hawsers also have high breaking strength, and the design often takes into account a safety factor. By selecting a sufficiently large diameter mooring hawser, it ensures your large vessels like oil tankers can absorb and withstand extreme dynamic loads while moving 360 degrees with the wind and waves, thereby ensuring your safety of oil and gas transportation operations.

Can I use Single Point Mooring Hawsers for other marine applications?

Yes, Single Point Mooring (SPM) hawsers can also be used for other marine applications such as:

Towing operations

Offshore platform mooring

Port and harbour mooring

Tugboat operations

Floating buoy mooring

Marine salvage, and more.

Duracordix can custom-make SPM mooring hawsers using materials like nylon, polyester, or UHMWPE to match your specific needs and operating environment.

Are there any certifications or standards for Duracordix Single Point Mooring Hawsers?

As a professional manufacturer of single point mooring hawsers, we offer:

International certifications like ISO 9001

Ship classification certifications from renowned organizations such as ABS, CCS, DNV GL, Lloyd’s Register, RINA, BV, and more

We ensure that you receive high-quality hawser mooring lines from Duracordix.