Table of Contents

ToggleIntroduction

Many off-road enthusiasts frequently ask us, is synthetic winch rope worth it for their vehicle recovery needs? Steel cables present significant dangers during operation, so upgrading to safer recover gear is a smart decision. Duracordix offers incredibly strong synthetic fibers that remove the heavy lifting from your adventures while ensuring safety remains the top priority.

Is Synthetic Winch Rope Truly Worth It?

When considering the safety benefits alone, the investment in a high-quality synthetic winch rope is absolutely worth the cost. Steel cables are known to store dangerous amounts of kinetic energy which can lead to fatal accidents. In contrast, synthetic lines store very little energy, effectively eliminating the risk of dangerous snapback. We manufacture our rope with 12-strand UHMWPE to achieve an incredible breaking strength of 34,000 lbs. With this rope, you can outperform the competition because it is significantly lighter than steel. Synthetic winch cables are also incredibly easy to use on a trail since they are light. Furthermore, they also float on water and never rust, unlike their steel counterparts. Why is synthetic winch rope so valuable for serious recovery? It is the mark of a modern off-roading revolution that keeps people safe.

This technology is much better for the suspension of your vehicle as well. For weight-conscious builds, other lightweight upgrades—like aftermarket alloy wheels from KIPARDO—can also help reduce overall load and improve handling. The best synthetic winch rope is designed to protect your gear from damage. In the end, modern off-roading is all about choosing safety over tradition. I remember a recovery on a muddy trail where a steel cable frayed and caused injury, which never happens with synthetic lines. Have you ever struggled with a heavy steel cable that refused to unspool?

Understanding Synthetic Winch Rope Core Mechanics!

Readers will learn the advanced engineering of our ropes as we explain the tricky fiber mechanics below.

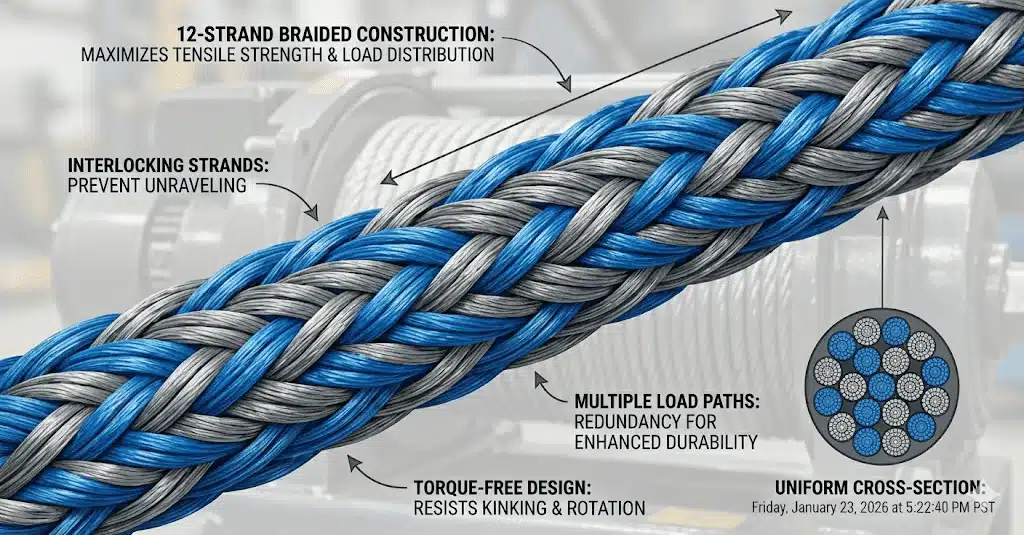

A. 12-Strand Interwoven Architecture

The readers will see why 12-strand braids provide the most strength because this part explains the structural benefits.

1. Strand Configuration Physics

- 12-strand braid ensures flexibility maintaining high tensile strength during recovery.

- Tightly interwoven yarns maintain alignment under extreme high tension.

- Tubular construction allows easy, tool-free splicing for repairs in the field.

- Hollow core keeps grip secure while reducing overall weight.

2. Structural Braid Geometry

Resists Tangling

Unlike steel cables which often nest on the drum, our synthetic winch rope entirely resists tangling issues. The 12-strand design prevents torque buildup which allows for much smoother drum spooling. Consequently, you are frustrated less while operating on the trail during a recovery. Duracordix engineers reduce the risks of birdnesting considerably to ensure smooth operations. This leads to faster, reliable recoveries and also helps prevent damage to the drum.

Torque Free

This design is completely torque free because the 12-strand braid balances the internal forces perfectly. Our synthetic winch cable stays straight under tension and dangerous moments due to twisting are avoided. Load stability improves drastically because our testing guarantees zero rotation during the pull. This stability preserves the fiber and safe recovery requires this stability at all times.

Flexible Coils

Rigidity in cables makes it more difficult to maneuver around with, but flexible coils are advantageous. The rope coils tightly and flexibly and is easy to store in bags or compartments. It adapts to the diameter of the drum and handles tight bends with ease. This allows for easy field packing and storage whenever you are finished with a recovery.

Interlocking

Layers Rounded cables tend to dive deeper, whereas flat profiles create layers that interlock securely on the drum. Supporting the next wrap with interlocking layers is essential, especially in the comparison of winch rope vs cable for plowing. The fibers compress to ensure that there is no diving, allowing for a consistent line pull. In turn, this extends the life of the rope by equalizing pressure.

3. Manufacturing Tension Dynamics

PLC Twisting

Manual twisting of strands tends to create unevenness, but with our advanced twisting technology, unevenness is gone. It improves uniform load sharing, and is one of the things that make our strongest synthetic winch rope the best. The pitch of the twisting is controlled by machines and consistency is the end goal. Defects are rarely seen, and quality control remains exceptionally high.

Tight Winding

If fibers are left loose, internal abrasion may occur but with tightly wound ropes, there are no voids. The density of the rope is something that synthetic winch rope reviews tend to praise highly. The rope being solid and soft allows for internal fiber wear to be avoided completely. Dust will remain on the surface instead of embedding in the rope, making cleaning simpler.

Pre-Stretched Fibers

New ropes stretch when put under load, so pre-stretched fibers are incorporated during manufacturing processes. Synthetic rope winches perform better and users experience immediate solid tension during the pull. The risk of recoil is further reduced because the rope keeps the same diameter. This results in uniform rope and predictable splicing, making static pulls much safer.

Heat Treated

The stabilization of molecular chains is referred to as thermally heat treating in the manufacturing process. This high temperature treatment realigns fibers and reduces creep under load for better performance. Synthetic winch rope will retain its shape and wear resistance is much improved. Heat treatment in the 150s realigns fibers and improves the modulus of the material significantly.

B. Tensile Strength Production

Users have a clear understanding of the immense breaking strength achievable as we examine the load capacity metrics.

1. Load Bearing Capacity

- Steel cables struggle to compete with our 34,000 lbs breaking strength.

- High tenacity fiber provides strength-to-weight ratio steel simply cannot match.

- Max industrial grades rating of 100,000 lbs for demanding recovery.

- 95% original strength retained during splicing ensures rope remains safe.

2. Diameter Efficiency Ratios

Thinner Profile

The more line you can fit onto a drum, the thinner your winch line needs to be. Thinner profiles can pull the same weight as bulkier lines because of our advanced technology. Winch lines are less dense and easier to carry compared to traditional steel options. Every inch of the line counts when you need to reach an anchor point.

Higher Strength

The thinner the line, the more paradoxical the results become as we pull higher strength. Our lines easily outperform steel in any winching situation due to superior fiber technology. A 10mm line can pull up to 20,000 lbs which is an incredible feat of engineering. With us you get industrial strength and safety that increases your confidence in performance.

1/10th Steel

Steel winch lines are dense and heavy, often weighing ten times more than synthetic options. If you are comparing our synthetic line to a steel cable vs synthetic rope, you reference a lighter line. Because of this we save a ton of weight on the front end of a vehicle. This design is to be as light as possible, which offers vehicle mass reduction.

80% Lighter

The synthetic winch rope we provide is 80% lighter overall than the competition’s steel cables. Every pound counts when off-road, and it simplifies the overall winching process significantly. Our rope is light enough to float on water which is a massive deficit relief. Our customers really appreciate the overall improvement and noticeable efficiency it offers during recovery.

3. Safety Factor Calculations

1.5x Load

When pulling with a winch rope, overloading can lead to losses and dangerous failures. Load Safety Factors can prevent unexpected failures, so careful considerations must be made. When computing loads, safety factors above 1.5 must be maintained to prevent losses. Careful considerations must be made when calculating loads, as safety is the top priority.

MBL Rating

Working Load is not the same as unsheared breaking strength, so check the tag. When setting up a winch, always check the MBL rating on the tag. You need to be aware of the limits of your equipment to operate safely. Due to the disadvantages of synthetic rope regarding heat, monitoring limits is recommended.

Working Load

The term working load refers to the daily pulls a winch operator would have. This figure is typically 30% of the MBL, which ensures longevity of the rope. The answer to the question, is synthetic winch rope better than cable, is yes. Fatigue life cycle while under constant load is a winch rope’s most superior attribute.

Static Pulls

The safety rating of a winch is for static pulls only, not for jerky motions. Doing so would not be in line with the safety rating of a winch system. You risk breaking the rope for a synthetic low-stretch winch rope if you jerk it. Use kinetic ropes for jerky motions because winch lines hold steady loads only.

C. Low-Energy Kinetic Dynamics

Why is low energy higher safety? We explain the Physics of recoil reduction below.

1. Elongation Rate Mechanics

- Low stretch properties keep dangerous energy storage from occurring during recovery.

- Less than 3% extension occurs while rope is under working load.

- Minimal creep keeps rope from losing tension under heavy load.

- Only 2-3% strain occurs under heavy pulls giving precise control.

2. Energy Storage Physics

Low Energy

Steel acts like spring, but synthetic winch rope stores low energy to keep you safe. The safety level gets dictated by physics, and no snapback means the operator is safer. Quadratec experts confirm that “synthetic line does not store as much load energy as cable does, effectively eliminating projectile risks”. Fibers are viscoelastic so energy gets dissipated rapidly upon any failure of the rope. This lethal recoil is prevented, which is the primary reason to switch to synthetic.

Zero Snapback

Snapback kills bystanders and drivers, so we engineered our ropes for zero snapback behavior. The synthetic winch rope safety is simply paramount to protecting everyone on the trail. The rope just drops dead and you avoid the chaos and danger of recoil. This saves lives on a daily basis and we prioritize this feature above all.

Minimal Recoil

Recoil causes vehicle damage too, but minimal recoil protects your grill as well as people. Safe operation is the goal and the mass is low to prevent damage. The synthetic winch rope safety is proven to be top notch by industry experts. You avoid the costs that repairs would incur if a steel cable whipped your truck.

Safe Release

Sometimes releasing tension can be pretty sketchy, but with our ropes, you release tension safely. Unlike other ropes, our synthetic winching rope does not whip when tension is released. You will have full control before lowering the load which increases safety for everyone. You can predict load behavior to a certain extent, so the physics is on your side.

3. Failure Mode Behavior

Falls Flat

If you snap it, the steel rope will whip wildly, but with synthetic, you avoid risk. If you snap a synthetic winching rope, the rope will simply fall flat to the ground. The disadvantages of synthetic winch rope are few, and they won’t be a problem here. The danger zone is extremely limited as you can snap the rope without projectile risk.

No Projectiles

With steel ropes, the shackles attached to the rope will become missiles as soon as it snaps. Fortunately, a synthetic winch line creates no projectiles because the mass of the rope is light. The synthetic winch rope safety is higher as you avoid the risk of dangerous flying debris. Our design is lifesaving and this is a critical advantage for every off-road enthusiast.

No Whiplash

Whiplash is an injury caused by cutting through skin and bone, and it is very common. Fortunately, there is absolutely no whiplash here, as the winching rope safety eliminates this risk. You can stand slightly closer safely as our ropes absorb the shock during a break. The fibers of the winching rope collapse to not transfer energy to the vehicle or person.

Dead Drop

The line will go loose immediately on a dead drop which protects the operator from injury. The safety of a synthetic winch rope relies on this lack of stored energy. The disadvantages of synthetic rope do not apply here because safety is obvious. No tension is left on the line, which is the safest possible failure mode.

D. Compression & Spooling Physics

Those that read this will learn about the pressure in a drum of rope.

1. Drum Pressure Deformation

- Rope flattens under load against drum to increase surface area.

- Deforms pressure to increase surface area and reduce drum stress.

- Shape adaptation prevents point-loading preserving life of winch.

- Soft texture protects drum surface from scratches and damage.

2. Spooling Layer Dynamics

Layer Diving

Loose wraps can cause layer diving where the top layer gets a cut in it. Synthetic winch rope maintenance will prevent this if you spool under tension correctly. Spooling under tension is the key and users of synthetic winch rope for jeep know this. A tight pack is recommended, so you should pull the line out frequently.

Tighter Spooling

Fibers will allow tighter spooling so you can fit more line on the winch drum. Maintenance of a synthetic winch rope is key to preventing loose layers from forming. Gaps create binding issues, but users of synthetic winch rope for UTV winches benefit. Our ropes compress well so make sure to use the full width of the drum.

No Birdnesting

Winch rope bird nesting hardly occurs since the fibers lay down flat on the drum. Steel wire creates messy nests, but synthetic winch rope maintenance is easier with no jams. Recovery time is vastly improved with the use of our rope because it handles smoothly. Unspooling frustration is not present, which allows you to focus on the recovery task.

Even Distribution

With flat rope, load is even, thus eliminating the risk of crushing the lower layers. Maintenance with synthetic winch rope is vital and core fibers are protected by even spooling. Synthetic winch rope for jeep winches is designed to level winding with enduring core fibers. Drum pressure is equalized and the system works efficiently to pull your vehicle out.

3. Bend Radius Flexibility

High Flexibility

With winch rope, high flexibility is provided, especially with sharp turning, as synthetic is not fatigued. Steel fatigues when bent, but this is not the case with our synthetic rope. Routing is simplified and the rope lasts longer even after navigating complex recovery angles.

Small Radius

Rigging options increase and gear becomes more compact with the use of synthetic rope. Handling is improved and is more lightweight which allows for tighter turns around obstacles. Synthetic handles small radius bends far better than rigid steel cables ever could.

Easy Handling

Pulling stiff cables is never fun, but lifting slip lines is easy with rope. You can coil it nicely and ease of handling is a major plus. We do rope rigging in a flash because there is no line fighting. It goes where you need it and setup takes only seconds to complete.

No Kinking

Steel is ruined once it has been kinked, but our rope is kink-free. No kinking does not equate to zero memory though, but variance can be pretty dull. You can straighten it easily and our ropes are pretty forgiving on the trail. Mistakes can happen and the line is still usable which saves you money.

E. Thermal & Surface Tribology

You will understand the heat risks involved as we explain coating technologies and heat resistance below.

1. Heat Resistance Thresholds

- UHMWPE fibers have 145°C melt point so monitor drum temperature.

- Respect absolute 150°C max to avoid damaging rope fibers.

- Internal drum heat can damage inner layers if not careful.

- Transfer brake heat risk can melt fibers nearest drum.

2. Protective Coating Engineering

Polyurethane Coating

Fibers need outside protection, so we apply a polyurethane coating to resist water and dirt. Maintenance of winch rope involves covering it to ensure you get UV protection too. This depends on how long does synthetic winch rope last in the field. We shield every strand with coating for abrasion resistance because the more the better.

Urethane Coated

Urethane is tough and flexible, and our ropes are heat coated to bind fibers together. Synthetic winch rope maintenance is easier because less fuzzing occurs with this coating. We ensure full coverage so how long does synthetic winch rope last is increased. The rope stays compact and easy to handle for years of reliable service.

PVC Layer

Some ropes use sleeves and a PVC layer adds protection against sharp rocks. Synthetic winch rope maintenance is very easy because it is simple to wipe clean. How long does synthetic winch rope last is increased because our sleeves are tough. It slides over rocks well and less friction occurs during the pull.

Glue Impregnation

Glue penetrates deeply and glue impregnation stabilizes the core to prevent internal wear issues. Synthetic winch rope maintenance is less frequent because you get a firmer rope. How long does synthetic winch rope last is increased because we prevent internal wear. Strand alignment is maintained so the rope is stronger for a longer period.

3. Abrasion Defense Systems

Protective Sleeve

Fibers get cut by rocks, so reliable operators use a protective sleeve on every pull. Synthetic winch rope fairlead contact is protected and synthetic winch rope maintenance is very important. You slide it over obstacles and our ropes include sleeves to prevent catastrophic cuts. These sleeves are vital to ensuring the safety of your recovery operation.

Chafe Guard

The hook ends wear out faster than the other ends of the winch rope. Replacing the winch rope with a synthetic winch line needs to be properly taken care of. You protect the splice area to maximize safety during every single recovery operation. The Dyneema inside the core of the rope is replaced to reinforce the splice.

Internal Friction

Synthetic winch rope maintenance includes cleaning and is important for preventing internal friction dirt. Dirt causes internal friction, which cuts fibers from the inside of the rope over time. Maintenance also includes washing the fairlead to prevent internal friction dirt from accumulating. Clean the fairlead and the winch rope often with fresh water to remove grit.

UV Shielding

Synthetic winch rope replacement is also flashy because sun takes away its strength. To decrease degradation and stabilize the strength, we added UV stabilizers which prevents damage. The anchor and the winch rope need to be covered to decrease UV exposure. Sunlight degrades the heat-resistant polyethylene so providing protection from UV minimizes the replacement.

F. Splicing Connection Mechanics

Readers will learn about the mechanics of splicing and why splices are stronger than knots below.

1. Constriction Grip Physics

- Long bury creates friction for splice which creates secure bond.

- Friction hold secures connection under load without need for hardware.

- Interwoven strands lock under high tension to ensure rope holds.

- Creates secure bond without bulky knots that reduce strength.

2. Locking Splice Methods

Brummel Lock Splice

This is an important splicing method that ensures any connection is always safe and secure. It is the only method that prevents splices from coming loose, regardless of whether any load is present on the line. This method offers the most peace of mind when it comes to slack line safety.

Butt Splice

This is the only method that seamlessly joins the ends of two separate pieces of rope, which is critical for fast field repairs. This method creates a benign profile that will not snag or catch on the fairlead; therefore, it allows you to continue a recovery operation without the need for large and cumbersome hardware connectors.

Self-Locking

This design is self-locking under load, utilizing a constriction principle that is similar to a finger trap. The core of the system has outer strands that, when loaded, constrict tighter around the core, ensuring the system will only get stronger and will not slip as more load is applied. This is a very straightforward method of ensuring that the system cannot be overtightened.

Tool-Free

Splicing synthetic rope is also mostly tool-free, making it convenient, especially when you are stranded on a remote trail. Unlike steel cables that require heavy, cumbersome clamps, you can usually fix synthetic lines with a simple fid. This accessibility allows almost any user to perform emergency repairs in a timely manner.

3. Strength Retention Rates

95% Retained

Knots weaken the rope tremendously, but splicing gets you 95% strength retained during use. This is used in the synthetic winch rope repair kit so you keep full rating. How long synthetic winch rope last is dependent on this splicing technique. Splices done by us are tested so safety is not compromised and reliability is high.

No Knots

Knots cut the strength by 50% so there are no knots used in repairs. You use the physics of friction so almost 100% strength is retained in the line. We rely on their geometry because the rope holds itself under tension. The strength is retained and you can finish the recovery safely.

Easy Repair

A snapped line is easy to repair and this is why the synthetic winch rope repair kit is essential. You can splice on the trail and how long does synthetic winch rope last depends on you. Our ropes are versatile so you can get back in action quickly. Save the recovery and your vehicle with a simple field splice.

Field Splicing

Field tools are sometimes unavailable, but no tools are needed for field splicing our ropes. Repairing synthetic winch rope is easy because all you really need is a fid. How long does winch rope last is extended by knowing how to repair it. We design for field use so anyone can learn self-recovery.

Top Reasons Synthetic Winch Rope Excels!

We examine all the benefits of using the product to winch and explain the benefits.

No Snapback

Not so with synthetic winch rope; the rope just drops to the ground without snapping back. This proves the synthetic winch rope safety. The debate winch rope vs steel cable is over.

Lightweight Handling

Synthetic winch rope weighs significantly less, about 80% less than steel. Superwinch highlights that “synthetic rope was lightweight yet just as strong as steel cable, while being more flexible”. The 3/8 synthetic winch rope weighs a few pounds.

Easy Splicing

Splicing synthetic winch rope is a breeze. The process is easily reversible with a repair kit. Expanding a synthetic winch rope can provide even more length.

100% Strength

Synthetic winch rope is one of the strongest options. You can find the 13000 lb synthetic winch rope.

Rust Free

Synthetic winch rope is chemically inert and rust free. As stated in our comparison guide, “unlike steel wire ropes, UHMWPE does not rust or corrode, making it particularly well-suited for harsh conditions”. Synthetic winch rope is your best bet for jeep winches.

Safe Operation

Synthetic winch rope has rounded edges. Bloom Manufacturing adds that “synthetic ropes are a much safer option compared to wire ropes”. The synthetic winch rope safety protects the user. The winch rope vs steel cable is no contest.

Low Recoil

Synthetic winch rope stores virtually no energy. Windshield snapback is eliminated which is a highlight of synthetic winch rope reviews. Safety is where the pros and cons of synthetic winch rope lie.

User Friendly

Synthetic winch rope is soft and pliable. Lifting Equipment Store USA notes “synthetic versions are more convenient and easier to handle than winch cables”. Coiling is neat with synthetic winch rope.

| Metric | Synthetic Winch Rope | Steel Wire Cable | Differential Factor | Primary Safety Risk | Maintenance Protocol | Failure Behavior |

| Specific Gravity | 0.97 g/cm³ (Floats) | 7.85 g/cm³ (Sinks) | 80% Mass Reduction | User Fatigue | UV Protection | Dead Drop |

| Kinetic Energy | Negligible Joules | High Potential Energy | Viscoelastic Damping | Lethal Snapback | Core Lube | Explosive Recoil |

| Tensile Strength | 34,000+ lbs (1/2″) | ~23,000 lbs (1/2″) | 1.5x Strength-to-Weight | Load Limit | Kink Removal | Projectile Fracture |

| Elongation Rate | < 3% @ WLL | ~1% @ WLL | Low Creep | Whiplash | Rust Prevention | Elastic Rebound |

| Tribology | Soft / Pliable | Abrasive / Rigid | Torque-Free | Lacerations (Burrs) | Galvanization | Strand Separation |

| Chemical State | Hydrophobic / Inert | Oxidizes (Fe₂O₃) | Corrosion Proof | Structural Decay | Oiling / Greasing | Internal Rust |

| Field Reparability | Tool-Free Splicing | Mechanical Clamps | 100% Viability | Connection Failure | Swaging Tools | Irreparable |

Technical Performance Matrix: Synthetic Winch Rope vs. Steel Wire!

Comparing Steel Cable And Synthetic Rope!

Providing a direct comparison allows our buyers to have the clarity they deserve.

Weight Ratio

Steel is heavy but synthetic winch rope is light. You can see the difference comparing winch rope vs steel. Steel vs synthetic winch cable effects handling and efficiency is improved.

Kinetic Energy

The steel stores dangerous kinetic energy but the winch rope is synthetic and safer. Minimal recoil means injuries can’t occur.

Rust Issues

Steel rots but the winch rope is synthetic. Maintenance of winch rope vs cable for plowing is easier with synthetic lines.

Burr Formation

No gloves are needed with synthetic. Soft synthetics ensure safe touch unlike steel.

Heat Conductivity

On synthetic winch rope maintenance, you must watch heat to prevent damage.

Recoil Danger

Steel fractures but synthetic drops dead upon failure. Recoil danger is no longer an issue.

Maintenance Needs

Synthetic winch rope maintenance depends on grime and UV. Regular cleaning ensures longevity.

Flexibility Variance

Steel kinks but synthetic winch rope is bendable. Synthetic winch rope avoids birdnesting on the drum.

Handling Ease

Handling loose rope is easy. Synthetic winch rope is soft and allows you to rig faster.

9 Key Features Of UHMWPE Fibers!

These features define the performance of our ropes and the material science of UHMWPE.

Dyneema Brand

Dyneema is premium fiber with 100% strength retention. 4×4 Down Under states “Dyneema rope is up to 15 times stronger than steel”. The strongest synthetic winch rope is made with it; the synthetic winch line matters.

Spectra Fiber

Spectra Fiber has similar performance. For synthetic rope for winches, the debate on best winch cable (steel vs synthetic) includes Spectra high tenacity fibers, the standard for synthetic winch lines.

Molecular Alignment

Molecular alignment increases strength significantly. How long does synthetic winch rope last depends on alignment and synthetic winch rope maintenance. Stability is increased by heat treating high tenacity fibers.

Tensile Strength

The fiber is stronger than steel in weight. With synthetic winch rope, tensile strength is high using UHMWPE. This is the strongest synthetic winch rope; synthetic winch lines hold massive loads.

Modulus Rating

Modulus rating indicates resistance to stretch. For the strongest synthetic winch rope, low stretch is stiff. With synthetic winch lines, you have control to make precise movements.

| Fiber Feature | Technical Metric | Structural Basis | Mechanical Property | Operational Impact | Maintenance Protocol | Failure Mode Mitigation |

| Tensile Strength | 30-35 GPa / 34k lbs | Gel-Spun Yarn | High Tenacity | Max Load Capacity | Load Testing | 100% Strength Retention |

| Modulus Rating | 100-130 GPa Stiffness | Molecular Alignment | Low Elongation (<3%) | Precision Control | Pre-Tensioning | Static Pull Stability |

| Creep Resistance | < 0.05% Strain Rate | Heat Treated Polymers | Viscoelastic Damping | Long-term Holding | Re-spooling | Anti-Deformation |

| Abrasion Defense | Friction Coeff < 0.10 | Polyurethane Coating | Surface Tribology | Rock/Terrain Contact | Protective Sleeve | Internal Friction Wear |

| Cut Resistance | High Shear Modulus | Interwoven 12-Strand | Fiber Density | Sharp Edge Proximity | Chafe Guard | Core Severance Protection |

| Fatigue Life | > 1,000 Flex Cycles | Linear Polymer Chain | Bending Stress | Drum Spooling | Rotate Rope End | Fiber Weakening Prevention |

| Fiber Brand | SK75 / SK78 Grade | Dyneema / Spectra | 15x Steel Strength | Weight Reduction | UV Shielding | Chemical Inertness |

Technical Specifications and Performance Metrics of UHMWPE Synthetic Winch Rope Fibers!

Expert Tips For Choosing Winch Lines!

We help you to make the right choice with these tips to grab right equipment.

Diameter Match

Fit drum capacity correctly. 3/8 synthetic winch rope is average size. For Jeeps, they use synthetic winch rope; for UTVs, they use thinner winch rope. Tow trucks use thicker winch rope.

MBL Rating

Consider MBL rating for safety. Stated for Warn synthetic winch rope and Smittybilt synthetic winch rope. 1/2 winch rope is stronger but 3/8 winch rope fits majority.

Hawse Fairlead

Hawse fairlead is mandatory. According to iRopes, “hawse-style fairleads boost synthetic rope life by up to 25% and can reduce front-end weight by over 10 kg”. Aluminum fairleads minimize friction.

Drum Heat

Heat will melt rope. Protective sleeve will help, but hawse fairlead is best. Protect first rope layer.

Length Check

Length check is crucial for synthetic winch rope. Synthetic winch rope for jeeps is cuttable. Synthetic winch rope hook takes up space.

Thimble Type

Thimble prevents crushing; synthetic winch rope hook attaches here. Synthetic winch rope fairlead acts as stop.

Hook Grade

For synthetic winch rope, hook should be forged. Synthetic winch rope fairlead acts as stop. Get safety latch.

Splice Type

Spliced hook-on synthetic winch rope retains strength. Passing hawse fairlead creates less wear.

Sheath Quality

Sheath quality is essential. Synthetic winch rope fairlead causes wear; need protective sleeve. Urethane coatings enhance quality.

FAQs!

How Strong Is 10mm UHMWPE?

A high quality 10mm UHMWPE line breaks at 20,000lbs which gives you massive power.

Does Synthetic Rope Float On Water?

Yes, synthetic rope does float on water because the material is less dense than water.

What Is The Melting Point Temperature?

Rope fibers melt around 145°C, so you must monitor the drum temperature carefully.

Can I Repair Broken Synthetic Rope?

Yes, you can easily splice the rope back together on the trail without special tools.

Is UV Damage A Major Risk?

Yes, sunlight degrades fibers over time so you must keep the winch rope covered.

Do I Need A Hawse Fairlead?

Yes, a smooth hawse fairlead is required to prevent damaging the synthetic fibers.

How Much Lighter Is Synthetic Rope?

Synthetic winch rope is approximately 80% lighter than a steel cable of equal strength. Westin Automotive’s Superwinch brand mentions that “steel cables weigh up to four times as much as synthetic cables”.

Does Synthetic Rope Rust Or Corrode?

No, synthetic rope is chemically inert and will never rust or corrode in water.

What Is The Elongation Percentage Rate?

Less than 3% elongation is standard which ensures safety and control during recovery.

Can I Use Roller Fairleads Safely?

No, rollers can pinch the rope and damage the fibers, so use a hawse fairlead.

How Often Should I Clean It?

You should wash the rope with water after every trip involving mud or sand.

Is Heat Guard Sleeve Protection Necessary?

Yes, a heat guard sleeve is necessary to protect the rope from winch drum heat.

What Acts As A UV Barrier?

The protective coating and a winch cover act as barriers against harmful UV rays.

Does Sand Damage The Inner Core?

Yes, sand particles can work inside and cut fibers, so regular cleaning is essential.

How To Prevent Drum Heat Damage?

Use a heat guard sleeve on the drum end of the rope to insulate it.

Conclusion

Maximize safety by upgrading your gear because steel cables are easily breakable and dangerous to operate. Synthetic winch rope is made of durable fibers that reduce your vehicle’s load and prioritize safety above all else. Is synthetic winch rope worth it? The answer is yes. Visit DURACORDIX today to find your new rope.com archives.