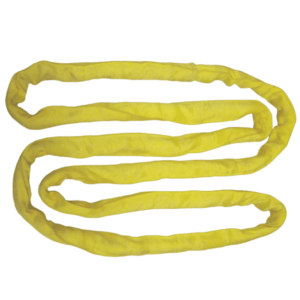

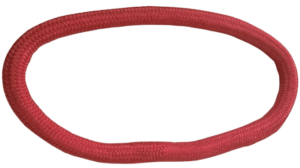

What Is Endless Round Sling

Our endless round slings are made from high-strength synthetic fibers, typically polyester and UHMWPE. With a continuous loop design and no seams, they avoid the weak points of traditional slings. This ensures more even load distribution, extending the sling’s lifespan while providing you safer and more cost-effective lifting operations.

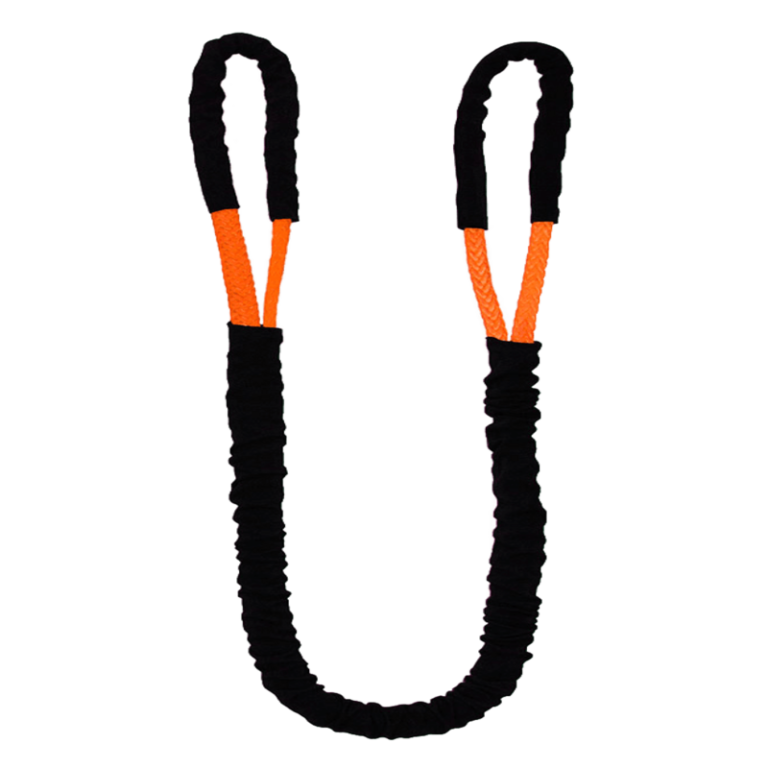

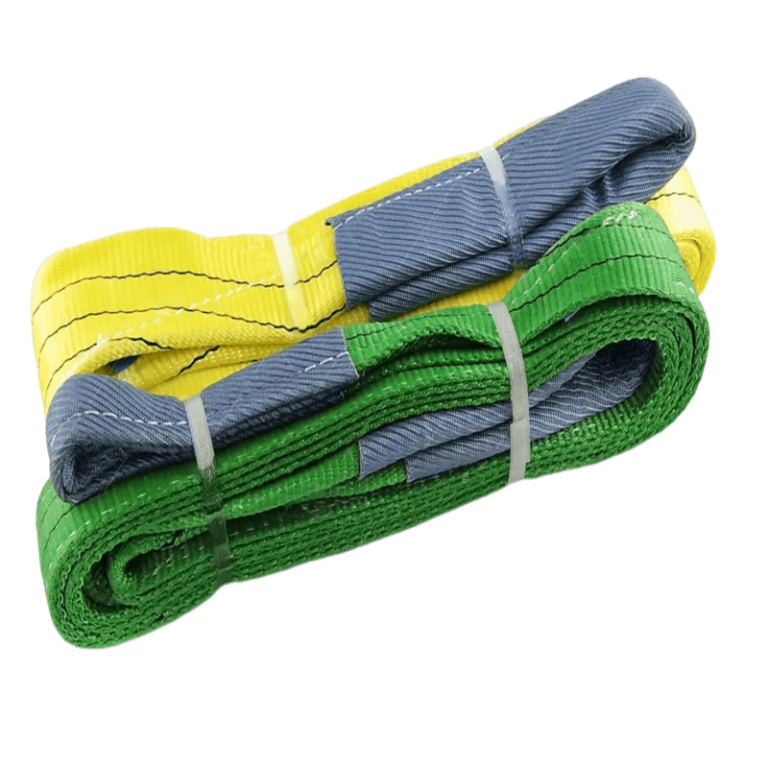

- Exceptional Strength

- Ultra-Lightweight

- Highly Durable

- Superior Safety