Trawl Warps

UHMWPE TRAWL WARPS

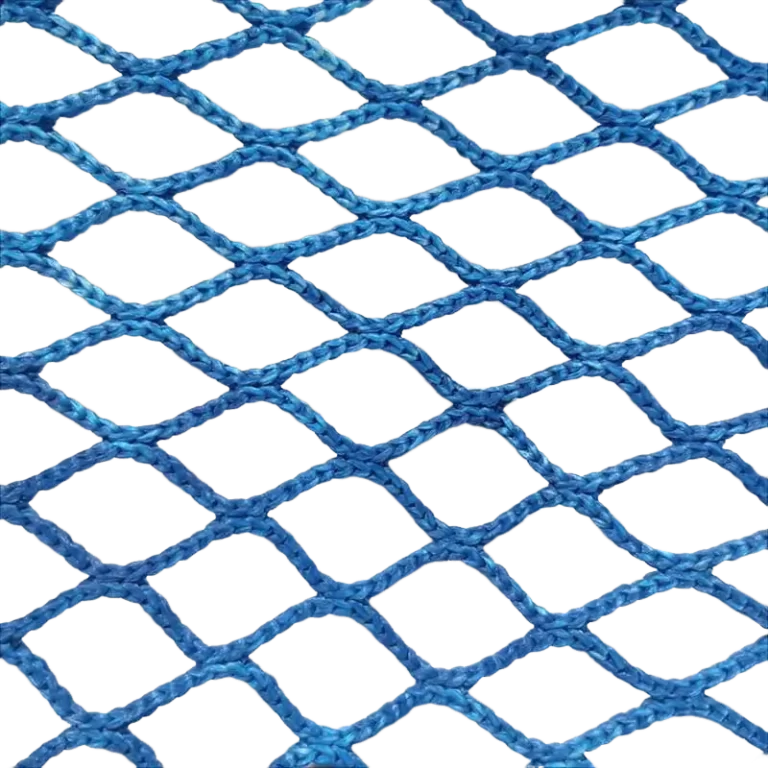

Duracordix Trawl Warps are crafted from high-strength UHMWPE, these 12-strand braided ropes redefine performance in pelagic fisheries. Lightweight yet robust, they optimize trawling, reduce fuel consumption, and enhance handling, ensuring precision and sustainability.

- Quick Response Time

- Superior Strength

- Reduced Maintenance

- Fuel Savings

Table Of Contents For This Page

To ensure easy access to the information you need, we’ve created this table of contents that will take you directly to the relevant section when clicked

- MAIN FEATURES

Hot Selling sizes

Top Picks: Most Popular Trawl Warps Dimensions Revealed

14MM

Lightweight and strong, ideal for smaller vessels, offering excellent control and durability for efficient trawling operations.

18MM

Versatile mid-sized choice, balancing strength and maneuverability, suitable for various fishing applications in diverse conditions.

28MM

A heavyweight for large-scale trawling, it delivers robust performance and dependable catch retrieval in challenging marine conditions.

Duracordix is a trawl warps manufacturer & Supplier in China.

we can produce various sizes for different applications and custom made for special projects.

No matter you’re looking for a wholesale supplier or custom made snatch strap, we can all help. contact Duracordix now.

- SIZES AVAILABLE

SPECIFICATION

Explore the Specifications of our UHMWPE Trawl Ropes For Your Application

| DIAMETER | DIAMETER | WEIGHT | KETX | KETX | BREAKING STRENGTH | BREAKING STRENGTH |

|---|---|---|---|---|---|---|

| mm | inch | 100m(kg) | standard | error | ton | kn |

| 12 | 1/2 | 8.8 | 87 | 5% | 12.12 | 121 |

| 14 | 9/16 | 12 | 119 | 5% | 15.4 | 153 |

| 16 | 5/8 | 15.5 | 151 | 5% | 20.6 | 205 |

| 18 | 3/4 | 19 | 190 | 5% | 23.9 | 238 |

| 20 | 13/16 | 23 | 225 | 5% | 28.99 | 289 |

| 22 | 7/8 | 28 | 276 | 5% | 33 | 322 |

| 24 | 1 | 37 | 368 | 5% | 38 | 371 |

| 28 | 1-1/8 | 50 | 490 | 5% | 57.5 | 562 |

| 32 | 1-5/16 | 62.5 | 621 | 5% | 68.5 | 671 |

| 36 | 1-1/2 | 77 | 767 | 5% | 80.4 | 789 |

| 40 | 1-5/8 | 87 | 868 | 5% | 98.2 | 964 |

| 44 | 1-3/4 | 96 | 955 | 5% | 118 | 1158 |

| 48 | 2 | 114 | 1137 | 5% | 139 | 1364 |

| 56 | 2-1/4 | 159 | 1547 | 5% | 184 | 1805 |

| 60 | 2-1/2 | 180 | 1784 | 5% | 199 | 1952 |

| 64 | 2-5/8 | 209 | 2021 | 5% | 222 | 2178 |

| 72 | 3 | 268 | 2598 | 5% | 274 | 2688 |

| 80 | 3-1/4 | 328 | 3195 | 5% | 333 | 3266 |

| 88 | 4 | 427 | 4170 | 5% | 390 | 3825 |

| 96 | 3-5/9 | 509 | 4970 | 5% | 455 | 4463 |

Note: other sizes are available upon request.

- MAIN FEATURES

Advantages Advantages OF Trawl Warps

Discover the Advantages of Duracordix Trawl Ropes!

Exceptional Strength

Benefit from an impressive tensile strength exceeding traditional materials by up to 15 times, ensuring unmatched reliability and safety in your trawling operations.

Lightweight

Experience a substantial weight reduction of up to 90%, lightening the load on your equipment and enhancing maneuverability, ultimately leading to significant fuel savings.

Abrasion Resistance

Synthetic Trawl Lines demonstrate exceptional resistance to abrasion, resulting in up to 5 times longer service life compared to conventional alternatives, reducing replacement costs.

Minimal Elasticity

With minimal elongation (less than 3%), achieve precise control and responsiveness, maximizing catch efficiency while minimizing energy consumption – a win-win for your bottom line.

- Happy Clients

What They Said

Customer Testimonials: Raving Reviews for Duracordix Trawl Lines

- Pain-Free Purchase

WHY CHOOSE

- Exceptional Durability: Duracordix's UHMWPE Trawl Warps are engineered to withstand the harshest marine conditions, addressing the pain point of frequent replacements due to wear and tear.

- Fuel Efficiency: These warps are significantly lighter than traditional steel warps, offering substantial fuel savings for trawler operators, addressing the pain point of rising fuel costs.

- Reduced Maintenance: With low elongation and high abrasion resistance, our warps require minimal maintenance, alleviating the hassle of constant upkeep associated with other materials.

- Safety Assurance: Unlike steel warps known for lashing out upon rupture, our UHMWPE fishing warps distribute energy linearly, enhancing safety for riggers and equipment.

- Cost-Effective: While the initial investment may be higher, the extended service life and reduced operational costs make Duracordix's synthetic fishing trawl ropes a cost-effective long-term solution, mitigating budget constraints.

- we make more

Related products

Discover High-Performance Marine Solutions for Your Diverse Needs.

FAQs

Answers to Your UHMWPE Trawl Lines Questions – Get Informed!

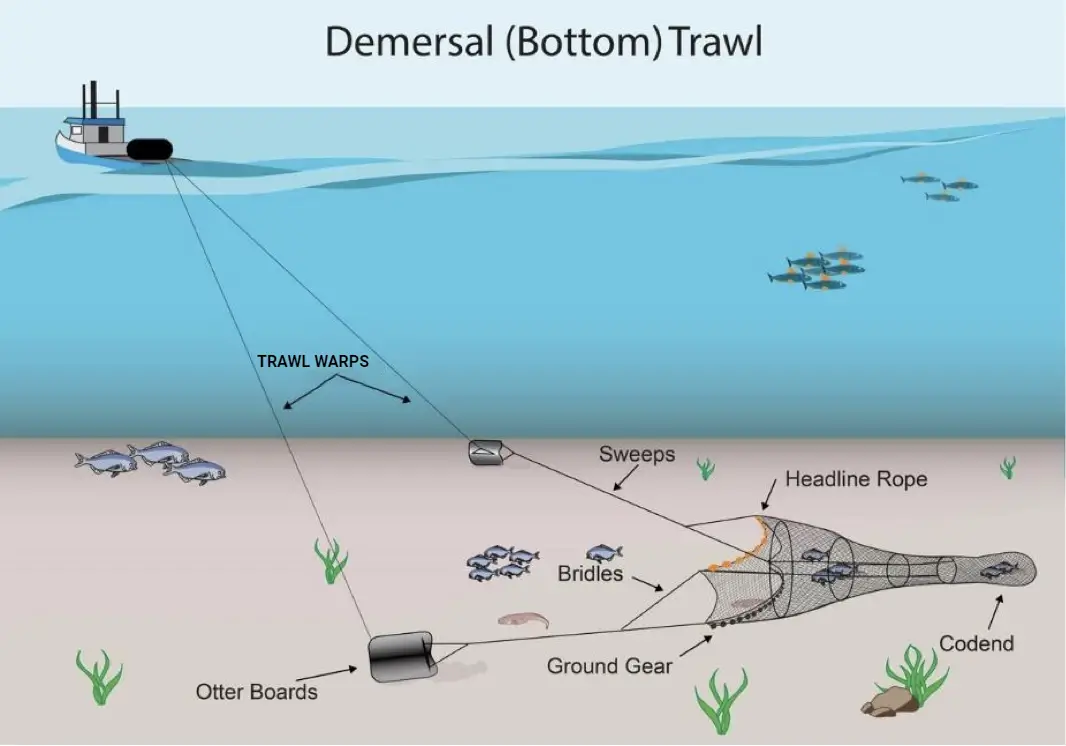

What are trawl warps?

Trawl warps are robust ropes used in commercial fishing, connecting vessels to trawl nets. They come in various materials, diameters, and strengths, with durability and proper maintenance being crucial for safe and effective trawling operations.

What materials are trawl warps made from?

Trawl warps can be made from various materials, including steel wire, synthetic fibers like UHMWPE (Ultra-High Molecular Weight Polyethylene), and a combination of materials to achieve strength and durability required for different fishing operations.

What are the advantages of UHMWPE trawl warps over steel wire?

UHMWPE (Ultra-High Molecular Weight Polyethylene) trawl warps offer several advantages over traditional steel wire warps in fishing operations:

Lightweight: UHMWPE trawl warps are significantly lighter than steel wire warps. This weight reduction makes handling easier, reduces fuel consumption, and contributes to vessel stability.

Strength: Despite their lightweight nature, UHMWPE trawl warps are incredibly strong. They have a high strength-to-weight ratio, making them as strong as steel while being much lighter.

Floatability: UHMWPE is naturally buoyant, which means these trawl warps float on water. This property helps prevent snagging on the seabed and makes retrieval easier.

Low Maintenance: Unlike steel wire warps, UHMWPE trawl warps don't require lubrication to prevent rust. They are more resistant to corrosion and degradation, resulting in lower maintenance costs.

Flexibility: UHMWPE trawl warps are more flexible than steel wire, allowing for smoother towing and reduced wear and tear on equipment. Their flexibility also contributes to ease of handling during deployment and retrieval.

Reduced Fuel Consumption: The lighter weight of UHMWPE warps reduces the overall weight of the trawl gear, leading to decreased fuel consumption and operational costs for fishing vessels.

Safety: In the event of a warp failure, UHMWPE warps have a lower risk of snapping back or causing injury compared to steel wire, which is known for its potential lash-back danger.

Abrasion Resistance: UHMWPE's abrasion resistance is excellent, ensuring a longer service life even in challenging marine conditions.

Environmental Benefits: Using UHMWPE trawl warps can contribute to more sustainable fishing practices by reducing the environmental impact associated with steel production and corrosion.

Improved Trawl Control: The lightweight and flexibility of UHMWPE warps enable better control of the trawl, making it easier to achieve desired fishing patterns and optimize catch.

How do I choose the right diameter for trawl warps?

Choosing the correct diameter for trawl rope is vital. Factors such as vessel size, trawl type, target species, depth, towing speed, and budget constraints must be considered. Expert advice and practical testing can help ensure an appropriate and efficient selection.

What is the breaking strength of UHMWPE trawl ropes?

The breaking strength of UHMWPE trawl ropes can vary depending on the diameter and construction. Generally, these ropes boast impressive strength, ranging from several tons to over 100 tons. It's essential to select a breaking strength suitable for your specific fishing needs and vessel capabilities.

Is synthetic trawl warp resistant to UV and chemicals?

Yes, synthetic trawl warp is UV-resistant, protecting against sun damage, and chemically resistant, capable of withstanding exposure to acids, bases, and solvents. This durability ensures their reliability in demanding marine settings.

What is the maximum working temperature for UHMWPE trawl warp?

UHMWPE trawl warp has a maximum working temperature of 60-65°C (140-149°F). Exceeding this range can weaken the material, affecting performance and safety. Adhering to these limits ensures the durability of the trawl warp.

Do UHMWPE trawl warps have low creep?

Absolutely, UHMWPE trawl warps boast low creep, guaranteeing minimal elongation under sustained tension. This characteristic preserves their length and strength over time, enhancing reliability and longevity in trawling. Low creep translates to fewer adjustments and replacements, ensuring cost-efficiency and dependability in marine operations.

Are UHMWPE trawl lines rotation-free?

Yes, UHMWPE trawl lines are rotation-free due to their torque-neutral construction. Unlike steel warps, they don't suffer from issues like "snaking," bird caging, or kinking. This ensures smoother, more controlled trawling operations and eliminates the need for complex anti-rotation measures, simplifying usage and reducing potential risks.

Can I use UHMWPE trawl warps over sharp edges?

Using UHMWPE trawl warps over sharp edges is not recommended. It can lead to cuts, abrasion abuse, and potential splice damages. Ensuring proper surface conditions is crucial for the longevity of the trawl warps and the safety of operations.

Does synthetic trawl warp require a protective cover?

Synthetic trawl warp can benefit from a protective cover to enhance their service life. A cover, such as Duracordix pro cover, provides greater abrasion resistance and helps protect the trawl warp from wear and tear, especially in demanding marine environments.

How do I inspect UHMWPE trawl ropes for damage?

To inspect UHMWPE trawl ropes for damage, follow these steps:

Visual Inspection: Examine the entire length of the trawl ropes for any visible signs of damage, such as cuts, abrasions, or irregularities in the rope's surface.

Check Diameter: Measure the diameter of the trawl warps at different points along its length to ensure it remains consistent. Any significant variations may indicate damage or wear.

Inspect the Cover: If your trawl warps have a cover, inspect it closely for signs of wear or damage. Look for fraying or loose fibers on the cover.

Check for Abrasion: Pay particular attention to areas of the warps that come into contact with winch drums or other equipment, as these areas are more susceptible to abrasion.

Look for UV Damage: Assess the trawl warps for any signs of UV damage, such as discoloration or a chalky appearance. UV exposure can weaken the rope over time.

Check for Knots: Ensure there are no knots or splices that could compromise the integrity of the trawl ropes.

Evaluate Elongation: Measure the elongation of the trawl warps to check if it falls within the specified range. Excessive elongation may indicate damage or wear.

Inspect Splices: If your trawl ropes have splices, examine them for any signs of fraying or loosening.

What are the main challenges when choosing trawl warps for a fishing vessel?

Choosing trawl warps for a fishing vessel involves several challenges, including:

Choosing trawl warps for a fishing vessel involves several challenges, including:

Material Selection: Deciding between materials like UHMWPE, steel wire, or other synthetics requires considering factors like strength, weight, and durability.

Strength and Diameter: Determining the appropriate breaking strength and diameter of the trawl warps to match the vessel's size and fishing requirements.

Budget Constraints: Balancing the cost of trawl warps with the vessel's budget while ensuring they meet performance standards.

Environmental Factors: Considering the impact of UV exposure, saltwater corrosion, and chemical resistance on the longevity of the trawl warps.

Safety: Ensuring the safety of crew members by selecting trawl warps that are rotation-free, have low creep, and resist backlash.

Maintenance: Evaluating the maintenance requirements of different trawl warp materials and designs to minimize downtime.

Regulations: Complying with local and international regulations related to fishing gear materials and construction.

Performance Metrics: Identifying the specific performance metrics required for successful trawling, such as buoyancy, abrasion resistance, and UV stability.

Trawl Configuration: Choosing trawl warps that match the vessel's trawl configuration, including doors, sweeps, and net design.

Can I use UHMWPE trawl warps in deep-sea trawling?

Yes, UHMWPE trawl warps are suitable for deep-sea trawling. They offer high strength, low weight, and resistance to the harsh marine environment, making them ideal for deep-sea fishing operations. Their durability and performance advantages contribute to efficient and productive trawling in deep waters.

How do UHMWPE trawl warps impact fuel consumption?

UHMWPE trawl warps reduce fuel consumption due to their lightweight design, minimizing energy needed for towing. This results in cost savings and improved environmental impact. The reduced weight also enhances vessel stability and performance, contributing to overall fuel efficiency in fishing operations.

Do UHMWPE trawl warps affect catch performance?

UHMWPE trawl warps positively impact catch performance. Their reduced weight and consistent trawl spread improve fishing results. The ability to adjust trawl doors, maintain spread, and reduce collapsing during turns enhances the catch rate, making them a valuable choice for commercial fishing operations.

What are the safety benefits of using UHMWPE trawl warps?

Using UHMWPE trawl warps offers several safety benefits. They have low recoil in case of rope rupture, reducing the risk to personnel and equipment. The absence of steel wires eliminates the hazard of protruding threads. Additionally, they require less maintenance, reducing the likelihood of accidents during upkeep.

How long do synthetic trawl ropes typically last compared to steel wire warps?

synthetic trawl ropes typically last significantly longer than steel wire warps. While steel warps often have a shorter lifespan due to corrosion and wear, synthetic uhmwpe warps can last for several years, making them a cost-effective and durable choice for marine operations.

Are UHMWPE trawl lines spliceable?

Yes, UHMWPE trawl lines are spliceable. This means they can be easily spliced or joined together, allowing for flexibility in creating longer lengths or custom configurations to suit specific fishing or marine needs. Splicing UHMWPE trawl line is a straightforward process that enhances their versatility and usability.

how to do maintenance for UHMWPE trawl warps?

Maintaining UHMWPE trawl warps is relatively simple, and proper care can extend their lifespan. Here are some maintenance tips:

Maintaining UHMWPE trawl warps is relatively simple, and proper care can extend their lifespan. Here are some maintenance tips:

Regular Inspection: Before each use, inspect the trawl warps for any signs of damage, wear, or abrasion. Look for any cuts, fraying, or deformities along the length.

Cleanliness: Keep the warps clean and free from debris, dirt, and saltwater. Rinse them thoroughly with fresh water after each use to remove salt and other contaminants.

Protection: If your trawl warps are not equipped with a protective cover, consider adding one to enhance abrasion resistance and prolong their life.

Storage: When not in use, store the warps in a cool, dry place away from direct sunlight. Avoid sharp edges or objects that could cause damage.

Avoid Overloading: Do not exceed the working load limits of the trawl warps. Overloading can lead to premature wear and damage.

Splicing: If splicing is required, follow manufacturer guidelines or consult with a professional rigger to ensure the splice is secure and meets safety standards.

Replace Damaged Sections: If you notice any significant damage or wear during inspections, consider replacing the damaged sections promptly. Regularly monitoring and addressing issues can prevent accidents and maintain performance.