Table of Contents

ToggleIntroduction

A winch is a mechanical device widely used to pull,lift, or move objects. it rotates to wind or release the rope under force.

A winch rope is the rope connected to your winch, and the main types of winch rope in use are steel wire ropes, often called winch wire, and synthetic ropes.

But when you’re choosing a winch rope, you may ask which one is right for you? Or perhaps ask yourself “Is synthetic winch rope better than steel rope?” Now you may find the answer with details like below.

Definition of two types of winch ropes

Steel Wire Rope

1. A steel wire rope is a rope made of strands of uniform steel wires twisted around a core, created through detailed steel wire rope manufacturing processes.

2. Your steel wire winch ropes are commonly made from galvanized steel wire, stainless steel wire, and carbon steel wire. They are made in 6-strand, 8-strand, 19-strand, or 37-strand structures. Steel wire ropes have high strength, good heat resistance, wear resistance and are barely affected by UV light.

Synthetic Winch Line

1. A synthetic rope for winch is a twisting or braiding rope made from kinds of man-made synthetic fibers.

2. The main types of synthetic winch rope include UHMWPE winch rope,nylon rope, polyester rope, polypropylene rope, and aramid rope (Kevlar rope). However, when choosing your rope, you may want to consider Dyneema synthetic winch rope (UHMWPE), which is now widely used for its high strength, excellent flexibility, and lightweight features that make it an ideal choice for you.

Comparison Chart – steel winch cable vs synthetic rope

| Dimension | Steel Wire Rope | Synthetic Rope |

| Strength | High strength, thicker for the same strength | Thinner, lighter for the same strength (e.g., UHMWPE) |

| Weight | Heavy, affects fuel and handling | Lightweight, easier to carry and use |

| Abrasion Resistance | Very wear-resistant, good for rough environments | More delicate, needs protective sleeve |

| Flexibility | Rigid, easy to tangle | Soft, coils easily, resists tangling |

| Safety | Burrs, strong rebound when breaking, gloves required | No burrs, small rebound, safer |

| Weather Resistance | UV-resistant, high-temperature resistant, rust-prone | Rust-free, corrosion-resistant, lower UV resistance |

| Operation | Heavy, stiff, more effort required | Light, soft, easy to wind/unwind, user-friendly |

| Maintenance | Requires cleaning, drying, oiling, rust-proofing | Easy maintenance with water cleaning |

| Splicing | Requires tools, difficult to repair on site | Easy to splice or knot on-site |

| Compression Resistance | Rigid, good for heavy loads | Deforms under pressure, may sink in heavy use |

| Applications | Construction, towing, heavy use | Off-road, rescue, marine, light-weight applications |

| Cost | Lower initial cost, higher maintenance cost | Higher initial cost, better long-term value |

Detailed Information Below for You

Strength

Synthetic Winch Cable:

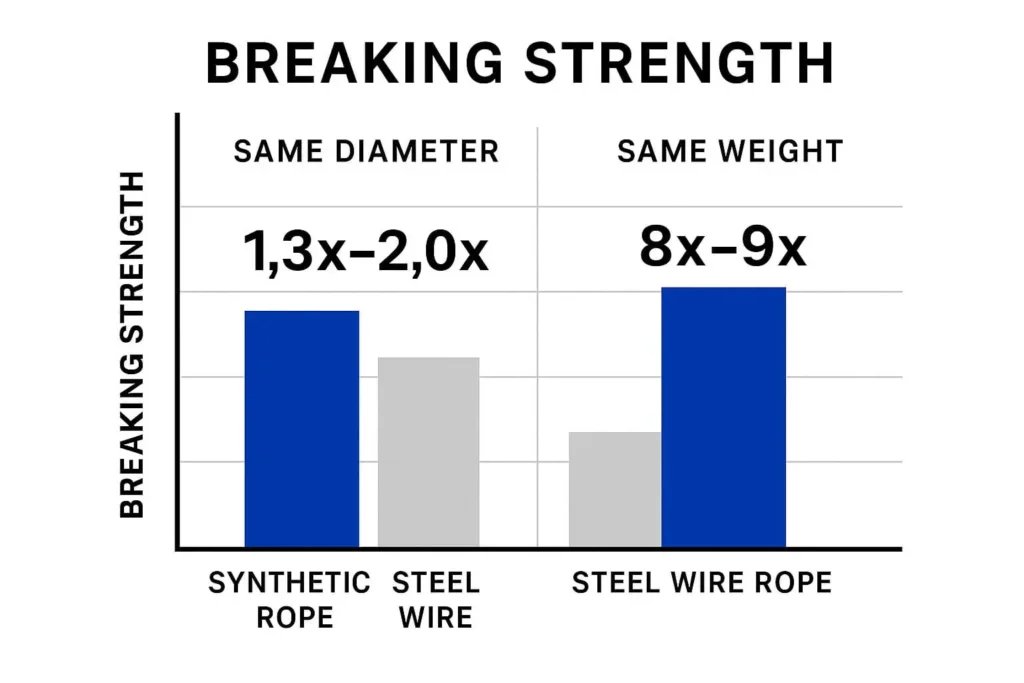

When you compare them, you’ll see that synthetic winch ropes are usually stronger than steel ropes of the same diameter, but much lighter.This matches what you will see in many synthetic winch rope reviews.

Among synthetic ropes, Dyneema (UHMWPE) ropes stand out. They are considered the strongest synthetic winch rope, strong and very light. At the same weight, they can be 8 to 9 times stronger than steel rope.

Synthetic ropes give you the pulling power you need while making it easier and less tiring to move heavy things.

Steel Wire Rope:

Steel ropes are also very strong. But for the same diameter or weight, steel rope is not as strong as synthetic rope.

This means you need a thicker, heavier steel rope to match the strength of a lighter synthetic rope.

Weight

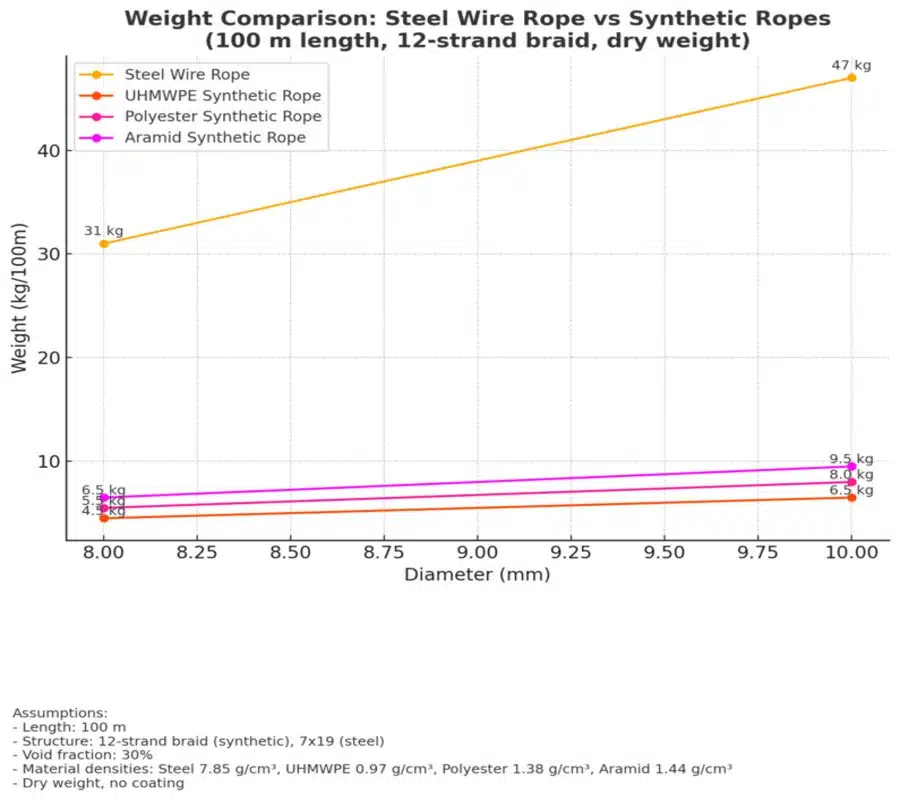

Note: Data is based on calculated weight using standard material density and a 30% weave void ratio; actual product weight may vary ±10% due to construction and coating.

Synthetic Winch Cable:

At the same strength, synthetic rope is always lighter, which makes it easier for women or anyone who wants less strain.

When you’re stuck in mud, rain, rough roads, or tough conditions and already exhausted, a light synthetic rope won’t make things harder.

Synthetic rope floats better than steel rope, doesn’t rust, and resists seawater corrosion, so it’s great for marine winch rope or ocean use. Its light weight also makes changing a boat winch rope much easier, especially when you choose a replacement winch rope that’s designed for these conditions, making it the ideal choice for you.

Steel Wire Rope:

Not just for off-road use, when you drive a vehicle with a heavy winch and steel rope every day, your fuel costs will keep going up, and the heavy weight can affect handling.

During use, inspection, maintenance, or storage, if you’re not strong enough to lift heavy things, a steel rope can be a real burden.

Abrasion Resistance

| Comparison of Abrasion Resistance for Common Winch Rope Materials (Dry Condition) | ||

| Material | Relative Abrasion Index (Steel Rope = 100) | Characteristics |

| High-carbon steel wire rope | 100 | Very high surface hardness and long abrasion life |

| Galvanized steel wire rope | 95–100 | Abrasion resistance close to high-carbon steel, with anti-rust coating |

| Stainless steel wire rope | 85–95 | Slightly lower abrasion, but excellent corrosion resistance |

| UHMWPE (Dyneema®/Spectra®) | 80–90 | Low friction, better abrasion resistance than most synthetic fibers, light, safe |

| Polyester rope | 60–75 | Stable dry/wet abrasion resistance, good UV resistance |

| Nylon rope | 50–65 | Average abrasion resistance, but maintains well after absorbing water |

| Aramid (Kevlar®/Technora®) | 85–95 | Cut-resistant and high-temperature-resistant, dry abrasion close to steel |

Data sources for reference:

● ASTM D3884 (Taber Abrasion Test)

● ASTM D6770 (Abrasion Resistance of Rope)

● Cordage Institute CI-1500

● Actual measured comparison of friction life (number of cycles on a steel drum)

Synthetic Winch Cable:

Synthetic rope is more delicate than steel rope when it comes to wear and tear. So how do you make the best use of it?

If you mainly use your winch rope for weekend off-roading or outdoor trips, or you’re confident you can avoid rough surfaces, synthetic rope is a good choice.

You can protect it by adding a synthetic winch rope protective sleeve, using the synthetic winch rope guide, or even wrapping a towel around areas of friction in an emergency.

These steps help reduce wear, extend the rope’s life, and save you money.

Steel Wire Rope:

Steel rope often looks thick and shiny, and it gives you the feeling that it’s tough.

That’s true. After using steel rope for a while, you’ll see how durable it is. When rubbing against trees, rocks, gravel, or sharp objects, steel rope performs very well and won’t let you down.

Flexibility

Maybe you have two friends with very different personalities: one is gentle, the other is hot-tempered.

Synthetic Winch Cable:

Synthetic rope is very flexible.

Whether you’re straightening out a tangled rope, tying knots, or joining sections together, the flexible rope makes everything easier.

When you use it in tight spaces, you’ll really notice how light and easy to handle synthetic rope is.

Steel Wire Rope:

Steel rope is the opposite.

It’s stiff and not very flexible, so it needs a larger bend radius. If it’s bent too often or too sharply, it can get damaged from fatigue.

In cold weather, steel rope becomes even stiffer, making it harder to use.

Safety

Synthetic Winch Cable:

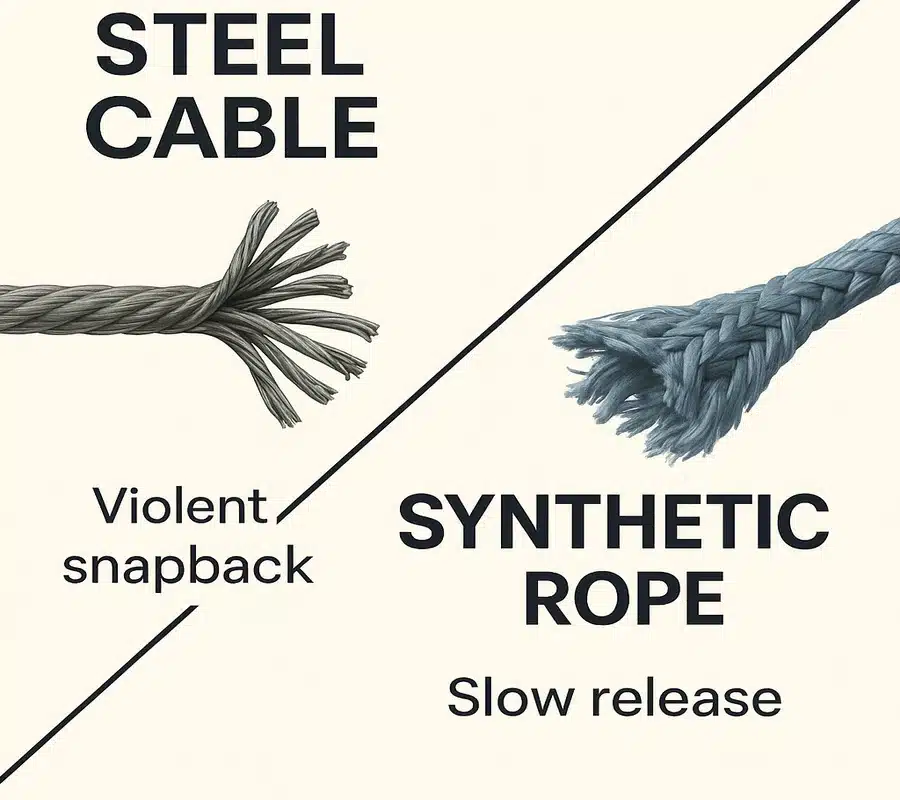

When you are pulling with a heavy duty synthetic winch rope, you’ll notice it’s lighter than steel rope at the same strength, and it stores less energy. That means if it breaks, it’s less dangerous.

Regular synthetic winch rope care will also help you reduce risks and keep the rope strong.

To make it even safer, you can add a winch damper to reduce the snap-back if the rope breaks.

If you want to use the color of the rope to give warnings or signals to others, the easy-to-dye synthetic rope will meet your needs better. Blue winch rope, red winch rope, yellow winch rope, orange winch rope – there’s always a color that suits your choice.

Steel Wire Rope:

Steel rope is very tough, but not unbreakable.

It can twist and tangle, and if you don’t check for damage, it could break suddenly during use.

Steel winch cable breaking can be very dangerous—the more force on it, the more harm it can cause to you, people, or property nearby.

Steel ropes can also develop broken strands or sharp burrs, which weaken the rope and can cut your hands if you don’t wear gloves or protection.

Weather Resistance

Synthetic Winch Cable:

If you need a winch rope for water, mud, wet areas, or salty conditions, synthetic rope won’t rust, so it’s safer—perfect for boat winches.

Its UV resistance is not as strong as steel rope, but it’s not weak. You can make it last longer in the sun by:

- Choosing materials with better UV protection, like UHMWPE.

- Using double-braided rope, which handles sunlight better than single braid or loose weave.

- Adding PVC or PU coating for a protective layer.

- Picking darker colors or black fibers that resist sunlight.

- Using UV covers or sleeves when storing or using it to block sunlight.

Synthetic rope can’t handle extreme heat like steel rope, but at normal temperatures it works just as well for off-road recovery, moving logs, or lifting heavy loads.

Steel Wire Rope:

No matter the weather—freezing cold, burning heat, rain, snow, or dusty conditions—you’ll always see steel rope being used.

Compared to synthetic rope, steel rope handles high heat better, is very resistant to UV rays, corrosion, and abrasion.

If you need a rope for very hot conditions, this matters:

HMPE synthetic rope melts at around 150°C (302°F). Heat from the winch drum could damage it and cause it to break. Steel rope can handle up to about 1300°C (2372°F), so it’s excellent in high-heat situations.

Operation

When using and maintaining a winch rope, you often need to carry it, wind and unwind it, and store it.

Synthetic Winch Cable:

Synthetic rope is lighter, so it’s easier and faster to use. The fibers are softer and safer to handle.

It’s flexible and doesn’t tangle easily. Even if it does, it’s much easier to fix than steel rope.

After using both steel and synthetic ropes, you’ll clearly feel that synthetic rope is lighter, easier, and safer to work with.

Steel Wire Rope:

Steel rope is heavy, hard to move, and not very flexible, so bending it takes effort.

To avoid injuries from sharp strands, you must wear thick protective gloves when handling steel rope.

Maintenance

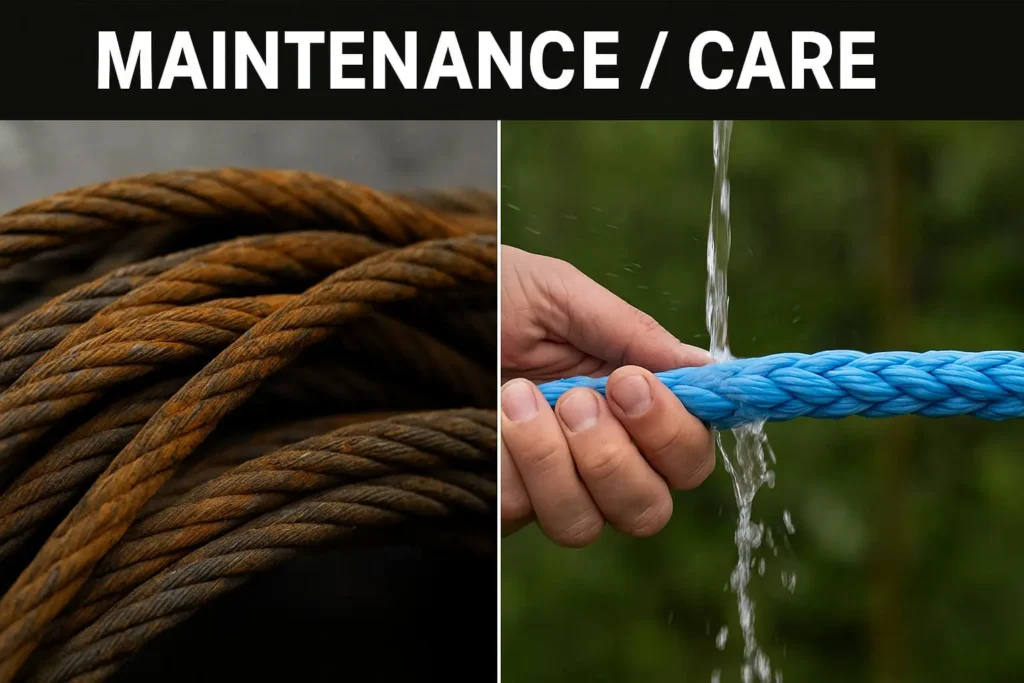

You should check your winch rope regularly. If you find damage, fix it right away to keep its strength and make it last longer.

Synthetic Winch Line:

When using synthetic rope, be careful: strong sunlight can age it, sharp objects can cut it, and hard particles can wear down the surface. Small debris can even get inside the rope and cause internal damage.

If the rope gets dirty, you should follow the steps for cleaning synthetic winch rope: wash it with room-temperature water or a mild neutral detergent, and let it dry out of direct sunlight.

Steel Wire Rope:

Steel rope can rust, so you need good steel winch cable maintenance. When it gets dirty or wet, you should clean it quickly and then apply a rust-preventing oil like WD-40 after it dries.

er it dries.Mud and grit can also get inside the rope and cause wear. Besides cleaning, you should also coat the rope with a special winch cable lubricant.

Splicing

Your winch rope might break or need to be made longer, so it’s important to know how to join ropes. Having a synthetic winch rope repair kit can make fixing damage faster and safer.

Learning about splicing synthetic winch rope is especially useful, as synthetic rope and steel rope are very different when it comes to splicing, and the difficulty is not the same.

When you learn a few winch rope knot techniques, you can repair or extend your rope quickly even without special tools.

Synthetic Winch Line:

Synthetic rope is light and flexible, so it’s much easier to splice. Here are some common methods:

- Long Bury Splice is a method used to join two ends of rope by inserting one end deeply into the other, creating a secure and smooth connection. It retains 85%-95% of the rope’s original strength and is commonly used for permanent repairs or lengthening ropes.

- Brummel Lock Splice is a splice method for synthetic ropes where the rope is looped through itself and locked with interwoven strands. It maintains 85%-95% of the rope’s original strength and is quick to make without tools.

- Butt Splice is a method of joining two ropes by aligning their ends and overlapping them slightly, then securing the connection with a series of interwoven strands. This splice maintains a strong connection and is typically used for extending ropes or creating permanent joins.

- Double Fisherman’s Knot is a strong knot used to join two ropes by tying two overhand knots around each other. It provides a secure, reliable connection and is commonly used in climbing, rescue, and other high-stress applications.

- Figure-8 Knot is a simple and effective knot used to create a secure loop at the end of a rope. It is easy to tie and untie, making it ideal for temporary connections and frequently used in climbing, rescue, and other outdoor activities.

If you learn to use soft shackles, you can also connect ropes quickly and safely.

Steel Wire Rope:

Splicing steel rope is much harder, and when you need to fix it, common methods for steel winch cable repair include:

- Swaged Fittings are metal connectors used to permanently join the ends of ropes, typically steel wire ropes. The rope is inserted into the fitting and then compressed (swaged) using a hydraulic machine to create a secure, strong bond.

- Woven Splice is a method of joining two ropes by interweaving the fibers of each rope. This splice creates a strong, durable connection and is commonly used for joining synthetic ropes, often for permanent repairs or extensions.

- Wire Rope Clips are metal clamps used to secure the ends of wire ropes by fastening them to the rope itself. They typically consist of a U-bolt, a saddle, and two nuts, and are used for making temporary or permanent loops in the rope.

Note: Whether splicing synthetic or steel rope, you should use the correct method or ask a professional’s guide.

Compression Resistance

Synthetic Winch Cable:

Synthetic rope is soft and thinner. When squeezed under heavy pressure, it can change shape. This can cause the top layers of rope on the winch to press into the lower layers or grooves.

When pulling heavy loads, you may find it harder to wind and unwind the rope.

Steel Wire Rope:

Steel rope is thick and stiff. Even under heavy pressure, the layers stay tight and don’t easily change shape.

Steel rope is better for very heavy loads or long periods of tension, and it makes winding and unwinding smoother.

Applications

Synthetic Winch Cable:

Because of its many good features, when choosing synthetic or steel winch cable, synthetic rope works well in these situations:

- 4×4 off-road recovery

- Outdoor rescue

- ATVs

- UTVs

- Small vehicle work

- Other special vehicles

- Marine and wet environments

Steel Wire Rope:

Steel rope handles high heat and friction and is good for long, heavy use. It’s best for:

- Frequent or heavy vehicle recovery

- Construction work

- Landscaping

- Land clearing

Cost

If you’ve decided on steel or synthetic winch cable, picking the right winch rope is key to saving money.

Synthetic Winch Cable:

Synthetic rope may cost more at first, and some may wonder is synthetic winch rope worth it. But if you use and care for it properly, it will last longer and lower your overall cost.

If you care more about long-term performance, easier handling, and better value, choosing the best synthetic winch rope for the money is the smarter choice.

Steel Wire Rope:

If your budget is tight, you use the winch often, or work in rough conditions, steel rope is still a cost-friendly option.

Keep it dry and protect it from rust to make it last longer. Poor use or maintenance can shorten its life and cost you more to replace it.

FAQs

1.Winch Rope Replacement – Can I do a synthetic winch rope replacement for my steel cable?

Yes. But before installing synthetic winch rope, you need to make some changes. Replace the fairlead with an aluminum hawse fairlead made for synthetic ropes, and add a rope guard to protect it.

2.What accessories are often used for off-road recovery or trailer winch rope setups?

Common synthetic winch rope accessories include: soft shackle, tree saver strap, winch rope protector, synthetic winch rope extension, winch rope stopper, winch rope thimble, winch cable tensioner and winch rope hook.

3.When is steel rope a better choice?

Steel rope works better in places with a lot of wear, heat, UV exposure, or a high risk of cutting.

4.Can synthetic winch ropes float?

Most synthetic ropes are lighter than water, so they float. UHMWPE and polypropylene float easily. Polyester and nylon sink, but with some force can float for short times.

5.How do synthetic ropes work in marine environments?

They are good for marine use. They don’t rust, resist corrosion, can float (depending on the material), and resist mildew. They stay strong in wet conditions but are weaker against UV and wear, so protect them.

6.Are synthetic winch ropes good for cold weather?

Yes. They usually work fine in the cold. UHMWPE stays flexible and strong even when frozen.

7.How much lighter are synthetic ropes than steel?

At the same strength, synthetic ropes are much lighter — about 6 to 8 times lighter than steel. They’re easier to carry and use while still meeting strength needs.

8.Can I reuse a rope after it breaks?

Yes, if handled properly. Repairing synthetic winch rope is easier because synthetic winch ropes are easy to knot or splice, and knowing how to splice synthetic winch rope makes repairs simpler. In contrast, splicing steel cables requires special tools and is more difficult.

9.Why is the correct rope diameter important?

Rope size affects strength. The wrong size won’t match your winch’s pulling power and may not fit the drum, which can cause slipping, tangling, or breaking.

10.Why is the correct rope length important?

If the winch rope length is too long, the winch can lose pulling power and the drum can jam. If the winch rope length is too short, you may not reach what you need to pull. In such cases, a synthetic winch cable replacement with the right length can solve the problem.

Conclusion

Now you may have your own idea about which is better synthetic rope or steel cable for winch, or if synthetic winch rope is worth it.

If you’re confused about choosing the right rope for your winching needs, contact the Duracordix team directly. Our custom made solution will meet your needs.

About The Author

Moses Xu

Hi, I’m Moses Xu, VP and Marketing Director at Duracordix. With 10+ years in high-performance synthetic ropes and netting, I specialize in export trade and marketing. Whether it’s HMPE, Kevlar, or nylon ropes, I’m happy to share insights and connect!