KEVLAR ROPE

High Performance Rope, Engineered For Extreme Operating Environments

Kevlar Rope

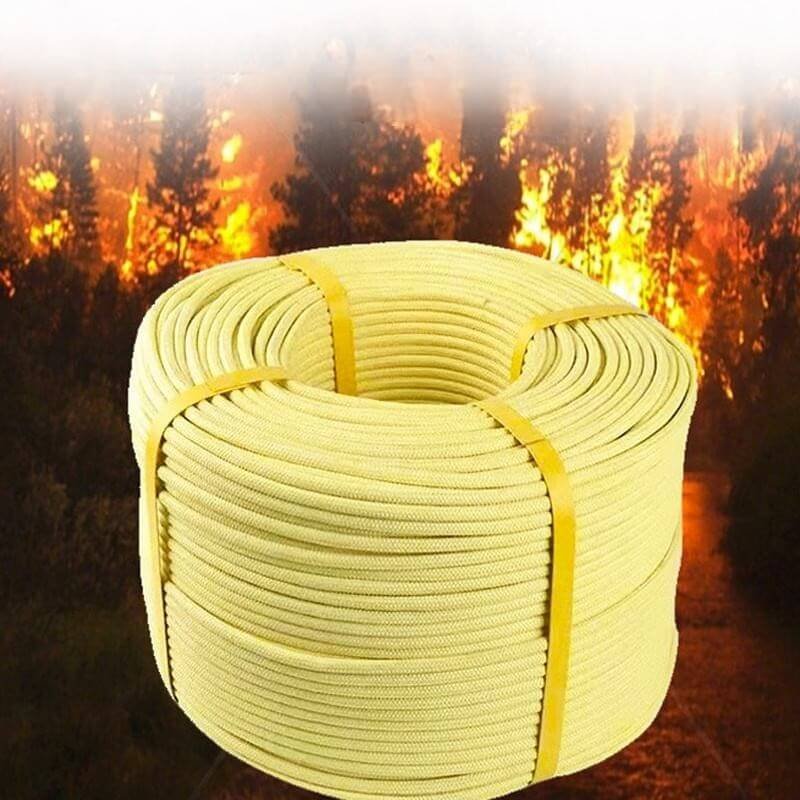

Duracordix Kevlar rope is a type of rope made from Kevlar brand fiber(kevlar thread), which are known for their high strength and resistance to heat( a melting point at 450°C )and chemicals. Kevlar is a synthetic material developed by the DuPont company in the 1960s. It’s a type of aramid fiber, similar to nylon but much stronger.

- High Tensile Strength

- Flame Resistant

- Low Stretch

- Chemical Resistant

- UV Stable

General Applications

High-Performance Kevlar Rope for Your Demanding Applications

Military & Tractical

Braided kevlar cord is light yet exceptionally strong for towing your military vehicles and constructing filed fortifications.also ideal for helicopter fasting rope and lifting sling. its natural matte finish is non-reflective and minimal noise during use, suitable for your covert military missons.

Fire Rescue

Excellent heat resistance and cut resistance, making it highly suitable for your rescue missions in high-temperature and complex environments such as fire scenes. also it’s an ideal personal safety rope for firefights.

Lifting & Climbing

Kevlar climbing rope ues as a low-stretch static rope, is ideal for use as a fixed line in your caving and mountain climbing. When used for rappelling, it resists damage from heat generated by friction and, thanks to its excellent cut resistance, offers you enhanced safety when navigating sharp rock surfaces.

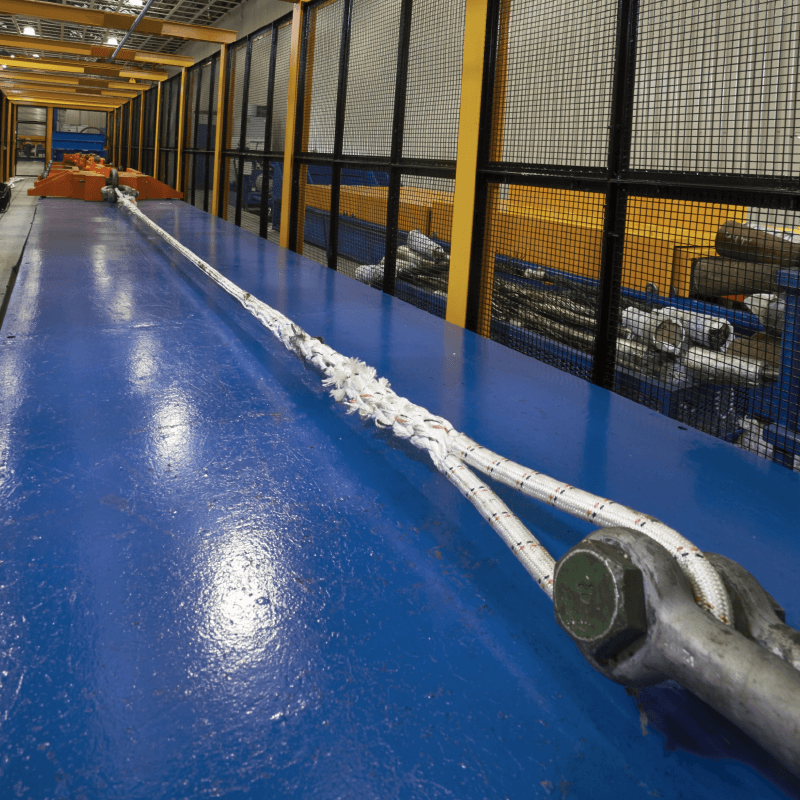

Maritime

Kevlar cordage offers excellent chemical resistance, UV stability, making it especially well-suited for your use as mooring ropes and tug towing lines—particularly for oil tankers. Its stable performance also makes it a reliable choice for lifelines and safety ropes.

It can also be used for applications such as paragliding lines, water ski tow ropes, fishing lines, kite strings, and fire props for stage

- Characteristics

main Properties

Exploring the Core Properties of Duracordix’s Kevalr(aramid) Rope

Kevlar ropes can withstand forces of up to 8 times greater than steel wire of equivalent weight, ensuring durability in extreme conditions.

With a decomposition temperature of 450°C (932°F), Kevlar maintains its strength properties in high temperature environments.

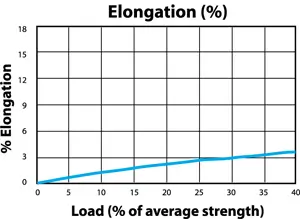

Exhibiting a mere 3.6% elongation at break, Kevlar ropes offer minimal stretch, ensuring optimal force transfer and stability during use.

With a resistance factor of 60% higher than standard fibers, it ensure a longer lifespan even in the roughest handling scenarios.

Kevlar exhibits minimal creep just 0.7% over 200 hours, ensuring consistent length and superior structural integrity under load.

- choose right sizes

Strength chart

Explore the tensile strength of Duracordix Kevlar(aramid) Rope!

| DIAMETER(mm) | CIRCLE(inch) | KTEX(g/m) | BREAKING STRENGTH(kn) |

|---|---|---|---|

| 6 | 3/4 | 30 | 19 |

| 8 | 1 | 52 | 34 |

| 10 | 1-1/4 | 81 | 55 |

| 12 | 1-1/2 | 120 | 75 |

| 16 | 2 | 210 | 130 |

| 18 | 2-1/4 | 265 | 172 |

| 20 | 2-1/2 | 328 | 205 |

| 24 | 3 | 462 | 308 |

| 28 | 3-1/2 | 632 | 429 |

| 32 | 4 | 830 | 539 |

| 36 | 4-1/2 | 1050 | 582 |

| 40 | 5 | 1290 | 715 |

| 44 | 5-1/2 | 1570 | 869 |

| 48 | 6 | 1860 | 1030 |

| 52 | 6-1/2 | 2190 | 1210 |

| 56 | 7 | 2540 | 1410 |

| 60 | 7-1/2 | 2910 | 1610 |

| 64 | 8 | 3310 | 1830 |

| 72 | 9 | 4190 | 2320 |

| 80 | 10 | 5180 | 2870 |

| 88 | 11 | 6270 | 3470 |

| 96 | 12 | 7460 | 4130 |

| 104 | 13 | 8750 | 4850 |

12fs

Duracordix is a kevlar rope manufacturer & wholesale supplier in China.

we can produce various sizes for different applications and custom made for special projects.

- Custom Made

Customization Options

Various Solutions to Meet Your Unique Requirements

- VS Steel Rope

Advantages

Lightweight, Unmatched Strength. Ideal Alternative to Heavy Steel Ropes.

Lighter than Steel

Stronger in Weight

Safer, Low Recoil

Kevlar aramid rope’s lightweight nature reduces strain on equipment, enhances portability, and improves maneuverability for easier handling in various applications. Kevlar is 6 times lighter than steel wire rope at the same strength.

The exceptional tensile strength of Kevlar rope ensures enhanced load-bearing capacity, allowing it to withstand heavy loads and demanding conditions with ease.

Kevlar cord minimizes the risk of sudden failures or breakages, providing increased safety during critical operations and reducing potential accidents.

| Material | Strength | Abrasion Resistance | UV Resistance | Stretch | Water Absorption | Melting Point | Applications |

|---|---|---|---|---|---|---|---|

| Kevlar | High | Excellent | Poor | Very Low(2%) | Low | 842F (450C) | Climbing, rescue, heavy lifting |

| UHMWPE | Very High | Excellent | Good | Low(3-4%) | Very Low | 300F (149C) | Winching, towing, marine, rigging |

| Nylon | Medium | Good | Fair | High(25%-30%) | High | 419F (215C) | General purpose, anchor lines, towlines |

| Polyester | Medium | Good | Excellent | Medium(10%) | Low | 489F (254C) | Sailing, rigging, towlines, mooring lines |

- Pain-Free Purchase

Why Choose

- Reliability: Our Kevlar rope, tested to endure 50% more load than standard ropes, guarantees durability and consistent performance you can trust.

- Expertise: Backed by 15+ years in the industry, we offer tailored guidance, assisting you in choosing the ideal rope type, diameter, and tensile strength for peak performance.

- Customization: Recognizing diverse needs, Duracordix offers tailored Kevlar rope solutions with 90% of our orders customized to client specifications, ensuring a perfect fit for every application.

- Customer Service: Duracordix's commitment is evident with a 96% customer satisfaction rate, ensuring swift responses and post-purchase support for a seamless buying journey.

- Safety: Our Kevlar ropes undergo rigorous testing, with a 99.8% pass rate, ensuring they meet stringent industry standards and deliver unmatched safety in operations.

- Cost-effectiveness: Offering Kevlar rope at prices 20% more affordable than market averages, we ensure unmatched value without compromising on safety or quality.

FAQs

Unraveling the Answers to Your Question About Kevlar Rope

What is Kevlar rope used for?

Kevlar rope is commonly used in applications such as mooring lines, rigging, winching, towing, rescue operations, and industrial lifting.

How strong is Kevlar aramid rope?

Kevlar aramid rope has an impressive tensile strength that can range from several thousand pounds to even tens of thousands of pounds depending on the diameter.

Is Dyneema better than Kevlar?

Dyneema has a higher tensile strength compared toK evlarr opeof similar size; however,K e vla ris known for its excellent heat resistance and ability to withstand high temperatures.

How do you tie a Kevlar rope?

Tying techniques forKEVLA Rropes are similar totyingother types ofropes,such as knots (e.g.,bowline knot, clove hitch) or splicing. It is advisableto consult reliable resourcesor seek expert advice for proper techniques.

Is Kevlar rope cut-resistant?

Yes,Kevlar Cord possesses high cut-resistant properties; however,it can still be cut with sufficient force or specialized tools designed for cutting it.

Does Kevlar aramid rope stretch?

Kevlar aramid rope has minimal stretch compared to other conventionalropematerials likenylon.This low-stretch property improves safety and stability in applications where minimal elongation is desired. degradation.

What type of rope withstands weather conditions?

Synthetic ropes like Kevlar ropeare highly resistant to weather conditionsincluding moisture,UV rays,saltwater exposure,and temperature variations,making them ideal for outdoorand marine applications.

Does Kevlar rope float?

No, Kevlar rope does not naturally float. However, it can be treated or coated to improve its buoyancy for specific applications.

How resistant is Kevlar rope to chemicals?

Kevlar ropes hows high resistance to most common chemicals found in industrial environments including acids and alkalis.It's importantto check the chemical compatibility chart provided by the manufacturerfor specific chemical exposures.

Is Kevlar stronger than nylon?

Certainly! Kevlar is significantly stronger than nylon. On average, Kevlar rope has a tensile strength that is about five times greater than that of nylon ropes of similar diameter. For example, while a typical nylon rope may have a tensile strength of around 5,000 pounds, a comparable Kevlar rope can handle an impressive 25,000 pounds or more.

What’s the maximum kevlar rope breaking strength you can offer?

For now, the maximum breaking strength of kevalr rope we can offer is 4850 kN. If you need a larger size, we can also customize it specifically for you.

Can I use Kevlar rope for towing vehicles?

Kevlar tow rope can be used for pulling and towing vehicles, but it is essential to consider the weight and load capacity of the specific Kevlar rope being used to ensure safety and effectiveness.

Can you make Kevlar Kite String?

yes, we can make kevlar kite string. Aramid fiber offers excellent abrasion resistance, low elongation, and cut resistance, giving it greater tensile strength and stability compared to traditional nylon lines. In applications such as sport kites or high-altitude single-line kites, aramid lines provide enhanced control, greater stability, and superior reliability with reduced risk of breakage.

Can Kevlar rope be used for high-temperature applications?

Yes, Kevlar rope has excellent heat resistance and can withstand high temperatures up to certain limits. However, it is important to consider the specific temperature range specified by the manufacturer for optimal performance.

What maintenance does Kevlar aramid rope require?

Regularly inspecting the rope for signs of wear,damage,or degradation,and replacing it if necessary,is recommendedto ensure safety and optimal performance.

How do I store Kevlar Cord correctly?

It is best to store Kevlar cord in a cool,d ryplace away from direct sunlight or extreme temperatures that could potentially degrade its material properties.

Can you splice or knot Kevlar rope?

Knotting or splicing Kevlar rope may compromise its overall integrity and strength.It is advisedto consult with experts on proper termination methods,such as using specialized hardware or stitching.

Why is Kevlar more durable than nylon?

Kevlar's exceptional durability can be attributed to its high tensile strength, heat resistance, and excellent performance under demanding conditions compared to nylon.

Can the Kevlar rope be custom made?

Absolutely! At Duracordix, we offer customizations for Kevlar rope to meet your specific requirements. Whether it's a particular length, diameter, or specialized coating, our team can tailor the Kevlar rope to suit your needs. Contact us for personalized solutions and exceptional performance.

How does Duracordix ensure the quality of Kevlar ropes?

At Duracordix , we have strict quality control measures in place throughout the manufacturing process. This includes using premium-grade materials, conducting rigorous testing procedures, and adhering to international standards to deliver top-quality products consistently.

Does Duracordix offer warranty coverage for kevlar rope?

Yes! We stand behind the quality and performance of our Kevlar ropes. We offer warranty coverage against manufacturing defects to provide you with peace of mind and assurance in your purchase.