nylon ROPE

Duracordix offers you different types nylon rope to meet your unique applciation

Nylon Rope

Duracordix Nylon rope is a type of synthetic rope made from polyamide, which are a type of polymer. our nylon ropes are popular and versatile type of rope that offers numerous benefits for various applications like mooring, offroad recovery, dynamic climnig,aqaculture etc.

- Strong and durable .

- Absorbs shock, reduces damage

- Great abrasion resistance

- Easy handling & splicing

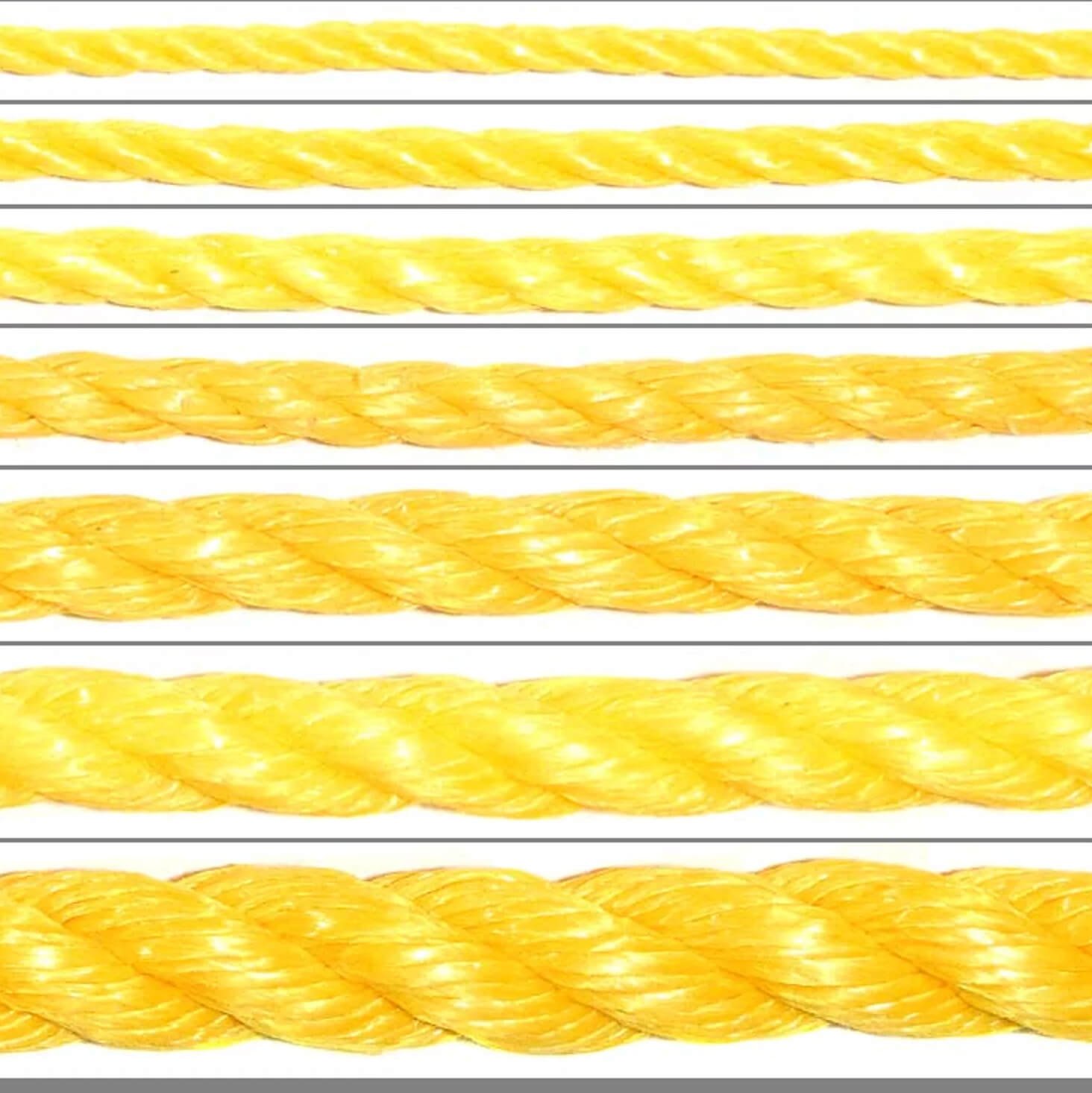

Types of Nylon Rope

As a nylon rope manufacturer, Duracoridx offers you different types for your specific uses

3 strand nylon rope

double braided Nylon rope

8 Strand nylon rope

Solid braided nylon rope

12 strand nylon rope

Main Characteristics

The material characteristics of Nylon fiber make it better suited to meet your specific needs

Melting Point: 210°C-250°C

Density: 1.14 g/cm³

Moisture Absorption: 4.5% of its weight

Elongation at Break: 20-40%

Thermal Conductivity: 0.25 W/m·K

Nylon rope exhibits good chemical resistance against most common solvents and chemicals. However, it can degrade in the presence of strong acids or phenols. It’s resistant to oils, alcohols, and aldehydes.

Extended sunlight exposure degrades nylon, reducing strength. Yet, even after 1000 hours of exposure, it retains over 60% of its strength

Nylon ropes boast high tensile strength, averaging 45-80 MPa. They exhibit exceptional fatigue resistance, retaining strength after enduring thousands of load-testing cycles.

Elastic Modulus:

2-4 GPa

Tensile Strength: 45-80 MPa

Flexural Strength: 60-100 MPa

Impact Strength: No break (Charpy, unnotched)

General Applications

Versatile, strong, and lightweight for diverse industry applications.

Ship Mooring: Duracordix Nylon mooring rope and SPM mooring hawser, used in mooring systems, offers you high strength and excellent elongation (20–30%), which effectively absorbs shocks caused by wind, waves, and currents. it can protect both your vessels and operating personnel from danger.

Fish Farming: Duracordix Nylon rope is used in aquaculture due to their flexibility, rust resistance and excellent elasticity. It can be used to connect fishing net cage frames and buoys, maintaining the stable shape of the net cage. it can be also used as mooring ropes to connect your fish net cages to anchor blocks, ensuring that your net cages do not drift due to wind, waves, and tides.

Vehicle Recovery: Nylon kinetic recovery ropes can pull your vehicles stuck in snow or mud out like a spring. it not only protect your vehicle but also ensures a safer and more enjoyable off-road experience for your team.

Climbing: Due to its superior elasticity and abrasion resistance, our nylon rope provides excellent cushioning when used as climbing ropes or for rapid rescue operations. It effectively absorbs the significant impact forces generated during descent, ensuring your safety during climbing or rescue. The high elasticity also reduces the impact on the body of your worker during tree climbing operations.

Military: Our nylon rope can be served as tactical rope for your fast-roping from military helicopters or for high-altitude rescue operations. It can also help your military vehicles or tanks safely recovered from muddy terrain. Additiaonly, it can be used as mooring rope or tugboat rope for naval vessels. Its excellent abrasion resistance and UV resistance make it suitable for various military deployment tasks.

Minning: Due to its ability to withstand dynamic loads, high elasticity, and great abrasion resistance, you can use Duracordix heavy duty nylon rope as kinetic rope for towing and recovering vehicles and heavy equipment in mines. It can also be used as winch rope for your pulley and winch systems. Although not as strong as HMPE winch lines, its super shock absorption properties make it widely used.

Advantages Of Nylon Rope

High Strength: Compared to natural fiber ropes, Duracordix nylon ropes have a very high breaking strength. For the same 20mm diameter, the nylon rope can withstand a tensile force of 92 kN, while Manila rope can only reach about 26 kN. This means you can use a lighter rope to accomplish the required tasks.

Best Shock Absorption: As a dynamic rope, our nylon rope offers you an elongation rate of up to 30%, providing a spring-like cushioning effect in applications such as ship mooring, anchoring, vehicle recovery, and climbing. This prevents force from being directly applied to your equipment or operators, ensuring the safety of your property and personnel.

Chemical and UV Resistance: Our nylon rope boasts excellent UV resistance and is resistant to corrosion from seawater, oil, and other chemicals. Unlike steel wire ropes, it will not rust, and with Duracordix’s special coating formula, its durability and lifespan are further enhanced, reducing your long-term costs.

Abrasion Resistance:Compared to steel wire ropes, using nylon ropes eliminates the hidden safety risks associated with friction or metal fatigue. They offer more stable load-bearing capacity, significantly reducing replacement frequency and long-term costs

Easy of Handling:With the same strength, its weight is only 1/7 that of steel wire rope, making it extremely lightweight and very flexible compared to steel wire rope. It is not only significantly improves work efficiency, reduces the labor intensity of your operators, but also enhances workplace safety.

Safety: Due to its excellent shock absorption properties, even when it breaks, it will not produce the huge recoil force like steel wire ropes, thus preventing danger to your equipment or personnel. It is especially suitable for mooring, off-road recovery, or mining equipment recovery, significantly improving safety.

Customization Service

Duracordix as a wholesaler of nylon ropes, offers various custom-made options to suit your specific needs

Why Choose

- Superior Quality: Duracordix's nylon ropes are made with high-quality nylon fibers, offering 10-15% higher tensile strength than competitors. We also conduct 100% visual inspection and in-house batch rope breaking strength tests to ensure consistent product quality and safety.

- Expertise in the Field: Through extensive project experience, Duracordix can provide you with recommendations and tailored solutions. We can better understand your needs and concerns for special projects. This reduces your communication costs and provides you with a more efficient working model.

- Customization: Duracordix can customize everything for you, whether you need twisted rope or braided rope, specific colors, coating formulas, custom sizes, or even specific raw materials.

- Fast Delivery: If the item is in stock, Duracodix can guarantee shipment the day after order confirmation. If it's not in stock, we can still arrange production as quickly as possible depending on the order quantity. Urgent orders can be shipped within 5-10 days. This reduces your inventory pressure and capital costs.

- Cost: Thanks to mass production and a stable customer base, Duracordix has found a balance between quality and manufacturing costs. While maintaining high quality, we still have a 5-10% cost advantage compared to our competitors, helping to reduce your procurement costs.

FAQs

Everything You Need to Know About Duracordix Nylon Rope

What is nylon rope?

Nylon rope is kind of plastic rope, made from a synthetic polymer fiber called polyamide. Based on the weaving method, it is usually divided into twisted nylon rope and braided nylon rope. Due to its high strength, excellent elasticity(up to 30%), and superior abrasion and corrosion resistance, nylon rope is widely used in mooring, anchoring, towing, off-road recovery, tree climbing, mountain climbing, and rescue operations. Compared to cotton rope, the service life of nylon rope can be 4 to 5 times longer.

It can also be combined with other synthetic fibers such as polyester or polypropylene to create blended ropes to meet specific needs.

What are the common sizes of nylon ropes manufactured by Duracordix?

The common sizes of nylon rope Duracrodix make like 3/8(10mm) nylon rope, 1/4 nylon rope, 1/2 nylon rope and also with 22mm and 28mm nylon rope. Duracordix Can also custom made any other sizes you need

nylon vs polyester rope, what's their main difference?

Nylon and polyester ropes differ significantly in their specific uses and performance due to their different materials. Nylon ropes, with their extremely high elasticity and elongation (up to 30%), are particularly suitable for dynamic cushioning applications such as mooring, recovery towing, and climbing.

Polyester ropes, on the other hand, have an elongation of only 10-15% but possess better UV resistance and abrasion resistance, making them more suitable for use in harsh outdoor environments, such as swing ropes or sailing ropes.

Can I use nylon rope for winch towing?

Absolutely! You can use nylon rope in a 12-strand or double-braided construction for your winch towing. Compared to steel wire winch rope, it is lighter and safer in case of breakage. However, due to the demand for high breaking strength, UHMWPE winch rope is becoming increasingly popular.

Can I use nylon rope for heavy-duty lifting applications?

Yes, nylon ropes possess sufficient tensile strength suitable for heavy-duty lifting tasks; however, it's crucial to consider safety factors and weight limits during usage.

Does humidity affect the performance of nylon ropes?

No significant impact occurs when exposed to humid conditions; however prolonged exposure may cause slight dimensional changes due to moisture absorption.

Are there different types of braids available in nylon ropes?

Yes, common braid patterns include diamond braid (solid construction), double braid (core inside a sheath), twisted/braided cordage (three-strand construction), among others.

Can I splice or knot a nylon rope easily?

While knots can be used temporarily with caution due to potential strength loss, splicing is the preferred method for creating permanent loops or joining nylon ropes.

What is nylon rope manufacturing process?

As a nylon rope manufacturer, Duracordix provide high-quality nylon ropes through the following manufacturing processes:

Nylon Fiber Procurement:

To guarantee the quality of the ropes, Duracordix does not produce our own fibers. For maintaining consistency in raw materials, we only source from the best nylon fiber suppliers in China. Before warehousing, all raw material fibers undergo random inspection to check if they meet Duracordix quality standards. Any substandard materials will result in the entire batch being returned.

Yarn Twisting or Braiding:

Using high-precision equipment and meticulous processes, nylon yarns are twisted or braided into strands, it ensures the resulting ropes have sufficient strength and stability.

Further Twisting and Braiding of Strands:

The strands are further twisted to form twisted nylon ropes, or braided into specific patterns to create braided ropes. Braided ropes typically have higher strength and are suitable for applications requiring greater strength.

Eye Splicing Customization:

According to the customer's specific needs, we make eye splicing on the finished nylon ropes. we can customize the required length and size to ensure the rope's functionality and usage requirements are met.

Coating Treatment:

To improve the tensile strength, abrasion resistance, UV resistance, and color of the nylon ropes, we use a specially formulated coating. The ropes are immersed in a special adhesive solution for 1 to 1.5 hours to fully strengthen them and increase their durability.

Drying and Testing:

After coating, the nylon ropes are naturally air-dried in a cool place to ensure a more stable structure. After drying, we conduct batch tensile strength testing to make sure the rope's tensile strength meets customer requirements. we can also provide relevant third-party testing certificates to ensure product reliability and safety.

Through these rigorous manufacturing processes, Duracordix is able to provide customers with high-standard nylon rope products.

How should I store my nylon rope when not in use?

To prolong the lifespan of nylon ropes, it's best to store them in a dry, cool place away from direct sunlight and chemicals.

Please also make sure after each use, you should clean the dirty, sand, or salt from the rope with a neutral detergent

Can I dye or color-code my nylon rope?

Yes, nylon ropes can be dyed using appropriate fabric dyes; however, it's essential to follow instructions carefully and ensure complete drying before use.

Is there any specific maintenance required for nylon ropes?

You should regularly inspect the rope and see if there are any wear, tear, fraying, or damage on the rope. you'd d better clean the rope with mild soap and water solution to remove dirt or contaminants.

What is the average lifespan of a nylon rope?

The lifespan of your nylon rope depends on several factors such as usage conditions, frequency of use, exposure to UV rays/chemicals; generally speaking, nylon ropes can use in 5~8years if properly maintained.

Are there any weight limitations associated with using nylon rope?

While strong overall tensile strength exists in nylon ropes, considerations like safe working load (SWL) limits must be adhered to during application-specific usage.

Can I cut Nylon Rope easily?

Yes! you can cut the nylon ropes easily by using sharp tools like scissors , knives etc.

Is Nylon Rope resistant against oils and greases?

Yes, you should be noted that while nylon has good resistance to oils, greases, and other chemicals, prolonged exposure to these substances can cause nylon ropes to soften and lose strength.

In this respect, polyester and UHMWPE rope are more suitable for long-term use in environments where they are exposed to these substances.

Can I use nylon rope for towing or pulling heavy objects?

Yes! Nylon ropes are commonly used for towing or pulling due to their excellent strength and shock-absorbing properties. However, it's important to consider the weight limits and safety factors involved.

Related products

Duracordix also offer other types of synthetic rope meet your project needs