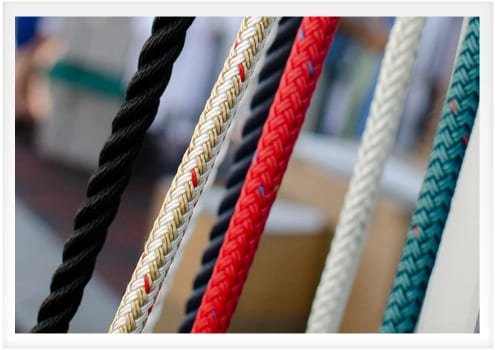

polyester rope

Duracordix Polyester Rope: Built to Last, Strong Enough for the Toughest Jobs

Polyester rope is a durable, weather-resistant synthetic fiber rope known for its excellent UV resistance and low stretch. Ideal for marine and industrial use, it offers strength, abrasion resistance, and reliability in harsh environments, maintaining flexibility and longevity.

- UV and weather-resistant

- Minimal stretch, maintains load stability

- High Strength and Durability

- Flexible and Easy to Handle

General Applications

Versatile polyester rope: ideal for marine, industrial, and outdoor applications.

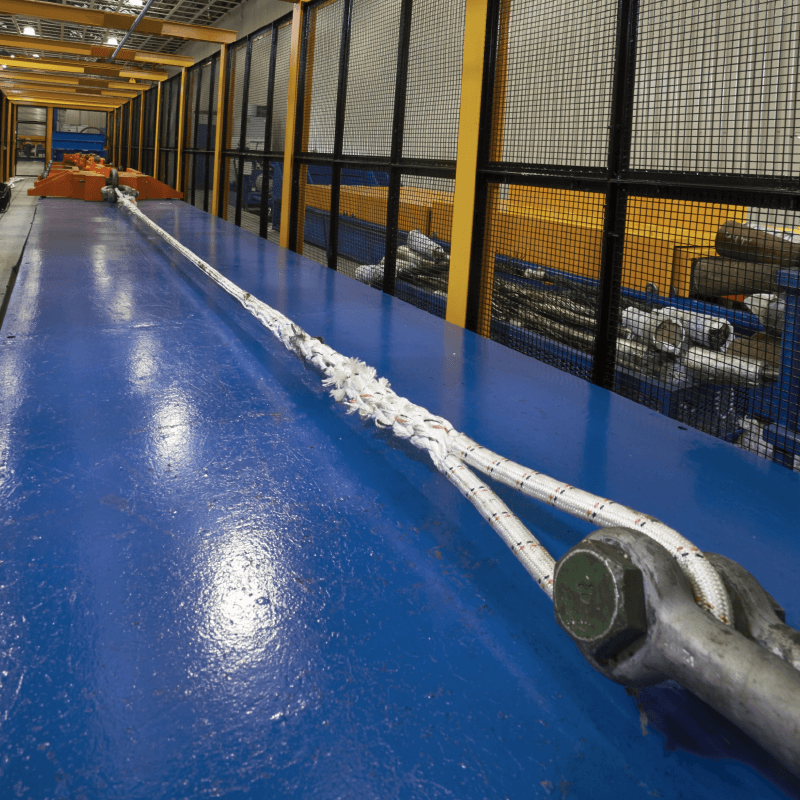

Lifting and Rigging

Reliable for heavy-duty lifting, offering strength and minimal stretch under load.

Fishing and Aquaculture

Suitable for nets, traps, and mooring applications in saltwater environments.

Agriculture and Landscaping

Great for securing structures, equipment, and general use in various outdoor settings.

Mining and Tunneling

Essential for equipment tie-downs, reinforcing safety measures, and providing secure line applications underground.

Construction and Utility

Used for safety lines, securing loads, and as general-purpose ropes in tough environments.

- Characteristics

main PROPERTIES

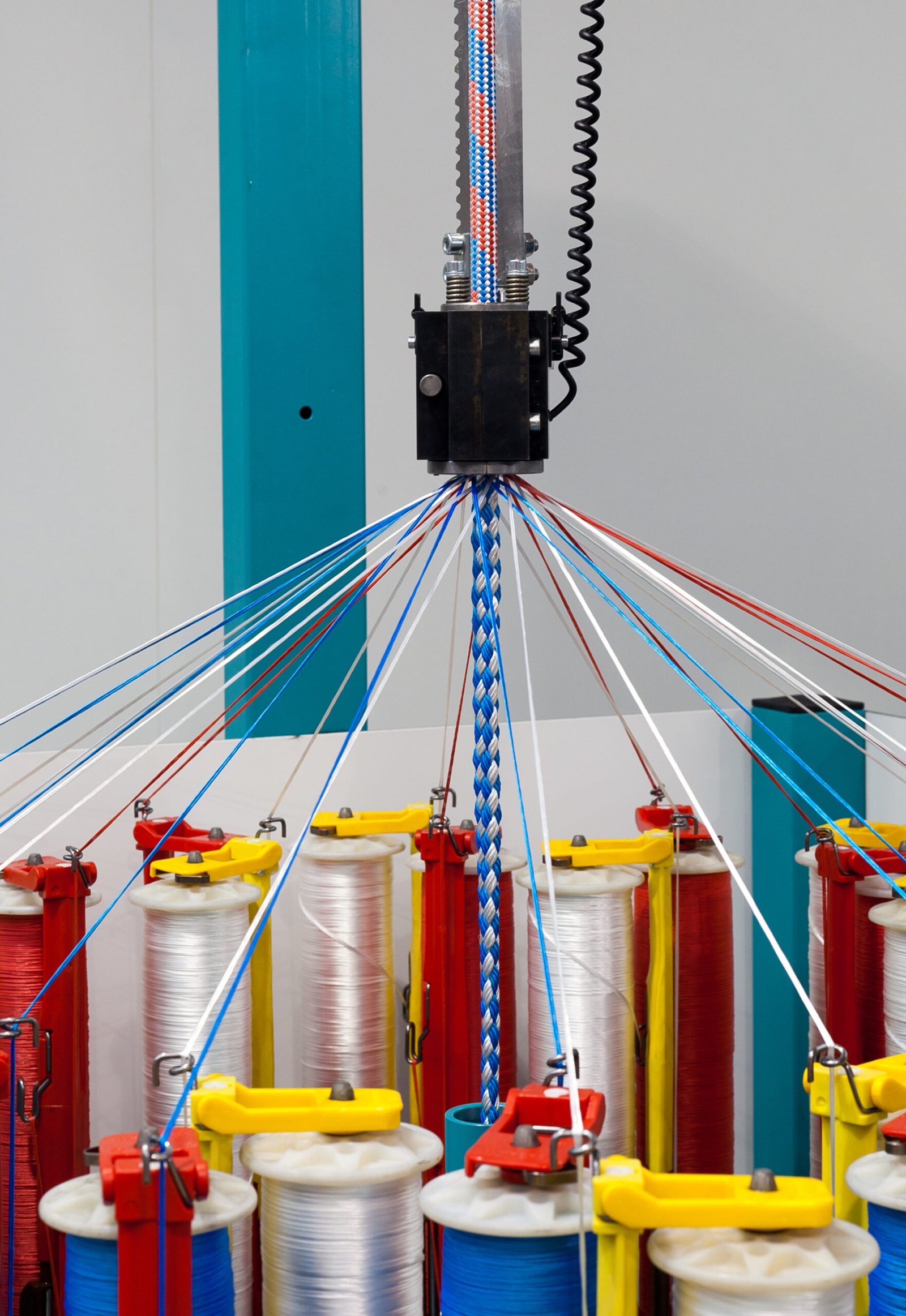

Exploring the Key Characteristics of Duracordix’s Polyester Rope

Melting Point: 265°C

Volume Resistivity: ~10^10 – 10^12 Ω.cm

Moisture Absorption: 0.4% – 0.8%

Boiling Water Shrinkage: 1% – 2%

Thermal Conductivity: 0.15 – 0.24 W/m·K

Density: 1.38 g/cm³

Strength: 7-9 g/d

Modulus: 100-120 g/d

Elongation at Break: 10% – 15%

UV and light exposure: Retains high strength after prolonged UV exposure, with strength retention above 80% after 1200 hours in intense sunlight.

Excellent chemical resistance against weak acids, alkalis, hydrocarbons, and common solvents, including seawater, gasoline, and dilute acids. Limited resistance to strong acids and alkalis.

High resistance to tensile fatigue: Maintains strength under repeated loading, with minimal degradation over extensive use.

- nylon vs polyester rope

ADVANTAGES

Strong UV resistance, excellent wet strength, and minimal stretch than nylon rope

Better UV Resistance

Superior Wet Strength

Reduced Stretch

Polyester rope withstands UV exposure eight times better than nylon, maintaining strength in sunlight and extreme weather for prolonged periods

Unlike nylon, polyester retains strength in wet conditions, making it three times more reliable in marine and humid environments.

Polyester has half the stretch of nylon, offering better load stability and reducing sagging, especially under heavy loads.

- choose your size

TECHNICAL STRENGTH CHART

| 8-Strand Rope Parameter Table | 12-Strand Rope Parameter Table | ||||||

|---|---|---|---|---|---|---|---|

| Dia. (mm) | Cir (inch) | Ktex (g/m) | Breaking Force (KN) | Dia. (mm) | Cir (inch) | Ktex (g/m) | Breaking Force (KN) |

| 24 | 3 | 437 | 90 | 24 | 3 | 437 | 91 |

| 28 | 3-1/2 | 594 | 120 | 28 | 3-1/2 | 594 | 122 |

| 32 | 4 | 778 | 154 | 32 | 4 | 778 | 157 |

| 36 | 4-1/2 | 982 | 190 | 36 | 4-1/2 | 982 | 194 |

| 40 | 5 | 1215 | 235 | 40 | 5 | 1215 | 240 |

| 44 | 5-1/2 | 1468 | 279 | 44 | 5-1/2 | 1468 | 285 |

| 48 | 6 | 1750 | 329 | 48 | 6 | 1750 | 338 |

| 52 | 6-1/2 | 2050 | 384 | 52 | 6-1/2 | 2050 | 392 |

| 56 | 7 | 2380 | 438 | 56 | 7 | 2380 | 448 |

| 60 | 7-1/2 | 2730 | 469 | 60 | 7-1/2 | 2730 | 499 |

| 64 | 8 | 3110 | 568 | 64 | 8 | 3110 | 579 |

| 72 | 9 | 3930 | 707 | 72 | 9 | 3930 | 721 |

| 80 | 10 | 4850 | 867 | 80 | 10 | 4850 | 884 |

| 88 | 11 | 5870 | 1040 | 88 | 11 | 5870 | 1054 |

| 96 | 12 | 6990 | 1230 | 96 | 12 | 6970 | 1255 |

| 104 | 13 | 8200 | 1420 | 104 | 13 | 8200 | 1448 |

| 112 | 14 | 9500 | 1620 | 112 | 14 | 9500 | 1652 |

| 120 | 15 | 10900 | 1865 | 120 | 15 | 10900 | 1902 |

Duracordix is a Polyester rope manufacturer & supplier in China.

we can produce various sizes for different applications and custom made for your special projects.

No matter you’re looking for a wholesale supplier or custom made polyester rope, we can all help. contact Duracordix now.

- Customer Voice

Client voice voice

- OEM service

Customization

To meet your unique and special needs and projects

- Pain-Free Purchase

WHY CHOOSE

Duracordix Polyester Rope

- Built to Last: Duracordix ropes are tough. We test each lot to handle UV, moisture, and abrasion so you can count on it when it matters.

- Experience That Matters: Years in the industry mean we know exactly what different fields need—whether you're in marine, construction, or agriculture, we get it.

- Made for You: Need a specific size or coating? We’ll make it happen. Our ropes are tailored to fit your exact needs without compromise.

- Always Here for You: We don’t just sell ropes; we’re here to help. Quick responses, clear answers, and a team that cares.

- Safety You Can Trust: Duracordix ropes are built to handle heavy loads and tough conditions, so you can work with confidence.

- Quality Without the High Price: Get top-notch ropes without breaking the bank. We keep prices fair, usually 15% below competitors, without skimping on quality.

FAQs

Everything You Need to Know About Duracordix Polyester Ropes

There are many types of ropes can be used on ships like polyester rope,nylon rope, Polypropylene Rope, UHMWPE rope,Manila Rope etc.

No, polyester rope does not float. Unlike materials like polypropylene or UHMWPE, polyester has a higher density(1.38 g/cm³) than water, which causes it to sink

The types of polyester rope are like Double-Braided Polyester rope,Solid-Braid Polyester Rope,3-Strand Twisted Polyester Rope,8-Strand and 12-Strand Braided Polyester Rope,Polyester-Nylon Blend Rope

Yes, polyester rope does stretch, but only minimally. It has low elongation(10~15%) compared to materials like nylon, making it ideal for applications where stability and reduced elongation are important.

For tree rigging, pruning, and climbing, the best ropes are typically made from polyester or a polyester blend due to their strength, low stretch, and durability.

Main types of mooring rope like nylon mooring rope, polyester mooring rope, polypropylene mooring rope and HMPE mooring rope.

Twisted polyester rope, also known as 3-strand twisted polyester rope, is made by twisting three strands of polyester fibers together in a spiral pattern. This classic rope construction gives it a slightly springy feel, making it strong, durable, and resistant to abrasion.

Nylon is stronger and stretches more, making it great for heavy loads and absorbing shock, like towing. Polyester, though slightly less strong, stays stable with low stretch and handles sun and weather better—perfect for long-term outdoor us

For your marine use, polyester rope is better than polypropylene. It’s stronger, resists UV damage, doesn’t absorb water, and is more durable. While polypropylene is lighter and cheaper, it lacks the reliability you needed in harsh marine conditions. you can choose polyester rope for long-lasting performance.