UHMWPE Rope

Unmatched Strength and Reliability for Heavy-Duty Jobs in Tough Environments

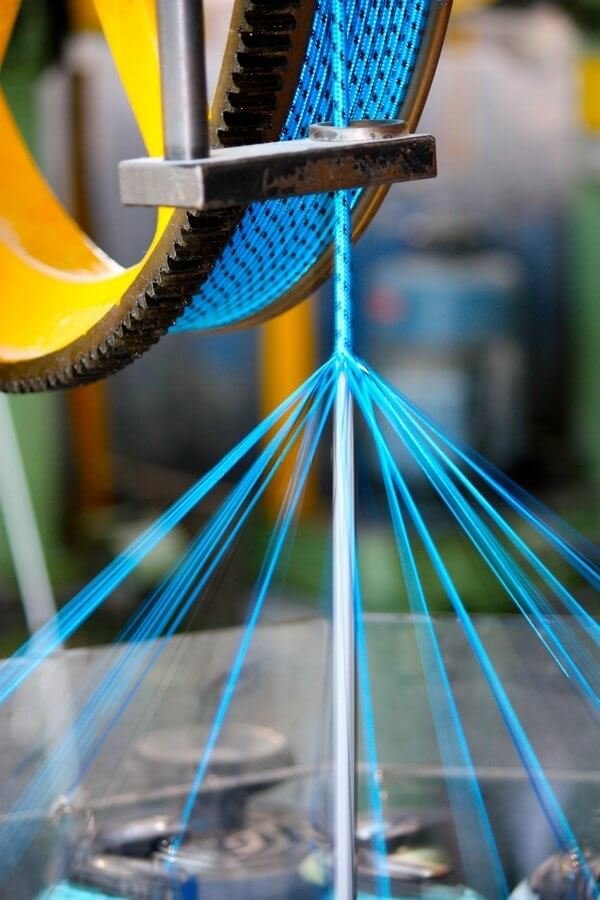

UHMWPE rope is a type of synthetic fiber rope made from ultra-high molecular weight polyethylene fibers. Designed for optimal handling, it combats abrasion and delivers lasting performance even in tough conditions.

- Ultra-light: Simplified handling, transport

- Great strength: Lasting, reliable

- Safer: Less recoil, risk

- Versatile: Numerous applications

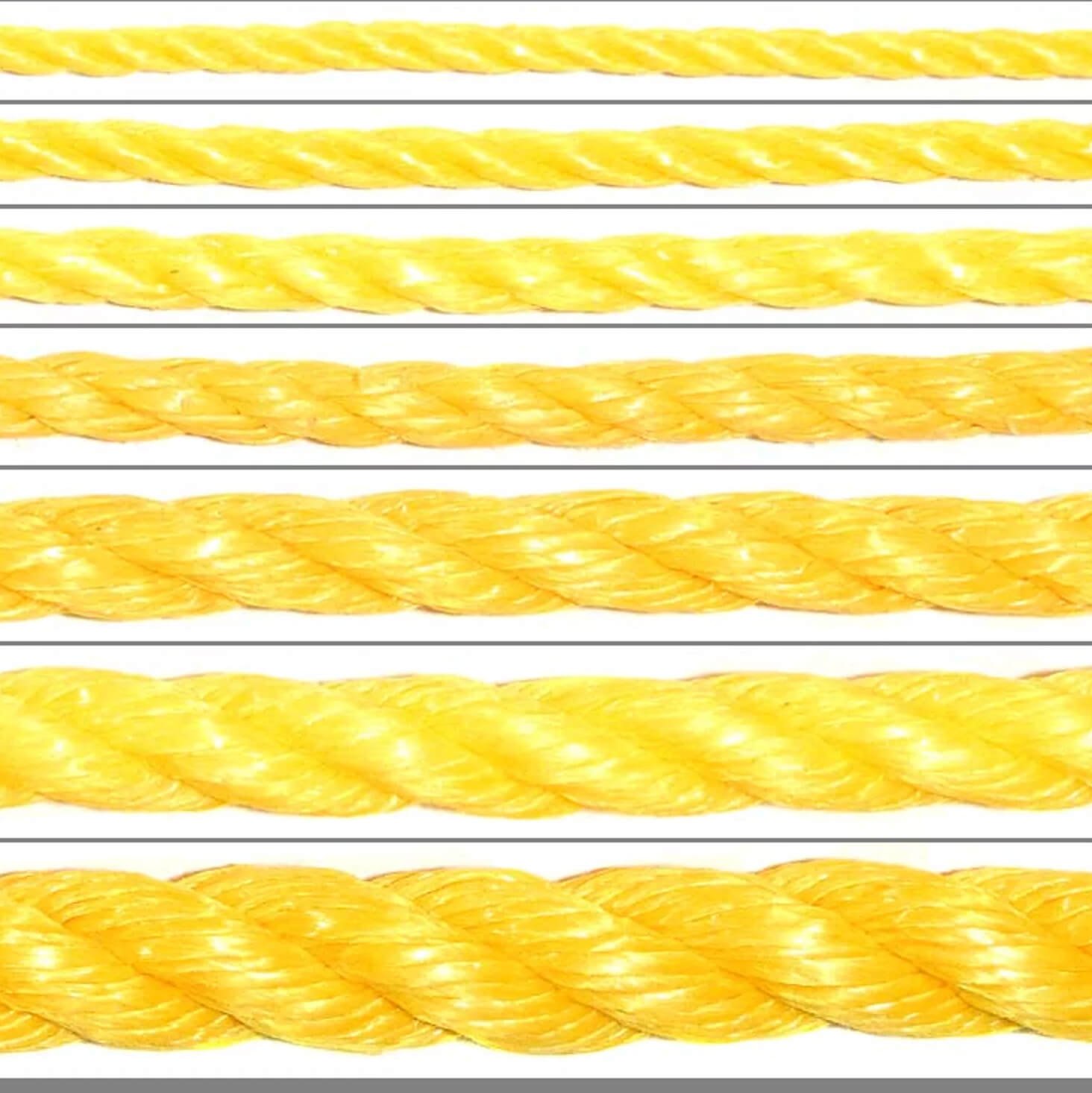

Our UHMWPE rope Products

General Applications

Designed for reliable and efficient performance in your specific applications.

4X4 Offroad: Whether it’s winch rope or soft shackle, our products enhance your vehicle recovery capabilities and safety in 4×4 field.

Marine & Ship: our products can improve the efficiency & safety of maritime operations and sports, also enhance your ability to handle various extreme environments.

Oil & Gas: Our products not only help with equipment fixation, towing, and lifting on oil platforms but also ensure effective connection with ships.

Fishing: our UHMWPE rope products like fishing nets, cages enhance your fishing efficiency, reduce replacement frequency, and lower the overall costs of your fishing and aquaculture operations.

- Characteristics

main features

Exploring the Core Features of Duracordix’s UHMWPE Rope

Melting point 135°C-145°C

Volume Resistivity: <10^14 Ω.cm

Moisture Regain: None

Boiling Water Shrinkage: <1%

Thermal Conductivity: 20 W/m·K

Excellent chemical resistance against distilled water, seawater, kerosene (10% detergent), gasoline, hydrochloric acid, acetic acid, toluene, sodium hydroxide solution, ammonium hydroxide solution.

Even after continuous exposure to light for 1500 hours, its strength retention rate remains above 90%, while other chemical fibers typically have a retention rate around 40% or even lower.

After conducting thousands of cycles of load testing under water conditions, its strength remains almost unaffected—exhibiting excellent tensile fatigue performance.

Density:0.97g/cm3

Strength:35-40g/d

Modulus:1000-1500g/d

Elongation at Break:3.5%

- uhmwpe vs steel

Advantages

UHMWPE ropes solve your pain points in safety, handling, and work efficiency

Lighter than Steel

Stronger in Weight

Safer, Low Recoil

UHMWPE ropes weigh 85% less than steel wire, making them far easier to handle, transport, and operate—all without compromising strength and performance.

UHMWPE ropes offer incredible strength—10 times stronger than steel wire ropes of the same weight. This unmatched durability provides the reliability you need, even in the toughest conditions.

When UHMWPE ropes break, they have far less recoil than steel wire ropes, making them up to three times safer. This reduced snapback greatly lowers the risk of injury during operations.

| Rope Material | Key Features | Tensile Strength | Elongation | Abrasion Resistance | UV Resistance | Chemical Resistance | Application Examples |

|---|---|---|---|---|---|---|---|

| UHMWPE | Ultra-lightweight, buoyant | Exceptional (15x stronger than steel by weight) | Low (3-4%) | Excellent | Good | Excellent | Marine, winches, lifting, extreme sports |

| Nylon | Soft, pliable, shock-absorbing | Strong (moderate compared to UHMWPE and Kevlar) | High (25-30%) | Good-Excellent | Fair-Good | Good | Mooring lines, anchor lines, tow ropes |

| Kevlar | Flame & heat-resistant, non-conductive | Outstanding (5x stronger than steel by weight) | Very low (2%) | Excellent | Excellent | Good | Hot air balloons, rescue lines, electrical applic |

- CHOOSE RIGHT SIZE

TECHNICAL SPECIFICATION

| DIAMETER | WEIGHT | KETX | BREAKING STRENGTH | ||||

|---|---|---|---|---|---|---|---|

| mm | inch | 100m(kg) | standard | error | ton | kn | |

| 5.00 | 3/16 | 1.70 | 16.62 | ±5% | 2.00 | 19.00 | |

| 6.00 | 1/4 | 2.30 | 23.00 | ±5% | 3.18 | 31.00 | |

| 8.00 | 5/16 | 4.10 | 40.00 | ±5% | 6.35 | 63.00 | |

| 9.00 | 23/64 | 5.10 | 50.50 | ±5% | 7.83 | 78.00 | |

| 9.50 | 3/8 | 5.60 | 55.75 | ±5% | 8.32 | 83.00 | |

| 10.00 | 13/32 | 6.10 | 61.00 | ±5% | 9.32 | 93.00 | |

| 11.00 | 7/16 | 7.50 | 74.00 | ±5% | 10.40 | 103.00 | |

| 12.00 | 1/2 | 8.80 | 87.00 | ±5% | 12.12 | 121.00 | |

| 14.00 | 9/16 | 12.00 | 119.00 | ±5% | 15.40 | 153.00 | |

| 16.00 | 5/8 | 15.50 | 151.00 | ±5% | 20.60 | 205.00 | |

| 18.00 | 3/4 | 19.00 | 190.00 | ±5% | 23.90 | 238.00 | |

| 20.00 | 13/16 | 23.00 | 225.00 | ±5% | 28.99 | 289.00 | |

| 22.00 | 7/8 | 28.00 | 276.00 | ±5% | 33.00 | 322.00 | |

| 24.00 | 1 | 37.00 | 368.00 | ±5% | 38.00 | 371.00 | |

| 28.00 | 1-1/8 | 50.00 | 490.00 | ±5% | 57.50 | 562.00 | |

| 32.00 | 1-5/16 | 62.50 | 621.00 | ±5% | 68.50 | 671.00 | |

| 36.00 | 1-1/2 | 77.00 | 767.00 | ±5% | 80.40 | 789.00 | |

| 40.00 | 1-5/8 | 87.00 | 868.00 | ±5% | 98.20 | 964.00 | |

| 44.00 | 1-3/4 | 96.00 | 955.00 | ±5% | 118.00 | 1158.00 | |

| 48.00 | 2 | 114.00 | 1137.00 | ±5% | 139.00 | 1364.00 | |

| 56.00 | 2-1/4 | 159.00 | 1547.00 | ±5% | 184.00 | 1805.00 | |

| 60.00 | 2-1/2 | 180.00 | 1784.00 | ±5% | 199.00 | 1952.00 | |

| 64.00 | 2-5/8 | 209.00 | 2021.00 | ±5% | 222.00 | 2178.00 | |

| 72.00 | 3 | 268.00 | 2598.00 | ±5% | 274.00 | 2688.00 | |

| 80.00 | 3-1/4 | 328.00 | 3195.00 | ±5% | 333.00 | 3266.00 | |

| 88.00 | 4 | 427.00 | 4170.00 | ±5% | 390.00 | 3825.00 | |

| 96.00 | 3-5/9 | 509.00 | 4970.00 | ±5% | 455.00 | 4463.00 |

Note: Larger sizes are available upon request to meet your specific project needs

Duracordix is a UHMWPE rope manufacturer & supplier in China.

No matter you’re looking for a wholesale supplier or custom made UHMWPE rope, we can all help. contact Duracordix now.

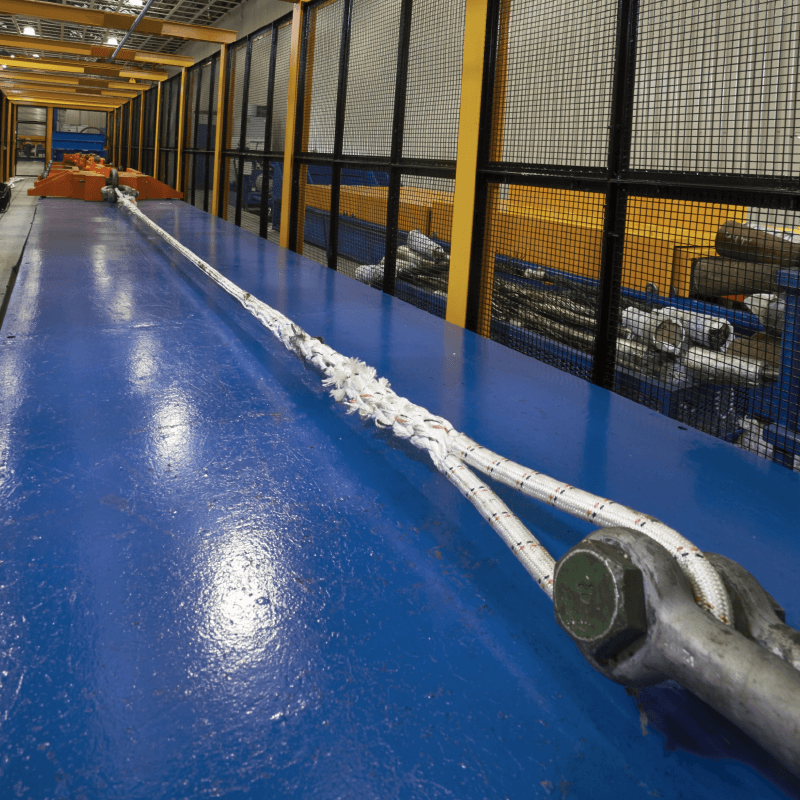

- quality control

UHMWPE Rope Test

Duracordix do regular rope test to ensure our quality to meet your needs

Customization Options

To Meet Your Unique Requirements

- Pain-Free Purchase

WHY CHOOSE

Duracordix UHMWPE Rope

- Superior Quality: Duracordix ensures top-quality UHMWPE ropes with rigorous testing. Boasting a 96% customer satisfaction rate, we prioritize excellence.

- Expertise in Field: With years in UHMWPE rope manufacturing, we deeply understand needs across automotive, heavy equipment, and military sectors.

- Customization Capabilities: Recognizing unique client needs, we offer custom diameter and length options on 90% of our products, ensuring the perfect fit.

- Exceptional Customer Service: Duracordix focuses on prompt, efficient service with a <4-hour response time, resolving 95% of inquiries in just one business day.

- Safety: Prioritizing user safety, our UHMWPE ropes are engineered to withstand demanding conditions, reducing risks and ensuring secure operations every time.

- Competitive Pricing: Balancing top-notch quality with competitive pricing, Duracordix delivers products at prices 20% lower than many competitors, without sacrificing reliability.

FAQs

Everything You Need to Know About Duracordix UHMWPE Rope

What is UHMWPE rope and what are its benefits?

UHMWPE (Ultra-High Molecular Weight Polyethylene) rope is a high-performance fiber rope known for its exceptional strength, low weight, and durability. It offers advantages such as high tensile strength, excellent abrasion resistance, low stretch properties, and resistance to chemicals and UV radiation.

How strong is UHMWPE rope compared to other types of ropes?

UHMWPE rope is incredibly strong; in fact, it has one of the highest strength-to-weight ratios among all synthetic ropes. It can be up to 15 times stronger than steel wire ropes of the same diameter.

Is UHMWPE rope suitable for marine applications?

Absolutely! Due to its high strength-to-weight ratio and water-resistant properties, UHMWPE ropes are widely used in various marine applications including mooring lines, towing lines, winch lines, and offshore operations.

Can I use UHMWPE rope for heavy lifting operations?

Yes! The outstanding strength of UHMWPE rope makes it ideal for heavy lifting tasks where superior performance is required. Its lightweight nature also reduces strain on equipment during lifting operations.

What are some common applications for UHMWPE rope?

UHMWPE ropes find extensive use in a wide range of industries and applications, including offshore operations, fishing and aquaculture, construction, mining, arboriculture (tree care), rigging in theater/stage productions, and recreational activities like camping and hiking.

Are UHWMPE ropes resistant to chemicals?

Absolutely! One of the key advantages of UHMWPE rope is its excellent resistance to a wide range of chemicals. It can withstand exposure to acids, alkalis, solvents, oils, fuels without significant degradation.

How should I care for my UHMWPE rope to ensure its longevity?

To maximize the lifespan of your UHMWPE rope , regular inspection is recommended for wear or damage. Proper cleaning when necessary using mild soap/water solution is also advised. Store it dry away from direct sunlight when not in use.

Is there any specific safety information that I need to be aware of while using UHMWPE rope?

While generally safe to handle , standard safety precautions like wearing protective gloves during handling or avoiding sharp edges that can cause abrasion on the surface should be followed

Can Duracordix provide technical specifications for its range of UHWMPE ropes?

Certainly! We have comprehensive technical specifications available for our UHMWPE ropes, including diameter options, breaking strengths, and weight per meter/foot details. Feel free to reach out to us for more information.

Are Duracordix's UHWMPE ropes compliant with industry standards?

Absolutely! Our products undergo stringent quality control measures and comply with relevant industry standards.with certification like ISO & CE, We prioritize delivering high-quality products that meet customer expectations consistently.

Can I request a sample of UHWMPE rope before placing a bulk order?

Yes! We understand the importance of evaluating the quality and suitability of our UHMWPE ropes before making a larger commitment. Reach out to us, and we'll be happy to provide you with a sample.

Do you offer technical support or assistance in selecting the right UHMWPE rope for my application?

Certainly! Our team of experts is available to guide you in selecting the most suitable UHMWPE rope based on your specific requirements. We aim to provide personalized assistance tailored to your needs.

Are there any limitations or precautions I should be aware of while using UHWMPE rope?

While highly durable and strong, it is important not to exceed the recommended working load limit (WLL) specified for each diameter of the rope. Additionally, avoid exposing the rope to sharp edges or abrasive surfaces that could compromise its integrity.

Can I use connectors or fittings with UHWMPE ropes?

Yes! Connectors or fittings can be used with UHWMPE ropes based on specific application requirements. It's crucial to ensure that compatible connectors/fittings are selected for optimal performance and safety.

Can I splice or knot a UHWMPE rope myself?

UHWMPE ropes can be spliced or knotted, but it is recommended to seek professional guidance or consult our technical support team for proper techniques and best practices to ensure the integrity of the rope.

How does Duracordix ensure the quality of its UHMWPE ropes?

At Duracordix , we have strict quality control measures in place throughout the manufacturing process. This includes using premium-grade materials, conducting rigorous testing procedures, and adhering to international standards to deliver top-quality products consistently.

Does Duracordix offer warranty coverage for its UHMWPE ropes?

Yes! We stand behind the quality and performance of our UHMWPE ropes. We offer warranty coverage against manufacturing defects to provide you with peace of mind and assurance in your purchase.