Table of Contents

ToggleIntroduction

Do you need to lift heavy loads? I know that selecting the right tool is very important for you. This guide explores all types of slings for lifting. You will learn about sling materials and safety. We will help you make a smart choice for your important job, so you can feel confident.

What Are the Main Types of Slings for Lifting?

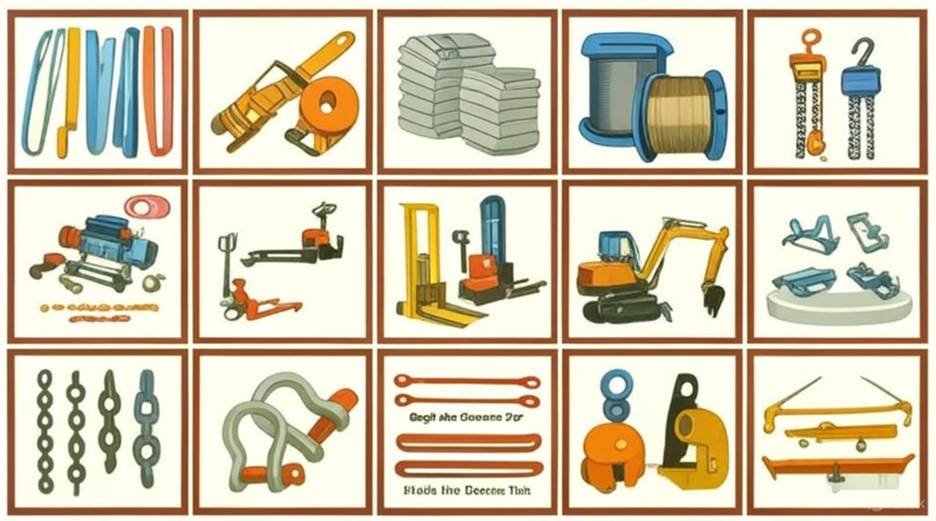

For you, understanding the main types of slings for lifting is crucial for workplace safety. It also helps with efficiency. You will find that there are three different types of slings: chain, wire rope, and synthetic slings. Each type offers unique benefits. These benefits are for various lifting jobs and work areas.

We will explore these different kinds of slings in detail together. This guide provides types of slings for lifting with pictures for clarity; consequently, you can select the best option for your needs.

Your Guide to the Smartest Buy in Types of Slings for Lifting!

Here is your detailed guide. It will help you select the perfect sling for your specific needs. We will cover the most important things for you to think about before you buy any types of slings for lifting.

Load Weight

You must first know the exact weight of your load. This step is critical for your safety and compliance; furthermore, it helps you choose the right equipment. The maximum safe load limits of a sling should always be more than your load’s weight. For instance, a 6 ton sling is needed for loads near that capacity. You must always check the rigging slings chart to confirm the limit before any job begins.

400°F Temperatures

When you work in hot places, you must pick a sling that can handle the heat. Chain slings are often your best choice for conditions up to 400°F. In contrast, synthetic web slings have lower heat tolerances. They can fail in extreme heat. You should always check the lifting slings specifications for heat ratings before use. This ensures your lifting web stays strong and safe.

Chemical Exposure

The chemicals in your work area are a big deal when choosing types of slings. For example, polyester lifting straps resist some acids well. However, acids can damage nylon lifting slings. So, they are not for all chemical areas. An HMPE lifting sling from Duracordix offers great resistance to many chemicals. Therefore, always match the sling to the chemical dangers in your workplace.

Sharp Edges

Loads with sharp edges are a big risk for many different types of slings for lifting. Synthetic slings are very easy to cut. This can make them unsafe. For these jobs, you should think about a wire mesh sling or a chain sling. These are more durable. Using protective sleeves can also prevent damage. Checking for tears is a key part of any sling inspection procedure, especially with sharp items. We at Duracordix want to ensure your safety.

Center of Gravity

Finding the load’s center of gravity is key. It helps you keep the load stable during a lift. An unbalanced load can tilt or slip. This creates a danger, especially when using hoisting sling types. Using a multi-leg sling, like a 4 way chain rigging assembly, helps spread the weight. This is different from a simple traditional sling. Good balance prevents shock loading slings and ensures a safe lift every time.

| Feature | Chain Slings (Grade 80/100) | Wire Rope Slings (EIPS IWRC) | Synthetic Web Slings (Polyester) | Synthetic Round Slings (Polyester) |

| Max Temp. | 400°F (204°C) | 400°F (204°C) | 194°F (90°C) | 194°F (90°C) |

| Abrasion | Excellent | Good | Fair | Good |

| Cut Resistance | Excellent | Good | Poor | Fair |

| Acid Resistance | Poor | Good | Excellent | Excellent |

| Elongation | ~1.5% | ~3-5% | ~3% | ~3% |

| WLL (1″ Single Leg) | ~8,800 lbs | ~9,800 lbs | ~6,200 lbs | ~9,000 lbs |

Table on Buying The Right Types of Slings for Lifting!

Choosing the Best Material for Lifting Slings!

Picking the right material is basic for safe and good lifting. This section looks at the properties of common sling materials. Knowing about these types of slings for lifting will help you.

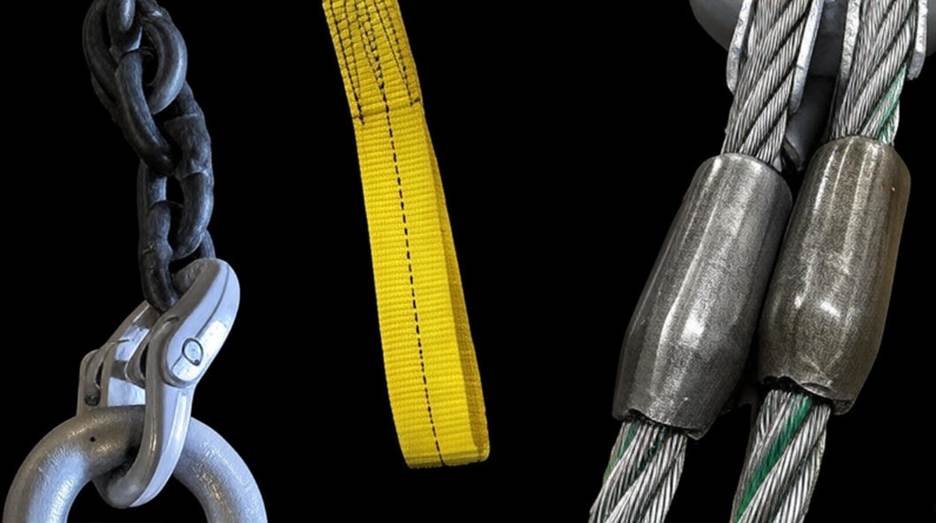

Alloy Steel

Alloy steel is great for heavy duty lifting slings. It is very strong and lasts a long time. It’s used for Grade 100 chains for tough jobs. These slings, including the chain cable sling, are great for hot places. When you compare chain vs wire rope, alloy steel chains resist crushing better. They are some of the best slings for lifting heavy loads.

Galvanized Wire

Galvanized wire is a top choice for a wire rope sling. It resists rust very well. This makes it good for sea jobs and outdoor sites. The process protects the steel cable sling from rust. This makes it last longer. You can often find a wire rope sling grainger sells that is made of this. It offers a good mix of strength and long life in tough spots. These are great types of slings for lifting.

UHMWPE Fiber

UHMWPE is a special fiber. It is used in advanced synthetic rope slings. An HMPE lifting sling is very light but stronger than steel by weight. This material resists chemicals and wear. It is perfect for special rigging. It is also used in a climbing sling anchor and other climbing slings and runners. Our company, Duracordix, provides custom types of slings for lifting using this fiber.

Polyester Webbing

Polyester webbing is a popular material for a synthetic web sling. It has low stretch and is versatile. These polyester lifting straps are color-coded for capacity. This makes safe load management simple for you. Unlike nylon, polyester resists acids and moisture. This makes a web sling specification good for many industrial places. You can find an endless polyester round lifting sling for continuous use. The difference between nylon and polyester sling is key for chemical safety.

Nylon Fiber

Nylon fiber is valued for its stretch. It can absorb shock loads. This is useful in some lifting cases. You can find nylon lifting slings in many forms, including endless nylon slings and eye-to-eye types. But nylon is not good for use with acids. Always check nylon slings capacity charts and the sling belt specification to be sure it is right for your job. These are popular types of slings for lifting.

| Feature | Alloy Steel Chain | Galvanized Wire Rope | UHMWPE Fiber | Polyester Webbing | Nylon Fiber |

| Material Grade | Grade 80, 100, 120 | EIPS, EEIPS | HMPE | Industrial Polyester | Type 6, 9 |

| Strength:Weight | 4:1 Design Factor | 5:1 Design Factor | >10:1 (Specific) | 5:1 Design Factor | 5:1 Design Factor |

| Temp. Range (°F) | -40 to 400 | -40 to 400 | -22 to 150 | -40 to 194 | -40 to 194 |

| Elongation @ WLL | < 1% | 3% – 5% | < 1% | ~3% | 8% – 17% |

| Abrasion Resist. | Excellent | Good | Excellent | Fair | Good |

| Chemical Resist. | Good (Alkali) | Fair | Excellent | Good (Acids) | Good (Alkali) |

Table on Best Material for Lifting Slings!

Chain Slings: The Toughest Types of Slings for Lifting!

Chain slings are known for their strength. They work in the toughest industrial places. Here we look at what makes them the best choice for heavy work. For you, these are the best types of slings for lifting.

Grade 100

Grade 100 alloy chain is a stronger standard for lifting slings with hooks. It gives about 25% more lift capacity than Grade 80. This allows for a lighter design without losing power. A 4 leg adjustable chain sling from this grade is very strong. It is one of the most reliable types of slings for lifting equipment.

EN 818

The EN 818 standard is a European safety rule for lift chains. Following this rule means the chain has passed tough tests. When you pick a chain sling that meets EN 818, you are buying a safe product. This is key for all types of crane slings and rigging, including a 4 way lifting chains assembly.

Four-Leg Configuration

A four-leg chain sling, or 4 leg chain sling, gives great stability. It’s for large or odd-shaped loads. This 4 way chain setup spreads the weight over four points. This stops tipping and gives you more control. It’s a common choice for heavy duty crane lifting straps jobs. The master link and shackles must be the right size for it to work safely.

400°F Resistance

A big plus for alloy chain slings is their heat performance. These slings can work safely up to 400°F. This makes them vital in hot work settings. You must know how many types of slings for lifting are not good for such heat. This resistance ensures they work where other materials would fail.

Fully Repairable

Chain slings are fully repairable. This saves you money over time. Unlike other slings, if one link is bad, it can be replaced by a pro. The whole sling can then be certified again for safe use. This makes certified lifting slings from chain a good buy for tough jobs. This is a big plus in the wire rope vs chain security debate.

Explore Synthetic Types Of Slings For Lifting!

Synthetic slings are light and flexible. They are a solution for many lifting needs. Let’s look at the key things that make them a popular choice. I know you will appreciate these types of slings for lifting.

7:1 Safety

Most synthetic slings have a 7:1 webbing sling safety factor. This means the sling’s break strength is seven times its work limit. This high margin protects against surprise shocks or wear. Following this is a key part of the safe use of wire rope slings and synthetics. It ensures a safe lift for you every time.

Duplex Webbing

A duplex webbing sling has two layers of webbing. This makes it stronger. This design is common in flat lifting slings. It gives a wider surface to support the load. The strong build of a webbing sling belt helps it last longer. This makes the duplex sling a good choice for general lifting, like with a lifting sling 5 ton capacity.

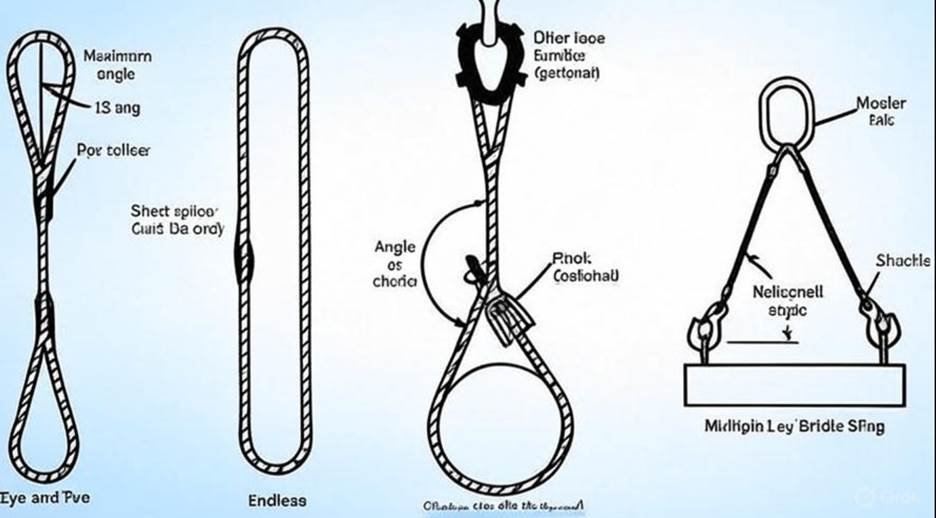

Endless Loop

An endless loop, or continuous slings design, is very versatile. It also lasts longer. Because it is a loop, the contact points can be rotated. This spreads wear out. This design is in both round lifting slings and flat web slings. This makes it a smart choice for you. It is ideal for all three main hitch types.

Color-Coded Capacity

To make things safer and easier, synthetic slings are color-coded by lift capacity. This system helps you quickly check if you are using the right sling for the load’s weight. For instance, a purple sling is for 1-ton, and green is for 2-tons. You can find lift it web slings with this feature. This visual check helps stop overloading and is key to how to select slings for lifting safely.

3% Stretch

Polyester is a common material for a web sling. It has a low stretch of about 3%. This small stretch gives you great load control. It lowers the risk of bouncing during a lift. This control is vital for exact placements. It also helps you avoid the dangers of shock loading. Duracordix provides types of slings for lifting with the best stretch control.

Wire Rope: The Versatile types of slings for lifting!

Wire rope slings are a strong and cheap answer for many industrial lift jobs. This part covers the main things that define their power and uses. You have many types of slings for lifting to choose from.

6×19 Construction

The 6×19 build is a very common type for wire rope lifting slings. This means the rope has 6 strands. Each strand has 19 wires. This design gives a good mix of wear resistance and flex. It makes the flexible wire rope slings good for many general lift jobs. This is a popular choice for many types of slings for lifting.

Flemish Eye

A Flemish eye splice is a better way to make an eye on a wire rope sling. The rope’s strands are split and then re-laid to form a loop. This loop is held with a steel sleeve. This makes a strong end. A Flemish eye gives more security than a simple turned-back eye. It is a sign of high-quality, custom wire rope slings.

IWRC Core

An Independent Wire Rope Core (IWRC) makes a sling stronger. It helps it resist crushing. The core is a smaller wire rope. It gives more support to the outer strands than a fiber core. This makes IWRC slings great for tough spots where the rope might be spooled under pressure. It also has better heat resistance, making the wire rope rigging last longer. This is more advanced than what is parallel lay rope.

400°F Limit

Wire rope slings with a steel core can be used up to 400°F. But it is vital to check the maker’s notes. High heat can weaken the rope’s lube and strength. For jobs over this limit, other types of slings for lifting, like alloy chains, are safer. Always think about heat when you look at types of slings for lifting.

5.7 Tonnes

The load limit of a wire rope sling depends on its size and build. For example, a 1-inch 6×19 IWRC steel sling may have a lift capacity of about 5.7 tonnes. It is key to check the wire rope slings capacity charts. This confirms the limit for different hitch types. Never go over the rated capacity. It can lead to the lifting rope failing.

How Do I Select the Right Types of Slings for Lifting?

Picking the right sling is more than just matching capacity. This guide will walk you through the key points for making a safe choice. I am here to help you select the right types of slings for lifting.

Working Load

The first step is to know your working load. The sling’s limit must be more than the object’s weight. The hitch type and angle will change the sling’s capacity. You must know how many types of lifting slings there are and check their ratings. This info is on the sling’s tag.

30-Degree Angle

The sling angle greatly changes its lift capacity. As the angle from the horizontal goes down, the tension on each leg goes up. At a 30-degree angle, a sling’s capacity is cut in half. So, you must account for this. A wider angle is safer. You should use a rigging supply store near me to find longer slings if you need them.

Master Link

A master link connects a multi-leg sling to the crane hook. It must be strong enough for the total load. For a 4 leg lifting chain sling, an oblong master link is used. Good selection ensures the whole lifting setup is safe, including lifting slings and shackles.

Shortening Hook

A shortening hook lets you change a chain sling’s length. This gives you flexibility. You can balance loads or adapt to different lifts without needing many slings. It is a key benefit of chain slings. Using one is a simple way to make your lifts more efficient, especially with uneven loads or tree rigging slings.

ASME B30.9

ASME B30.9 is a key safety standard. It gives rules for making, using, and checking slings. Following this standard is vital for safety. It covers all major lifting sling types, including chain, wire rope, and synthetic. At Duracordix, all our certified wire rope sling products meet or exceed these standards. You get a safe product from us.

What Are the Safety Standards for Lifting Slings?

Following safety standards is a must for any lift. This part covers the key rules that ensure the safe use of all lifting slings. I want you to be safe when choosing from these types of slings for lifting.

OSHA 1910.184

The OSHA 1910.184 standard is a key part of lifting slings regulations. It gives the rules for the design, check, and use of all types of slings for lifting. You must follow it to ensure a safe work site and avoid fines. The standard covers all details. It is a must-read for anyone in charge of lifting and rigging equipment near me.

ASME B30.9

The ASME B30.9 standard goes with the OSHA rules. It gives more technical details. It covers sling build, load ratings, and test rules. This standard is key for makers and you. For example, it gives charts for wire rope safety factor calculation. It also guides on the proper use of different types of slings for lifting and sizes.

CE Mark

The CE mark shows a product meets EU safety standards. For types of slings for lifting for sale, this mark means the product has been tested and meets EU rules. When you buy slings for use in Europe, make sure they have the CE mark. This gives you more trust in the product’s quality.

Legible ID

Every sling must have a clear ID tag. This tag gives key safety info. It includes the maker, load limits, and a serial number. If this tag is missing or you can’t read it, the sling must be taken out of use. This rule applies to all lifting cables equipment. It ensures you always have the info you need.

WLL Tag

The WLL tag is the most vital info on a sling. It clearly states the max load the sling can handle in different setups. You must never go over this limit. A missing or unclear WLL tag makes the sling unsafe. Checking this tag is a basic step in every pre-lift check to stop accidents. This is true for all different types of slings for lifting.

| Feature | Wire Rope Sling | Chain Sling | Synthetic Web Sling | Synthetic Round Sling | Metal Mesh Sling |

| Material | EIPS/XIPS Steel | Alloy Steel (Gr 80/100) | Nylon/Polyester | Polyester Core Yarns | Carbon/Stainless Steel |

| Design Factor | 5:1 (Min) | 4:1 (Min) | 5:1 (Min) | 5:1 (Min) | 5:1 (Min) |

| Temp. Range (°F) | -40 to 400 | -40 to 400 (Gr 80) | -40 to 194 | -40 to 194 | -50 to 550 |

| WLL (Example) | 0.65T (1/4″ 6×19) | 3.5T (9/32″ Gr 80) | 3100 lbs (2″ 2-ply) | 5300 lbs (Vertical) | 4600 lbs (2″ 10-ga) |

| Inspection Freq. | Daily/Periodic | Daily/Periodic | Daily/Periodic | Daily/Periodic | Daily/Periodic |

Table on Safety Standards for Lifting Slings!

Mastering Inspection for All Types of Slings for Lifting!

Regular checks are the best way to ensure sling safety and stop accidents. This guide shows the key check practices for all types of sling. I will guide you on how to inspect your types of slings for lifting.

Daily Inspection

Before each shift, a qualified person must do a visual check of every lifting sling. This check should look for clear damage, like cuts or wear. It is a quick but vital step to find problems before they cause a failure. This is for all gear, from a simple belt sling to a big assembly. This is different from how you check types of slings for fractures in a medical setting.

Annual Check

Besides daily checks, a full annual check must be done by a skilled inspector. This check is more detailed and needs records. The inspector will look for hidden wear. Following this yearly rule is key to keeping your rigging equipment certification. This ensures your slings are safe. This is more detailed than checking types of shoulder slings.

Broken Wires

When you check a wire rope sling, you must look for broken wires. By ASME rules, the sling must be removed if you find 10 or more broken wires in one rope lay. For a wire sling, even a few broken wires can mean a loss of strength. This check is more detailed than for types of slings medical gear. Quick removal of a bad steel rope sling is key for safety.

Heat Damage

Heat damage can weaken any sling. It is very risky for synthetic and wire rope types. Look for signs of melting or charring on the sling. On a metal sling or steel sling, look for color changes. Any sling with heat damage must be thrown out. It cannot be fixed and used safely again. Duracordix wants you to be safe.

Kinks, Tears

Kinks, tears, and holes are big damage signs. A sling with these must be removed from use right away. A kink in a cable sling makes a weak spot. A tear in a synthetic web sling can cut its strength a lot. You must also check the lifting chokers and end parts. Unlike types of slings for hoyer lifts, industrial sling failure can be very bad. So, careful checks are vital for all types of slings for lifting.

Real-World Scenarios for Types of Slings for Lifting!

Knowing how different types of slings work in real jobs is key to picking the right one. Let’s look at some common uses for various types of slings for lifts.

Steel Mills

Steel mills are very tough on lifting gear. There is extreme heat and heavy loads. For this, alloy chain slings are the best choice. They can handle high heat and rough work. When you think of types of slings for lifting for steel, chain is the most durable. A synthetic sling would not last here. This is very different from a patient lift harness.

Marine Operations

Marine jobs need slings that resist salt water. Galvanized wire rope slings and synthetic slings from HMPE fiber are great for this. Unlike a sling purse pattern, these materials are made to last. They lift boats and hold cargo. Unlike a sling bag back, these offer strength for tough sea jobs.

Construction Sites

Construction sites need many lift solutions. Durable wire rope slings are a common choice for their strength. But synthetic web slings are often used for delicate things to stop scratches. This is a place where you will see many different types of slings for lifting equipment at work. Duracordix offers strong types of slings for lifting for any construction job.

Offshore Drilling

Offshore platforms need very strong slings. They must resist bad weather and chemicals. High-performance synthetic slings are popular here. They are light and easy to handle. Heavy-duty wire rope slings are also used for their strength. The choice here is vital. It’s not like choosing between types of rifle slings or a small bag sling.

Automotive Manufacturing

In car making, slings move heavy parts like engines. To protect surfaces, soft synthetic slings, like wide web slings, are often used. The use is very different from tree rigging slings or types of slings for mechanical lifts for patients. The goal is to handle parts safely without any damage.

What are the Different Hitches for Lifting Slings?

How a sling is attached to a load is called the hitch. It is as vital as the sling itself. This part explains the three main hitches and how they affect lift capacity. As a user of types of slings for lifting, this is important for you.

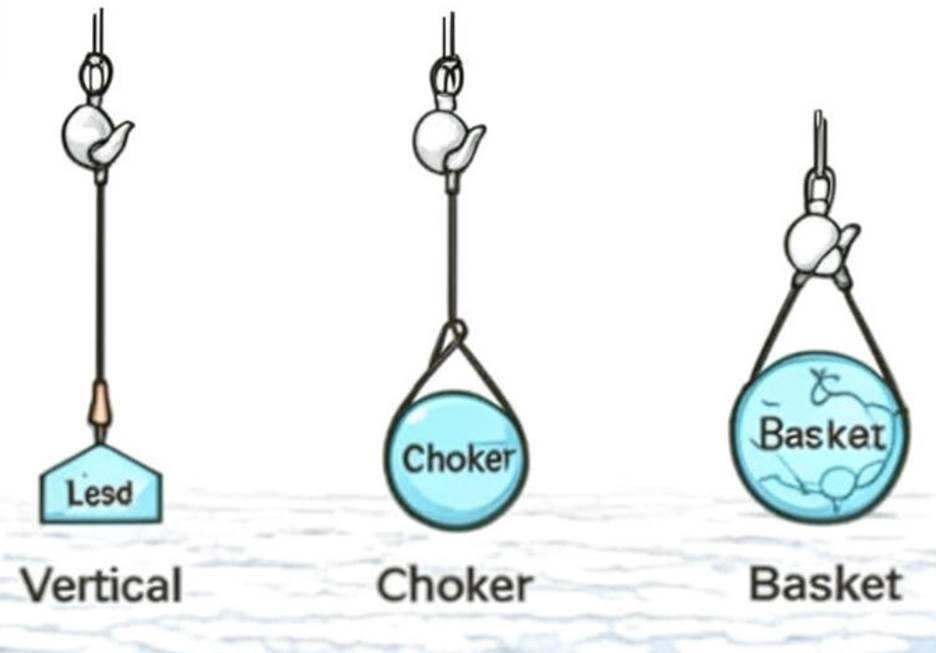

Vertical Hitch

A vertical hitch is the simplest. A single sling leg connects a hook to the load. This uses the full capacity of the sling. But it gives little load control. It is best for straight, stable lifts. It is not for long loads that may tilt. This is a basic skill when using types of slings for lifting, different from complex rope slinging methods.

Choker Hitch

A choker hitch wraps the sling around the load. One end goes through the other’s eye. This creates a tight grip. A choker sling rigging setup cuts the sling’s lift capacity. It often goes to 80% or less. It is key to account for this. This is not a choker strap for fashion. This hitch is a workhorse for rigging many types of slings for lifting.

Basket Hitch

A basket hitch holds the load from below like a cradle. Both sling eyes are on the hook. This spreads the load’s weight between the two legs. This can give up to double the capacity of a single hitch. It gives great load control. It is great for lifting balanced objects. A double length sling is often needed for this, and it works with many types of slings for lifting.

Double Capacity

When you use a true vertical basket hitch, you get double the capacity. This is because the load is spread over two legs. This makes the basket hitch a great choice for heavy loads. But, as the angle between the legs gets smaller, the capacity will also go down. Always check the sling’s chart to confirm the capacity for your basket hitch angle. This principle is key for these types of slings for lifting.

80% Capacity

When you use a choker hitch, the sharp bend in the sling weakens it. As a result, the lift capacity is usually cut to 80% of the sling’s vertical limit. For angles less than 120 degrees at the choke point, this capacity is cut even more. It is vital to use this new number to stop overloading the sling. Knowing this is key to using a lifting sling or any lifting sling straps safely. Safe use of these types of slings for lifting is paramount.

| Feature | Vertical Hitch | Choker Hitch | Basket Hitch (90°) | Basket Hitch (60°) | Basket Hitch (45°) | Basket Hitch (30°) |

| Load Capacity | 100% WLL | ~75-80% WLL | 200% WLL | 173% WLL | 141% WLL | 100% WLL |

| Sling Legs Used | 1 | 1 | 2 | 2 | 2 | 2 |

| Load Control | Low | High | Very High | High | Moderate | Low |

| Sling Stress | Tension | Bending/Tension | Tension | Increased Tension | Higher Tension | Max Tension |

| Grip Type | Direct | Cinching | Cradling | Cradling | Cradling | Cradling |

| Use Case | Stable, Direct Lifts | Bundles, Pipes | Balanced Loads | Wide Loads | Angled Lifts | Low Headroom Lifts |

| Angle Factor | N/A | <120° Reduction | 2 | 1.732 | 1.414 | 1 |

Table on Hitches for Lifting Slings!

Key Trends in Types of Slings for Lifting!

The lifting industry is always changing. This part shows the key trends that are shaping the future of lifting slings. I want you to be aware of the new types of slings for lifting.

UHMWPE Slings

UHMWPE slings are a top new trend. These synthetic rope webbing for lifting options are stronger than steel by weight. They are light and easy to use. They resist chemicals and wear well. The HMPE lifting sling is becoming the new standard for special, big lifts. They are more advanced than patient slings and represent modern types of slings for lifting.

Custom Labels

Modern slings now have strong, custom labels. They often have RFID chips for tracking. These tags let you track check histories and use data. This tech improves safety and makes tracking easy. Unlike simple tags that wear off, these give good ID for the sling’s whole life. This is a big step for the safety of all types of slings for lifting.

Anti-Cutting Sleeves

To fix the problem of sharp edges on synthetic slings, makers now offer special sleeves. These covers are made from cut-proof materials. They shield the sling from harm. Using a sleeve can make your slings last much longer. This is a better fix than simple wear pads. You can even find a sling shackle with these features.

3000 Ton

As projects get bigger, the need for huge lift solutions has grown. Slings that can lift up to 3000 tons are now real. These are often made from UHMWPE fibers. They are used for huge offshore projects. These are not your normal types of slings for lifting, but very special tools. They show the amazing new tech from providers like Duracordix.

Your Next Step for Buying Lifting Slings from Duracordix!

When you are ready to get high-quality lifting solutions, we are here for you. This guide explains how to get the perfect slings for lifting for your needs.

Custom Quote

Every lift job is different. That is why we offer a custom quote service for you. Just give us your needs. Our team will make a detailed offer for you. This ensures you get the right products at a good price. This is better than looking at a list of wire rope slings for sale; we provide various types of slings for lifting.

Expert Consultation

If you are not sure which types of slings for hoists or cranes you need, our experts can help. We can help you with materials, setups, and safety rules. This service is good for those who need to know things like how to measure round sling length. Our experts at Duracordix will guide you on all types of slings for lifting.

Tailored Solutions

We specialize in tailored solutions. We go beyond standard products. If you need a special length or part, we can make it for you. This includes a custom eye to eye web sling or a multi-leg system. We promise to give you a product from our various types of slings for lifting that fits your needs perfectly.

Specify Load

To give you the best advice, you must specify your load details. This includes the weight and size. You should also describe the lift site. The more info you give, the better we can tailor a sling solution. This is more exact than fitting types of transfer sling for sit to stand lift and requires specific types of slings for lifting.

FAQs!

Here are some frequently asked questions about types of slings for lifting.

What is the WLL for Grade 80 chain?

The load limit for Grade 80 chain changes by its size. For example, a 3/8-inch chain has a limit of about 7,100 pounds. Always check the maker’s notes and the ID tag on the sling to confirm the capacity. This is very different from the needs of types of slings for hoyer lift equipment.

How does sling angle reduce lift capacity?

As the angle between the sling legs gets smaller, the tension on each leg goes up. This cuts the lift capacity. At 60 degrees, the capacity is about 86% of the vertical rating. At 30 degrees, it drops to 50%. It is vital to use a sling that is long enough when considering different types of slings for lifting.

Can you repair a damaged webbing sling?

No, a bad webbing sling cannot be fixed. It must be removed from use right away. Rules prohibit the repair of synthetic slings. Any fix would weaken the webbing. Unlike wrist wraps lifting aids, a bad sling is a big safety risk. The only safe choice is a new one.

What are OSHA’s daily inspection rules?

OSHA says all slings must be checked by a skilled person before each use. This check should look for damage like cuts, burns, or bad fittings. If any damage is found, the sling must be removed from use. This is a key safety rule for all lifting cables.

Which sling resists acidic chemicals best?

Polyester and UHMWPE (HMPE lifting sling) slings resist acids best. Polyester is good against many common acids. For wider chemical resistance, UHMWPE is a better choice. Nylon slings are not good for use in acid as they can be weakened. Duracordix has the best types of slings for lifting.

Conclusion

You now know how to choose lifting slings. Consider your load weight and work environment carefully. Selecting the best material ensures your complete safety and peace of mind. Our guide covered many types of slings for lifting. You can find your perfect lifting solution with us. Visit DURACORDIX for our expert help today.

About The Author

mOSES Xu

Hi, I’m Moses Xu, VP and Marketing Director at Duracordix. With 10+ years in high-performance synthetic ropes and netting, I specialize in export trade and marketing. Whether it’s HMPE, Kevlar, or nylon ropes, I’m happy to share insights and connect!