soft shackle

Your Safer, Lighter, and Stronger Alternative to Traditional Steel Shackles

What Is A Soft Shackle?

A soft shackle is a connecting device made from high-performance Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers. Due to its lightweight, high strength, safety, and flexibility, it has gradually become the ideal alternative to traditional steel shackles or stainless steel shackles.

You can use soft shackles in a variety of applications, particularly in vehicle recovery, marine mooring, sailing, heavy lifting, climbing and else.

Hot Selling sizes

As a supplier and manufacturer of soft shackles, we offer a range of sizes to meet your specific needs.

3/8" sOFT SHACKLE

Idear for quickly connecting off-road vehicle recovery, securing sailboat sails, connecting ropes, as well as light lifting,rigging and mooring

1/2" SOFT SHACKLE

Ideal for medium-duty tasks such as off-road recovery, marine towing, construction lifting, and transportation. it connects and secures related objects

7/8" SOFT SHAKCLE

This heavy duty soft shackle can be used for mining, oil and gas, heavy towing or lifting operations, providing efficient and stable connections.

| Diameter | Diameter | Breaking Strength | Length | Color |

|---|---|---|---|---|

| mm | inch | UHMWPE Fibre | mm | any |

| 5 | 3/16 | 8200lbs (2200kg) | 30-50 | any |

| 6 | 1/4 | 9900lbs (4500kg) | 35-50 | any |

| 8 | 5/16 | 18700lbs (8500kg) | 40-60 | any |

| 10 | 3/8 | 29000lbs (13200kg) | 50-70 | any |

| 12 | 1/2 | 39000lbs (17700kg) | 60-75 | any |

| 14 | 9/16 | 54400lbs (24700kg) | 70-90 | any |

| 18 | 3/4 | 95000lbs (43000kg) | 80-120 | any |

Note: other bigger sizes are available upon request.

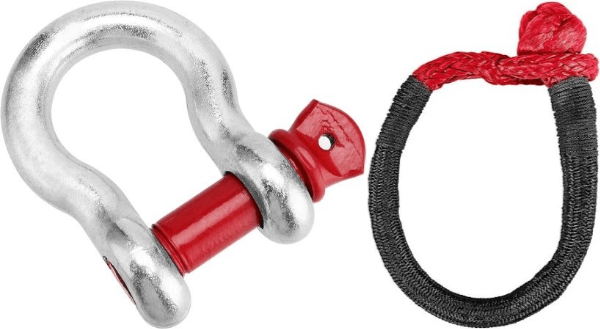

Soft shackle

Hard Shackle

Which is better for your use? let’s find out their difference

Soft shackles are quite different from hard shackles, you can check the details here

- Material: Syntheitc Soft shackles are made from lightweight UHMWPE fibers, usually featuring a movable polyester cover or a fixed double-braided cover. In contrast, hard shackles are made from metals like steel or stainless steel.

- Weight: Due to the difference in materials, fiber rope shackles are lightweight and flexible, whereas steel shackles are noticeably heavier.

- Strength:Due to the excellent strength-to-weight ratio of UHMWPE rope, soft shackles are 30% stronger than traditional steel shackles at the same weight.

- Flexibility: Soft shackles are very flexible, making them easy to secure and carry. You can adjust their shape as needed. In contrast, metal shackles are rigid and not that flexible.

- Safety:In off-roading, soft recovery shackles don’t have the recoil force like metal shackles, which helps better protect your life and vehicle safety.

- Heat Resistence:The melting point of UHMWPE fiber is 145°C, so it can’t handle higher temperatures. but metal shackles have superior heat resistance, making them better suited for high-temperature environments

- Flotation: Due to the buoyant properties of UHMWPE rope(also known as dyneema rope), soft shackles can float on water or mud, making them easy to spot. but metal shackles cannot float and are more likely to be lost.

- Corrosion Resistence:Soft shackles not only resist rust, but they also have excellent resistence against chemicals. In contrast, steel shackles can corrode and rust over time.

How To Use Soft Shackles

You should use the soft shackle in a proper way to ensure its performance and safety

- Preliminary Check: Before each use, you should inspect the soft shackle for any damage, cuts, or wear. Only use the soft shackle if it is in perfect condition, ensuring it is free from any defects or damage.

- Choose the Appropriate Size: You need to assess the required working load and ensure that the soft shackle breaking strength exceeds the load requirements. Failing to do so could lead to the soft shackle’s failure, resulting in serious safety accidents.

- Connecting the Soft Shackle: After loosening the diamond knot, thread the tail end of the soft shackle through or around the connection or recovery point, such as a Jeep tow hitch, snatch ring, or mooring rope eye. Finally, pass the diamond knot back through the tail loop and tighten it to ensure a secure and stable connection.

- Disassemble and Store: Once you’ve completed the task, remove the load and loosen the soft shackle. Take the diamond knot out of the tail loop and check the shackle for any damage, such as cuts or tears. If it’s dirty or muddy, rinse it with fresh water and let it dry. To prevent aging, store it in a cool, dry place. If you have a recovery kit bag, it’s best to store it there.

- Happy Clients

Client voice

Real Stories, Real Success: Customer Testimonials on Duracordix Soft Shackles

FAQs

Answers to Your Questions About Duracordix’s Durable and Versatile Soft Shackles.

What are the applications of soft shackle?

- 4x4 off road recovery: soft shackle can be used to connect with winch rope, tow strap, snatch ring and other tow points

- Marine: soft shackle can be used to connect the mooring rope with other tow point or to secure rigging, anchors on sailboats and yachts

- Industrial setting: soft shackles are used for lifting and connecting heavy equipment and objects.

How much weight can a soft shackle hold?

Soft shackles have impressive strength-to-weight ratios. Depending on the type and diameter, they can typically handle loads ranging from hundreds to thousands of kilograms.

Are soft shackles as strong as steel shackles?

Yes, soft shackles made with high-performance fibers like UHMWPE or Dyneema® are incredibly strong and can match or exceed the strength of steel shackles with significantly less weight.

What is button knot soft shackle?

Can I use a soft shackle for lifting heavy objects?

Soft shackles designed for lifting purposes may be suitable for certain applications; however, always consult industry-specific guidelines and adhere to safe working load limits specified by manufacturers.

Is there any risk of abrasion damage when using a soft shackle?

Abrasion damage can occur if the surface where the rope contacts sharp edges repeatedly without protection.However,some models come with protective sleeves to minimize the risk.

Are soft shackles more expensive than traditional metal shackles?

Soft shackles can be cost-effective due to their long-lasting durability and performance benefits. While they may have higher upfront costs, they often provide better value over time.

How do I clean a dirty soft shackle?

Soft shackles are usually easy to clean by rinsing with fresh water and mild soap if necessary. Avoid using harsh chemicals or abrasive cleaners that could damage the fibers.

Can I use a soft shackle for overhead lifting applications?

We produce soft shackles specifically designed for overhead lifting; however, always consult industry-specific guidelines and adhere to safety regulations when considering their use.

How to make a soft shackle?

You can diy soft shackle as following instructions:

1.Materials and Tools Preparation: Prepare 12-strand HMPE rope, scissors, a lighter, and gloves.

2. Make the loop

Put on gloves and use the scissor to cut the appropriate length of rope, fold it in half, and determine the size of the loop you need. Then tie a double bowline knot or a figure-eight knot to create a stable loop.

3. Make Termination Knot

At the other end of the soft shackle, take the tail of the rope and wrap it around the main rope, creating several loops to form a knot that will close the loop. The most commonly used knots for this are the diamond knot or button knot.

4. Final Inspection

Use a lighter to melt the end of the rope to prevent it from fraying. Check the knot to make sure it’s tight and secure, and ensure there are no loose parts.

What are the common types of soft shackle knot?

the common knots for soft shackle is like Double Bowline, Figure Eight, Alpine Butterfly, and Button Knot. every type of knot provide different advantages while using.

Is there an age limit on how long i can keep using my old shackels ?

Lifespan depends on various factors such as frequency of usage ,environmental conditions,and visible signs of wear & tear.It is recommended to replace aged or damaged equipment promptly

Do you have soft shakcle kit?

yes, the soft shackle kit can be customized for you with 2 pairs of soft shackles. We can also offer you the complete soft shackle recovery kit that includes a winch line, tow strap, tree saver, snatch block, snatch ring, winch damper, gloves, and other essential accessories. Custom recovery kits are available to meet your specific needs.

What is the best soft shackle for you?

The best soft shackle for you should be chosen based on several factors, including the quality of the material, size, knot design, required strength, and the intended application. Consider the variety of colors and visibility options, as well as whether the shackle features a high-wear protective sheath to extend its lifespan. Brand reputation is also an important factor. Recommended brands include ARB, Duracordix, Factor 55, and X-Bull, all of which are known for their high-quality soft shackles and can meet your needs across different scenarios.

Is it possible to repair a damaged soft shackle?

The feasibility of repairing a damaged soft shackle depends on the extent of damage. Minor wear can sometimes be repaired using splicing techniques; however,it is recommended that severely damaged or compromised units should be replaced entirely

Is there any specific training required for using a soft shackle ?

While not mandatory ,training on proper usage,safety guidelines,and inspection protocols provided by manufacturers would significantly enhance safe usage practices

I'm unsure which size or type of soft shackle is best suited for my needs.Can you help me choose?

Absolutely! Our team at Duracordix is here to assist you with choosing the right size,type,and specifications based on your specific requirements.Just reach out to us,and we'll guide you through the selection process.

Related products

Explore our Range of Related Products for Enhanced Performance