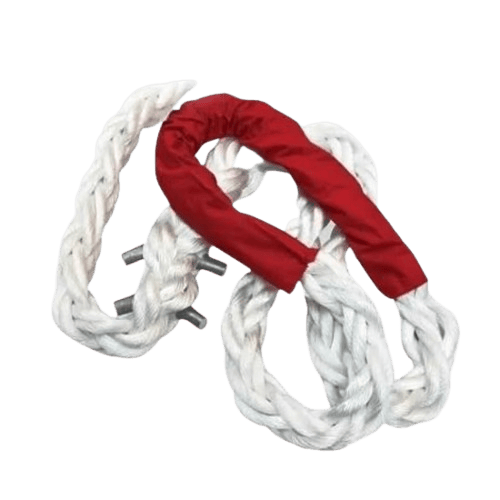

HMPE mooring rope

The strongest, super lightweight, low-stretch solution to ensure your mooring system is safe and efficient.

HMPE mooring Rope

Duracordix HMPE mooring ropes are woven and made from ultra-high molecular weight polyethylene (equivalent to Dyneema material). they offer you extremely high strength, lightweight properties, excellent abrasion resistance, and low elongation. This makes them a high-performance solution for securing your vessels in the harshest marine and offshore environments like strong winds and rough seas.

Meantime it also improves your mooring operation efficiency and safety. They are an excellent alternative to steel wire mooring ropes.

Duracordix, as a mooring rope manufacturer, provides high-performance mooring solutions to enhance your efficiency & safety

Characteristics

- Melting Point: 150℃

- Specific Gravity: 0.97g/cm3(Float on water)

- Elongation at break: 3~5%

- High UV Resistance

- Excellent Abrasion Resistance

- Does not absorb water

- Super Lighweight

- Great Resistance to salt water,oil, detergents, mineral acids etc.

- Highest Tensile Strength Among Synthetic Rope

Our HMPE Mooring Ropes

As a mooring rope supplier, we offer various options of hmpe mooring rope to meet your needs.

8 Strand Mooring Rope

12 Strand hMPE Mooring Rope

Double Braided HMPE Mooring Rope

HMPE Mooring Rope Size Chart

| DIAMETER | DIAMETER | WEIGHT | KETX | KETX | BREAKING STRENGTH | BREAKING STRENGTH |

|---|---|---|---|---|---|---|

| mm | inch | 100m(kg) | standard | error | ton | kn |

| 12 | 1/2 | 8.8 | 87 | 5% | 12.12 | 121 |

| 14 | 9/16 | 12 | 119 | 5% | 15.4 | 153 |

| 16 | 5/8 | 15.5 | 151 | 5% | 20.6 | 205 |

| 18 | 3/4 | 19 | 190 | 5% | 23.9 | 238 |

| 20 | 13/16 | 23 | 225 | 5% | 28.99 | 289 |

| 22 | 7/8 | 28 | 276 | 5% | 33 | 322 |

| 24 | 1 | 37 | 368 | 5% | 38 | 371 |

| 28 | 1-1/8 | 50 | 490 | 5% | 57.5 | 562 |

| 32 | 1-5/16 | 62.5 | 621 | 5% | 68.5 | 671 |

| 36 | 1-1/2 | 77 | 767 | 5% | 80.4 | 789 |

| 40 | 1-5/8 | 87 | 868 | 5% | 98.2 | 964 |

| 44 | 1-3/4 | 96 | 955 | 5% | 118 | 1158 |

| 48 | 2 | 114 | 1137 | 5% | 139 | 1364 |

| 56 | 2-1/4 | 159 | 1547 | 5% | 184 | 1805 |

| 60 | 2-1/2 | 180 | 1784 | 5% | 199 | 1952 |

| 64 | 2-5/8 | 209 | 2021 | 5% | 222 | 2178 |

| 72 | 3 | 268 | 2598 | 5% | 274 | 2688 |

| 80 | 3-1/4 | 328 | 3195 | 5% | 333 | 3266 |

| 88 | 4 | 427 | 4170 | 5% | 390 | 3825 |

| 96 | 3-5/9 | 509 | 4970 | 5% | 455 | 4463 |

- NOTE:

- - Our Rope design force is according to standard of OCIMF MEG4

- - The length of HMPE mooring rope can be in 150m,220m or any costm made length.

- - Other sizes are available upon request

Advantage of HMPE Mooring Rope

OEM & Custom Made Service

- Length & Diameter: Duracordix can provide mooring ropes of different diameters to suit your strength requirements, and also offer different lengths depending on your specific application, such as 50m, 100m, 220m, 500m, or other lengths.

- Color Options: Duracordix understands your color needs in different scenarios. We can customize eye-catching colors such as yellow, blue, orange, and red, as well as more subtle colors like gray and black.

- Construction: we can make you the braided mooring rope or twisted mooring rope as requested, we can also provide you the mooring lines in 3strand, 8strand, 12strand or double braided for your unique needs.

- Material:Whether you need HMPE mooring rope, nylon mooring rope, polyester, PP or PE, or mooring ropes made of mixed materials, we can customize them for you.

- Chafe Protection:Duracordix understands that protecting mooring ropes is crucial throughout the entire mooring system. so Duracordix has developed a series of chafe protection products, such as choke protection, Dura Guard, and PR wear protection, to prolong the service life of your mooring lines.

Client Voice

Our customers share their marine mooring rope experiences and successes

Certifications-- Duracordix Offer

Why Choose Duracordix

- Proven Quality: Duracordix mooring lines are exported to 30 countries, our quality is recognized by customers.We also provide third-party international quality certifications such as CCS, ABS, LR, RINA, BV, and DNV GL and MEG4 certfication.

- Safety: Due to its properties, Duracordix mooring line does not recoil with the same force as steel wire ropes. Additionly, we also have anti snap backn mooring rope minimizes recoil,it can ensure the safety of your personnel and equipment.

- Cost Effective: Duracordix has optimized the UV resistance and fatigue resistance of our mooring ropes through improviness of the rope manufacturing process, Our mooring line can last for over 6 months longer than others, it reduceg replacement frequency and lowering the total life cycle cost.

- Customer Service: Duracordix's sales and technical personnel will work together to customize your mooring solution based on your needs, ensuring 24/7 online communication and providing prompt responses and solutions to your questions.

FAQs

You Can Find More Details About Mooring Systerm and Mooring Rope

What is mooring?

Mooring is the process of securing a boat or ship to a fixed point, like a dock, pier, or buoy, so it stays in place. This is typically done using ropes, chains, or cables to keep the vessel steady, even in changing tides and strong winds, ensuring it doesn’t drift or move unexpectedly.

Do you know the types of mooring?

Yes, there are several types of mooring, each suited to different situations and vessel types:

Single-Point Mooring (SPM): Anchors a vessel to one point, typically a buoy, allowing it to pivot with the wind and tides. Often used for large tankers.

Multiple-Point Mooring: Uses several mooring lines connected to various fixed points, like buoys or the seabed, keeping the vessel more secure and stable. Ideal for offshore drilling or heavy vessels.

Conventional (Dock) Mooring: Ties the vessel directly to a dock using lines from the bow, stern, and sides. Common in marinas and ports for smaller boats and ships.

Mediterranean Mooring: The vessel’s stern faces the dock while the bow is anchored, allowing more boats to fit along a dock. Often used in crowded marinas.

Dynamic Positioning (DP): Uses a computerized system and thrusters to keep a vessel stationary without physical mooring lines. Commonly used on offshore vessels needing precise positioning.

Should a synthetic mooring rope in use ever be knotted?

A synthetic mooring rope in use should never be knotted, because knotting can reduce the rope's breaking strength by at least 50% and it also create a weak point in the entire rope.

This makes the rope susceptible to creep under normal operating conditions due to reduced strength, it may lead to insufficient tensile strength and eventual ropefailure.

What is the best rope for mooring line?

The best material for mooring ropes depends on the specific application and requirements. UHMWPE is generally considered the best for their lightweight, high strength and durability.

How do you choose the right mooring rope size?

The diameter and length of a mooring rope depend on your vessel’s size, weight, and the load it’ll need to handle. Be sure your mooring winch can support the rope size you choose. As a rule of thumb, the rope length should be at least 1.5 times the vessel's length to ensure secure mooring and enough flexibility for shifting conditions.

Related products

Duracordix also supply other related products to your mooring system.